Tensile Testing - Outreach

advertisement

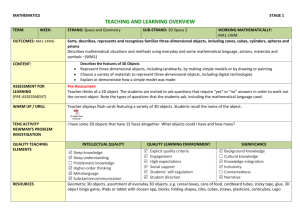

Materials Science Tensile Testing Masterclass Teacher Notes 0 Contents Page 2: Tensile Testing – A Simple Introduction Ref. Physics Education: 41:1:57-62 http://www.iop.org/EJ/toc/0031-9120/41/1 An article for teachers describing a simple investigation that has applications across the ability and secondary age ranges. The investigation can be considered simply as a way of teaching scientific methodology, or as an introduction to tensile testing at A-level. Page 10: Stress-Strain Diagrams Recorded on a Tensometer An overview for teachers covering the interpretation of (engineering) stress-strain diagrams. Page 14: Elastic Limit and Limit of Proportionality – A Closer Look A more detailed analysis of the elastic limit and why the limit of proportionality is located just beyond the linear part of the curve. Page 16: Acknowledgements Page 17: Appendices Images and charts that illustrate the experiments described in “Tensile Testing – A Simple Introduction” and also from the Tensile Test Masterclass. 1 Tensile Testing – A simple Introduction Ref. Physics Education: 41:1:57-62 http://www.iop.org/EJ/toc/0031-9120/41/1 Preamble If an engineer wanted to design a bridge to span a river, it would be absurd to consider building it out of papier-mâché or rubber. We know this because we know something about the demands that will be put on the bridge and we know that these materials do not satisfy the requirements. After considering other materials, perhaps titanium or high tech aluminium alloys, we may discount them on the grounds of cost – even if they do have suitable mechanical properties to make a good bridge. Eventually we may decide on steel; but which one? There are thousands to choose from. Which has the best properties at an affordable price? The cost effectiveness of any material is a matter not to be dealt with here but we must ask “which steel has the most appropriate physical properties”. In order to answer this question, we must conduct tests on different steels and compare the results when samples of the steel are tested to destruction. Since metals have excellent tensile properties, they tend to be used in structures where tensile properties are important. To help with engineering design, data on the tensile properties of metals is widely available to enable Engineers to select the most appropriate material for their project. Much of the data is obtained from tensile tests which provide information on Young’s Modulus, Yield Stress, Tensile Strength (TS) and breaking strength. The data are usually linked to the hardness, microstructure of the material and, in the case of carbon steels, the amount of carbon (alloying material) contained in the steel. By linking the properties to the composition and microstructure of the material, we are taking the first steps towards understanding why these materials behave in the way they do, and how to modify the properties of materials to perform different tasks. Plain Carbon Steels 0% C 0.15% C 0.45% C 0.65% C 0.8% C 10m Typical microstructures and properties of “normalised” (slow cooled) carbon steels. Figure 1: Properties of carbon steels as a function of percentage carbon content. In conclusion, tensile testing is important to help in the selection of the most appropriate material for many engineering projects and for developing techniques to modify a material’s properties so that we can customise the material to a specific purpose. 2 Introduction I still recall the difficulty that I had, as a sixth former, in understanding the shape of the Load v Extension graphs of ductile metals illustrated in my Physics text books. The initial linear, elastic region was no problem and the rising curve of the plastic region was also understandable, but after the maximum tensile strength (UTS) – a decreasing load resulting in a continued increase in the length of a specimen? Engineering Stress (Nm-2) Increasing extension for a Decreasing load? No way! It seemed counter-intuitive! If I had had the benefit of the following very simple investigation, I may have been able to grasp the subject more firmly at an earlier stage. This exercise helps, not so much to explain the effect, but to give a concrete experience of the effect. In this way, the experience fits the data and the data become more acceptable. O O1 Strain (Dimensionless) Fig. 2: Schematic stress v strain diagram for a ductile metal Although my primary intention for this experiment is that it should be an introduction to tensile testing for sixth formers with a follow-up of a piece of extension work (no pun intended) involving a visit to the Materials Department in which I work to carry out tests on carbon steels, the experiments also make an excellent exercise for KS3 and KS4 pupils of all abilities. After all, few pupils of any ability will refuse an opportunity to play with plasticine – and they will learn something as they do it. If this can satisfy the requirements of and count towards coursework, then it is worth giving a try! Experiment Overview Metals combine both elastic and plastic deformation when tested to destruction but it is the plastic deformation that is most likely to cause difficulties in understanding. To model the plastic component, we turn to an ideal plastic material, i.e. plasticine. Rolled into cylinders, the plasticine can be pulled slowly but steadily (constant, slow strain rate) between the