Advanced three-dimensional two-phase flow

advertisement

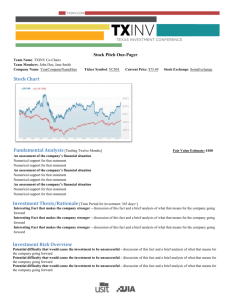

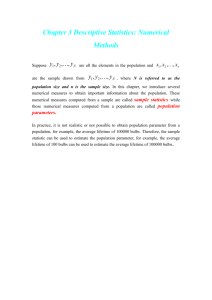

ADVANCED THREE-DIMENSIONAL TWOPHASE FLOW SIMULATION TOOL FOR APPLICATION TO REACTOR SAFETY CO-ORDINATOR Dr. H. PAILLERE CEA Saclay, DEN/DM2S/SFME F-91191 Gif-sur-Yvette Cedex FRANCE Tel: +33.1.69.08.84.09 Fax: +33.1.69.08.82.29 LIST OF PARTNERS 1. 2. 3. 4. 5. 6. 7. CEA Saclay and Grenoble, France EDF Chatou, France JRC Ispra, Italy GRS Garching, Germany MMU, United Kingdom VKI, Belgium PSI, Switzerland CONTRACT No: FIKS-CT-2000-00050 EC Contribution: Total Project Value: Starting Date: Duration: 533563345 EUR 799 723 EUR 1 888 691 01/09/2000 39 months CONTENTS LIST OF ABBREVIATIONS EXECUTIVE SUMMARY A. OBJECTIVES AND SCOPE B. WORK PROGRAMME B.1 Critical evaluation and limitations of TH relationships and closure laws for 3D twophase flow models B.2 Experimental and analytical work in support of TH analysis of 3D two-phase flow B.3 Set-up of data structure and I/O formats for 3D module components B.4 Development of advanced numerical methods for 3D simulation of two-phase flow B.5 Industrial validation of milestones B.6 Preparation of exploitation by industrial code developers and users and dissemination C. WORK PERFORMED AND RESULTS C.1. Hyperbolic schemes for nearly incompressible two-fluid flow: the phase separation test case C.2 Hyperbolic schemes for strongly compressible two-phase flow: the Super Canon test case C.3 Experimental data for multi-dimensional bubbly flow code validation C.4 Coupling of fluid dynamic codes (system / multi-dimensional) C.5 Dissemination of results and exploitation of results CONCLUSIONS REFERENCES 533563345 LIST OF ABBREVIATIONS AUSM Advection Upwind Splitting Method CEA Commissariat à l’Energie Atomique CFD Computational Fluid Dynamics EDF Electricité de France FVS Flux Vector Splitting GRS Gesellschaft für Anlagen und Reaktorsicherheit JRC Joint Research Centre LWR Light Water Reactor MMU Manchester Metropolitan University PSI Paul Scherrer Institute RDS Residual Distribution Scheme SCM Split Coefficient Matrix TH Thermal-Hydraulics VFFC Volumes Finis à Flux Caractéristiques VKI Von Karman Institute for Fluid Dynamics 533563345 EXECUTIVE SUMMARY The ASTAR project was officially launched together with the EUROFASTNET (project FIKS-CT-2000-20100) concerted action project on September 1st, 2000, and for a duration of 36 months (extended to 39 months). The main objective of the ASTAR project was to substantially enhance the three-dimensional two-phase flow prediction capabilities of current Thermal-Hydraulic (TH) codes for safety relevant phenomena in present or future innovative Light Water Reactors (LWRs) (eg. flow instabilities, steep gradients, critical heat flux, etc), by laying the scientific and technical basis for a new generation of codes for improved multi-dimensional two-phase flow simulation. This aim was to be achieved by further development and adaptation of state-of-the-art numerical techniques for transient two-phase flows allowing a high resolution of complex multi-dimensional flow processes, while taking into account industrial requirements such as code robustness and accuracy. It must be emphasized that successful simulation of physical diffusion and transfer processes can only be achieved by combining such models with high resolution schemes whose numerical diffusion is at least an order of magnitude lower than the physical diffusion. This is not possible with the present generation of codes whose numerical methods, though extremely robust, are overly diffusive and only first order accurate in space or time. These codes are also essentially one-dimensional in nature. The major task of the project was the development and verification of new multidimensional (1D,2D,3D) Thermal-Hydraulic code module components which are expected to overcome many of the deficiencies and limitations of present TH-code like CATHARE, ATHLET, TRAC or RELAP5, which have been identified and documented for a number of years in OECD/CSNI workshops dedicated to thermal-hydraulic codes [1,2]. Enhancing the three-dimensional modeling capability of existing system codes is another objective of the ASTAR project, and as a proof of feasibility, a coupling between the multi-dimensional module component (FLUBOX) and the existing system code ATHLET was performed in the frame of this project. Concerning the verification of the improved prediction capabilities, a number of numerical and physical benchmark calculations have been performed including test cases of industrial interest such as bubble plume flows (for which a well instrumented experiment was conducted