file - Centre for Healthcare Related Infection Surveillance

advertisement

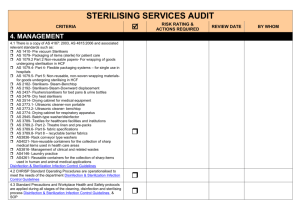

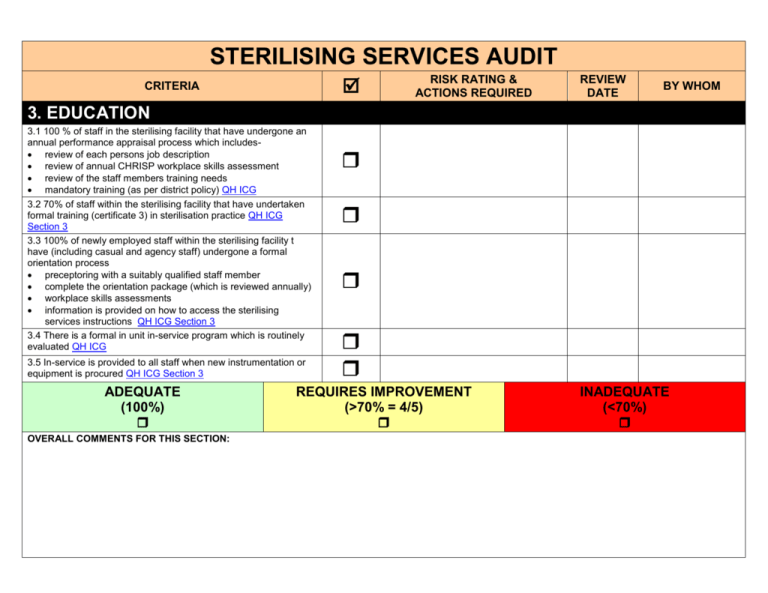

STERILISING SERVICES AUDIT CRITERIA RISK RATING & ACTIONS REQUIRED REVIEW DATE BY WHOM 3. EDUCATION 3.1 100 % of staff in the sterilising facility that have undergone an annual performance appraisal process which includes review of each persons job description review of annual CHRISP workplace skills assessment review of the staff members training needs mandatory training (as per district policy) QH ICG 3.2 70% of staff within the sterilising facility that have undertaken formal training (certificate 3) in sterilisation practice QH ICG Section 3 3.3 100% of newly employed staff within the sterilising facility t have (including casual and agency staff) undergone a formal orientation process preceptoring with a suitably qualified staff member complete the orientation package (which is reviewed annually) workplace skills assessments information is provided on how to access the sterilising services instructions QH ICG Section 3 3.4 There is a formal in unit in-service program which is routinely evaluated QH ICG 3.5 In-service is provided to all staff when new instrumentation or equipment is procured QH ICG Section 3 ADEQUATE (100%) OVERALL COMMENTS FOR THIS SECTION: REQUIRES IMPROVEMENT (>70% = 4/5) INADEQUATE (<70%) STERILISING SERVICES AUDIT CRITERIA 4. MANAGEMENT 4.1 There is a copy of AS 4187 (2003) and associated relevant standards such as: AS 1410- Pre vacuum Sterilisers AS 1079- Packaging of items (sterile) for patient care AS 1079.2 Part 2 Non-reusable papers- For wrapping of goods undergoing sterilisation in HCF AS 1079.4- Part 4- Flexible packaging systems – for single use in hospitals AS 1079.5- Part 5: Non-reusable, non-woven wrapping materials- for goods undergoing sterilising in HCF AS 2182- Sterilisers- Steam-Benchtop AS 2192- Sterilisers-Steam-Downward displacement AS 2437- Flushers/sanitisers for bed pans & urine bottles AS 2478- Dry heat sterilisers AS 2514- Drying cabinet for medical equipment AS 2773.1- Ultrasonic cleaner-non portable AS 2773.2- Ultrasonic cleaner- benchtop AS 2774- Drying cabinet for respiratory apparatus AS 2945- Batch-type washer/disinfector AS 3789- Textiles for healthcare facilities and institutions AS 3789.2- Part 2- Theatre linen and pre-packs AS 3789.6- Part 6- fabric specifications AS 3789.8- Part 8 – recyclable barrier fabrics AS3836- Rack conveyor type washers AS4021- Non-reusable containers for the collection of sharp medical items used in health care areas AS3816- Management of clinical and related wastes AS4146- Laundry practice AS4261- Reusable containers for the collection of sharp items used in human and animal medical applications QH ICG Section 3 4.2 CHRISP Standard Operating Procedures are operationalised to meet the needs of the department QH ICG Section 3 4.3 Standard Precautions and Workplace Health and Safety protocols are applied during all stages of the cleaning, disinfection and sterilising process QH ICG Section 3 & SOP RISK RATING & ACTIONS REQUIRED REVIEW DATE BY WHOM STERILISING SERVICES AUDIT CRITERIA 4. MANAGEMENT cont. 4.4 Items designed to be reprocessed are processed to a level for their intended use eg cleaning followed by sterilisation for all critical items QH ICG Section 3 4.5 Manufactures instructions are provided and available to staff for the processing of reusable medical devices QH ICG Section 3 and Cleaning Resources 4.6 Material Safety Data Sheets (MSDS) are available for all cleaning agents and chemicals which have been read and understood by staff prior to initial use SOP1.3 & QH ICG Section 3 4.7 Labelling on cleaning agents are to comply with any statutory