Type of VP/MAP cooked meat

advertisement

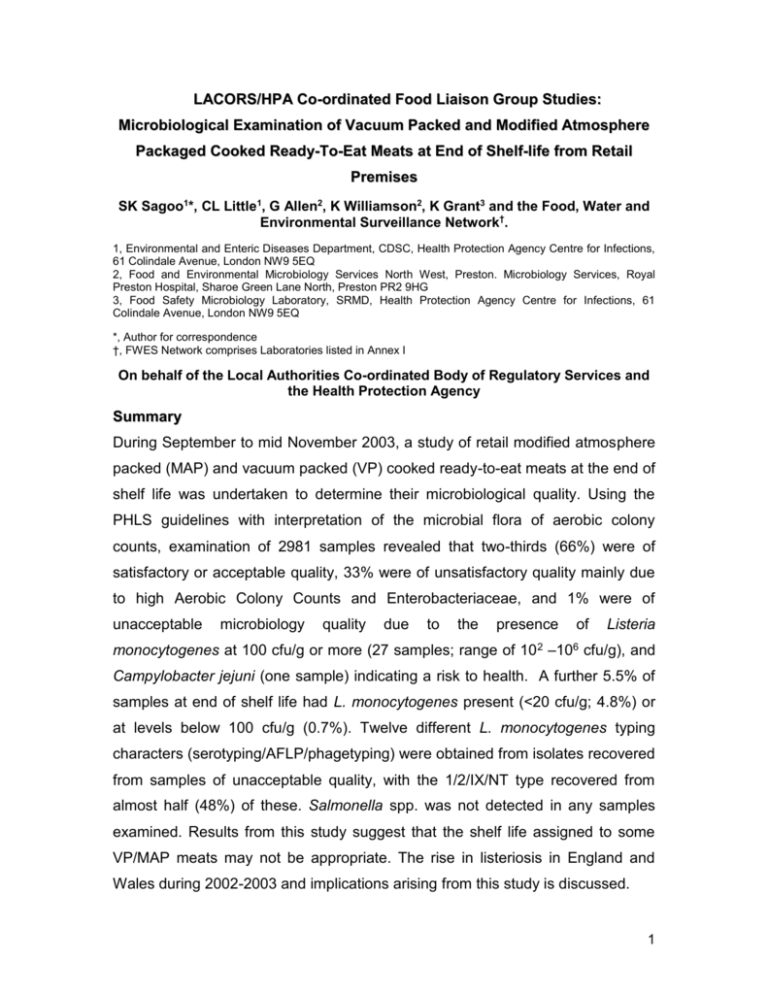

LACORS/HPA Co-ordinated Food Liaison Group Studies: Microbiological Examination of Vacuum Packed and Modified Atmosphere Packaged Cooked Ready-To-Eat Meats at End of Shelf-life from Retail Premises SK Sagoo1*, CL Little1, G Allen2, K Williamson2, K Grant3 and the Food, Water and Environmental Surveillance Network†. 1, Environmental and Enteric Diseases Department, CDSC, Health Protection Agency Centre for Infections, 61 Colindale Avenue, London NW9 5EQ 2, Food and Environmental Microbiology Services North West, Preston. Microbiology Services, Royal Preston Hospital, Sharoe Green Lane North, Preston PR2 9HG 3, Food Safety Microbiology Laboratory, SRMD, Health Protection Agency Centre for Infections, 61 Colindale Avenue, London NW9 5EQ *, Author for correspondence †, FWES Network comprises Laboratories listed in Annex I On behalf of the Local Authorities Co-ordinated Body of Regulatory Services and the Health Protection Agency Summary During September to mid November 2003, a study of retail modified atmosphere packed (MAP) and vacuum packed (VP) cooked ready-to-eat meats at the end of shelf life was undertaken to determine their microbiological quality. Using the PHLS guidelines with interpretation of the microbial flora of aerobic colony counts, examination of 2981 samples revealed that two-thirds (66%) were of satisfactory or acceptable quality, 33% were of unsatisfactory quality mainly due to high Aerobic Colony Counts and Enterobacteriaceae, and 1% were of unacceptable microbiology quality due to the presence of Listeria monocytogenes at 100 cfu/g or more (27 samples; range of 10 2 –106 cfu/g), and Campylobacter jejuni (one sample) indicating a risk to health. A further 5.5% of samples at end of shelf life had L. monocytogenes present (<20 cfu/g; 4.8%) or at levels below 100 cfu/g (0.7%). Twelve different L. monocytogenes typing characters (serotyping/AFLP/phagetyping) were obtained from isolates recovered from samples of unacceptable quality, with the 1/2/IX/NT type recovered from almost half (48%) of these. Salmonella spp. was not detected in any samples examined. Results from this study suggest that the shelf life assigned to some VP/MAP meats may not be appropriate. The rise in listeriosis in England and Wales during 2002-2003 and implications arising from this study is discussed. 1 Introduction Pre-packed sliced meats make up a third of the UK sliced meat market and ham is the most popular sliced meat accounting for over half of UK sales 1. Most prepacked sliced meats are purchased from multiple retailers1 and market growth of retail sliced meats in the UK between 1999 and 2003 increased by 111%, and was worth £570 million in 20032. Modified Atmosphere Packed (MAP) and vacuum packed (VP) sliced meats have become increasingly popular due to consumer demands for fresher, longer shelf-life convenience foods that are safe, nutritional and organoleptically pleasing. Vacuum packaging is essentially the evacuation of air from a package that is then hermetically sealed. With MAP, air is again removed and replaced by a strictly controlled gaseous mixture comprising of carbon dioxide, oxygen and/or nitrogen. A UK industry code of practice exists that provides information on available VP and MAP methods 3, 4 . Both packaging techniques have the potential to increase the shelf life of many chilled foods without adversely affecting the quality. Whilst changing the atmosphere may retard the growth of spoilage organisms, it may allow growth of psychrotrophic pathogenic bacteria such as Clostridium botulinum and Listeria monocytogenes. The UK industry code of practice advises that the shelf life of VP/MAP cooked, uncured meats should not exceed 10 days at 3-8ºC unless its microbiological safety under extended storage conditions can be demonstrated. Cured meats such as ham typically have specific controlling factors and therefore can have a longer shelf life of more than 10 days 3. Temperature control regulations require that chilled VP/MAP foods, including cooked meats, must be stored and displayed at or below 8ºC in retail premises5. However, manufacturers often use a storage temperature of less than 3ºC during predistribution and generally recommend 5ºC or less for domestic storage by the consumer6. Refrigeration storage temperatures may therefore vary from predistribution, retail and the consumer home. 2 Contaminated food is considered to be the main source of L. monocytogenes infections in humans, including ready-to-eat meats, which have been responsible for causing major outbreaks of L. monocytogenes in France, Norway, Australia, and the US 7-11. Although listeriosis is a rare disease in the UK in contrast to infection caused by other major bacterial foodborne diseases 12 it remains a cause for concern due to the increased risk posed to vulnerable groups and severity of disease12,13. L. monocytogenes grows at refrigeration temperatures and has the ability to colonise and become endemic in the food processing environment, including process equipment, with potential contamination of endproducts. With a growing demand for ready-to-eat products with extended shelf life this poses a serious challenge to the food industry and is of great concern. The draft EC Regulation on microbiological criteria for foodstuffs proposes that L. monocytogenes should be below 102 cfu/g during the shelf life of ready-to-eat foods14. VP/MAP cooked meats were the focus of regional studies involving Local Authority food liaison groups in the North West and East of England during 200215-17. Almost 2% of VP/MAP meats at end of shelf life were found to be of unacceptable microbiological quality due to levels of L. monocytogenes in excess of 100 cfu/g, A valid shelf life and appropriate temperature control provided is therefore paramount for the microbiological safety of these products. As a consequence of the regional investigations a national study was undertaken in 2003 as part of the Local Authority Co-ordinators of Regulatory Services (LACORS), and the Health Protection Agency (HPA) Coordinated Food Liaison Group Microbiological Sampling Programme. The aims of the study were to determine the microbiological quality of VP/MAP cooked ready-to-eat meats on sale in the UK at the end of their shelf life. This included identifying the predominant microflora of high Aerobic Colony Counts (ACCs) from samples to provide a more helpful interpretation of the microbiological quality of cooked meats. 