at PSI to yield two-phase flow field measurements for 3D model development and code validation), counter-current flows, natural convection and boiling/condensation in large water pools or gravity-driven flows at low (near atmospheric) pressure. Comparisons of calculations using existing methods (known as elliptic or pressurebased methods) such as found in the commercial CFD software CFX or the newly developed CEA/EDF NEPTUNE-3D code were also made, so as to illustrate the clear benefit that the new methodologies can bring. These benchmark cases are extracted from a list of flow cases which the industrial partner, EDF, regards as being important challenges for two-phase flow codes – and related to issues of safety and performance evaluation. Furthermore, it is also believed that no single method can satisfactorily resolve all these benchmark problems, and that alternatives to the current simulation technology have to be developed. This synthesis report describes the work program and the different work packages of the project. Difficulties that were encountered, as well as technical achievements are described. Dissemination of the work through publications and open workshops are also described. Finally conclusions concerning the ASTAR project and future prospects that would make use of the ASTAR deliverables are made. 533563345 A. OBJECTIVES AND SCOPE One of the major conclusions from the OECD/CSNI "Workshop on Transient Thermal-Hydraulics and Neutronics Codes Requirements " in Annapolis (1996) as well as in Barcelona (2000) (Ref.[1,2]) was that existing thermal-hydraulics codes used in the nuclear industry no longer represent the present state-of-the-art in physical and numerical modeling and do not make use of the increased performance of present computer hardware. Specific code deficiencies identified include the prediction of flows with steep parameter gradients (e.g. two-phase mixture levels), strong thermal non-equilibrium effects, counter-current flow conditions, critical (choked) flow conditions, transients conditioned by low driving heads like natural convection, stratification in large water pools, or general three dimensional flow phenomena. All these deficiencies are a consequence of oversimplified modeling of complex two-phase flow processes and consequential drawbacks and limitations of the numerical methods used in those codes. These deficiencies have motivated the development of a new class of two-phase flow methods (Ref.[3-10]), which may be seen as extensions of high resolution numerical schemes used for single-phase gas dynamics (see (Ref.[11]) for a comprehensive review), building on well-recognized techniques such as wave decomposition and upwind differencing techniques. Just as their single-phase counterparts, these schemes are characterized by low numerical diffusion, high resolution capture of shocks and sharp contact discontinuities and conservation properties through a finite volume formulation. For non-equilibrium two-phase flow, however, this numerical technology has not been thoroughly evaluated and compared to the less accurate though more mature numerical methods at the heart of today’s thermal-hydraulic two-phase flow codes such as CATHARE (Ref.[12]) or ATHLET (Ref.[13]). The ASTAR project aimed precisely at further improving the accuracy and robustness of the new twophase flow methods, together with systematic evaluation and benchmarking, on a series of test-cases covering a wide range of flow regimes, as well as on a specially designed bubbly flow experiment, fully instrumented for validation of field codes. This is of course only the first step in the validation process. During the course of the project, multi-dimensional modules were further developed and improved. These components are modules of existing thermal-hydraulic or CFD codes developed by the partners (for example, TRIO_U at CEA, SATURNE at EDF, ATFM at JRCIspra or FLUBOX at GRS), and dedicated to the modeling of two-phase flow. Table I summarizes the status of knowledge and the expected benefits to be gained from the project as identified at the beginning of the project, and the achieved progress by the end of the project. B. WORK PROGRAMME The work program consists of in-house numerical developments performed on the partners’ codes (at the start of the project these were: at CEA, TRIO_U; at EDF, SATURNE; at JRC, ATFM; at GRS, FLUBOX), experimental work performed at PSI in the LINX facility, and validation and analysis activities. Besides the management work-package, the work was organized in 6 work-packages: 533563345 B.1 Critical evaluation and limitations of TH relationships and closure laws for 3D twophase flow models WP1 was concerned with the critical evaluation of the state-of-the-art in 3D transient two-phase flow, and limitations of present models with respect to interfacial transfer processes, transition from two-phase to single phase flow, etc. The SOAR was produced jointly by the ASTAR and the EUROFASTNET consortia. A common basis for the physical modeling of two-phase flow was adopted by the ASTAR partners, based on the equal pressure two-fluid model used in many system codes (CATHARE, ATHLET, RELAP5, TRAC), with added differential terms (virtual mass, interfacial pressure correction) to render the model hyperbolic (Ref.