27706 Demonstrate knowledge of laboratory

advertisement

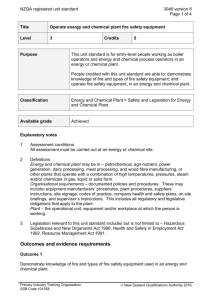

NZQA registered unit standard 27706 version 1 Page 1 of 4 Title Demonstrate knowledge of laboratory micropropagation processes and exflask and acclimatise plants in a nursery Level 4 Credits 10 Purpose People credited with this unit standard are able to: demonstrate knowledge of the stages and processes of micropropagation for plants in a laboratory; exflask and acclimatise plants in a nursery environment; and keep records of micropropagation. Classification Horticulture > Nursery Production Available grade Achieved Entry information Recommended skills and knowledge Unit 27707, Demonstrate knowledge of plant propagation by budding, grafting, layering and tissue culture; and Unit 27708, Demonstrate knowledge of sexual and asexual plant propagation; or demonstrate equivalent knowledge and skills. Explanatory notes 1 Definitions Exflasking also referred to as deflasking is the process of removing the propagated materials from their protected environment. General greenhouse condition refers to weaning and the gradual exposing of the plants to higher light, less humidity and air movement. Hardening off also called weaning refers to a term used in the nursery stages of micropropagation, when the plants are removed from laboratory conditions and are prepared for a natural growing environment. Workplace procedures refer to oral or written instructions to staff on procedures for the worksite and equipment. 2 Legislation relevant to this unit standard includes but is not limited to the Health and Safety in Employment Act 1992; the Resource Management Act 1991, the Plant Variety Rights Act 1987; and their subsequent amendments. Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016 NZQA registered unit standard 27706 version 1 Page 2 of 4 Outcomes and evidence requirements Outcome 1 Demonstrate knowledge of the stages and processes of micropropagation for plants in a laboratory. Evidence requirements 1.1 The plant selection process is explained in terms of obtaining suitable plant material. 1.2 The processes of cleaning, cutting and the establishment of plant material into aseptic conditions is explained in terms of their importance to successful micropropagation. 1.3 The multiplication stage for multiple shoot development is explained in terms of the plant requirements. 1.4 The process of root initiation and development is explained in terms of the plant requirements. Outcome 2 Exflask and acclimatise plants in a nursery environment. Evidence requirements 2.1 Plants are taken from the laboratory container and carefully placed into nursery trays containing new, well drained growing media in accordance with workplace procedures. 2.2 New plants are handled with care, protected and kept moist with water to prevent moisture loss, in accordance with workplace procedures. Range 2.3 Trays containing plants are placed in an environment that maintains consistent high humidity. Range 2.4 tweezers to lift out delicate plants, remove excess agar, sufficient water to keep plants turgid at all times, no draughts, no high lighting. may include - misting, fogging, tenting methods. Plants are gradually introduced to general greenhouse conditions, kept in a humid environment until they harden off and new roots develop that are sufficient for the plants to be self sustaining. Range a minimum of ten days sometimes to up to three months with a gradual reduction in humidity, increased lighting, air movement. Outcome 3 Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016 NZQA registered unit standard 27706 version 1 Page 3 of 4 Keep records of micropropagation. Evidence requirements 3.1 Records required for the micropropagation processes in a laboratory are described in terms of information collected. Range 3.2 may include - genus, species, cultivar, code, source of micropropagation material, collection dates, initiation dates, cultures used, growth room conditions, any further culturing dates root and shoot growth development, operator, shipping dates. Nursery records are maintained relating to the use of micropropagated material in the nursery in accordance with workplace procedures. Range may include plant name - genus, species and/or cultivar, date and batch number, laboratory source, exflasking date, moisture level requirements, growing media rooting times, rooting and saleable percentages, potting dates, ongoing growing requirements including feeding and trimming, shipping dates. Planned review date 31 December 2017 Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 19 April 2012 N/A Consent and Moderation Requirements (CMR) reference 0032 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016 NZQA registered unit standard 27706 version 1 Page 4 of 4 Comments on this unit standard Please contact the Primary Industry Training Organisation standards@primaryito.ac.nz if you wish to suggest changes to the content of this unit standard. Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016