3 Materials and Methods Sample Collection VP/MAP cooked ready-to-eat meats collected from retail premises were examined at end of shelf life by 37 laboratories (HPA, HPA Collaborating and non-HPA) in the UK between the 1st September and 10 th November 2003 according to a standardised protocol. VP/MAP meats included in the study were those that were sliced, wafer thin or portions of meat. Fermented or dried meat products and pate were specifically excluded from the study. Samples (~100g) were collected and transported to laboratories by staff from 348 local Environmental Health Departments, involving 52 Local Authority Food Liaison Groups, in accordance with the Food Safety Act 1990, Code of Practice No 7 18 (revised in 2004) and guidance on microbiological food sampling19. Information on the VP/MAP meat samples and retail premises was obtained by observation and enquiry and recorded on a standard proforma. This included information on the premises and practices with regard to type, and temperature, of the display area, packaging practices, presence of a hazard analysis system and the level of food hygiene training received by the manager. Food hygiene inspections of premises are carried out by environmental health officers to assess hygiene and compliance with public health protection aspects of food law 20. Some food premises and businesses pose a greater risk to the consumer than others, which is reflected by the frequency of inspection. Premises rated Inspection Rating Category A posed the greatest risk and were visited at least once every six months while premises rated Inspection Rating Category F posed the least risk and were visited at least once every five years. Environmental health officers also consider the number of customers likely to be put at risk if there is a failure in food hygiene and safety procedures in a particular premise, and award a consumer at risk score accordingly. Scores range from 0 (very few customers at risk) to 15 (a substantial number of customers at risk). Confidence in management and food safety management systems are also assessed and 4 scored accordingly. Confidence in management scores range from 0 (highly confident) to 30 (no confidence). Sample Examination On receipt at the laboratory samples were stored in a monitored laboratory refrigerator at 6±2ºC until the end of shelf life (i.e. use by date), whereupon samples were examined. Aerobic Colony Counts (ACC), Enterobacteriaceae, Escherichia coli, Clostridium perfringens, Staphylococcus aureus, total Listeria spp. including L. monocytogenes were enumerated or presence sought in accordance with HPA Standard Microbiological Methods21-27. Presence of Campylobacter spp. were sought by enrichment in Bolton Selective Enrichment Broth with incubation at 37°C for 4 hours, followed by further incubation at 41.5°C and subculture to Campylobacter selective agar (CCDA) after 442 h. Inoculated plates were incubated at 41.5°C for 48 h, and colonies identified as described in HPA Standard Microbiological Method F2128. Presence of Salmonella spp. were sought in accordance with BS EN 1S0 6579:200229. Isolates of L. monocytogenes at levels at 102 cfu/g or more were sent to the Food Safety Microbiology Laboratory (FSML), HPA Centre for Infections for further characterisation by sero- and phage typing, and amplified fragment length polymorphism (AFLP). Isolates of Campylobacter spp. were sent to the Laboratory of Enteric Pathogens (LEP), HPA Centre for Infections for typing. To improve the interpretation of the microbiological quality of cooked meats the predominant microflora of high ACCs obtained from samples were identified. For ham and tongue samples with ACCs at 107 cfu/g or more and for other meats (e.g. beef, pork, poultry, etc.) with ACCs at 106 cfu/g or more the predominant microflora was determined by carrying out the Gram stain, catalase and oxidase tests. The percentage component of high ACC results were reported in to three groups as follows: Lactic acid bacteria (Gram positive and catalase negative; i.e. lactobacilli and streptococci) 5 Gram negative and oxidase positive bacteria (e.g. Pseudomonas spp., Aeromonas) Gram negative and oxidase negative bacteria (e.g. Enterobacteriaceae, Acinetobacter) Microbiological results were compared to the PHLS Guidelines for the microbiological quality of some ready-to-eat foods sampled at the point of sale (Table 1). The PHLS guidelines do not include interpretation of the component microflora of the Aerobic Colony Counts. For the purpose of this study if an unsatisfactory Aerobic Colony Count consisted predominantly of lactic acid bacteria it was classified as unsatisfactory only if levels exceeded 10 8 cfu/g. If Gram-negative bacteria predominated the Aerobic Colony Count was deemed unsatisfactory if the level exceeded 107 cfu/g. Table 1. PHLS guidelines for the microbiological quality of some ready toeat foods sampled at the point of sale30: Key to classification of sliced meat Criterion Aerobic Colony Count (All meats other than ham and tongue) Aerobic Colony Count (Ham, tongue) Enterobacteriaceae Escherichia coli Staphylococcus aureus Clostridium perfringens Listeria spp. (total) Listeria monocytogenes Campylobacter spp. Salmonella spp. *N/A, Not Applicable Microbiological quality (cfu per gram unless stated) Satisfactory Acceptable Unsatisfactory Unacceptable/ potentially hazardous <105 105-<106 >106 N/A* <106 <102 <20 <20 <20 <20 <20 Not detected in 25g Not detected in 25g 106-<107 102 - <104 20 - <102 20 - <102 20 - <102 20 - <102 20 - <102 >107 104 102 102 - <104 102 - <104 102 N/A N/A N/A N/A 104 104 N/A 102 Detected in 25g Detected in 25g 6 Statistical Analysis Descriptive and statistical analysis of the data was undertaken using Microsoft excel version 9 and Epi Info version 6.04d. Relative proportions were compared using chi-squared (χ2) and fishers exact test. Results Bacteria isolated from VP/MAP ready-to-eat meats Of the 2981 samples examined, 1362 were ham and tongue and of these, 56% (757) had ACCs of 107 cfu/g or more. Of the 1619 other meat samples, 65% (1047) had ACC levels in excess of 106 cfu/g. Enterobacteriaceae were present at 104 cfu/g or more in 15% (458) of samples (Table 2). E. coli was present at 102 cfu/g or more in 0.3% (10) of all meat samples. Total Listeria spp. (including L. monocytogenes) was detected in 6.4% (191) of samples, and also present in 1% (29) of samples in the range of 20 to less than 100 cfu/g, and in a further 1.4% (43) of samples at 100 cfu/g or more. L. monocytogenes was detected in 4.8% (143) samples, and also present in 0.7% (20) of samples in the range of 20 to less than 100 cfu/g and in a further 1% (27) of samples at 100 cfu/g or more (ranging from 1.0x102 to 2.4x106 cfu/g). The Listeria isolates recovered from samples with levels in excess of 102 cfu/g were L. innocua (5), L. seeligeri (2), L welshimeri (2) and L. monocytogenes (27; serotype 1/2 (22), 4b (2), non-typable (1) (Tables 3 and 4)). Campylobacter spp. (C. jejuni HS44 PT70) was detected in 0.03% (1) sample (turkey, MAP). Salmonella spp. was not detected from any of the samples examined. 