UHV#6, Nanoreactor

advertisement

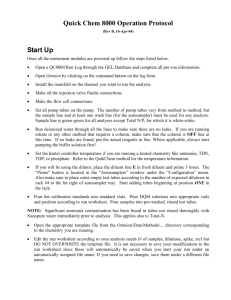

Description of Nano-Reactor Vacuum Procedures Prepared for: Francisco Zaera By: Christopher H. Clark Egor Podgornov Updated by Yurii Larichev (09/2009) Contents 1. Introduction .................................................................................................................... 1 2. Basic Vacuum Procedures ............................................................................................. 1 2.1 Start-up ...................................................................................................................... 1 2.1.1 Evacuation.......................................................................................................... 1 2.1.2 Bakeout ............................................................................................................. 3 2.1.3 Filament Degassing ............................................................................................ 5 2.2 Normal UHV Operations .......................................................................................... 6 2.3 Shut-down ................................................................................................................. 6 3. Experimental Procedures ............................................................................................... 7 3.1 Ar+ Sputtering ........................................................................................................... 7 3.2 Oxygen Annealing .................................................................................................... 8 3.3 Temperature Programmed Desorption (TPD) .......................................................... 9 3.5 Gas Mixing.............................................................................................................. 10 3.6 Work with Nanoreactor 11 i 1. Introduction Basic operation and care of the Nanoreactor vacuum system consists of three modes: start-up, normal operation, and shut-down. In addition to the basic modes of operation, there are more advanced modes of experimental operations within the realm of normal ultra-high vacuum operations. The current procedures for some basic experimental operations available in the Nanoreactor system are: Ar+ sputtering, oxygen annealing, temperature programmed desorption (TPD), different chemical reactions, and gas mixing. Here the procedures for these operational and experimental modes will be discussed. Figure 1 gives a connection diagram that will be referenced throughout this procedural description. 2. Basic Vacuum Procedures 2.1 Start-up The start-up procedure for obtaining clean vacuum conditions in the Nanoreactor apparatus can be broken up into three stages: initial evacuation, bake-out, and degassing. Evacuation is achieved when the maximum allowable vacuum is achieved in both chambers without filling the diffusing pump cold trap, CT2, or baking the apparatus out. 2.1.1 Evacuation The procedure for evacuating the apparatus is as follows as referenced to Figure 1: 1) With valves V6, V12 and V14 closed, turn on the turbo-pump roughing line mechanical pump MP1 and the diffusion pump roughing line mechanical pump MP2. 2) Wait for SV1 and SV2 to open and the foreline pressure to drop to 10-3 torr range. 1 Figure 1: Vacuum Connections Diagram for the “Nanoreactor” Ultra High Vacuum (UHV) System V14 valve located between SV2 and V12 2 3) Evacuate the high vacuum pump forelines, as measured by thermocouple gauges TC2 and TC4, into the mtorr (10-3 torr) range. 4) Slowly open valves V6, V12 and V14 assuring that the pressure measured by TC2 and TC4 are in the same general range and do not exceed 5 torr (to prevent diffusion pump oil back streaming assure that V6 is always opened prior to V12 and TC2 is at a lower pressure than TC4). 5) Once the valves are fully open and TC2 and TC4 are stable in the mtorr range (10-3 torr) the diffusion pump, DP, can be turned on. This is done by first throttling the cooling water supply valve to the diffusion pump, while observing the liquid flow meter, to above 2 liter per minute (LPM). Next, the diffusion pump protective lockout system (located in the instrument control rack) is turned on. Then, the diffusion pump heater variac (located at the bottom of the instrument control rack) is turned on to 70% of total power. The diffusion pump is operating once the oil temperature exceeds 180°C. 6) Once the diffusion pump is operating (about than 280-290°C is the normal operating temperature) the turbomolecular pump, TP, can be turned on. To turn on the TP, first the cooling water supply valve to the turbo pump should be throttled, while observing the liquid flow meter, to above 2 liter per minute (GPM). Next, the Leybold-Heraeus Turbotronik NT 450 turbomolecular pump controller should be powered up and the start button pressed. The pump will then begin to spin-up. The controller “normal operation” indicator light will be illuminated when the pump is operating properly. 7) Once the TP and DP are operating properly, the main chamber ion gauge, IG2, and the probe chamber ion gauge, IG1, controllers and filaments can be turned on and set in their normal operational modes. A leak-free unbaked system should reach an ultimate pressure in the main chamber, as measured by IG2, of ~5-6*10-9 torr. The absence of leaks should be further verified by the absence, or insignificance, of a mass spectrum peak at 32 AMU. If a leak is detected, the leak should be located using the helium leak detection method and fixed. 