SOP Appendix (Policies and Procedures)

advertisement

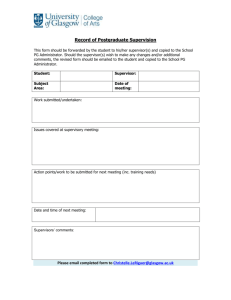

SOP APPENDIX Policies and Procedures The previous Food Safety Plan may stand on its own but many times you will be required to expand a policy or procedure into more than a few sentences. In these instances, you need an SOP Appendix. The following are policies and procedures I acquired from many other Food Safety Plans. Please use parts of any that you feel describes your food safety operation. The number following the policy/Procedure refers to the question on the USDA GAP/GHP Verification Audit Form. TABLE OF CONTENTS Policy/ Procedure Page # Traceability (with code system) (G-1) 1 Recall Program (G-2) 2 Employee Training Policy (G-4,5,11,12,13) 3 Hand-washing Policy (G-7) 4 Blood and Body Fluids ( G-13) 5 Procedure for Handling a Septic or Sanitation Hazard in the Field. (2-5) 5 Procedure for Light Bulbs and Glass in Harvest Areas (2-11) 6 Contingency Plan Regarding Contamination of Produce or Farm Field (2-12) Hairnet / Beardnet Policy (3-13) 6 Clothing and Jewelry Policy (3-14) 6 Policy on Procedures for Handling /Disposition of Finished Product that is Opened, Spilled or Comes in Contact with the Floor. (3-26) 7 Thermometer Calibration Procedure (4-20) 7 6 1 Policy on Transporters Requirements. (4-26) 8 Storage and Equipment Cleaning Procedures 9 Worker Training – English 10 Worker Training - Spanish 12 Traceability (with code system) o o o o The traceablility system will be able to trace “one step forward”. The Natural Farms label with address will be on each case along with a code/lot number which will be assigned each day. The code/lot system will be as follows; 1st digit = product code (see below) 2- 6nd digits = Date product was picked (Julian code of year + last 2 digits of year). 7th digit = Field number ( See map of where the various fields are located) 8th digit = Picker number Product Codes; o P= Pears o A = Apples o G = Grapes Example; A143116 3= Apples picked the 143rd day of 2011 in field #6 by picker #3 Records shall be kept in the company sales office that includes the code/lot data for a period of at least two years. Date of sale, name of buyer and how we can contact in the event of a recall is necessary. The code/lot identifier will be recorded on all invoices delivered to the customers and any other types of paperwork required. A Daily “Produce Tracing Log” shall be filled out each day. It is the responsibility of the assistant shift foreman to fill out and submit this form every day produce is harvested. We provide the following information with each delivery: - Our farm name - The name of the crop 2 - The date harvested - Contact information for our farm We keep records of each sale that includes the harvest location, date of sale, the name of the buyer, and how we can contact them in the event we determine the lot was likely to have become contaminated. Recall Program This farm has a written procedure in place in the event that a recall is necessary. It is the duty of the operations manager to assemble a team for recall purposes if the need should arise. In the event the operations manager is unavailable, the assistant shift foreman will oversee recalls. In the event of a recall, the following steps will be taken; Immediate oral notice will be made followed by a written notification to any affected customers. Information will include the code/lot numbers and date shipped, as well as the reason for the recall. Affected customers will be instructed to destroy all affected product. A full credit will be issued for the affected product. This farm performs a mock recall at least annually to test the effectiveness of the recall system. In the mock recall, we develop a contamination scenario story, select a specific date of harvest and with the information from the code/lot identifier, determine the delivery destination, amount of produce from the original shipment that could effectively be recalled and the disposition of the produce that could not be effectively recalled is ascertained. The mock recall information is recorded in the documents section. Employee Training Policy Training on proper sanitation and hygiene practices is provided to all harvesters and handlers at least once each season before harvesting begins. If a worker does not follow acceptable sanitary practices, he/she is verbally corrected and retrained if needed. Repeated lapses in good sanitary and hygienic practices are grounds for dismissal. Health and hygiene policies also apply to anyone else who enters crop production areas (e.g. owners, supervisors, visitors, inspectors, etc.). 1) All workers who handle harvested product are trained in the following knowledge areas ● When and how to correctly wash hands ● Requirement to wear reasonably clean clothes that protect the product from bodily sources of contamination. 