7 Table 2. Microbiological results of 2981 VP/MAP ready-to-eat meats at end of shelf life ND* in 25g Aerobic Colony Counts Enterobacteriaceae Escherichia coli Staphylococcus aureus Clostridium perfringens Listeria spp. (total) -L. monocytogenes Campylobacter spp. Salmonella spp. 2717 2953 2971 D§ in 25g <10/ <20† 110 1994a 2952b 2951b 2948a 191 (&<20b) 143 (&<20b) 1 20<102 102 <103 103 <104 104 <105 105 <106 106 <107 107 NE¶ 46 138 6 9 4 29 20 121 184 155 207 2 190 188 1 330 183 437 45 1 1579 29 25 13 12 10 4 3 13 13 19 21 29 11 5 27 10 2 1 *ND; Not detected; §D, Detected; ¶NE, Not examined (full set of microbiological parameters not performed on sample due to insufficient sample collected) †, cfu/g a, lower limit of detection 10 cfu/g; b, lower limit of detection 20 cfu/g Table 3. Listeria spp. present in VP/MAP cooked meats at 102 cfu/g or more Listeria spp. No. Samples* L. monocytogenes 27 L. innocua L. seeligeri L. welshimeri Total 5 2 2 36 Meat type (No. Samples) Ham (10), turkey (6), chicken (5), beef (4), corned beef (2), Ham (2), beef (2), chicken (1) Ham (2) Ham (1), Pork (1) *, Six isolates were not typed L. monocytogenes isolate types present in VP/MAP cooked meats at 102 cfu/g or more Twelve different L. monocytogenes typing characters (serotyping/AFLP/phage typing) were obtained from samples with levels of 10 2 cfu/g or more, i.e. of unacceptable microbiological quality (Table 4), with the 1/2/IX/NT type recovered from almost half (48%; 12/25) of these. Approximately half (48%; 12) of the isolates were obtained from meats produced by Manufacturer A, with the typing character 1/2/IX/NT predominating in these samples (8; 67%). These adverse results were reported to the appropriate food authority, manufacturer and the Food Standards Agency and full investigations were undertaken. 8 Table 4. Typing characters of L. monocytogenes isolated from VP/MAP cooked meat of unacceptable microbiological quality at end of shelf life Typing character No. Samples* Meat type (No. Samples)¶ 12 Beef (1†), Chicken (3‡), Ham (5), Turkey (3) Beef Chicken Turkey Corned beef† Beef Beef (1), Ham (2) Turkey Corned beef Ham Chicken Ham (Serotype/AFLP§/phagetype) 1/2/ IX/NT 1/2/II/Y 1/2/VII/NT 1/2/XI/NT 4b/V/A 4b/II/NT 1/2/II/Z 1/2/IX/Y 1/2/IX/VV 1/2/II/NT NT/XI/NT 1/2/NT/WW Total 1 1 1 1 1 3 1 1 1 1 1 25 *, Two isolates were not typed §, Amplified fragment length polymorphism ¶, MAP meats unless stated (†, Vacuum packed; ‡, 1 sample of chicken was vacuum packed) Microbiological quality of VP/MAP cooked ready-to-eat meats Based on the PHLS microbiological guidelines for some ready-to-eat foods sampled at the point of sale (Table 1) and without interpretation of the component microflora associated with high ACCs, a quarter (24%; 715/2981) of the VP/MAP meat samples were satisfactory, 13% were acceptable, and 62% were of unsatisfactory microbiological quality (Fig. 1). However, 1% (28) of samples were of unacceptable microbiology quality due to the presence of L. monocytogenes at 102 cfu/g or more (27), and C. jejuni (1). For some cooked sliced meats the ACC can reach 10 8 cfu/g or more during shelf life due to the presence and growth of lactic acid bacteria without detrimental effect to the product. However presence of Gram negative bacteria in high numbers (>107 cfu/g) may cause spoilage31, usually due to slime production or taste taint. High ACC results from samples were therefore examined to identify the bacteria that predominated. The majority (88% 1587/1804) contained lactic acid bacteria (Table 5), which comprised the entire component (100%) of the 9 ACC, 2% (40) of samples with high ACC levels contained Gram-negative oxidase positive bacteria and 10% (177) of samples contained Gram-negative oxidase negative bacteria (Table 5). Table 5. Predominant microflora of high Aerobic Colony Counts from VP/MAP cooked meats at end of shelf life Predominant bacteria of ACC Ham, tongue (≥107 cfu/g; n=757) Other meats (≥106 cfu/g; n=1047) All meats Gram positive, catalase negative (Lactic acid bacteria*) Gram negative, oxidase positive (e.g. Pseudomonas spp., Aeromonas) Gram negative, oxidase negative (e.g. Enterobacteriaceae, Acinetobacter) 715 (94%) 872 (83%) 1587 (88%) 12( 2%) 28 (3%) 30 (4%) 147 (14%) (n=1804) 40 (2 %) 177 (10%) *, lactobacilli, streptococci Re-evaluation of the results following interpretation of high ACCs according to their predominant flora (>108 cfu/g LAB; >107 cfu/g Gram negative bacteria) classified 46% (1381/2981) of the VP/MAP meat samples as satisfactory, 20% (600) as acceptable, 33% (972) as unsatisfactory and 1% (28) as unacceptable microbiology quality (Fig. 2). Fig 1 Microbiological quality of VP/MAP cooked meats at end of shelf-life; without interpretation of high ACCs (n=2981) Acceptable 13% Unsatisfactory 62% Satisfactory 24% Unacceptable /potentially hazardous 1% 10 Fig 2 Microbiological quality of VP/MAP cooked meats at end of shelf-life; with interpretation of high ACCs (n=2981) Acceptable 46% Satisfactory 20% Unacceptable /potentially hazardous 1% Unsatisfactory 33% Product information in relation to microbiological quality Data analysis was carried out on samples and product information using the PHLS microbiological guidelines with interpretation of ACCs. Type of VP/MAP cooked meat Almost half (45%; 1351/2981) of the VP/MAP meat samples collected were ham, followed by turkey (18%), chicken (17%), beef (12%) and pork (7%) (Fig 3). Significantly more samples of chicken (45%; 224/495), beef (43%; 160/371) and turkey (41%; 219/523) were of unsatisfactory or unacceptable quality compared with ham (23% 317/1351) or pork (32% 67/206) (p=0.0001). 