SHALLOW WELLS: - Water Services Trust Fund

1.

DESCRIPTION OF TECHNOLOGY

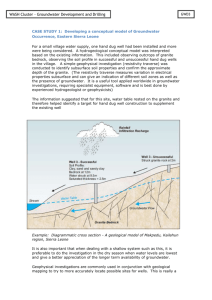

A hand dug well is a means of accessing groundwater from a high water table aquifer. It is normally more than

0.8m in diameter and less than 25m in depth. To extract water from the well lifting devices such as buckets, chain and windlass and handpumps are used. (These have been discussed in a fact sheet on lifting devices)

Hand dug wells are in two types: i.

Traditional Wells:

These are hand-dug holes that penetrate the water bearing formations. They are usually unlined, have no adequate above groundwater protection and are very susceptible to contamination. These are not being encouraged. ii.

Conventional/Improved Traditional Wells:

These are dug by hand using hoes, picks or jackhammers. Conventional wells have 3 main parts described below:

Below water level lining which prevents the well from collapsing but also allows water to enter the well. Thus, lining in this portion is in porous concrete or

deliberately perforated with small holes.

Lining above water level made either from non-porous pre-cast concrete rings, masonry with bricks, or concrete blocks, etc. The main purpose is to prevent the well from collapsing. In firm and consolidated formations it may not be necessary

to line this portion. If that becomes the case, at least the top one metre of the well should be lined and grouted to prevent the ingress of contaminated surface water.

The well head which is a stone, brick or concrete apron with the above ground well lining (headwall) that is raised to a convenient height for the chosen method of drawing water. The apron provides a firm platform for users and prevents contaminated water from seeping back into the well but directs it away from the well to a soakaway (filled with stones) through the drainage channel. The covered headwall prevents spilt water, runoff, debris, people, animals, birds; etc from entering or falling inside and also keeps sunlight out thereby keeping the water temperature low and constant.

Wells are suitable in areas of high groundwater table (less than 25m) with sufficient quality and quantity of groundwater throughout the year.

A properly constructed conventional well can service 200 people while unimproved traditional well can service up to 100 people. In comparison with other water sources it provides low yields, typically 5m

3

per day and it provides large storage volume due to its size. A conventional well can last over 50 years.

2. DESCRIPTION OF O&M ACTIVITIES i.

Operation

Operation of a well involves abstracting from a well using the installed lifting device.

Where the production of a well is less than the demand, daily monitoring of the water level maybe a necessary operation activity.

1

ii.

Maintenance

Properly constructed wells require very little maintenance. Maintenance is normally carried out by users or a caretaker except for larger repairs that may require

specialised skills and equipment. Maintenance activities may involve the following:

Checking daily for visible foreign bodies or debris in the well and removing them.

Cleaning of the concrete apron

Checking the fence and drain and repair or clean when necessary

Unblocking soakaways

Check and repair cracks or ruptures in the concrete apron and the well lining above water level.

Check and correct erosional effects to avoid undermining of the apron. Ensure no latrines, animal kraals or other contamination sources are constructed within 30m from the well.

Water level in a well is lowest at the end of the dry season. It is necessary at this stage to empty the well, remove debris and clean algae off using a brush and clean water. Where necessary, carry out repairs and then disinfect with chlorine. Dry wells can be re-deepened and lined with smaller diameter rings.

3. O&M REQUIREMENTS

The table below shows the O&M requirements for a hand dug well

ACTIVITY

Well site cleaning

Well disinfection

Clean well

Cleaning of drain

Repair of fence

Repair of apron, headwall

& drain

Repair lining

FREQUENCY

Daily

Occasionally

Annually

Occasionally

Occasionally

Annually

HUMAN RESOURCES MATERIALS & SPARES

Local

Local

Local

Local

Chlorine

Local

Local

Wood, nails, wire and mesh

Cement, sand, gravel, bricks

TOOLS & EQUIPMENT

Brooms, buckets

Bucket

Brush, bucket, ropes

Hoes,spades, wheelbarrows, bucket

Saw, machete, axe, hammer, pliers e.t.c

Trowel, buckets, wheelbarrow & spade

Pump, bucket, ropes Occasionally Local Cement, sand, gravel, bricks, concrete rings e.t.c

