Paper

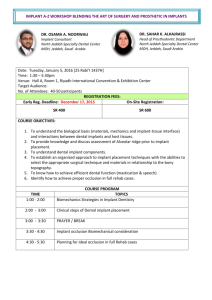

advertisement

IMPLICATION OF NEW IMPLANT SYSTEMS FOR COMPLEX TREATMENT OF PATIENTS WITH MAXILLOFACIAL DEFECTS V.N.Antsiferov 1, G.I.Rogozhnikov 2, N.B.Astashina 2 1 Scientific Center of Powder Material Science of SEIHPI «Perm state technical university», Perm, Russia 2 SEIHPI «Perm state medical academy n.a. ac. Е.А. Vagner» MHRF, Perm, Russia Abstract At the moment the problem of searching new methods for the treatment of the patients with maxillary bone defects caused by traumatic injuries of maxillofacial area is to be of current interest. Therefore the group of authors developed new implant systems made of biologically inert materials with the application of advanced technologies: compound dentalalveolar implant and the implant with ferromagnetic. The usage of proposed structures will allow to raise the quality of complex treatment for patients with maxillofacial defects. At the moment the problematic treatment of patients with maxillary bone defects is to be of current interest. In the recent years the number of patients with traumatic injuries of maxillofacial area cased by majour and local armed conflicts, terroristic acts, technogenic accidents and catastrophes. Multiple and multisystem injuries of maxillofacial area are found with 18 % of the total number of trauma patients. The injuries of facial skeleton, gunshot wounds cause defects and distortions both for bone tissues and soft tissues of face. A great number of recent researches indicate extreme difficulties in providing specialized medical treatment for the patients with maxillofacial tissue injuries. Therefore new implant systems made of biomaterials for surgical substitution of submaxilla defect and also performing rational maxillofacial prosthetics afterwards will help to regain patients’ total ability to work and have social functions which seemed to be lost. The urgency of the issue is in choosing the most adapted material to replace bone defects of maxillary and eliminate maxillofacial area distortions. In order to restore a missing maxilla part there used both auto-, alloplastic and implant materials. However apart from the positive characteristics the stated substances might also have strong disadvantages, in particular, the retrieval of autotransplant might also cause extra injury of a patient. Automaterials do not always provide the possibility to fully restore anatomy shape of maxilla. The allotransplantation method is not able to solve the stated problem due to the fact that there is no available bank of cadaveric tissues, moreover, there is a big issue of tissue incompatibility. The creation of allotransplants bone banks is recently limited because of HIV infection and hepatitis B,C. Today there is great interest in using implants from various materials for endoprosthesis replacement (metals, ceramics, and composites). Various metal alloys (aluminum, nickel, nickelic titanium etc) are being used for the purpose of enthesis. It is determined that the stated metals have a range of essential disadvantages: formation of microdefects and cracking, metalloz and corrosion, insufficient plasticity. When using metal structures there might occur tissue reaction against external temperature 1 influence. All the above mentioned facts sufficiently diminishe its dental implant usage. Implants made of “pure” carbon-based materials have undeniable advantages. They have high plasticity, biological inertia, non-toxic, non-carcinogenic and corrosive properties, they are also fatigue loading resistant. Their elasticity modulus is similar to the elasticity modulus of bones, and electric conductivity is similar to the body tissue one. Carbon-based materials have low indices of friction wear. Carboncarbon composite material was developed in Russia which was named “Uglecon-M” – medical carbon. The scientists of Perm state medical academy (Vagner E.A., Denisov A.C., Kislyh F.I., Rogozhnikov G.I., Letyagina R.A.) researched the properties of this material and it was introduced into clinical practice. In 1990 “Uglecon-M” was approved to be used as endoprosthesis replacement material in dentistry. According to its chemical composition it is practically “pure” carbon and represents the composition of carbon fiber and pyrocarbon. The following material is valuable for the opportunity to provide prosthetic repairs of all native bone parameters, including architectonics and elastic modulus value. Further improvements and usage of this material for implant constructions of maxillary bones have determined the urgency of the issue. At the moment there is great concern about orthopedic rehabilitation of patients with maxillofacial area defects. The orthopedic rehabilitation success of patients depends on bone tissue defect scope and distribution. A tooth which borders on the defect often misses alveole wall from the side of resection, such teeth are normally floating. A thick layer of cicatrical-transformed floating of mucous coat is often developed at the regenerated area which leads to balancing and ejection of removable denture. The stabilization of orthopedic construction is nearly impossible in case transplant area has a direct transition of cheeks and lips mucus membrane into the floor of the mouth or the sublingual swab is located above the regenerate level. The essential defect value, reduced prosthesis area, floating side tissues, masticatory and facial muscles tonus