11 Fig 3 Types of VP/MAP ready-to-eat meat collected from retail premises (n=2981) Chicken 17% Turkey 18% Other (Duck, lamb, haslet etc) 1% Beef 12% Pork 7% Ham 45% Over two-thirds of samples collected were sliced meat (67%; 1992/2981), 18% (549) were wafer thin meats, 4% (122) were portions (e.g. chunks, shavings, strips) and for 11% (318), this information was not recorded. The proportion of sliced, portioned and other meat products of unsatisfactory or unacceptable microbiological quality was higher (36%, 37% and 33%, respectively) when compared to wafer thin meat (26%). This finding was only significant when comparing sliced meat to wafer thin meat (p=0.0001). Most samples (80%; 2391/2981) were MAP, 18% (525) were VP, and for 2% (65) of samples, this information was not recorded. Significantly more samples that were VP (43%; 228/525) were of unsatisfactory or unacceptable microbiological quality compared to those that were MAP (31%; 751/2391) (p=0.0001). The majority of cooked meat samples (95% 2844/2981) were not packaged on the premises, 4% (113) were and for 1% (24) of samples, this information was not recorded. Although represented in comparatively low numbers, more samples packaged on the premises were of unsatisfactory or unacceptable 12 microbiological quality (48%; 54/113) compared to meat samples packaged elsewhere (32%; 934/2844). Four (119/2981) percent of samples were packed more than once in their history as a ready-to-eat product, 22% (676) were not, but for 74% (2186) of samples this information was not known. Proportionally the number of unsatisfactory or unacceptable VP/MAP meat samples packed more than once was higher (38%) compared to those that were not (36%), however this finding was not statistically significant. The majority (96%; 2871/2981) of meat samples were not organic, 1% (27) were and for 3% (83) of samples, this information was not recorded. The proportion of samples of unsatisfactory or unacceptable microbiological quality that was not produced organically was higher (33%) when compared to organic meats (15%), however this was not statistically significant. Approximately two-thirds (67%; 1990/2981) of samples were recorded as of UK origin, 12% (360) were non-UK produced (i.e. of other EU or Third Country origin) and for 21% (631) of samples, this information was not recorded. There was no significant difference in the proportion of meat samples of unsatisfactory or unacceptable microbiological quality when comparing samples that were imported (30%) with those that were not (35%). Cooked meats packaged on the premises Of the 113 meat samples packaged on the premises, most were VP (96%; 108), and the remainder were MAP (4%; 5). Forty eight percent (52/108) and 40% (2/5) of VP and MAP meat, respectively, packaged on the premises were of unsatisfactory or unacceptable microbiological quality. However it should be noted that the sample number of MAP meats packed on the premises is small and that no statistical conclusions should be drawn from these results. 13 Almost two-thirds (63%) of samples were packaged with machinery used for only cooked ready-to-eat food, and a quarter (26%) were packaged with machinery used for both raw meat and cooked/ready-to-eat food (Table 6). The different uses of the packaging machinery had no significant effect on the microbiological quality of the VP/MAP meats with regard to samples of unsatisfactory or unacceptable microbiological quality (Table 6). Most (86%) samples were packed using packaging materials kept in a visually clean area and away from any source of contamination as judged by the sampling officer (Table 6). No significant difference in the proportion of samples that were of an unsatisfactory or unacceptable microbiological quality was found between those packed in a visually clean area compared to those that were not (Table 6). The majority (81%: 92/113) of samples were packed with machinery that was cleaned in between uses, 10% were not and for 9% of samples, this information was not recorded. Of the samples collected from premises where the machinery was cleaned in between uses, almost half (46% 42/92) of the machinery were cleaned using disinfectant, 30% using detergent, 15% using a sanitizer and for 9%, this information was not recorded. There was no significant difference in the microbiological quality of VP/MAP meats in relation to the cleaning practices used on packaging machinery (Table 6). Forty five percent of samples were packaged using machinery that had the original manufacturers machinery instructions available (Table 6). However, the presence or not of the original manufacturers machinery instructions had no significant effect on the microbiological quality of the VP/MAP meats with regard to samples of unsatisfactory or unacceptable microbiological quality (Table 6). 14 Table 6. Microbiological quality of VP/MAP meats in relation to packaging practices on the premises Packing Details No. Samples No. samples of unsatisfactory or unacceptable quality (%) (n=113) (%) Packaging machinery used for: Raw Meat Cooked RTE* food Both raw meat & cooked RTE food Not Recorded 8 71 29 5 (7) (63) (26) (4) 2/8 (25%) 35/71 (49%) 14/29 (48%) 3/5 (60%) Packing material kept in a visually clean area: Yes No Not Recorded 97 6 10 (86) (5) (9) 47/97 ((48%) 1/6 (17%) 6/10 (60%) Packing machinery cleaned in between uses: Yes No Not Recorded 92 11 10 (82) (9) (9) 44/92 (48%) 5/11 (45%) 5/10 (50%) Original manufacturers instructions available for packaging machinery: Yes No Not Recorded 51 52 10 (45) (46) (9) 24/51 (47%) 25/52 (48%) 5/10 (50%) Meat packaging included in retailer’s hazard analysis system: Yes No Not Recorded 92 12 9 (82) (10) (8) 43/92 (47%) 6/12 (50%) 5 /9 (55%) Meat product with shelf-life of ≥10 days: Yes No Not Recorded 88 20 5 (78) (18) (4) 40/88(45%) 11/20(55%) 3/5 (60%) Comprehensive risk assessment undertaken for product with shelf-life ≥10 days (n=88) Yes No Not known Not Recorded 56 23 4 5 (64%) (25%) (5%) (6%) 23/56 (41%) 12/23 (52%) 2/4(50%) 3/5 (60%) *RTE, Ready-to-eat For most (82%) samples packaged on the premises, meat packaging was included in the retailer’s hazard analysis system (Table 6). The inclusion or not 15 of meat packaging in the hazard analysis system had no significant effect on the microbiological quality of the VP/MAP meats with regard to samples of unsatisfactory or unacceptable microbiological quality (Table 6). Over three-quarters (78%) of the products packed on the premises had a shelf life of more than 10 days, and of these 64% had undertaken a comprehensive risk assessment (Table 6). A higher proportion of the samples sampled with a shelf life of 10 or more days and where a risk assessment had not been undertaken for product shelf life were of unsatisfactory or unacceptable quality (52%) compared to those sampled which had such a risk assessment undertaken (41%), although this was not significant (Table 6). Premises Information Storage and display temperature The majority (97%) of samples were stored in a visually clean display area as judged by the sampling officer, and most samples (87%) were displayed in upright units with shelves (Table 7). There was no significant difference in the proportion of unsatisfactory or unacceptable samples and the visual cleanliness or the type of display unit the VP/MAP meat was displayed in (Table 7). At the time of sampling, the air temperature between VP/MAP meat on display was equal or below 