3 ● Prohibition from handling produce if symptoms of an infectious disease exist. Workers with a diarrheal disease or symptoms of other infectious disease are instructed to report this to their supervisor and are assigned to non-produce handling areas. ● Knowledge and proper use of pre-harvest and/or post-harvest application materials ● Prohibition of use of harvest containers for carrying or storing non-produce items during the harvest season ● Requirement to seek prompt treatment with clean first aid supplies for cuts, abrasions and other injuries ● Requirement to dispose of produce that has come into contact with blood or other body fluids and to report this to a supervisor ● Requirement to report product contamination by chemicals, petroleum, pesticides, glass, a major spill or leak of field sanitation units or toilet facilities, or other contaminating factors 2) Training records are kept on file for the duration of the growing season and include: ● When training occurred ● Who attended each training session ● What topics were covered and training method used An example of an employee signed policy form in English and in Spanish is at the end of the SOP Appendix section. Hand-Washing Policy: Employees who handle harvested produce are required to follow proper sanitation and hygiene practices including washing their hands. 1) 2) 3) 4) 5) 6) 7) Everyone must wash their hands before beginning work and returning to work after taking breaks, going to the restroom, eating, smoking, or otherwise compromising the sanitary nature of their hands. Signs in English and the native language of the workers are posted in lavatories, eating areas, and smoking areas to instruct employees to wash their hands before beginning and returning to work. Proper hand-washing technique includes the following: Wet hands with clean water (warm is preferred if available), apply antibacterial soap, and work up a lather. Rub hands together for at least 20 seconds. Clean under the nails and between the fingers. Rub fingertips of each hand in suds on palm of opposite hand. Rinse under clean, running water. Dry hands with a single-use towel. Hand sanitizer alone is not an acceptable practice. 4 Blood and body fluid A written policy is in place whereby produce that have come in contact with blood or other body fluids will be disposed using the most appropriate method for the situation (e.g. buried, burned, etc.). Equipment surfaces that have come into contact with blood or other body fluids will be cleaned and disinfected with bleach or other safe disinfectant. Should the food product or food handling contact surfaces come into contact with blood or other body fluids, workers will cease operation immediately. The contaminated food surfaces must be thoroughly cleaned and properly disinfested, preferably with a quaternary ammonium product. Any affected produce will be disposed of through regular disposal avenues typically used by the farming operation for trash removal. All effort will be made to insure the contaminated produce does not enter the food chain. If blood or other bodily fluid should ever come in contact with the field or the produce it will be immediately dealt with by whoever finds the contamination. If that person is not able to immediately deal with the contamination, that person will mark the area and immediately notify a supervisor who will take appropriate action. If there is blood in the field, all contaminated surfaces will be removed to a plastic bag with a shovel or gloved hands and placed in a trash can. All affected soil will be shoveled up around and under the area and will be removed. Make sure you have either provided first aid or called 911 for the person who is bleeding. 1. 2. 3. 4. 5. 6. 7. Procedure for Handling a Septic or Sanitation Hazard in the Field Sanitation facilities that have been tipped over or are in any way not available for use will be noted immediately and dealt with in a manner that minimizes the risk of contaminating the produce. In the case of a sanitation unit spilling or any other septic leakage occurring in or near field boundaries, the following cleanup steps will be performed: Any affected produce is immediately disposed of in a covered waste bin. The contaminated area will be marked off with caution tape or string. Signs in appropriate languages will be posted at the perimeter prohibiting entry to the contaminated area. People and animals will be kept out until the area is sufficiently decontaminated. Any solid waste still resting on the surface will be collected, shoveled up, and removed to the waste bin. Any affected permanent structures will be hosed off and disinfected with a dilute bleach solution. The sanitation unit will be cleaned up and replaced by the company providing the units and maintenance services. 