Extraction and Properties of Metals

advertisement

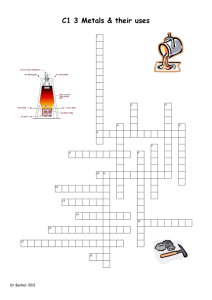

Extraction and Properties of Metals Ore An ore is a metallic mineral from which the metal can be extracted profitably. The ores can be: 1. Sulphide ores – CuS (Copper sulphide), PbS (Galena), HgS (Cinnabar) 2. Carbonate ores – CaCO3, PbCO3 3. Oxide ores – Fe2O3 (Haematite), Fe3O4 (Magnetite), Al2O3.2H2O (Bauxite) Metallurgy It is the science of extraction of metals in their pure form from their ore. Metallurgical processes The processes, which are involved in the extraction of metals from their ores, are called metallurgical processes. Gangue They are impurities and unwanted materials like sand, soil and some other minerals, which are associated with the ore. Uses of Metals 1. Metals like gold and silver are used in jewellery because they have a good lustre and don’t corrode easily. 2. Metals like copper and aluminium are used to make electrical wires because they are good conductors. Al is light and cheap. 3. They are used to make utensils because they are good conductors of heat, like Cu, Al, etc. 4. Due to their tensile strength metals like iron are used for construction purposes. 5. Note: We should not store pickles, chutneys, juices, etc. in aluminium foil because the acids in them react with Al to form poisonous salts. Steps involved in metallurgy 1. Concentration of the ore: The ores are associated with impurities called gangue. Concentration involves separation of gangue from the ore. 2. Conversion of Sulphide/Carbonate ore: They are converted to oxide ores because it is easier to extract metals from the oxides rather than directly from the sulphides. Heating the sulphide/carbonate ores in the presence of oxygen does this. 3. Reduction of oxides: This can be done by reducing the ore to give impure metal. 4. Refining of impure metal: The metal that is reduced is still impure and has to be refined to give the pure metal. This can be done by electrolytic refining. Concentration of the ore Depending on the ore, different methods of concentration are used. They are: 1. Hydraulic Washing: The ore is first crushed and powdered. The powdered ore is washed with a stream of water. The lighter impurities get washed away by the water and the heavier ore particles are left behind. This method is used for ores of lead, tin, etc. 2. Magnetic separation: Some ores are magnetic in nature. Magnetic ores are separated in this way. The ores is crushed and put on a conveyor belt and made to pass over a magnetic roller. The impurities fall over separately as soon as the conveyor belt turns. The ore particles are attracted to the magnetic and collect separately a little distance away. This method is used for ores such as magnetite (iron). 3. Froth floatation: This method is used to extract sulphide ores. A tank is taken with water. A little pine oil is added to it. The powdered ore is then added to the tank. The mixture is stirred and air is blown into it. Froth is formed at the surface of water. The sulphide ore particles are wetted by the oil and these particles come up with the froth to the surface. The impurities are left behind and they settle at the bottom of the tank. Conversion of the concentrated ores into their metallic oxides Concentrated ores need to be converted to pure metals. The methods of conversion are: 1. Roasting: In this process, the metal ore is heated in the presence of air. 2Cu2S + O2 → 2Cu2O + 2SO2 2. Calcination: When the ores are heated in the absence of air, the process is known as calcination. This is used only for carbonate ores. CaCO3 → CaO + CO2 PbCO3 → PbO + CO2 ZnCO3 → ZnO + CO2 Reduction of Metal oxides into Metals 1. Smelting: It is the reduction of the oxides in the presence of carbon (coke). 