5°C for over two-thirds (68%) of samples, and above 5°C and equal or below 8°C for a further quarter (23%) of samples (Table 7). The storage temperature of packaged meat on display had no significant effect on the microbiological quality of VP/MAP meat with regard to samples of unsatisfactory or unacceptable microbiological quality (Table 7). Most (93%) samples had storage temperature information present on the packaging, of which 61% advised to keep the product refrigerated and 32% specified a refrigeration temperature (Table 7). Where a particular storage temperature was provided on the 16 packaging, 75% specified to store between 0-5°C, 15% between 2-5°C, 5% specified at less than 7°C and another 5% specified at less than 8°C. Table 7 Microbiological quality of VP/MAP meats in relation to their display and storage Storage and display details Display area visually clean: Yes No Not recorded No. Samples (n=2981) (%) No. samples with unsatisfactory or unacceptable quality (%) 2883 39 59 (97) (1) (2) 969/2883 (34%) 9/39 (23%) 22/57 (37%) 2604 137 72 107 (87) (4) (2) (3) 848/2604 (32%) 54/137 (39%) 29/72 (40%) 44/107 (41%) 61 (2) Storage temperature on packaging: Keep refrigerated No temperature indicated Temperature specified Not recorded 1806 145 953 77 (61) (5) (32) (2) 535/1806 (29%) 53/145 (36%) 373/953 (39%) 39/77 (50%) Air temperature between packaged meat on display: Below 5ºC Above 5ºC and equal/below 8ºC Above 8ºC Not recorded 2030 685 160 106 (68) (23) (5) (4) 668/2030 (33%) 242/685 (35%) 51/160 (32%) 39/106 (37%) Temperature of display unit monitored by retailer: Yes No Not recorded 2752 103 126 (93) (3) (4) 919/2752 (33%) 39/103 (38%) 42/126 (33%) Temperature of display unit monitored by: (n=2752): Link to local/remote computer Thermometer in unit Temperature probe 931 1211 610 (34) (44) (22) 325/931 (35%) 438/1211(36%) 237/610 (39%) Type of display unit: Upright with shelves Upright with hooks Chest Other (e.g. flat units, wire racks, boxes) Not recorded 25/61 (40%) The majority (93%) of retailers monitored the temperature of the display unit, of which a thermometer in the unit was used by almost half (44%), 34% used a link 17 to a local/remote computer, and 22% used a temperature probe (Table 7). A higher proportion of the samples from display units where temperature was not monitored were of unsatisfactory or unacceptable quality (38%) compared to those from units where temperature was monitored (33%), although this was not significant. In display units where temperature was monitored, more samples sampled from units where a temperature probe was used were more likely to be of unsatisfactory or unacceptable quality (39%) compared to those sampled from units where temperature was monitored by a link to a computer (35%) or by a thermometer in the unit (36%) (Table 7). Type of premises Sixty one percent (1822/2981) of samples were collected from supermarkets, and 30% (909) from convenience/corner shops. The remaining 9% of samples were collected from licensed butchers (3%; 87), greengrocers (1%; 23), delicatessens (1%; 20) non-licensed butchers (<1%; 3), market stalls (<1%; 7) and other premises (4%; 107), such as bakeries, wholesalers and farm shops (Table 8). Fifty-two percent (950/1822) of samples from supermarkets were ‘own label’ products. In comparison, virtually all samples from greengrocers, butcher shops, and delicatessens were ‘branded’ products. The proportion of VP/MAP meat samples from convenience/corner shops (35%), delicatessens (40%), market stalls (42%), greengrocers (52%), licensed butchers (53%) and other premises (42%) of unsatisfactory or unacceptable microbiological quality was higher when compared to those collected from supermarkets (31%). This finding was only significant when comparing samples from convenience shops (p=0.0302), licensed butchers (p=0.0001), and greengrocers (p=0.0405) to those from supermarkets. 18 Food hygiene inspection Half (50%) of the samples were collected from premises categorised as Inspection Rating Category C (inspected at least every 18 months) (Table 8). More samples of unsatisfactory or unacceptable microbiological quality were collected from premises with inspection rating category D (37% 211/569) than premises with ratings of C (31%), B (35%) and A (26%) (Table 8). This finding was only significant when comparing samples collected from premises rated as category D to those rated as C (p=0.01). Most of the samples were obtained from premises categorised in consumer at risk score 5 (few numbers of customers, 60%) and 10 (intermediate numbers of customers, 23%) (Table 8). In proportion more samples collected from premises with consumer at risk scores of 0 to 5 (very few to few numbers of customers, 34%) were of unsatisfactory or unacceptable microbiological quality compared to those from premises with consumer at risk scores of 10 to 15 (intermediate to substantial number of customers, 30%) (Table 8). Most samples were collected from premises that had a confidence in management score 5 (moderate confidence in management/control systems, 39%) and 10 (some confidence in management/control systems, 37%) (Table 8). There was no significant difference in the proportion of unsatisfactory or unacceptable samples from premises with different confidence in management scores (Table 8). Hazard analysis system Eighty percent of samples were collected from premises that had a hazard analysis system in place (63% documented, 11% undocumented; 6% documentation status not recorded) (Table 8). Samples collected from premises without a hazard analysis system in place were more likely to be of unsatisfactory or unacceptable microbiological quality (36%) compared to those collected from premises where hazard analysis was in place (33%) (Table 8). 