2.1.2 Bakeout Once the Nanoreactor system reaches its ultimate unbaked pressure the system should be baked to remove water. The procedure for bake-out is as follows: 3 1) Four variacs are needed for bakeout to proceed. Three variacs should be distributed with no more than 1.5 kVA of total heater load plugged into a single variac. The fifth variac should be used to power the halogen light. Care should be taken that each variac has its own power circuit (laboratory outlets are numbered and overlap can be easily identified). 2) Assure vacuum chamber is properly grounded by testing the chamber resistance with respect to each heater set. This is an important safety precaution as a heater short could cause equipment damage and/or a personnel safety hazard. 3) Assure that the entire chamber is wrapped in aluminum foil to prevent convective and radiation heat losses. 4) Turn all four variacs with heaters plugged into them on and set them at 70% power. Turn the variac with the halogen light plugged into it on and set it to 80%. 5) Assure that the gas manifold cold trap, CT3, is filled with liquid nitrogen (it must be full throughout bakeout to assure water is removed and oil vapors are removed and not added). Additionally, the manifold mechanical pump, MP3, must be operating with a manifold pressure, as measured by TC1, in the mtorr range. 6) Open the probe chamber and main chamber bypass valve, V11. 7) Open leak valve LV1 until the main chamber pressure, as measured by IG2, is stable at 1x10-7 torr. Then open LV2 until the main chamber pressure, as measured by IG1, is stable at 2x10-7 torr. 8) Turn off ion gauges, both IG1 and IG2. 9) The crystal should take ~2h to reach 200°C. The crystal temperature or any part of the chamber should not exceed 200°C. All parts sealed with rubber gaskets or viton o-rings should no exceed 150°C (rotary platform and valve V11). The turbo pump should not exceed 120°C. If any of these limit temperatures are exceeded the power on the heater attached to the corresponding part should be turned down. 10) After the crystal temperature has reached 200°C bake-out should continue for ~10 h. 11) At the end of bake-out the variacs should be turned off and the leak-valves cooled to room temperature and then shut. 12) Fill cold trap CT2 with liquid nitrogen. 13) The gas manifold, vol 1, should be filled with ~200 torr, as measured by the manifold diaphragm gauge (DG), of pure oxygen. 4 14) The oxygen leak to the vacuum chambers should be adjusted, using LV1 and LV2, so the pressure will not exceed 10-7 torr. 15) Throttle valve V11, allowing oxygen is leaking into the probe chamber. 16) Wait until chambers cool to room temperature. 17) Once chamber has cooled to room temperature, close leak valves. A leak free system that has been baked out should reach an ultimate pressure ~2*10-9 torr in main chamber and ~5*10-9 torr in probe chamber. 2.1.3 Filament Degassing The last stage of the start-up procedure is the degassing of instruments with filaments. The instruments that need degassed are the two mass spectrometers, the LEED electron gun, the “extra” electron gun, the Ar+ ion gun, the two ion gauges, and the halogen light. This should be done shortly after bake out is complete (preferably while the chamber is still warm). The procedure for filament degassing is as follows: 1) Turn on main chamber ion gauge to degassing mode, IG2. 2) Turn on probe chamber ion gauge to degassing mode, IG1. This is done by first putting the grey emission control knob (secondary knob) to zero. Then turn the black knob to degas. Next turn on the filament and finally turn the grey emission on slightly, ~1 (if use of the probe chamber mass spectrometer is not planned within one day this step should be avoided as not to burn out the filament). 3) Turn on the two probe chamber and main chamber mass spectrometers to 75% of the normal filament current in Faraday Cup mode. 4) Turn the ion gun knob to degassing mode. 5) Turn on the “extra” electron gun and set it to limit current of 1.5-2A. This is done by plugging in only the filament wires (4 and 5) with no high voltage source. 6) Turn on LEED electron gun and set it to a filament current of 1.5-2A. 5 7) Leave all filaments on for 2-3 minutes, then turn off the mass spectrometer and electron gun filaments. Once filament degassing is complete and ultimate pressure is reached, the chamber is considered to be in operational mode. (In current system mode LEED unit disassembled from main chamber and changed steel blank). Now LEED unit kept in room 137 and need to repair. 2.2 Normal UHV Operations Normal operational mode requires very few procedures outside of the realm of details involved in specific experiments. To assure the Nanoreactor has a good clean vacuum in operational mode the liquid nitrogen tank hooked to the auto-fill system for CT2 should always keep the cold trap full. This requires changing the liquid nitrogen tank every 2 days depending on the tank used. A daily check of the chamber should include assuring the pressure is in range (10-9 torr in the main chamber), CT2 is full of liquid nitrogen, the diffusion pump is at the proper temperature (290°C), and the roughing lines for the diffusion pump and turbomolecular pumps are at a pressure of 5x10-3 torr or below (this assures the zeolite traps ZT1 and ZT2 are clean and the mechanical pumps MP1 and MP2 are operating properly). Also needs to add a little quantity of water to chiller 1-2 times per week. In case any chiller brokerages ask Wayne Goodman. Once per 4 month is recommended baking zeolite traps and changing oil in mechanical pumps (especially in MP3). 