2CuO + C → 2Cu + CO2 2ZnO + C → 2Zn + CO2 2PbO + C → 2Pb + CO2 2Fe2O3 + 3C → 4Fe + 3CO2 2. Electrolytic reduction: Metals such as Al, Mg and Ca are very reactive, so their oxides cannot be reduced to metal by smelting. The oxides of these metals are reduced by electrolytic reduction. The ore is taken in molten form in a tank and electricity is passed through this molten oxide, The molten oxide is known as the electrolyte. The oxide splits up on passing electricity. The metal and oxygen are obtained at the two different electrodes. 2Al2O3 → 4Al + 3O2 Refining of the metal to obtain pure metal The metal obtained after reduction is still impure. Refining is done to get the pure metal from the impure metal. Generally, refining is done by electrolytic refining. A thin strip of pure metal is taken as the positive electrode and a thick impure metal rod is the negative electrode. A solution of metal salt is the electrolyte. When current is passed impure metal goes into the solution and only the pure metal out of this deposits on the thin pure rod. The impurities remain in solution and settle down. Extraction of Iron from Haematite Iron has the following ores: 1. Haematite – Fe2O3 2. Magnetite – Fe3O4 Iron is generally (commercially) extracted from Haematite. I Concentration of the Ore Most of the impurities are removed by washing. Further extraction of iron from ore is carried out in a Blast Furnace. II Reduction of the Ore (Blast Furnace) It is a furnace which is lined inside with fire bricks. The furnace has pipes at the sides near the bottom from which hot air is blown out. The charge which consists of the crushed ore (Fe2O3) + Limestone + Coke is fed into a blast furnace from the top. The core reacts with Oxygen from the hot air to form carbon dioxide. C + O2 → CO2 The carbon dioxide formed further reacts with carbon and gets reduced to carbon monoxide. CO2 + C → 2CO Iron oxide ore is then reduced by CO. Fe2O3 + 3CO → 2Fe + 3CO2 SiO2 is a major impurity in the iron oxide ore. Silicon dioxide is removed with the help of CaCO3. CaCO3 → CaO + CO2 Calcium carbonate decomposes with heat to give calcium oxide (CaO) and carbon dioxide (CO2). The CaO formed reacts with impurities Silicon dioxide and forms CaSiO3 (molten) and is called slag. CaO + SiO2 → CaSiO3 (molten) The molten slag forms a layer above the molten iron called slag. Slag has two purposes: 1. It forms a layer above molten iron, so it prevents the iron from getting oxidised to iron oxide. 2. The formation of slag removes the impurity silicon dioxide. Extraction of Copper from its ore Copper has the following ores: 1. Copper Pyrites – CuFeS2 2. Copper Glance – Cu2S 3. Cuprite - Cu2O Copper is commonly extracted from its sulphide ore, copper pyrites. I Concentration by ‘Froth Floatation’ II ‘Roasting’ to get CuO III Reduce CuO by ‘Smelting’ to Cu IV ‘Electrolytic Refining’ of Cu In the electrolytic refining of copper, a thick impure copper rod is one of the electrodes and the other electrode is a thin pure copper rod. A solution of CuSO4 is taken as the electrolyte. The electrodes are connected to a battery. The thick impure rod forms the Cathode. When the electricity is passed the metal from the impure rod goes into the solution and deposits on the pure copper on the thin rod, that is, the cathode. The impurities (like, gold and silver) remain in the solution and settle down at the bottom of the tank and is called anode mud. In some time, the pure copper rod gets thicker and the other gets thinner. Extraction of Aluminium I Concentration of the ore II ‘Calcined’ to remove water and make bauxite dry III Made purer by adding NaOH IV Electrolytic Reduction of Al2O3 to get Al Cryolite (Na3AlF6) is added to lower the melting point of allumina to get molten aluminium oxide in the cell. It also makes allumina a better conductor of electricity. The graphite lining on inner walls of cell forms the cathode. Graphite rods or plates form the anode. The electrolyte is allumina + cryolite. Aluminium gets deposited at the cathode. Oxygen gets liberated at the anode and eats away the plates and has to be replaced from time to time. 2Al2O3 → 4Al + 3O2 Slag Slag is formed in the blast furnace with the reaction of