19 Table 8 Microbiological quality of VP/MAP meats in relation to premises details Premises Details No. Samples (n=2981) (%) No. samples of unsatisfactory or unacceptable quality (%) Premises Type Supermarket Convenience/corner shop Licensed butchers Delicatessen Greengrocers Non-licenced butchers Other (e.g. baker, market stalls, wholesalers, petrol forecourt) Not recorded 1822 909 87 20 23 3 114 (61) (30) (3) (1) (1) (<0.1) (4) 567/1822 (31%) 321/909 (35%) 46/87 (53%) 8/20 (40%) 12/23 (52%) 1/3 (34%) 45/114 (39%) 3 (<0.1) - 46 220 1481 569 304 31 330 (2) (7) (50) (19) (10) (1) (11) 12/46 78/220 466/1481 211/569 96/304 12/31 125/330 (26%) (35%) (31%) (37%) (31%) (40%) (38%) 22 1792 706 46 415 (1) (60) (23) (2) (14) 11/22 610/1792 219/706 6/46 154/415 (50%) (34%) (31%) (13%) (37%) 138 1158 1095 135 32 423 (5) (39) (37) (4) (1) (14) 50/138 368/1158 369/1095 42/135 4/32 157/423 (36%) (32%) (34%) (31%) (12%) (37%) 1877 337 164 324 279 (63) (11) (6) (11) (9) 636/1877 118/37 41/164 117/324 88/279 (33%) (35%) (25%) (36%) (31%) 2320/2981 1441/2320 509/2320 92/2320 150/2320 128/2320 395/2981 266/2981 (78) (62) (22) (4) (6) (6) (13) (9) 788/2320 509/1441 155/509 34/92 49/150 35/128 130/395 88/266 (34%) (35%) (30%) (37%) (33%) (27%) (33%) (33%) Inspection Rating Category Category A B C D E F Not Recorded Minimum Frequency of Inspection At least every 6 months At least every year At least every 18 months At least every 2 years At least every 3 years At least every 5 years Consumer at Risk Score 0 (Very few) 5 (Few) 10 (Intermediate) 15 (Substantial) Not recorded Confidence in Management 0 (High) 5 (Moderate) 10 (Some) 20 (Little) 30 (None) Not recorded Hazard Analysis system In place and documented In place and undocumented In place; documentation status not recorded Not in place Not recorded Management Food Hygiene training Received training and attended -Basic 6 hour course -Intermediate course -Advanced course -Other recognised course -Not specified No training Not Recorded 20 Food hygiene training Over three-quarters of samples (78%) were collected from premises whose managers had received food hygiene training (Table 8). No significant difference was found between premises with managers that had received food hygiene training or not and samples that were of unsatisfactory or unacceptable microbiological quality (Table 8). Discussion Although listeriosis is a relatively rare disease, the severity of the disease and the frequent involvement of manufactured foods, especially during outbreaks, mean that the social and economic impact of listeriosis is among the highest of the foodborne diseases14. An important factor in foodborne listeriosis is that the pathogen can grow to significant numbers at refrigeration temperatures when given sufficient time. L. monocytogenes is able to grow in sliced meats, even if stored under appropriate refrigeration conditions32-34. Factors affecting the growth of L. monocytogenes in foods include product formulation, storage time and temperature, and interactions with other microorganisms present in the product. In VP and MAP meats, lactic acid bacteria (LAB) can reach the stationary of the growth cycle phase without product spoilage. This can slow, or even prevent, the subsequent growth of L. monocytogenes. However, the extent of that growth suppression is not known with certainty 35. The shelf life of a product is the time after production during which it remains acceptable, i.e. both safe and of good quality, for consumption36. The end point of shelf life for perishable chilled foods may be defined by levels of microorganisms present based on recommended guidance 30,31. A number of different groups of spoilage organisms could be present in chilled meat products, including LAB, Enterobacteriaceae and Pseudomonads37. The total bacterial count (Aerobic Colony Count (ACC)) therefore can provide an assessment of the overall microbiological levels within a food product. However determination of count levels needed to be augmented by tests to determine the types of flora 21 present, as a high ACC in itself may not indicate poor quality. Using this information about component microflora, this study has shown that 66% of MAP/VP meat samples at end of shelf-life were of satisfactory/acceptable quality, a third (33%) were of unsatisfactory quality and 1% were of unacceptable microbiological quality, or were a potential risk to public health according to published microbiological guidelines30. Unsatisfactory microbiological results were mainly due to high levels of ACC, namely LAB at 10 8 cfu/g or more and/or Enterobacteriaceae in excess of 104 cfu/g. High ACCs and Enterobacteriaceae levels can indicate that the cooking process was inadequate, that post processing contamination had occurred, that the length of time and temperature control in storage or facilities was inadequate to prevent bacterial growth, or that a combination of these factors was involved. A previous UK study in 1995 reported a lower proportion (10%) of pre-packed sliced cooked meats at end of shelf-life that had LAB present at or over 10 8 cfu/g, and found that microbial growth of spoilage organisms, such as LAB and Enterobacteriaceae, had occurred during storage after slicing and packaging1. It is therefore important to minimise post processing contamination as well as enforcing strict temperature control throughout storage and whilst on retail sale to minimise any proliferation of the organisms in food. The pathogens L. monocytogenes, Staph. aureus, and C. perfringens were detected in 190 (6.4%), 9 (0.3%) and 4 (0.1%) samples, respectively in this study. In addition, Campylobacter spp. was detected from one sample. An earlier UK study of pre-packed sliced meats tested at the end of shelf life found that 5.3% of samples contained L. monocytogenes, 1% Staph. aureus, 0.2% C. perfringens, and Campylobacter spp. was detected from one sample1. Three regional studies in England during 2002 reported a similar prevalence of L. monocytogenes in MAP/VP sliced meats at end of shelf-life (5.0% - 5.3%)15-17. The prevalence of L. monocytogenes at unacceptable levels observed in MAP/VP meats in the current study (1%) was comparable to that previously found in England (0.6%-1.7%)1,15-17 Denmark (1.4%)38 but higher than that in 22 Ireland (0%)39. The presence of these organisms, and in particular the presence of L. monocytogenes at unacceptable levels, demonstrates the need for good hygiene practices during processing to prevent contamination and emphasises the importance of strict temperature controls during the shelf-life of VP/MAP ready-to-eat sliced meats. In 2002 to 2003 there was a marked increase in the number of Listeriosis cases reported in England and Wales and included three outbreaks (one linked to butter, two linked to sandwiches) 40. Furthermore, the same rise in Listeriosis has also been observed in other European countries (Denmark, Germany, Netherlands) 41. Microbiological sub-typing has been helpful in unravelling what appears to be a complex epidemiological picture. The predominant typing character (48%; 1/2/IX/NT) of L. monocytogenes recovered from VP/MAP meat samples of unacceptable microbiological quality in this study has also been observed in a very small number (4) of human cases of L. monocytogenes during 2003 (K Grant, HPA Centre for Infections pers comm). A greater proportion of VP meats at end of shelf life were of unsatisfactory or unacceptable microbiological quality (43%) compared to MAP meats (31%). Those meats packed on the retail premises had a higher proportion of unsatisfactory and/or