5 8. The spillage event and corrective actions will be written down in the field sanitation log and kept in our records. Procedure for Light Bulbs and Glass in Harvest Areas Light bulbs and glass on harvesting equipment are to be protected so as not to contaminate produce or fields in the case of breakage. Should glass break on harvesting equipment, workers will cease operation immediately. Any affected produce will be disposed of through regular disposal avenues typically used by the farming operation for trash removal. All effort will be made to insure the contaminated produce does not enter the food chain. Workers are instructed and expected to report such breakage to their supervisors. Broken glass should also be properly handled by placing it in a cardboard box that is sealed, and placed in a secure trash can. Contingency Plan Regarding Contamination of Produce or Farm Field Contamination by chemical, petroleum, pesticide or any other contaminating factor is a serious matter. All due diligence efforts are to be made to insure this contamination does not occur. Should contamination by chemical, petroleum, pesticide or any other contaminating factor occur on harvesting equipment, workers will cease operation immediately. Any type of leak or spill needs to be reported to the supervisor for immediate attention. Any affected produce will be disposed of through regular disposal avenues typically used by the farming operation for trash removal. All effort will be made to insure the contaminated produce does not enter the food chain. Workers are instructed and expected to report such contamination to their supervisors. Hazardous Chemicals - Workers are instructed to throw away any product that has become contaminated by toxic chemicals such as fuel, pesticides, or other harmful substances during harvesting operations and to report the incident to their supervisor. Supervisors are to determine the cause of the incident and to correct procedures and conditions if necessary. Hairnet/ Beardnet Policy This farming operation have a written policy regarding the wearing of hair nets/beard nets in all processing, storage and transportation areas and it is being followed by all employees and visitors. Clothing and Jewelry Policy Employees will maintain proper hygiene while working. This includes staying clean and wearing clean clothing to work. . Employees are not to wear jewelry in crop handling areas. Non6 removable jewelry needs to be reported to a supervisor on advisement for how to cover the jewelry (eg. waterproof gloves). • • • • • • • • • Employees should not wear loose clothing and instead should wear snug-fitting clothes. Large chains and necklaces will not be allowed in the processing house or in the field for safety reasons. Bracelets are not allowed for the same reason. Items that are allowed: Watches Wedding rings or other fairly simple rings Necklaces that stay covered by clothing Unobtrusive earrings that stay near the head and pose no risk to falling out Other concealed or covered jewelry Do not keep cell phones or other items in pockets where they are at risk of falling out. Policy on Procedures for Handling /Disposition of Finished Product that is Opened, Spilled or Comes in Contact with the Floor. Should the finished packed product become opened, spilled or come into contact with the floor, workers will cease operation immediately. Any affected produce will be disposed of through regular disposal avenues typically used by the farming operation for trash removal. All efforts will be made to insure the contaminated produce does not enter the food chain. Workers are instructed and expected to report such events to their supervisors. Thermometer Calibration 1. 2. 3. 4. 5. Melting point of ice method Place ice in a container and allow melting to begin. Stir to insure the temperature in the ice/water mixture is uniform throughout the container. When the container is filled with a 50/50 ice and water solution, insert the thermometer and wait until the temperature stabilizes. If the thermometer is properly calibrated it should read 32ºF (0ºC). If the thermometer is not reading 32ºF (0ºC), adjust the thermometer (if possible), use the temperature difference to adjust for the readings, or replace the thermometer. Avoid adding tap water to the ice (to obtain the 50/50 mixture) because the mixture will not be 32ºF (0ºC) rather at a higher temperature. The calibration will be more accurate if ice is used. Reference: 7 “Food Store Sanitation”, 1998, Sixth Edition, Gravani, Robert B., Rishoi, Don C., Cornell University Food Industry Management Distance Education Program, Lebhar-Friedman Books, Chain Store Publishing Corp. Policy on Transporters Requirements Trailers are to be inspected before loading any produce into them. Should a refrigeration unit be required on the trailer, it must be sufficient in size and properly working. This farming operation has a written policy stating that produce is only to be shipped with like produce. Fertilizers, pesticides, meat poultry, fish or similar products will not be mixed in the trailer. This farming operation has a written policy stating that should a manifest indicate a temperature to maintain during transport, all efforts will be made to insure that that temperature is maintained. This is included as part of the food safety and security program of this farming operation. This farming operation has a written policy stating that produce will be loaded into the trailer with the utmost care to prevent damage and contamination. Should load shifting be an issue in the transport, all reasonable steps will be taken to prevent any shifting of the load during transit. While not all produce requires refrigeration during transport, should a manifest indicate a temperature to maintain during transport, all efforts will be made to insure that that temperature is maintained. Should ice (manufactured on site