[14-19]). Generic constitutive closure laws for interfacial drag for example were also agreed. A selection of numerical and physical benchmark problems of industrial interest was also made which specifies the physical models to be used, and thus allows to compare the different characteristic-based upwind schemes developed in WP4, and evaluate their numerical accuracy and robustness. B.2 Experimental and analytical work in support of TH analysis of 3D two-phase flow WP2 dealt with comprehensive experiments in the LINX facility of PSI, focusing mainly on the bubbly flow regime. These experiments, required advanced measurement techniques (double contact optical probe, PIV, electromagnetic velocimeters) and have provided a valuable data-set for validation of multi-dimensional simulation tools. B.3 Set-up of data structure and I/O formats for 3D module components WP3 was meant to investigate the feasibility of developing generic modular components, which could be shared and coupled to the different partners’ codes, by setting-up a common data-structure and designing suitable input/output formats. Difficulties linked to the different programming languages used (F77, F90, C, C++) were encountered which could not be solved in the framework of the project. However, a recommendation to use a common exchangeable data format, the CFD General Notation System (CGNS, http://www.cgns.org ) was adopted by all partners for future developments. CGNS was actually implemented in the GRS code FLUBOX. B.4 Development of advanced numerical methods for 3D simulation of two-phase flow WP4 dealt with the developments and improvements of the numerical techniques: low diffusion upwind differencing based on Riemann-solver techniques (Roe solver, Characteristic Flux VFFC scheme, Flux Vector Splitting scheme, Residual Distribution Scheme, Advection Upwind Splitting Method), specific treatment for non-conservative terms, source terms and low Mach number effects, phase disappearance and implicit time-integration algorithms. A scalar convection-diffusion equation for modeling of interfacial area concentration transport was also implemented in the JRC ATFM code, to evaluate the effect of coupling of such an equation to the two-fluid model, as well as to assess its potential with respect to dynamic flow regime modeling. 533563345 B.5 Industrial validation of milestones WP5 was concerned with the verification and validation of the numerical methods on the set of benchmark problems selected in WP1. Continuous feed-back on the development phase (WP4) took place as the numerical methods were applied to the different test cases. Comparisons with elliptic solvers (as in the commercial CFX code or the NEPTUNE code) were also made. Unfortunately, the simulation of the LINX experiments with hyperbolic methods could not be fully performed within the project, as the work on benchmark definition and comparison took more time than anticipated, and so results have only been compared qualitatively to the experimental data. B.6 Preparation of exploitation by industrial code developers and users and dissemination WP6 focused on the dissemination of the results and the preparation of exploitation by industrial code developers and users. For the latter, strategies for coupling the 3D modular components to existing system codes such as ATHLET were investigated by GRS. Concerning the dissemination aspects, a web-site was set up (http://www.grs.de/astar ) and an open work-shop was also organized to give visibility to the work and to get feed-back from the scientific world (see web site for details). Finally, a link with the ECORA project (http://domino.grs.de/ecora/ecora.nsf ) was also made, in terms of an ASTAR contribution to the ECORA Best Practice Guidelines, based on the experience gained in WP5. The work program was modified towards the end of the project, through a contract amendment, to take into account a reduced participation of CEA due to an internal decision to stop the development of two-phase flow models in the TRIO_U code and to