Well re-deepening & lining

Occasionally Local or zone Hoe, spade, wheelbarrow bucket,

4. ACTORS INVOLVED AND SKILLS REQUIRED IN O&M

ACTOR

Users

Caretaker

ROLES/RESPONSIBILITIES

Use water, keep site clean, assist with major maintenance tasks, conduct preventive maintenance, fund rising, disseminate hygiene messages, reporting, manage borehole use

Enforcement of hygiene rules, Conduct preventive maintenance

SKILLS

V-WASHE Committee

Basic skills in cleaning and disinfecting, hygiene education and preventive maintenance as well as organizational skills

Organisational skills

Well

Conduct hygiene education, organize major repairs, facilitate preventive maintenance,

Rehabilitate wells Special technical skills Specialized

Contractor

SUB-WASHEs Organisational skills

D-WASHEs

Funding Agencies

Facilitate formation of O&M committees, Conduct monitoring of

O&M activities, training Caretakers, Conduct participatory education for V-WASHEs, plan for O&M, facilitate site selection

Facilitate major repairs, monitoring, Conduct O&M needs assessments, capacity building of SUB-WASHE

Provide financial support

Facilitation and organisational skills

Financial management skills

Organisational Aspects

Implementation of O&M activities requires well-defined structures, roles and responsibilities, a clear mechanism for decision-making and an effective support system.

2

In Northern Province the primary actors in O&M activities are communities. They should establish an organization to effectively deal with issues of control, supervision of water use, prevention of contamination, execution of O&M activities, financing, monitoring of water quality e.t.c. Although the number of O&M activities for wells is limited and not costly, they should nevertheless be given adequate attention as absence of maintenance activities may lead to abandonment or collapse of wells. A properly organized and managed system will assist reduce social conflicts over O&M issues.

5. CAPITAL AND O&M COSTS

Capital costs depend on a large number of factors and vary considerably. Main factors that influence initial costs include the soil formation, size of the well, depth of the well and the materials used for lining. Under normal conditions, a 1.7m diameter dug well, 15m deep with 4m-water column would cost approx zk10, 000,000 in

Northern Province (Department of Water Affairs, 2004).

O&M costs include personnel costs for labour, materials like cement and rehabilitation costs. Rehabilitation costs are relatively high and may cost as much as

1,000 US dollars (zk5, 000, 000.00 – Dec 2004 exchange rate).

6. LIMITATIONS, PROBLEMS, AND REMARKS

Limitations

Common limitations to wells are:

Successful construction of a well depends on hydro geological conditions, depth and thickness of aquifer and rock formation

Because of the above factors, a well may be constructed in a location far from user households and may not be efficiently used.

By law, wells should not be sunk in places near latrines or livestock kraals as they would easily be contaminated. Usually the distance between these and the well should not be less than 30 metres.

The initial capital required is often beyond the capacity of poor rural communities

Problems

Common problems with wells are:

Collapse of a well due to absence of or poor lining or improper maintenance

Drying up of a well or reduction in yields due to:

(i) Not taking into account dry seasons conditions

(ii) Water abstraction is higher than natural recharge rate

(iii) Reduced inflow of groundwater due to clogging of lining

Contamination of groundwater through the well itself or through seepage.

Remarks

Hand dug wells are the oldest means of abstracting groundwater for drinking and even for irrigation. If properly constructed and maintained they provide a reliable and safe water supply. Their use can be enhanced by proper apron design and construction, providing facilities for washing clothes and bathing and by diverting wastewater to irrigate vegetables and fruit trees.

3

For rural water supply, wells are more convenient than boreholes because virtually all

O&M activities can be performed at local level. Wells can be constructed using locally available tools, materials and skills. They provide greater storage volume and quiet flexible to the lifting devices installed.

7. FURTHER REFERENCE

International Research Centre (IRC), Linking Technology Choice with Operation and Maintenance for Low Cost Water Supply and Sanitation, 1997. The Hague,

Netherlands.

P-WASHE Northern Province, Manual on Conventional Hand Dug Wells, 2004.

Kasama, Zambia (unpublished)

P-WASHE Northern Province, Manual on Traditional Water Well, 2004.

Kasama, Zambia (unpublished)

4