fingers. Arm muscles registering the variable force required and the plastic flow experienced directly through the fingers. The plasticity of the plasticine can be modified by adding another material that does not deform plastically (referred to as an inclusion); I use carborundum, simply because I have some available, but the method works just as well with coarse sand (builders version not the fire-bucket kind). Changes in the ductility can easily be measured and related to the amount of inclusions added to the material. This is analogous to carbide precipitates in carbon steel. Needless to say, as with all models, there are weaknesses: plasticine behaves as though it is amorphous and the metals are crystalline. Plasticine behaves as a fluid and metals flow by a slip mechanism along slip planes. However, there are so many slip planes in so many randomly oriented grains (crystals) that the metal (once undergoing plastic flow) has some similarities to plastic flow in a fluid. 3 Preparation Plasticine Pupils could prepare their own specimens, though it would be better if they could be prepared by a lab technician beforehand as this takes time and some care is needed. It is best to have specimens that you know are made up correctly if you want to use them with other groups. Use a different colour of plasticine for each specimen. Each specimen should contain 35.0 ± 0.1 g of plasticine. To minimise the risk of anomalies, plasticine should be used from the same source; that is, the same manufacturer and approximate age. Note: The consistency of the results obtained will improve as the plasticine is used – possibly due to a more even dispersion of the “sand” grains and possibly improved wetting of the grains with oil from the plasticine and hence improved continuity between sand and plasticine phases. When first prepared, the differences between different samples may not be evident, but they do improve with age and use. There are several effective ways of mixing – either to flatten the plasticine, sprinkle some of the sand over the surface and fold it in, sprinkle onto a flat, clean surface and roll the plasticine over it. The plasticine must be thoroughly rolled, folded and kneaded to ensure good mixing. This is important! The colours and amounts described below are suggestions only and you can tailor the amounts to your own needs and availability of material. Colour Code (suggested) Green Red Blue Purple Brown Mass of “Sand” / g ± 0.1 0.0 4 6.4 9 12 Mass per specimen / g 36.0 40 42.4 45.0 48.0 0 10 15 20 25 Sand % of total mass Table 1: Mass of “sand” added to each 35g of plasticine Once specimens have been made, it is inevitable that they will get mixed up by pupils. Try to avoid mixing the colours, but providing colours are not mixed, it is a simple task to reweigh the plasticine to recover samples for next time. Test Specimens Specimens should be rolled into cylinders of about the same diameter, of about 1.5cm. It is important that the diameters are as close as possible to begin with. The properties of plasticine are temperature dependent, so with this in mind, either the specimens should be tested immediately after rolling, or they should all be left to reach the same temperature. With a little inventiveness, the investigation could be extended to compare results at different test temperatures by placing specimens in small plastic bags and leaving in a waterbath to reach a steady state temperature. A further extension would be to use different grades of sand, or different granular materials such as talc. In another experiment that could be used as a follow-on investigation, a simple hardness tester can be used to test the hardness of the different specimens. 4 Technique Before starting, it would be wise to weigh the total mass of each colour of plasticine. This provides the easiest and quickest method to monitor the return of at least most of the plasticine at the end of the lesson. The specimens should be held in the fingers of both hands with tips of fingers and thumbs roughly in the centre. Pull firmly but gently to make the ends move apart at a constant rate. This is essential, as different results are obtained by different strain rates – greater strain rates produce less ductile results. In itself, this is an important point to make and pupils can try this in the practice stages. Be aware that some pupils (particularly the younger or sillier ones) may deliberately let their hands fly apart when the specimen breaks and so hit people next to them. It would therefore be useful to get pupils to stand apart during the testing. Things to observe This section deals with the perception during the test and gives pupils an opportunity to be descriptive about what they experience in an “Observations” section. Starting with “Pure” plasticine: It is helpful to close your eyes when doing this – it helps to cut out extraneous distractions and focuses the attention on your muscles and sense of touch. More consistent results would be obtained if each pupil makes her / his own individual tests – not least of all because some will pull faster than others, produce cylinders of different diameters or simply hold the specimens in a different grip. Notice that it is relatively hard at first to pull the plasticine. The plasticine feels to be flowing, sliding under the fingertips At the same time – Your muscles can relax a little to maintain the constant strain rate At the end – Almost no force is