or not) or cold water be used for cooling in this farming operation, the source of the water will be potable and the ice or cold water will be manufactured, transported and stored under sanitary conditions. Should ice (manufactured on site or not) be used for cooling in this farming operation, there will be regularly scheduled cleaning and sanitizing of the ice production facility (if on site), ice storage facility and any ice handling or transportation equipment. Sanitary conditions will be maintained in all areas where ice is manufactured, transported or stored. Should climate controlled rooms be used to store produce, the temperature will be maintained at the recommended temperature for that produce. Should climate controlled rooms be used to store produce, temperatures will be regularly checked and recorded in a log. The thermometer(s) used to take the temperature will be regularly checked for accuracy. If this is not done by the computer monitoring system automatically, a log will be kept. Storage and Equipment Cleaning Procedures 8 The procedures below describe the proper cleaning and sanitation procedures used to clean most farm and storage equipment used in handling produce 1. Remove all plant and debris from the storage floor, plenum, duct pipes and/or from equipment used for production and handling. 2. Thoroughly wash all components of the storage facility and/or equipment with soap and water or steam using a high-pressure sprayer and then rinse. 3. Use an appropriate, registered, and labeled disinfectant. 4. When disinfecting, make sure the sprayer pressure and volume are sufficient to effectively clean all surfaces. Wet all surfaces thoroughly and allow the disinfectant to remain on the surfaces for at least 10-15 minutes to be fully effective. 5. Make sure to thoroughly clean the inside of duct pipes. 6. Close up the storage facility for maximum disinfectant effectiveness and then open the facility, allowing all surfaces to dry. 7. Follow label and supplemental label instructions. 8. Remember, storage and/or equipment cleaning and disinfecting are critical components of good food storage management. Employee Health and Hygiene Policies All employees and visitors to the location are required to follow proper hygiene procedures. Employees must wash their hands before beginning or returning to work (eg. from all breaks, use of restroom facilities). Signs will be posted in designated areas to remind you of this policy. Rest areas and restrooms will be equipped with soap and water for washing hands. Only use single-use towels to dry hands and place in waste receptacle. Hand washing water must be potable. However, in some instances, the operation may add chlorine or other acceptable agents to potable water in order to further reduce the possibility of contamination during hand washing. Although this water may not be suitable for drinking it shall be acceptable for hand washing. Employees will use the restrooms in a manner to maintain usability and will report any lack of usability to a supervisor. Used toilet tissue must be placed into the toilet fixture. Employees should not wear loose clothing and instead should wear snug-fitting clothes. Employees are not to wear jewelry in crop handling areas. Non-removable jewelry needs to be reported to a supervisor on advisement for how to cover the jewelry (eg. waterproof gloves). 9 Smoking, eating and drinking are allowed in designated areas only. Signs will be posted to remind you of those locations. Enclosed vehicles may be used as a designated location. Only bottled water is acceptable in the work area provided it is in clear plastic containers and stored below the product flow zone. Glass containers are not allowed in the fields, storages or near the harvest operation. Garbage containers will be provided and maintained in the eating area. If you are experiencing flu like symptoms or have infectious conditions, you are prohibited from handling harvested produce. If you have knowledge of harvested produce that has come in contact with blood or other body fluids, you must report it to supervisors so that contaminated produce can be discarded. Produce that have come into contact with blood or other body fluids will be disposed of, buried, burned or put into safe garbage container. Machinery that has come into contact with blood or other body fluids will be disinfected with bleach or other safe disinfectants. First aid kits are available for all employees. Any cuts, abrasions or other injuries must be immediately reported to a supervisor and properly and promptly treated. You are required to always be watchful for foreign material such as; glass, metal, golf balls, packaging materials, rocks, bones, personal effects, insects, rodents, parts or feces. Any broken glass must be immediately reported to a supervisor for proper clean up. Any type of foreign material must be removed from the harvested produce or avoided in the field. If you are unable to remove the foreign material, contact your supervisor with information on the location of the material. You need to be alert for potential chemical hazards such as pesticides, oils, and fuels. Any type of leak or spill needs to be reported to the supervisor for immediate attention. Employees who are stationed around equipment must know the location of the controls to safely start and stop machinery. You must notify a supervisor immediately if there are any unsafe conditions with the equipment that may endanger employees or contaminate produce. 