make it hard to select the orthopedic treatment method for the patients with maxillary defects. The performed researches had a purpose to develop the program of complex treatment for patients with maxillary defects using biologically inert structural materials and advanced technologies. Therefore new implant systems are developed from biologically inert materials with the application of nanotechnologies – combined carbon-titanium dentoalveolar implant and carbon implant with ferromagnetic for magnetic fixation of removable dentoalveolar dentures. Combined carbon-titanium dentoalveolar implant (fig. 1) has two parts: maxilla part made of carbon-based material “Uglecon-M” (fig. 1a) which helps to fully replace maxilla defect; and dental part (fig 1b) made of titanium alloy which acts as support to fix the following orthopedic construction. When choosing biologically inert structural materials to build up the dental part of the dentoalveolar implant we focused our attention on titanium alloy with alpha structure ВТ-5Л, which is one of most producible ones. Its corrosion resistance in mouth cavities complies with precious metals, its elastic modulus is similar to bones. Dentoalveolar implant is produced in the following way: there is a hole made in the maxillary carbon implant where a titanium dental implant is fixed. The latter consists of a barrel produced from sintered powder titanium of ВТ-5Л grade and an auxiliary bar with suprastructure made from solid titanium alloy by milling. Therefore when working out the stated system, porous and nonporous components were build 2 up. To create strong connection between the construction elements titanium powder is used (an average diameter of particles is 50 micron) introduced into dental and maxilla implant clearance. When working there were applied the methods of nanostructures synthesis with the fixed shape and size to produce implants with improved, stable biocompatible, physical and mechanical properties. The adhesion strength of titanium dental implant with carbon material was provided with the help of sintering of the assembled construction in the vacuum furnace at 1280 ° C within 3 hours due to the creation of the hardened layer between titanium and carbon implants. For the adhesion quality examination of titanium dental part with carbon maxilla implant mechanical tests were performed at the tensile-testing machine Hekkert HP 100/1 with the measurement range of 0,4 kN. The contact area of titanium auxiliary bar with maxillary part was calculated according to the following formula: S = r 2 h r , r – titanium auxiliary bar diameter; h – the height of generatrix cylindrical contact surface between auxiliary bar and carbon material “Uglekon-M”. The experiment results showed that the adhesion strength between titanium auxiliary bar and the carbon maxilla part was 7,6 MPa which is some higher than the adhesion strength of carbon composition material “Uglekon-M”. а b c Fig.1. Combined carbon-titanium implant: a) maxilla implant; b) dental implant; c) produced carbon-titanium implant. The incorporation of titanium part into the carbon composite material helped to create a brand new dentoalveolar implant with the positive effect of raising the treatment effectiveness due to preventive measures for after surgical complications, good fixation and stabilization of follow-up dentoalveolar prosthesis, availability and biologically inert properties of the materials used, it is also free from immunologic havoc when the material is being introduced in the body, consequently it has no necessity to pull it out. There is an option to produce tailor-made implants. The identified substitution constructions are easy to be sterilized and fit. One of the perspective approaches to the problem of complex maxillofacial prosthesis attachment is using continuous magnetic field. The applied public health service implemented magnetic unit struction with titanium coating to fix movable 3 dentoalveolar prosthesis which was developed by the group of authors. In the suggested structure the ferromagnetic component is introduced into the root of the tooth which limits the defect. However not all the clinical settings have all the notified conditions. In this respect an implantation system was developed which consists of carbon implant with ferromagnetic for magnetic fixation of movable dentalalveolar prosthesis (fig.2.). Fig.2. Carbon maxilla implant with introduced ferromagnetic (horizontally cut). The offered appliance (fig.3.) has maxilla implant (4), made of carbon material “Uglekon-M” and an inside fixed ferromagnetic component (5). The adhesion strength of ferromagnetic and carbon material is provided by sintering the assembled structure in the vacuum furnace at the temperature up to 1100 °C. The structure (fig.4) provides the usage of movable dentoalveolar prosthesis (1), with the samarium-cobalt magnetic elements introduced into the artificial teeth of prosthesis (2) with magnetic circuit made from ferromagnetic (3), through which the magnetic circuit is closed. Between maxilla implant (4) and the denture bases of movable prosthesis (1) there is mucous membrane (6). The magnetic element (2) has a cylinder shape and can be located in any magnetic circuit area (3). To improve biological characteristics and strength properties the samarium-cobalt magnet and ferromagnetic component are coated with titanium alloy ВТ1-00 with ion-plasma sputtering method. The