obligations and includes the following information: name of product name and addresses of manufacturer description & purpose of the product directions for dilution and use batch number expiry date advice not to mix cleaning agent with other chemicals safety & first aid instructions specific storage requirements SOP1.3 & Chem Alert 4.8 Chemicals used within the department are registered with the Therapeutic Goods Association QH ICG 4.9 Manufacturers instructions are followed in relation to load content QH ICG Section 3 4.10 Process in place for the notification of the manager or shift supervisor for all faults or failed processes (e.g. cleaning cycles, sterilising loads) SOP 4.11 Staffing profile is reviewed annually and meets the needs of the unit Business Planning Framework 4.12 Clear professional and operational reporting structure within the facility is evident QH ICG Section 3 4.13 Incidents relating to the processing of reusable medical equipment are reported, risk rated and actioned within corporate and facility policy and the unit is provided with a summary of incidents regularly QH ICG Section 3 RISK RATING & ACTIONS REQUIRED REVIEW DATE BY WHOM STERILISING SERVICES AUDIT CRITERIA RISK RATING & ACTIONS REQUIRED REVIEW DATE BY WHOM 4. MANAGEMENT cont. 4.14 The sterilising processing facility has standard operating procedures for the following: collection of used reusable items for areas outside the sterilising processing facility eg ward, other facilities cleaning items, equipment and the environment inspection of cleaned items assembly and disassembly of items handling and processing of specialised items packaging of items loading of items for processing sterilisation cycle process for linking steriliser cycle batch information to items that have been sterilised to the patient calibration, routine monitoring and recording of sterilising equipment and cycles unloading of sterilisers storage of sterile items validation of process for sterilisers management of deviations and faults associated with processing of items distribution of sterile items recall of supplies or stored loads complaints procedure QH ICG Section 3 & SOP ADEQUATE (100%) OVERALL COMMENTS FOR THIS SECTION: REQUIRES IMPROVEMENT (>70% = 10/14) INADEQUATE (<70%) STERILISING SERVICES AUDIT CRITERIA RISK RATING & ACTIONS REQUIRED REVIEW DATE BY WHOM 5. CONSULTATION 5.1 There is a formal communication process established between the sterilising facility and operating theatre for the following: purchasing of instrumentation changes to configuration of instrument trays operating theatre scheduling development and review of instrument count sheet QH ICG Section 3 5.2 There is a clearly defined relationship between sterilising services and other services within the district/facility, including but not limited to: infection control maintenance department patient safety officer peri-operative and surgical services clinical procurement officer QH ICG Section 3 5.3 There is a formal consultation process with the manager of the sterilising facility for the purchase of all reusable medical devices QH ICG Section 3 5.4 The design and workflow supports designated areas for cleaning, packaging, sterilising and storage of sterile items Building & Refurbishment 5.5 Operation manuals for the sterilisers are readily available for maintenance and sterilising staff to access QH ICG Section 3 5.6 Each steriliser and associated equipment has a preventative maintenance program (monthly, quarterly, annually) QH ICG Section 3 5.7 Medical records departments are consulted about the management of sterilising records that are to be archived QH ICG Section 3 ADEQUATE (100%) OVERALL COMMENTS FOR THIS SECTION: REQUIRES IMPROVEMENT (>70%= 5/7) INADEQUATE (<70%)