unacceptable samples (48%) compared to those that were not (32%). Additionally, a higher proportion of meats packed on the premises with a shelf life of 10 days or more and where a risk assessment had not been undertaken for product shelf life were shown to be of unsatisfactory and/or unacceptable microbiological quality. In relation to the potential for growth of psychrotrophic C. botulinum during storage, the UK industry code of practice advises that the shelf life of a chilled MAP/VP food (i.e. one stored at 3-8°C) should not exceed 10 days unless its safety under expected storage conditions can be demonstrated3,4,41. Due attention should also be given to the effect on storage for other food pathogens, such as L. monocytogenes, which would also be relevant to the subsequent shelf-life3. The influence of packaging type and 23 place of packaging on L. monocytogenes contamination and microbiological quality of MAP/VP meats warrants further investigation. Slicing is a process that is carried out post-cooking and poses a microbiological risk because of the potential for recontamination via the slicing blade. In recent years, wafer thin sliced meats have been introduced onto the market. This product is sliced thinner than traditional sliced meats. In this study, slice width was found to have an effect on microbiological quality, with more sliced meats being of unsatisfactory and/or unacceptable quality (36%) compared to wafer thin meats (26%). This may be due to a difference in the way the meat is sliced and equipment cleaned. Cooked meat slicing machines if incorrectly cleaned can be a source of contamination and cross-contamination 42,43. Samples collected from display units where temperature was not monitored were more likely to be of unsatisfactory or unacceptable quality (38%) compared to those from units where temperature was monitored (33%). In conjunction with implementing HACCP principles as the basis for the retailers’ product safety management systems, correct maintenance of storage temperature is vital for ensuring the microbiological safety and stability of chilled food products. The performance of the proposed distribution chain should therefore be validated and monitored and taken into account when specifying shelf life of the product6. The long shelf life of VP/MAP meats may allow the population of L. monocytogenes to reach unacceptable levels, i.e. over 100 cfu/g. It is clear that efforts must be made either to ensure that the product does not become contaminated before final packaging, or to reduce shelf life so that recontamination does not result in the growth of the organism to high numbers. Where the product is sold through other outlets, the performance of the proposed distribution chain should be taken into account when specifying shelf life of the product6, in particular the point that refrigeration storage temperatures will vary 24 from pre-distribution, retail and the consumer home. An alternative strategy would be to re-formulate products to retard greatly, or inhibit altogether, the growth of this organism. Acknowledgements The authors would like to thank all the staff in the Environmental Health Departments throughout the UK who collected samples for this study, and all the staff in both HPA and non-HPA laboratories who performed microbiological examination. Thanks are extended to FSML and LEP (HPA Centre for Infections) for typing isolates, to David Lock at LACORS for co-ordinating the participation of Environmental Health Practitioners and advice from the LACORS Food Examination Focus Group, to the Regional Food, Water and Environmental Coordinators Forum and Heather Aird for advice on the sampling protocols, and to Lillian Hucklesby for entering the data. 25 References 1. MAFF. A national study on ready-to-eat meats and meat products, Part 3. MAFF: 1996, London. 2. Chilled Food Association. 2003 UK Retail Prepared Chilled Food Market. Available at :<http://www.chilledfood.org/Content/Market_Data.asp>. 3. CCFRA. A Code of Practice for manufacturing of Vacuum and Modified Atmosphere Packaged Chilled Foods. Guideline No.11, May 1996. CCFRA: Chipping Campden. 4. ACMSF. Report on vacuum packaging and associated processes 1992. HMSO, London. 5. Food Safety (Temperature Control) Regulations 1995. The Stationery Office, London. 6. Chilled Food Association. Guidelines for Good hygienic practice in the Manufacture of Chilled Foods. 1993. CFA, London. 7. de Valk, H., Vaillant, V., Jacquet, C., Rocourt, J., Le Querrec, F., Stainer, F., Quelquejeu, N., Pierre, O., Pierre, V., Desenclos, J. and Goulet, V. (2000) Two consecutive nationwide outbreaks of Listeriosis in France, October 1999-February 2000. American Journal of Epidemiology 154, 944-950. 8. Frye, D., Zweig, R., Sturgeon, J., Tormey, M., LeCavalier, M., Lee, I., Lawani, L.and Mascola, L. (2002) An outbreak of febrile gastroenteritis associated with delicatessen meat contaminated with Listeria monocytogenes. Clinical Infectious Diseases 35, 943949. 9. CDC Incidence of foodborne illnesses- FoodNet 2002. MMWR Morb Mortel Wkly Rep. 2003 18;52(15):340-3 [PubMed-Indexed for Medline] 10. Lassen, J. Caugant DA. Outbreak of listeriosis in Trondelag. MSIS-rapport. Communicable Diseases Report Norway, 1992; 20: 43. 11. Sim J, Hood, D, Finnie L, Wilson M, Graham, Brett M, Hudson JA. Series of incidents of Listeria monocytogenes non-invasive febrile gastroenteritis involving ready-to-eat meats. Letts Appl Microbiol 2002; 35: 409-13. 12. Adak GK, Long SM, O’Brien SJ. Trends in indigenous foodborne disease and deaths England and Wales 1992 to 2000, Gut 2002; 51: 832-41. 13.Chief Medical Officer (CMO) Listeria found in Pate. Press release 82/299. 1989, DH, London. 14. Commission of the European Communities. Draft Commission Regulation on microbiological criteria for foodstuffs SANCO/4198/2001 Rev.15 26 15. Williamson, K, Allen, G, and Bolton, FJ. The microbiological quality of modified atmosphere packaged ham. Report Number 204001. 2002. Greater Manchester / Lancashire / Preston PHLS Liaison Group. Available at: www.tameside.gov.uk 16. WiIIiamson, K, Allen, G, Bolton, FJ. The microbiological quality of modified atmosphere packaged cooked meats. Report Number 204013. 2003. Greater Manchester / Lancashire / Preston PHLS Liaison Group. 17. Aird H, Richards, J, Allen, J. Vacuum and modified atmosphere packed cooked meat shelf-life investigation 2003. Eastern-regions co-ordinated food sampling programme. 18. Food Safety Act 1990 Core of Practice No.7: Sampling for analysis and examination (Revised October 2000). London: FSA, 2000. [Revised in 2004; Food Safety Act 1990 Code of Practice. London: FSA, 2004. Available at www.fsa.gov.uk] 19. LACORS. LACOTS Guidance on food sampling for microbiological examination. 