magnetic field lines in the offered structure are directed along the closed circuit inside the magnetic element and ferromagnetic part. 1 2 3 5 x 6 d 4 Fig. 3. Magnet lock model: 1 – dentoalveolar prosthesis; 2 - samarium-cobalt magnet; 3 – magnetic circuit; 4- dental implant; 5 – ferromagnetic; 6 – mucous coat. Russian and foreign scientific articles describe analogues of suggested combined implants in the form of maxilla carbon implants without entering the dental part. The 4 disadvantages of such implants is that during orthopedic treatment after using it there is no regular ability to create favourable conditions for further prosthetic repairs. The fact that there is dental part in the offered implant systems provides the full-scale maxilla defect replacement and the incorporation of dental or ferromagnetic components allows to create an additional fixation area for further orthopedic structure. To research the reaction of bone tissue on the implants incorporation of the introduced structure (fig. 4 a,b) there was used an experimental group of 10 male pigs of “Landras” breed, weight from 17 to 18.5 kg, age 52-55 days. The tested animals (fig. 5a) had their formed segmental defects of submaxilla incorporated with the proposed implant constructions (fig. 5 b,c). b а Fig.4. Implants, prepared for replacement of bone tissue defect: a) combined dentalalveolar implant; b) carbon maxilla implant with ferromagnetic. а c b Fig. 5. Experiment description: a) there was a segmental defect made in the submaxilla of the tested animal; b) combined dentalalveolar implant was incorporated; c) carbon maxilla implant with ferromagnetic was fixed. The results estimation of osteoplasty was performed on bases of clinical observation data, tissue reaction of the host bed after 1, 5, 10, 20, 30, 90, 150 days. 5 After 6 months the tested animals were taken out of the experiment. When analyzing the experimental results it was defined that the visual examination of the host bed status after 6 months of the experiment launch, there was no delay in the operated submaxilla growth in comparison with the sound part. All the implants tightly adhered the bone, the soft tissue surrounding the implant were not changed. After the tested animals were taken out of the experiment when estimating the macromedications (fig. 6), traced with formaline solution there was stated an adherence of proposed structures with bone tissue. The incorporated dental and ferromagnetic components were sustainably adhered with maxilla parts of the implant systems. Fig.6. Macromedication (after 6 months of the experiment launch): The implant is fixed to the bone issue. In the structure of the implant-bone block boundary (fig.7.) there were found reparative regeneration processes of the damaged bone tissue. 1 2 3 4 Fig.7. The structure of the implant-bone block boundary: The impant (1) between collagen fibers (2); bone tissue bars (3); vessels (4). Van Gieson’s stain, zoom X400. Vast areas of disorderly arranged collagen fibers which “grow through” (stitch) the implant were defined at the boundary area of “implant-bone tissue” (fig.8). They are surrounded by thick vascular bed of great vessels. 6 3 1 2 Fig. 8. The boundary area of “implant-bone tissue”: Implant (1) between collagen fibers (2); vessels (3). Van Gieson’s stain, ampl. X400. Good vascular supply on the boundary area of “implant-bone tissue” (fig.9) provides the differentiation of osteogenic cells in osteoblast which is considered to be one of the most important terms in osseogenesis. 1 3 2 Pic. 9. The boundary of “implant-bone tissue” area: Collagen fibers growth (1); vessels (2); Newly formed trabecula of bone (3). Van Gieson’s stain, ampl. X400. Due to these a non-mineralized osteoid is formed. Collagen fibers get saturated with osteoid which leads to the formation of trabeculas of bone from coarse-fibered bone tissue (fig.10). Osteoblasts are located on the edge of trabeculas of bone. High content of osteocytes is identified in trabeculas of bone (the content of those in lamellar tissue is lower). Lacunae with osteocytes cells do not have regular orientation. The observed regenerative processes in the destruction area will further allow replacement of coarse-fibered bone tissue by lamellar bone tissue of maxilla. 7 2 1 3 3 Рис. 10. Trabeculas of coarse-fibered bone tissue: Vessel (1); collagen fibers (2); osteocytes (3). Van Gieson’s stain, ampl. X400. Results of the experiments conducted to define strength characteristics of the offered systems and study the reactions of bone tissue when implanting, allow to conclude that it is possible to use them during complex treating the patients with submaxilla defects. Positive effect from the application of developed structural systems results in the increase of the treatment efficiency due to the preventive care of postoperative complications, biocompatibility of the materials, possibilities to produce tailor-made implants, shortening treatment period, absence of necessity to remove the implant, good fixation of dentoalveolar prosthesis. All the abovementioned advantages provide improvement of health and health-related quality of life for patients. The article is being published with the financial support of RFFI grant, project №090899128 “Development of biologically inert composite materials for development of complex implant systems within the program of complex rehabilitation of patients with submaxilla defects”. 8