2.3 Shut-down When there is maintenance or upgrades needed to the chamber, power outages, or problems with equipment it becomes necessary to shut down the chamber and break 6 vacuum. The procedure for doing so is specific as not to damage the pumps or contaminate the system. The procedure for shutting down the system is as follows: 1) Turn off the liquid nitrogen auto-fill mechanism used for the diffusion pump cold trap, CT2, and flush all the liquid nitrogen from this trap. 2) Once the liquid nitrogen is removed from CT2 and the cold trap has reached room temperature, turn the diffusion pump heater variac off (this allows the interlock to stay on and the temperature of the diffusion pump to be monitored as it cools). 3) Turn off the ion gauges, IG1 and IG2. 4) Once the diffusion pump has cooled below 100°C valves V6, V12 and V14 can be closed and the turbomolecular pump turned off. (the turbo pump can be slowed with a controllable leak of argon, but it otherwise takes ~15 minutes to reach a complete stop). 5) Once the turbomolecular pump has stopped affix the kwik-flange connection (blank) between V12 and V14 placed into a full Dewar of liquid nitrogen and slowly open V12 to fill the chamber with nitrogen. Once the chamber has been filled with nitrogen at atmospheric pressure the system is considered shut-down. 3. Experimental Procedures 3.1 Ar+ Sputtering Ar+ sputtering is a common method of crystal cleaning that removes surface material through accelerated collision of large argon cations. In the nano-reactor chamber the system Ar+ sputtering is to obtain a clean metal single-crystal surface. The general procedure for Ar+ sputtering is as follows (ion energy, sample current, and sputtering time must be varied depending on the material, literature should be reviewed to identify the specific sputtering conditions): 1) The crystal should be oriented at a 45° to the incident ion beam at the same height as the ion beam. 7 2) The gas manifold should be filled with ~50 torr of Ar, as measured by the manifold DG (the manifold cold trap, CT3, should be filled prior to pumping the manifold or filling it with any gas). (WARNING: If opening of the main valve to the argon cylinder is needed, disconnect it from the manifold, to prevent accidental pressurization if the pressure regulator fails) 3) LV1 should be opened until the system pressure, as measured by IG2, is ~10-6 torr. 4) Once Ar is flowing through LV1 to the ion gun, the ion gun power supply should be turned on, the function knob placed in “operate” mode, and the ion energy set to the desired value (~2 keV). 4) LV1 should then be adjusted to obtain the desired sample current (the sample current is measured by measuring the current in μA between the sample and the ground). 5) The sample current can be optimized by adjusting the x, y, and z position of the sample. 6) Once the desired sputtering conditions are reached the sputtering should continue for the desired amount of time (5-15 minutes). 6) Once the desired sputtering time has elapsed the function knob should be turned to “0” and the ion energy to 0. Once Ar+ sputtering is complete the sample is usually annealed in oxygen. 3.2 Oxygen Annealing Oxygen annealing is done to “burn off” carbon on the surface and mobile subsurface carbon. Before beginning oxygen annealing the literature should be consulted to prevent oxygen diffusion into the bulk of the sample or sample oxide formation. 1) The gas manifold should be filled with ~100 torr of oxygen, as measured by the manifold DG (the manifold cold trap, CT3, should be filled prior to pumping the manifold or filling it with any gas). 2) LV2 should then be adjusted until the desired oxygen pressure is reached, usually 2x10-7 torr as measured by IG2. 8 3) The sample should then be heated quickly to the desired annealing temperature, usually 1000-1100 K, and held there for the desired length of time (10s-10min. depending on the type of crystal and its initial cleanliness). 4) The crystal should then be cooled in oxygen to room temperature. 5) Once the crystal has cooled to room temperature, the oxygen leak should be terminated by closing LV2. 6) A temperature programmed desorption (TPD) should be conducted to desorb oxygen adsorbed during crystal cooling in oxygen and assess amount of carbon still present at the crystal surface. Oxygen annealing is almost always followed by TPD, to ascertain the approximate amount of carbon removed. Oxygen annealing is generally done when one suspects that carbon from experiments or the vacuum environment has diffused into the subsurface. 