develop instead together with EDF the NEPTUNE multi-dimensional solver. More work was carried out by GRS, on the investigation of coupling strategies between a system code and a multidimensional module. C. WORK PERFORMED AND RESULTS In this section and because of lack of space, only some of the main achievements of the project are illustrated and commented. The experimental results represent a unique set of data for the validation of multi-dimensional bubbly flow. The results of the numerical benchmark problems prove the feasibility of the numerical methods developed in the project, and show that they provide a sound basis for the development of robust and accurate schemes for multi-phase flow. C.1. Hyperbolic schemes for nearly incompressible two-fluid flow: the phase separation test case This is an isothermal transient test case to investigate gravity-induced phase separation and related counter-current flow conditions. It tests the ability of the methods to predict counter-current flow conditions as exist in many reactor safety-related transients. Initial conditions represents a vertical pipe of height L = 7.5 m filled with a homogeneous two-phase mixture of specified void fraction = 0.5. The specific challenge here is the prediction of two steep void waves traveling simultaneously from the top and bottom ends into the pipe, g 533563345 which, when meeting at the middle section, results in the formation of a sharp interface (liquid level) after phase separation is complete. For the flow velocities in the quasi-stationary middle section of the pipe, as well as for the propagation of the void waves, an analytical solution exists allowing direct comparison with the CFD calculations. The pressure remains close to the initial value of 1 bar and temperature changes are negligible. Important modeling issues are the interfacial forces including interfacial drag, pressure forces and virtual mass effects. Heat and mass transfer, lift forces, wall friction and turbulent diffusion effects are ignored. Interfacial drag is modeled by a simple law based on relative phase velocity (squared). This test proves that hyperbolic methods, though designed to deal with highly compressible flow, can successfully solve nearly incompressible flow. C.2 Hyperbolic schemes for strongly compressible two-phase flow: the Super Canon test case From the Super-CANON test program, an experiment has been selected with a rather high initial pressure (p = 150 bar) and a temperature of 300 oC (equivalent to a sub-cooling of 42 deg C). The test consists in a very fast depressurization of the contents (sub-cooled hot water) of a horizontal tube 4.389 m long and 100 mm internal diameter, by opening a ''break'' equivalent to 100 % pipe area. During the first 10 ms of the transient, the governing phenomena are the fast propagation of an expansion (rarefaction) wave into the pipe and the incipient boiling (flashing). The later period of the transient is characterized by the possible occurrence of critical flow conditions at the pipe exit and strong mechanical disequilibrium between the phases. The predicted results depend strongly on the physical modeling of the flashing phenomenon, the mixture speed of sound and the occurrence of choked flow phenomena. This test provides a strong coupling between the flow and phase change (evaporation) processes. Figure 2 shows that no specific problems were encountered in predicting the fast depressurization with either the Flux Vector Splitting (FVS), the Split Coefficient Matrix (SCM) or the Roe methods. The temporary occurrence of critical flow conditions (choking) at the pipe exit is internally handled as a condition when the slowest pressure wave propagation velocity becomes zero. Some remaining differences between the predictions and measured pressure data, as shown in Figure 2 are the result of the specific modeling of the evaporation rate which governs the whole blow-down process. This tests shows that hyperbolic solvers can successfully solve highly compressible two-phase flow with phase change and heat transfer. C.3 Experimental data for multi-dimensional bubbly flow code validation Within the ASTAR project, experiments on bubble plumes have been carried out in the LINX test facility at PSI (see Figure 3). Although bubble columns have many practical applications, the tests were not aimed at simulating a particular situation, rather they were performed under well controlled initial and boundary conditions to provide a database for code improvement and validation. Isothermal tests have been carried out by injecting air into the bottom of a cylindrical liquid pool through a specially designed circular injector