10 Keep any type of chemical containers away from harvested produce and raw produce storage areas. Monitor crop production areas and document the presence, signs, or non-presence of wild or domestic animals entering the land/production or storage areas. I have received orientation on the above information and fully understand the required policy. Employee Signature_________________________ Date___________________ Supervisor Signature_________________________ Date___________________ Políticas de Higiene y Salud de los Empleados Todos los empleados y visitantes a las instalaciones deben seguir los procedimientos de higiene adecuada. Los empleados deben lavarse las manos antes de iniciar o regresar a trabajar (ejemplo: después de todos los descansos, uso del baño). Avisos serán colocados en las áreas designadas para recordarles de esta política. Áreas de descanso y baños estarán equipadas con agua y jabón para lavarse las manos. Sólo utilizar toallas de un solo uso (desechables) para secarse las manos y luego colocarlas en el recipiente de basura. El agua para lavarse las manos debe ser potable. Sin 11 embargo, en algunos casos, puede agregar cloro u otros agentes aceptables al agua potable para contribuir a reducir la posibilidad de contaminación durante el lavado de las manos. Aunque esta agua puede no ser adecuada para beber será aceptable para lavarse las manos. Los empleados utilizarán los servicios sanitarios de una manera adecuada y le informarán de cualquier problema con las instalaciones sanitarias a un supervisor. El papel higiénico usado debe colocarse en el inodoro. Los empleados no deben usar ropa suelta y en su lugar deben llevar ropa ajustada. Los empleados no deben usar joyas en laso de áreas de cultivo. Joyería que no se puede remover necesita ser reportada a un supervisor para asesoramiento acerca de cómo cubrir la joyería (ej. guantes a prueba de agua). Fumar, comer y beber sólo será permitido en zonas designadas. Se colocarán avisos para marcar esos lugares. Vehículos cerrados pueden utilizarse como un área designada. Sólo agua embotellada es aceptable en el área de trabajo, siempre que sea en contenedores de plásticos transparentes y almacenados debajo de la zona de flujo de producción. No se permiten envases de vidrio en los campos, almacenes o cerca de la recolección de la cosecha. Contenedores de basura serán proporcionados y mantenidos en el área de alimentación. Si presenta síntomas de gripe o padece de alguna infección, le está prohibido entrar en contacto con los productos cosechados. Si tiene conocimiento de productos cosechados que han estado en contacto con sangre u otros fluidos corporales, deberá informar a los supervisores para que los productos contaminados pueden descartarse. Productos que han estado en contacto con sangre u otros fluidos corporales se desecharán, enterrarán, quemarán o serán puestos en contenedor de basura seguro. Maquinaria que entre en contacto con sangre u otros fluidos corporales será desinfectada con lejía u otros desinfectantes seguros. Botiquines de primeros auxilios estarán disponibles para todos los empleados. Cortes, abrasiones u otras lesiones deberán informarse inmediatamente a un supervisor y tratarse correctamente y sin demora. Tiene que estar siempre alerta a materiales extraños como: vidrio, metal, pelotas de golf, materiales de empaque, rocas, huesos, efectos personales, insectos, roedores o excremento. Cualquier vidrio roto debe ser reportado inmediatamente a un supervisor para proceder a removerlo adecuadamente. 12 Cualquier tipo de material extraño debe ser eliminado de los productos cosechados o evitado en el campo. Si no puede retirar el material extraño, póngase en contacto con su supervisor con la información sobre la ubicación del material. Es necesario estar alerta a posibles riesgos químicos como pesticidas, aceites y combustibles. Cualquier tipo de fuga o derrame debe informarse al supervisor para atención inmediata. Empleados que estén trabajando alrededor de equipo pesado deben conocer la ubicación de los controles para iniciar y detener la maquinaria de manera segura en caso de emergencia. Debe notificar a un supervisor de inmediato si hay cualquier condición insegura con el equipo que pueda poner en peligro a los empleados o contaminar la producción. Mantenga cualquier tipo de contenedores químicos alejados de los productos cosechados y de las áreas de almacenamiento de productos crudos. Es necesario supervisar las áreas de producción de cultivos y documentar la presencia, signos o ausencia de animales salvajes o domésticos que entren a los campos/zonas de producción o almacenamiento. He recibido orientación sobre la información anterior y comprendo plenamente la política necesaria. Firma del Empleado _________________________ Fecha ___________________ Firma del Supervisor _________________________ Fecha ___________________ 13 14