3.3 Temperature Programmed Desorption (TPD) TPD is a powerful technique for not only determining crystal cleanliness, but ascertaining interesting surface chemistry of adsorbates. Although the procedure outlined here will be for TPD following oxygen adsorption, the procedure could be applied to many other adsorbates by changing the ramping rate, final temperature, and masses observed in the mass spectrum. The procedures for collecting mass spectrometer data are explained in the manual for the software on CD. The procedure for TPD is as follows: 1) Once the sample has cooled to room temperature, the mass spectrometer should be prepared to monitor masses of expected desorption (or reaction) products. For oxygen TPD this should be masses 32 (O2), 28 (CO), and 44 (CO2). 2) The temperature program should then be set (at the temperature controller) to ramp at the desired rate (usually 8 K/s) to the desired temperature (usually 1100 K=827 °C). 3) The UTI mass spectrometer (MS) controller for the main chamber mass spectrometer should be turned on, then turned to “FAR CUP” mode, the filament emission current set, and finally the controller set in “MULT” mode. It should be 9 noted that if the MS controller is not set to “EXT” mode and is instead set to “NORM” the computer will not record the mass spectrum. 4) Next the mass signal of the masses of interest should be recorded by the computer. 5) Once it is assured that the mass spectrum is being recorded correctly (although the signal for mass 32 (O2) should be nearly 0, there will always be some signal at mass 28 (CO) and mass 44 (CO2) in the system due to unavoidable diffusion pump back streaming), the temperature program should be started and the temperature desorption spectra (TDS) recorded. 6) Not recommended cooling crystal holder to liquid nitrogen because holder can get a little leak (to the 10-8 torr) during liquid nitrogen cooling. 7) For MS high sensitivity gain of photomultiplier must be 100000 and higher. Actually you can slightly increasing voltage on multiplier for increasing gain, but in this case photomultiplier can be damaged more quickly comparing to default voltage. (In any question about MS see UTi 100C manual). 3.5 Gas Mixing The Nanoreactor system has been designed with a gas manifold allowing for accurate mixing of two gases. This procedure is crucial for gas phase catalytic kinetic study. The procedure for mixing to gases in the gas manifold is: 1) Pump (with MP3) the entire manifold (by opening V10), up to the leak valves LV1 and LV2, and the gas supply lines up to the regulators (the regulators should be pressurized with pure gas). This entails assuring that V1, V2, V3, V4, V5, V7, V8, V9, and V10 are open. As mentioned previously, the manifold cold trap, CT3, should be filled prior to pumping the manifold or filling the manifold with any gas. 2) With V10 still open, close V1, V4, V7, V8, and V9. 3) Assure that the DG controller reads zero (there is a zero setting on the controller, operated by a set screw). 4) Next calculate the desired mixture as follows: Vol1 1 P2 P1 Vol 2 x A (1) 10 Equation 1 is used to calculate Vol 1/Vol 2 (3.3 for 26 mL bulb and 1.1 for 90 mL bulb), the ratio of the manifold volume (Vol 1) to the bulb volume (Vol 2) (this is constant for a given bulb Vol 1). P2 is the value calculated, where this is the pressure set in the manifold with V3 closed, P1 is the initial bulb pressure (set as desired), and xA is the volume fraction of the desired component. Example: For a 1:10 mixture of CO:O2, where xA=0.1, first pressurize Vol 1 to P1=50 torr (this value is chosen). Next, evacuate Vol 2. Then, pressurize Vol 2 to P2=500 torr. Finally, open V3 to mix. 5) Close V10. 6) Throttle the valve of the concentrated component (V1, V2, V7, or V8), and pressurize Vol 1 to P1 (usually about 500 torr) as measured by DG 7) Close V3 and evacuate the manifold (by opening V10 and then closing V10 once the manifold pressure, as measured by TC1, has dropped below 50 mtorr). 8) Throttle the valve of the dilute component (V1, V2, V7, or V8), and pressurize the manifold, Vol 2, to P2, as measured by DG. 9) Open V3 to create binary mixture. 10) Open either V4 to allow introduction of mixture through the doser at LV1. This procedure can be extended to ternary mixtures. 3.6 Work with Nanoreactor After crystal cleaning and preparation gas mixture you can work with Nanoreactor: 1. Shifted crystal to the gas nozzle. The optimal distance between surface and gas nozzle is about 100-200 mkm. For measuring this distance you can use correlation between distance and charge. For measuring this charge you need to use a special tester. The second way is just using photo camera and measured the distance by photo pictures. 2. When crystal achieved optimal distance to nozzle turn on the gas flow using LV1. Maximal gas pressure in capillary is about several torr. Pressure in chambers in this case is about 10-5-10-6 torr range. Maximal local pressure on crystal surface is about 0.04 torr. 11 For more precision calculating of local pressure needs to use old reports of E. Podgornov. (These data calculated for H2/C2H4 mixtures only. In cases different gas mixtures you need additionally made calculations of gas flows). 3. In bottle for gas mixture you need hold gas by high pressure (0.5-1.0 atm). It needs for more stability gas flow. Usually, during the time gas flow became slowly down. 4. After ending experiment stopped gas flow by LV1. Shifted crystal from nozzle to the opposite direction. Than open valve located near LV1 and wait some time for gas evacuated. 12