2002. Available at www.lacors.com 20. Food Safety Act 1990, Code of Practice No 9: Food Hygiene Inspections. (Revision October 2000). London: FSA, 2000. [Revised in 2004; Food Safety Act 1990 Code of Practice. London: FSA, 2004. Available at www.fsa.gov.uk] 21. Health Protection Agency (HPA). Standard Methods for Food Products. Aerobic Colony Count at 30oC:Surface Plate Method. Standard Method: F10. London: HPA, 2003. Available at: www.hpa.org.uk 22. Health Protection Agency (HPA). Standard Methods for Food Products. Aerobic Colony Count at 30oC:Spiral Plate Method. Standard Method: F11. London: HPA, 2003. Available at: www.hpa.org.uk 23. Health Protection Agency (HPA). Standard Methods for Food Products. Enumeration of Enterobacteriaceae. Standard Method: F23. London: HPA, 2003. Available at: www.hpa.org.uk 24. Health Protection Agency (HPA). Standard Methods for Food Products. Enumeration of Escherichia coli. Standard Method: F20. London: HPA, 2003. Available at: www.hpa.org.uk 25. Health Protection Agency (HPA). Standard Methods for Food Products. Enumeration of Clostridium perfiringens. Standard Method: F14. London: HPA, 2003. Available at: www.hpa.org.uk 27 26. Health Protection Agency (HPA). Standard Methods for Food Products. Enumeration of Staphylococcus aureus. Standard Method: F12. London: HPA, 2003. Available at: www.hpa.org.uk 27. Health Protection Agency (HPA). Standard Methods for Food Products. Detection and Enumeration of Listeria monocytogenes and other Listeria spp.. Standard Method: F19. London: HPA, 2003. Available at: www.hpa.org.uk 28. Health Protection Agency (HPA). Standard Methods for Food Products. Detection of Campylobacter spp. F21. London: HPA, 2003. Available at: www.hpa.org.uk 29. British Standard Institute. BS ENISO 6679:2002 Microbiology of food and animal feeding stuffs- Horizontal method for the detection of Salmonella spp. BSI, London. 30. PHLS. Guidelines for the Microbiological Quality of Some Ready-to-Eat foods sampled at the Point of Sale. Comm Dis Pub Health 2000; 3 163-7. 31. IFST. Development and use of microbiological criteria for foods. 1999. IFST, London. 32. Glass KA, Doyle MP. Fate of Listeria monocytogenes in processed meat products during refrigerated storage. Applied Environmental Microbiology 1989; 55: 1565-1569. 33. Beumer, RR, te Giffel, MC, de Boer E, Rombouts FM. Growth of Listeria monocytogenes on sliced cooked meat products. Food Microbiol 1996; 13: 333-340. 34. Uyttendaele M, Rajkovic A, Benos G, Francois K, Devlieghere F, Debevere J. Evaluation of a challenge testing protocol to assess the stability of ready-to-eat cooked meat products against growth of Listeria monocytogenes. Int J Food Microbiol 2004; 90: 219-236. 35.FAO/WHO Risk assessment of Listeria monocytogenes in ready-to-eat foods. 2004, FAO/WHO. 36. IFST. Shelf-life of foods –Guidelines for it’s determination and prediction. 1993 IFST, London 37. CCFRA. Evaluation of Product Shelf life for Chilled Foods. Guideline No.46, 2004. CCFRA: Chipping Campden. 38. Nørrung B, Andersen JK, Schlundt J. Incidence and control of Listeria monocytogenes in foods in Denmark. Int J Food Microbiol 1999; 53: 195-203 39. Food Standards Agency Ireland. Microbiological quality/ safety report of pre-packed cooked Sliced meats. 1st Quarter National Microbiological Survey (NS1) 2003, FSAI. http://www.fsai.ie/surveillance/food/prepacked_cooked_sliced_ham.pdf 40. CDR weekly (2004). Listeria monocytogenes infections in England and Wales in 2004. CDR Weekly 14,37. Available at: www.hpa.org.uk 28 41. FSA. FSA Guidance on the Safety and Shelf-life of Vacuum and Modified Atmosphere Packed Chilled Foods with Respect to Psychrotrophic Clostridium Botulinum, August 2003, Paper ACM/654. Available at: www.food.gov.uk/multimedia/pdfs/acm654.pdf. 42. Elson, R., Burgess, F., Little, C.L., Mitchell, R.T. 2004. Microbiological examination of ready-to-eat cold sliced meats and pâté from catering and retail premises in the United Kingdom. Journal of Applied Microbiology, 96: 499-509. 43. Little, C.L., de Louvois, J. 1998 The microbiological examination of butchery products and butchers’ premises in the United Kingdom. Journal of Applied Microbiology 85, 177186. 29 Annex 1: Participating Laboratories and Local Authority Food Liaison Groups Table I: Participating HPA and HPA Collaborating Laboratories and number of samples HPA Region Laboratory Name East Chelmsford Number of Samples 143 Norwich 167 London London FWEM1 139 South East Ashford 102 Brighton 192 West Midlands North West North East, Yorkshire & the Humber South West East Midlands Reading 16 WEMS2 103 Birmingham 89 Coventry 129 Hereford 24 Shrewsbury& Telford 78 Stoke 102 Chester 55 Preston 190 Carlisle 34 Hull 119 Leeds 92 Middlesbrough 123 Newcastle 101 Sheffield 146 Bristol 161 Exeter 67 Gloucester 47 Plymouth 22 Truro 89 Leicester 130 Lincoln Total 175 2835 1, London Food, Water & Environmental Microbiology Laboratory 2, Wessex Environmental Microbiological Service Table II: Participating Other Laboratories and number of samples Nation Laboratory Northern Ireland Scotland Belfast City Hospital Aberdeen City Council Public Analyst Edinburgh A & S Services Glasgow Scientific Services Bangor Cardiff Rhyl Wales Total Number of Samples 53 4 2 30 55 37 19 200 30 Table III: Participating Food Safety Liaison Groups and number of samples Local Authority Food Liaison Group Berkshire Number of Samples 11 Buckinghamshire 6 Cambridgeshire 40 Cheshire Cleveland 39 67 Cornwall 89 Cumbria 41 Derbyshire 75 Devon 62 Dorset Durham 40 24 East Sussex 81 Essex 80 Gloucestershire 57 LFCG1 Greater London NE Sector 22 LFCG Greater London NW Sector LFCG Greater London SE Sector 28 28 LFCG Greater London SW Sector 24 Greater Manchester 72 Hampshire & Isle Of Wight 56 Hereford & Worcester 54 Hertfordshire & Bedfordshire Humberside 33 108 Kent 102 Lancashire 108 Leicestershire 130 Lincolnshire 77 Merseyside 10 North Yorkshire Northamptonshire 91 71 Northern Ireland Food Group2 53 Northumberland 21 Norfolk 120 Nottinghamshire 100 Scottish Food Enforcement Liaison Committee3 Shropshire 36 34 Somerset 27 South West Yorkshire 61 Staffordshire 112 Suffolk 67 Surrey Tees Valley 57 3 Tyne & Wear 63 Wales North Group 80 Wales South East Group 39 Wales South West Group 2 Warwickshire West Midlands 56 101 West of England 86 West Sussex 55 West Yorkshire 62 Wiltshire Total 74 3035 1, London Food Co-ordinating Group 2, Northern Ireland Food Group comprises of the Eastern, Northern, Southern and Western Groups 3, SFELG comprises of Central Scotland, Fife & Tayside, Lothian & Scottish Borders, North Scotland, and West of Scotland 31