containing 716 calibrated needles. The carefully chosen gas injection rates and gas superficial velocity range correspond to the discrete bubbly flow regime assuming that bubble coalescence and break-up effects remain low. The air injector enables the creation of a broad, axis-symmetric bubble plume with an average bubble diameter of about 3 mm and with large liquid recirculation zones around it. 533563345 The tests were carried out following a test matrix in which parameters such as gas injection rate and water level were varied. To investigate specific two-phase flow parameters in the plume, multidimensional measurements have been carried out. A particle image velocimetry (PIV) set-up was used to measure 2-dimensional liquid- and bubble-velocity fields in a vertical plane. Double-tip optical probes were used for local void-fraction measurements giving information also on bubble size and interfacial area concentration. Some measured average void-fraction distributions are depicted in Figure 4 showing the rise in the void fraction values for increasing gas injection rates. Two corresponding average velocity distributions, also shown in the figure, reflect a similar trend for both the liquid and bubble velocities. Corresponding calculations are presently underway and comparisons with measured data will be included in future publications. The selected experiments performed in the LINX facility are genuinely 3-dimensional in nature. During the start-up of the test, a bubble plume rises upward and, after reaching the free surface, a steady (time-averaged) flow pattern is established. Depending on the relative height of the liquid level, flow instability may develop characterized by a periodic oscillation of the bubble plume (meandering flow pattern). A qualitative picture is given in Figure 5 (left) showing the void distribution and velocity fields for gas and liquid calculated by the FVS method of JRC using a quasi 2-dimensional grid with 2500 hexagonal cells. The calculation clearly shows the recirculation pattern in the liquid pool and gas disengagement at the mixture level free surface at about 1.0 m. Comparison with experimental data and computations with elliptic solvers (NEPTUNE solution, shown right) are discussed in (Ref.[22]). C.4 Coupling of fluid dynamic codes (system / multi-dimensional) Thermal-hydraulic system codes for the fluid flow simulation in nuclear power plants (e.g. ATHLET (Ref.[13])) consist of a network of one-dimensional objects. These objects simulate pipes, pumps, pressurizers, the lower plenum, the reactor core, etc. Each facility component and consequently the complete power plant facility can be assembled from these basic objects. In situations where multidimensional effects become important, multidimensional objects must be added to the network of the one-dimensional objects. The multidimensional object might be any multiphase CFD code. The coupling of multidimensional objects with the one-dimensional network of a system code consists of mainly three tasks. o The first task is the exchange of the relevant data common to both systems. For this one needs an interface for the data exchange between the differently structured programs. o The second task is the physical coupling. The programs may use different physical models for the simulation of the fluid flow (e.g. in two-phase flow the models range from homogeneous models to fully separated two-fluid models). Another problem is the different spatial dimension (1-d and multi-d) of the approximation. Depending upon technical requirements meaningful connections must be established. Finally the different numerical spatial resolution might be a problem (e.g. staggered or nonstaggered grids). o The third task is the efficient solution of the coupled system. The fluid flow in the network of one-dimensional and multidimensional objects is described by systems of nonlinear time-dependent ordinary differential equations. For both systems there exist 533563345 efficient implicit solution methods. But the coupled system must be solved implicitly also, otherwise it will suffer from Courant limit restrictions. The problem size of the combined system is the sum of the problem sizes of the separate systems, and the matrix of the linear system of the combined problem is accordingly upsized. Hence, much larger linear systems of equations than that of the separate systems must be solved. In a prototype coupling of ATHLET and FLUBOX performed in the framework of the project, it was shown how the combined system can be solved in an efficient way [20], where the solution process of the implicitly coupled combined system maintains the solution methods for each separate system. Figure 6 illustrates this coupling, with an application to the calculation of the flow in the downcomer of the UPTF. C.5 Dissemination of results and exploitation of results The results of the ASTAR project have been published in the open literature, whether on an individual basis or as a result of a joint project (Ref.