EIT 437 1001 - Great Basin College

advertisement

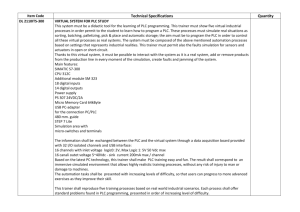

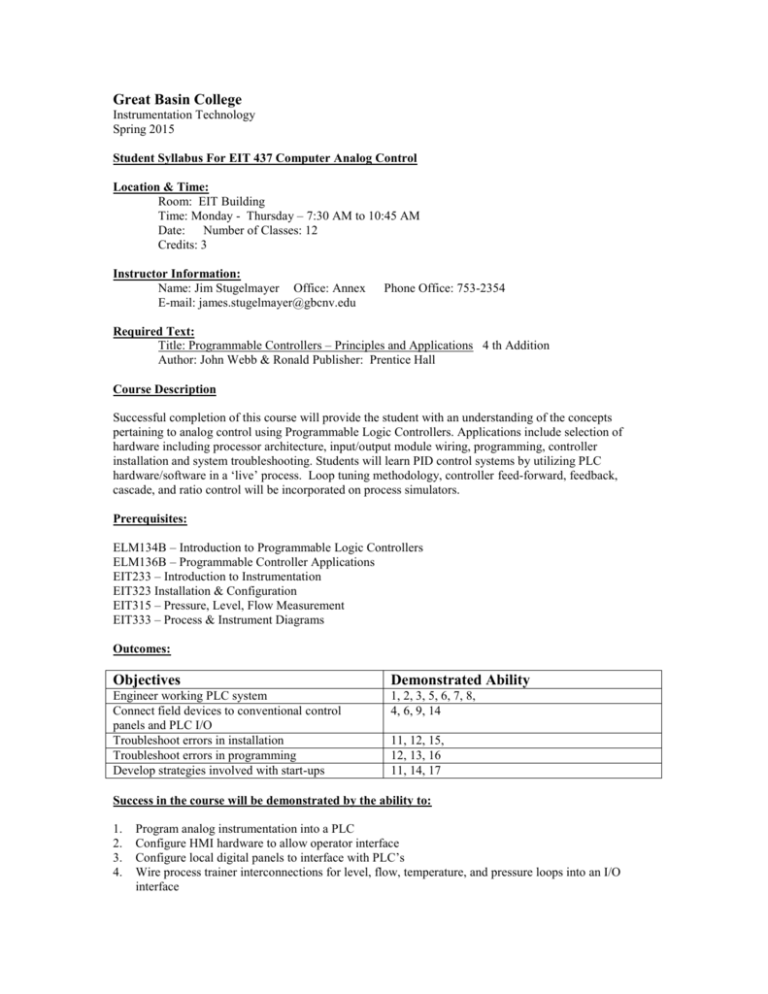

Great Basin College Instrumentation Technology Spring 2015 Student Syllabus For EIT 437 Computer Analog Control Location & Time: Room: EIT Building Time: Monday - Thursday – 7:30 AM to 10:45 AM Date: Number of Classes: 12 Credits: 3 Instructor Information: Name: Jim Stugelmayer Office: Annex E-mail: james.stugelmayer@gbcnv.edu Phone Office: 753-2354 Required Text: Title: Programmable Controllers – Principles and Applications 4 th Addition Author: John Webb & Ronald Publisher: Prentice Hall Course Description Successful completion of this course will provide the student with an understanding of the concepts pertaining to analog control using Programmable Logic Controllers. Applications include selection of hardware including processor architecture, input/output module wiring, programming, controller installation and system troubleshooting. Students will learn PID control systems by utilizing PLC hardware/software in a ‘live’ process. Loop tuning methodology, controller feed-forward, feedback, cascade, and ratio control will be incorporated on process simulators. Prerequisites: ELM134B – Introduction to Programmable Logic Controllers ELM136B – Programmable Controller Applications EIT233 – Introduction to Instrumentation EIT323 Installation & Configuration EIT315 – Pressure, Level, Flow Measurement EIT333 – Process & Instrument Diagrams Outcomes: Objectives Demonstrated Ability Engineer working PLC system Connect field devices to conventional control panels and PLC I/O Troubleshoot errors in installation Troubleshoot errors in programming Develop strategies involved with start-ups 1, 2, 3, 5, 6, 7, 8, 4, 6, 9, 14 11, 12, 15, 12, 13, 16 11, 14, 17 Success in the course will be demonstrated by the ability to: 1. 2. 3. 4. Program analog instrumentation into a PLC Configure HMI hardware to allow operator interface Configure local digital panels to interface with PLC’s Wire process trainer interconnections for level, flow, temperature, and pressure loops into an I/O interface 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. Design control loops for PLC and/or conventional operation Incorporate interlocks for emergency shutdown Relate P&ID drawings into HMI software (EIT333) Engineer units of measure for process trainer into operator useable values Use data logging to report useful measurements Transmit values to other devices for control or monitoring using hardwired or telemetry techniques After all components are installed and tested, proceed to a systematic start-up Understand documentation and specifications of instruments involved and relevant PLC hardware Develop block diagrams of file structure Create a plan to utilize more than 2 drops for networking applications Wire current and voltage loops Utilize proper process control strategies Troubleshoot process process upsets and know how to resolves issues Assignments/Content/Schedule: Class 1 Lecture - Overall PLC systems Class 2 Lecture - The PLC as a computer, I/O Modules, Power supplies Class 3 Lecture - Programming formats Class 3 Lab – Program basic closed loop feedback level control Class 4 Lecture – Flow charting a process Class 4 Lab – Wire process trainer to I/O Class 5 Lecture – Input and output registers Class 5 Lab – FORCE I/O to loop check instrument integrity Class 6 Lecture – PLC Table and register MOVES Class 6 Lab – Tie in external monitoring equipment Class 7 Lecture – PLC analog signal processing Class 7 Lab – Start-up process trainer, verify I/O Class 8 