silicon dioxide (sand) and calcium oxide. Slag forms a protective layer over the molten iron and prevents it from oxidising into iron oxide and also removes the major impurity sand. Flux Flux (calcium carbonate) is added with the charge. It helps in the extraction of the metal and helps in forming the slag. Types of Iron Pig Iron This is the iron produced in the blast furnace. It is the cheapest form of iron. It has impurities such as Si, P and S. Hard, brittle Not malleable and ductile Gets rusted easily Can be melted and made into cast iron. Wrought Iron It is the purest form of iron. It has 0.2% carbon. It is manufactured by heating Pig iron with FeO. Stronger than pig iron Malleable and ductile Steel An alloy of iron containing 0.5% to 1.5% carbon. An alloy is a homogeneous mixture of 2 or more metals or sometimes a non-metal in small quantities. Steel is tough and hard, malleable and ductile. By adding Ni and Chromium, we get stainless steel. Reaction of Metals With Acids Na + HCl → NaCl + H2 Mg + 2HCl → MgCl2 + H2 Zn + 2HCl → ZnCl2 + H2 2Al + 6HCl → 2AlCl3 + 3H2 With Oxygen 4Na + O2 → 2Na2O Mg + O2 → MgO Al + O2 → Al2O3 With Water 2Na + 2H2O → 2NaOH + H2 2K + 2H2O → 2KOH + H2 Ca + H2O → Ca(OH)2 + H2 Mg + H2O → MgO + H2 Zn + H2O → ZnO + H2 Fe + H2O → Fe2O3 + H2 Displacement Reaction CuSO4 + Fe → FeSO4 + Cu In the above reaction, iron displaces copper from Copper Sulphate solution to form Iron II Sulphate (Ferrous Sulphate) solution. This reaction occurs because iron is more reactive than Copper. The ferrous sulphate solution is greenish, so the blue colour fades and we get a light greenish solution. Copper gets deposited on the iron rod as a reddish brown coat. Displacement reaction is that in which a metal higher up in the reactivity series can replace a metal less reactive in its salt solution. Zn + CuSO4 → ZnSO4 + Cu Mg + CuSO4 → MgSO4 + Cu Mg + FeSO4 → MgSO4 + Fe ZnSO4 + Cu → ZnSO4 + Cu AgNO3 + Cu → Cu(NO3)2 + Ag Unreactive Metals Some metals do not react easily and are called noble or unreactive metals. Eg: Au, Ag and Pl Corrosion Wasting away if metals layer by layer due to its reaction with air and moisture. Corrosion of iron is called rusting. When copper corrodes, its surface is turned green due to the formation of Copper Carbonate. Silver forms silver sulphide (Ag2S) and its surface becomes black. This is called tarnishing. Silver reacts with H2S in the air and forms Ag2S. Iron forms hydrated ferric oxide which is called rusting. Aluminium reacts with air to form Aluminium Oxide which forms a protective layer on the surface and prevents Al under it from further corrosion. Rusting Fe rusts to form a reddish-brown deposit. This is: Fe2O3.xH2O (x is the number of water molecules) Rusting requires both air and water (moisture). Even if one of the factors is absent, Fe does not rust. Prevention of Corrosion 1. Painting: Paint cuts off the direct contact of air with the iron surface. 2. Greasing/Oiling: This also cuts off the direct contact between the metal and air. 3. Galvanizing: In galvanizing, we deposit a layer of a metal that is less reactive (zinc) on the more reactive metal (iron). Zinc is more resistant to corrosion than iron and in galvanized iron, supply of air and water is cut off from the iron. 4. Electroplating: It is a process of deposition of a superior metal (more resistant to corrosion) on the surface of an inferior metal by the process of electrolysis. Eg: Artificial Jewellery 5. Anodising: Anodising is deposition of a thin uniform layer of aluminium oxide on aluminium metal surface by electrical processes. 6. Alloying: An alloy is a homogeneous mixture of a metal with one or more other metals and sometimes a non-metal. (Eg: Carbon is small amounts). Advantages of alloying 1. Prevents corrosion 2. Changes the properties of the metal Solder is an alloy of Sn + Pb and has a melting point less than Pb and Sn. Hence it is used for soldering. 3. Increases chemical resistance of the metal 4. Makes metal harder