[21,22]). A workshop was also organized in Sept. 2003 to disseminate the results to the scientific community (see the project web page, http://www.grs.de/astar ). The results of the project were published in the proceedings of the FISA-2003 Symposium (http://www.cordis.lu/fp5-euratom/src/evfisa2003.htm ) as well as in a special issue of Nuclear Engineering and Design (Ref.[23]). In terms of exploitation of results, GRS plans to continue the development of the FLUBOX code as its multi-dimensional two-phase flow calculation tool. At CEA and EDF, the development of hyperbolic discretization schemes will continue in the framework of the NEPTUNE project, in the OVAP module. This work may be the subject of European involvement in the NURESIM integrated project which is being envisaged. CONCLUSIONS The ASTAR project came to an end in November 2003. During its three year course, progress has been made in the numerical solution of two-fluid flow problems using characteristic-based methods. Individual efforts initiated in the different partner organizations were combined to make further progress and improvements possible. More could certainly have been done if the developments had been performed in a single code platform or with easily exchangeable modules. This is a difficulty that will have to be overcome in future projects dealing with inter-institutional code development. The benchmarking exercises performed in the project were difficult to define precisely, but proved important to separate the effect of the physical models from the effect of the numerical discretization technique, and to establish the level of accuracy and robustness of the different methods. Comparisons with standard solvers such as those of CFX or the elliptic NEPTUNE code have shown that the hyperbolic schemes can deal with both compressible and nearly incompressible flow. More needs to be done on the side of validation however, both in terms of multi-dimensional flows and other flow regimes. The fact that most of the techniques developed in the ASTAR project work on unstructured grids should facilitate their application to complex geometries. The valuable experimental data set produced in the ASTAR project on bubbly flows should be exploited in the near future. 533563345 REFERENCES [1] Proc OECD/CSNI Workshop on Transient Thermal-Hydraulic and Neutronic Codes Requirements, Annapolis, Md, USA, 5-8 Nov. 1996, NUREG/CP-0159, NEA/CSNI/R(97)4. [2] Proc. OECD/CSNI Workshop on Advanced Thermal-Hydraulic and Neutronic Codes, Barcelona, Spain, April 10-13, 2000. [3] TOUMI, I., KUMBARO, A., 1996, An Upwind Numerical Method for Two-Fluid TwoPhase Flow Models, Journal of Computational Physics, 124, pp.286-30. [4] GHIDAGLIA, J.M., KUMBARO, A., LE COQ, G., 2001, On the numerical solution to two fluid models via a cell-centred finite volume method, European Journal of Fluid Mechanics, B/Fluids, 20, No.6, pp.841-867. [5] PAILLERE, H., CORRE, C., GARCIA-CASCALES, J.R., 2003, On the extension of the AUSM+ scheme to compressible two-fluid models, Computers and Fluids, 32, pp. 891916. [6] ROMSTEDT, P., 1990, A Split-Matrix Method for the Numerical Solution of Two-Phase Flow Equations, Nuclear Science and Engineering, 104, pp.1-9. [7] GRAF, U., 1993, A Numerical Solution Method for Multidimensional Hyperbolic TwoPhase Flow Models, Proceedings 3rd Nuclear Simulation Symposium, Schliersee, Germany [8] STAEDTKE, H., WORTH, B., FRANCHELLO, G., 2001, On the hyperbolic nature of Two-phase Flow Equations: Characteristic Analysis and Related Numerical Methods, Godunov Methods: Theory and Applications, (Ed. E. F. Toro), Kluwer Academic/Plenum Publishers, New York. [9] STAEDTKE, H., BLAHAK, A., WORTH, B., 1997, Modelling of Interfacial Area Concentration in Two-Phase Flow Systems, 8th Int.l Meeting on Nuclear Thermal Hydraulics, Kyoto, Japan, September 30 - October 4, 1997. [10] STAEDTKE, H., FRANCHELLO, G., WORTH, B., 1995, Numerical Simulation of Multidimensional Two-phase Flow based on Flux Vector Spliiting, 7th International Meeting on Nuclear Thermal Hydraulics, NURETH7, Saratoga Springs, NY, USA, Sept. 1995. [11] TORO, E.F., 1999, Riemann Solvers and Numerical Methods for Fluid Dynamics, Springer, Berlin Heidelberg. [12] BESTION, D., 1990, The physical closure laws in the CATHARE code, Nucl. Eng. Design, 124, pp.229-245. [13] TESCHENDORFF, V., et. al., ATHLET