Lecture – Typical PID functions Class 8 Lab – Control level in process trainer with PLC Class 9 Lecture – Network communication Class 9 Lab – Read process values at remote locate Class 10 Lecture – Troubleshooting PLC malfunctions Class 10 Lab – Find/Evaluate/Repair introduced errors into control system Class 11 Lab – Incorporate flow loop into system. Configure PLC for Cascade Control Class 12 Lab – Demonstrate viability of control system; hand in all drawings, schematics, and wiring diagrams. Show how a feedback and ratio control system can be utilized with the existing instrumentation. Homework is required each week with quizzes every other week and a final exam. Evaluation and Grades: Grade values are as follows: A- Superior 4.0, B -Above Average 3.0, C- Average 2.0, D- Below Average 1.0, F- Failure 0.0 IIncomplete, W- Withdrawal Evaluation of student performance will be based on the following: Quizzes 20% Homework 20% Lab 25% Final 35% “I” – Students may receive a final report of “I”, or incomplete, if they have completed at least ¾ of the course with a grade of “C” or better, but are unable to complete the class for good cause. You must arrange for the incomplete with your instructor and acknowledge the statement of work you must complete to receive a final grade. You have until March 15th for Fall Semesters and October 25th for Spring and Summer Semesters to complete the work for the final grade. An incomplete not made up within this time period will have a grade assigned by the instructor, which could be and “F” or “W”. “W” - Students may opt for withdrawal up to the 13 th week of classes. It is your responsibility to withdraw formally from a course. Instructors have the option of assigning a failing grade for unofficial withdrawals. The “W” is not used in computing your cumulative grade-point average. It will appear, however, on your transcript, and will always be a permanent part of it. Veterans who withdraw from classes after the official add/drop period may experience penalties, and may be required to pay back all or part of the benefits received for that course. If you are veteran contemplating changes in enrollment, you should get the advice of the Director of Student Financial Services. Student Responsibility: In this course as in the workplace, students must attend class and turn assignments in on time. Attendance will be taken daily and will count toward the final grade. All assignments must meet designated deadlines (no late assignments). Late assignments will be accepted only by prior arrangements. If a class must be missed, the student must notify the instructor in advance. Absenteeism and tardiness will reflect on the final grade. Four (4) absences, lecture/lab, will be considered a WITHDRAWAL from the course. Tardiness will count as one-half of an absence. Each absence will reduce the final grade by 3%. Because this is a lab-oriented course, student participation is essential. All students must observe school policies on attendance and conduct. Safety: All students participating in laboratory activities at school or on site will be required to review and sign Electrical Technology GBC Safety Procedures. No student use of laboratory /tools will be allowed unless authorized supervision is present or special permission has been granted by the instructor. Disabilities: GBC supports providing equal access for students with disabilities. An advisor is available to discuss appropriate accommodations with students. Please contact the ADA Officer (Julie Byrnes at 775.753.2271 at your earliest convenience to request timely and appropriate accommodations.