Home Page, http://www.grs.de:8081/garching/athlet/athlet.htm , 2003 [14] BOURE, A., 1975, On a Unified Presentation of the Non-Equilibrium Two-Phase Flow Models, Proceedings of ASME Symposium, New York. [15] DELHAYE, J.M., ACHARD, J.L., 1976, On the Averaging Operators Introduced in Two-Phase Flow Modelling, Proceedings of CSNI Specialist Meeting on Transient TwoPhase Flow, Toronto. [16] DREW, D., CHENG, I.,, LAHEY, R.T., 1979, The Analysis of Virtual Mass Effects in Two-phase Flow, International Journal of Multiphase Flow, 5, No. 4, pp.233-242. [17] DREW, D., LAHEY, R.T., 1979, Application of General Consitutive Principles to the Derivation of the Multidimensional Two-phase Flow Equations, International Journal of Multiphase Flow, 5, pp.243-264. [18] HEWITT, G., et al, 1986, Workshop on Two-phase Flow Fundamentals as published in Multiphase Science and Technology, Vol 6. 533563345 [19] ISHII, M.,, 1975, Thermodynamics of Two-Phase Flow, Eyrolles, Paris. [20] GRAF, U., 1998, Implicit Coupling of Fluid-Dynamic Systems: Application to Multidimensional Countercurrent Two-Phase Flow of Water and Steam, Nuclear Science and Engineering, 129, 305-310 [21] STAEDTKE, H., et al., The ASTAR project: status and perspective, 10th Int. Topical Meet. Nuclear Thermal-hydraulics NURETH-10, Seoul, Korea, 6-13 October, 2003 [22] MIMOUNI, S., et al., ASTAR: benchmarking of test cases, ASTAR International Workshop on ”Advanced Numerical Methods for Multidimensional Simulation of Twophase Flow”, September 15-16, 2003, GRS Garching, Germany [23] STAEDTKE, H., et al., Advanced three-dimensional two-phase flow simulation tools for application to reactor safety (ASTAR), Nuclear Engineering and Design, to be published (2005) 533563345 TABLES: Table I. Two-phase CFD codes used and developed further in the ASTAR project Partner Physical model Numerical method CEA Name twophase flow CFD Code TRIO_U Two-fluid 1-pressure model, interfacial pressure correction to render hyperbolic Approximate Riemann Solver (Roe or VFFC schemes, unstructured finite volumes) in OVAP module. C/C++. Also elliptic method (ICE) available in TRIO_U. EDF SATURNE Two-fluid 1-pressure model JRC ATFM Two-fluid 1-pressure model, virtual added mass to render hyperbolic Elliptic method (SIMPLEC algorithm, collocated unstructured finite volumes). Also a hyperbolic scheme (VFFC). Fortran 77. Flux Vector Splitting method (unstructured finite volumes). Fortran 77 GRS FLUBOX Two-fluid 1-pressure model, interfacial pressure correction to render hyperbolic 533563345 Split Coefficient Matrix Method (Cartesian grids only, finite differences). Fortran 90. Status at the beginning of project 3D solver developed. Incorporation of physical modeling terms still missing. 1st order time & space accurate scheme. Implicit time-integration Two-fluid air/water flow only. No heat transfer model. 2D unstructured meshes. 2nd order space & time accurate scheme. Implicit scheme. 2D solver with physical modeling terms. Implicit timeintegration with error control. Expected status at end of project Achieved status at end of project 3D solver (hyperbolic & elliptic methods) for two-phase flow with heat transfer, validated on ASTAR benchmarks CEA/EDF: Merge of TRIO_U/OVAP and SATURNE/VFFC into FLICAOVAP code (hyperbolic methods) 3D solver (hyperbolic and elliptic solvers) validated on ASTAR benchmarks, Energy equation added, 2D solver validated on ASTAR benchmarks 3D solver validated on ASTAR benchmarks. Coupling exercise with ATHLET code. Development of NEPTUNE-3D based on SATURNE elliptic solver (elliptic methods) Energy equation added, 2D solver validated on ASTAR benchmarks 3D solver validated on ASTAR benchmarks. Coupling exercise with ATHLET code. 0.00 -0.2 0 FIGURES: 1 2 3 4 5 6 7 distance x [m] 0.50 0.50 t0 0.0 0.0 1 1 2 2 3 3 4 5 4 5 distance x [m] distance x [m] 6 6 7 0.2 0.2 SCM method (GRS) 1.00 1.00 velocity velocityug,ugu , lu[m/s] l [m/s] AUSM method (CEA) 0.75 0.75 0.50 0.50 0.25 0.25 0.00 0.00 0 0 1 1 2 2 3 3 4 5 4 5 6 6 distance x [m] distance x [m] 2 3 2 3 4 4 5 distance 3 4x [m] distance x [m] distance x [m] 5 6 5 6 7 6 7 -0.2 7 SCM method FVS method (JRC) (GRS) CFX4 method (PSI) SCM method (GRS) t6 0.75 0.75 0.50 0.50 0.25 liquid 12 2 1 23 34 45 56 3 4 5 6 distance x [m] 2 3 4x [m] 5 distance distance x [m] distance x [m] 67 7 6 1 2 3 4 5 6 distance x [m] 0.25 12 2 1 23 34 45 56 3 4 5 6 2distance 3 x [m]4x [m] 5 distance distance x [m] distance x [m] 67 7 6 0.2 -0.2 0.50 0.25 0.25 void fraction [/] velocity ug, ul [m/s] 2 3 4 distance x [m] 533563345 5 6 7 1 1 23 34 45 56 1 2distance distance 3 x [m]4x [m] 5 67 7 6 7 0.1 0.0 -0.1 0 1 0.1 0.1 0.0 0.0 -0.1 -0.1 -0.2 12 -0.2 1 0 0 0.2 velocity ug, ulug[m/s] velocity , ul [m/s] 0.50 AUSM method (CEA) 0 -0.1 -0.1 7 AUSM method (CEA) AUSM method (CEA) 0.00 0.0 0.0 -0.2 7 AUSM method (CEA) 0.1 1.00 0.75 1.00 0.25 0.1 0.2 distance x [m] 0.50 1 1 CFX4 method (PSI) 0.2 0.75 0 0 0.1 -0.2 0.00 0 01 0.00 0 7 -0.1 -0.1 0.2 0.50 -0.1 0.25 -0.1 voidvoid fraction [/] [/] fraction velocity ug, ul [m/s] void fractiong [/] 0 0.0 0.0 -0.2 SCM method (GRS) (PSI) CFX4 method AUSM method (CEA) CFX4 method (PSI) 1.00 1.00 0.00 0.1 7 0.75 0.0 0.0 0.50 -0.1 2 2 -0.2 7 0.75 1. Phase separation problem: time-evolution of void fraction, comparison between Figure 0.75 and CFX code (elliptic method). FVS, SCM, AUSM schemes (hyperbolic methods) 0.0 0.25 1 1 0.2 0.2 0.50 0 0 0.1 1.00 0.1 1.00 0.1 0.75 CFX4 method (PSI) 1.00 -0.1 -0.1 0.2 gas -0.2 0.00 -0.2 0 01 0 0.00 1 0 7 7 0.0 0.0 -0.2 1 2 1 0.25 -0.2 0.00 -0.2 0 01 0 0.00 1 0 7 voidvoid g [/]g [/] fraction fraction 0.00 0.00 0 0 void fraction [/] void fractiong [/] 0.1 0.1 -0.1 -0.1 0.25 0.25 t0 0.00 0 0 0.00 1 0 voidvoid g [/]g [/] fraction fraction t7 0.25 0.25 t1 1.00 velocity ug, ul [m/s] velocity ug, ul [m/s] void fractiong [/] void fractiong [/] t1 0.75 0.75 t0 0.2 0.2 FVS method (JRC) CFX4 method (PSI) 1.00 1.00 velocity ug, ulug[m/s] velocity , ul [ -0.1 0.50 0.50 velocity ug, ulug[m/s] velocity , ul [m/s] 0.25 0.0 0.75 velocity ug, ulug[m/s] velocity , ul [m/s] 0.50 t7 1 voidvoid g [/] fraction fraction velocity ug, ul [m void fractiong 0.75 2 3 4 distance x [m] 5 6 7 -0.2 0 1 0 1 v o id fr a c tio ng p r e s s u r e [b 1 80 40 2 3 0 .7 5 2 0 .5 0 0 .2 5 1 3 0 0 .0 0 .1 0 .2 0 .3 0 .4 0 .0 0 0 .0 0 .5 0 .1 0 .2 tim e t [s ] 0 .3 0 .4 0 .5 tim e t [s ] 160 1 .0 0 F V S m e th o d ( J R C ) 120 1 .0 0 v o id fr a c tio ng [/] v o id fr a c tio ng [/] r e a[b p r epsrseusrseu [b r]a r] 160 S C M m e th o d ( G R S ) 120 1 2 1 80 80 40 2 3 40 3 0 0 .0 0 0 .0 3 0 .1 0 .2 0 .3 0 .4 0 .5 0 .1 tim e t [s 0] .3 0 .2 0 .4 0 .5 3 3 V Smme e (JR RC S CFM ththo odd ( G S )) 0 .7 5 0 .7 5 2 0 .5 0 1 0 .5 0 0 .2 5 1 2 0 .2 5 0 .0 0 0 .0 0 .0 0 0 .0 0 .1 0 .2 0 .3 0 .4 0 .5 0 .1 0 .2tim e t [s 0 ].3 0 .4 0 .5 tim e t [s ] tim e t [s ] 160 1 .0 0 S C M m e th o d ( G R S ) A U S M m e th o d ( C E A ) 120 120 1 1 .0 0 ida cfrtio a cntio[/]ng [/] v o vido fr g p r epsr seusrseu[b ] a r] r ea r[b 160 2 1 80 2 80 40 40 3 0 0 .0 3 .1 0 0 0 .0 0 .2 0 .1 0 .3 tim 0e .2t [s ] 0 .4 0 .3 0 .7 5 3 S C M m e th o d ( G R S ) 3 A U S M m e th o d ( C E A ) 0 .7 5 1 1 0 .5 0 0 .5 0 2 0 .2 5 2 0 .2 5 0 .0 0 0 .0 0 .0 0 0 .0 0 .5 0 .4 0 .1 0 .2 0 .3 tim 0e.2t [s ] 0 .1 tim e t [s ] 0 .4 0 .3 0 .5 0 .4 tim e t[s ] 160 1 .0 0 A U S M m e th o d ( C E A ) 120 1 .0 0 R o e s c h e m e (C E A ) 120 o idfr afrca tio c tionng[/][/] v ovid p r e sp sr eusrseu [b r e a[br ]a r ] 160 1 2 80 80 40 40 3 0 .0 0 .1 0 .2 0 .3 0 .4 0 .1 tim 0e.2t [s ] 0 .3 0 .4 A U S M m e th o d ( C E A ) 0 .7 5 R o e s c h e m e (C E A ) 0 .7 5 0 .5 0 1 3 0 .5 0 2 0 .2 5 1 0 .2 5 2 0 .0 0 0 .0 0 .0 0 0 .0 0 0 0 .0 3 0 .1 0 .2 0 .3 0 .4 0 .1 tim0e.2t[s ] 0 .3 0 .4 tim e t [s ] tim e t [s ] 160 v o id fr a c tio n [/] p r e s s u r e [b a r ] 1 .0 0 Figure 2: Fast depressurization of pressure and void fraction, comparison R o e s c h ecase, m e ( C Etime-evolution A) 120 R o e s c h e m e (C E A ) between FVS, SCM and Roe schemes 0 .7 5 and experimental results 80 40 3 0 .5 0 1 0 .2 5 2 0 0 .0 0 .1 0 .2 tim e t [s ] 533563345 0 .3 0 .4 0 .0 0 0 .0 0 .1 0 .2 tim e t [s ] 0 .3 0 .4 vent liquid free surface pressure vessel (D=2 m) spout windows recirculation zone plume needle plate (d=300 mm) gas inlet Figure 3: The LINX test facility 533563345 water level : 1.5 m (above injector) measuring elevation: 55.2 cm (above injector) 4 air injection rate: 60 nl/m 3.5 30 nl/m 0.7 0.6 15 nl/m 0.5 7.5 nl/m vertical velocity [m/s] Void fraction [%] 3 2.5 2 1.5 0.4 liquid 15nl/m liquid 30nl/m bubble 15nl/m bubble 30nl/m 0.3 0.2 1 0 -25 -15 -5 0 5 r [cm] water level : 1.5 m (above injector) measuring elevation: 55.2 cm (above injector) 0.1 0.5 15 25 0 5 10 r [cm] 15 20 Figure 4. Radial void-fraction distribution for increasing air injection rate (left); liquid and bubble velocity distributions for two corresponding injection rates (right). Figure 5. left, 2-D calculation for the LINX facility, hexagonal grid with 3000 computational cells (hyperbolic FVS method) ; right, 3-D calculation (void fraction) performed with the NEPTUNE code (elliptic method) 533563345 Gik ik ATHLET COLD LEG (1D) Y X Z Figure 6. Coupling of a multidimensional module with a system code: prototype work between ATHLET and FLUBOX, example of an application to the UPTF Test 6 case. 533563345