needed, the plasticine flows steadily and the sample necks down to a fine point – maybe 1 mm or less in diameter if done carefully. Repeating the above method for plasticine mixed with sand, it may be observed that the initial force is the same, or even slightly larger. The flow of the plasticine decreases with increasing sand content. The necked diameter of the final specimen (12 g sand) is almost the same as the original diameter of the cylinder. Placing the two broken halves together, it is possible to see a permanent increase in length. This permanent extension could also be measured and found to be related to the amount of sand added. This part is probably more appropriate for top GCSE or A’ level classes as there needs to be more careful preparation of the samples to produce specimens of consistent dimensions. Observations of the fracture surface are important. The surface shows the characteristic “dimpled” structure of a ductile failure. A piece of “sand” would be the stress concentrator responsible for the dimpled appearance as the plasticine flows around the sand. This feature is mimicked in the ductile failure of metals which exhibit a similar dimpled surface with inclusions associated with each dimple – either in the surface being examined or its matching half. 5 Measurements Each test should be carried out at least twice. If results agree closely, an average can be calculated. If they are deemed to be significantly different, pupils must decide if the conditions were the same for both tests and if one should be discarded. A third test would then be carried out. There will be inevitable scatter of results, particularly if care is not taken to make initial diameters and other variables consistent – such as temperature, which will change as the specimen is worked. The minimum diameter should be identified and a measurement made; either circumference, diameter or cross sectional area – depending on the abilities of the class (Cross sectional area would be more “professional”). Permanent extension could be recorded by placing the broken ends together and measuring the final length of the specimen. Expressing changes in dimensions as a percentage of the original quantity (or change in original quantity) makes allowance for random variations in the initial dimensions of different specimens by standardising the results for any diameter / length. Quantity Diameter Area Length Initial /mm D1 A1 L1 Final /mm D2 A2 L2 D2 / D1 A2 / A1 L2 / L1 (D1 – D2) / D1 or… (D1 – D2) / D1 x 100% (A1 – A2) / A1 or… (A1 – A2) / A1 x 100% (L2 – L1) / L1 or… (L2 – L1) / L1 x 100% Normalised (no units) Change or… % change Figure 2: Data to be collected and how to treat the results Treatment of Results Graphs of “Cross Sectional Area” etc. versus “Percent of Sand” should be plotted. Pupils should use their graphs to predict values for a specimen made of, say, 6.5g of sand, before preparing a sample and testing it. Alternatively they could be given a specimen of unknown plasticine / sand composition, and they must determine the sand composition by testing and comparing to their own results. Given the considerable variations in the initial size of the starting cylinders, strain rate, possibly temperature and a range of other variables, pupils will be able to accept the variations that they get in their measurements. It is recommended that the normalised results are used wherever pupils can treat results this way. The fact that a pattern does emerge is an opportunity to discuss error within data-points and to introduce the concept of error bars for the brighter pupils. 6 Cut-Out Calliper Fig. 3: Cardboard callipers. Copy onto card, cut out and join using a paper clip to provide a hinge. Pupils (especially younger ones) can then measure diameters more consistently without scoring the plasticine too deeply. 7 Glossary of Terms Term Explanation Brittle Cracks easily. A crack is started (initiated) and rips through the material with little energy used. Opposite = Tough Ductile The property that allows a material to undergo a large permanent shape change due to the application of a tensile force. Plasticine is a definitive material to illustrate this property. The equivalent property for compressive forces is malleable. Elastic The property that allows a material to regain its original shape once a deforming force is removed. A metal spring is an excellent material to illustrate this property. Opposite = Plastic Elastomer A rubbery, polymeric material that exhibits approximate elastic properties. Engineering Stress If stress is given by Load / Cross Sectional Area, as necking occurs and area decreases then localised stress also increases. However, this is difficult to measure in-situ and does not provide additional useful material (since the useful limits of the material as a structural material have been far exceeded). To simplify matters, the “Engineering Stress” is defined as Load / original cross sectional area. Also see Stress and True Stress Hard A material property that describes the resistance of a material to being deformed. Opposite = Soft Load The Force in Newtons applied to the specimen. Necking The localised deformation and characteristic thinning of a specimen during ductile flow. Plastic The ability of a material to undergo permanent shape change Opposite = Elastic Stiffness The resistance of a material to elastic deformation. Engineering Strain The ratio of extension to original length: usually expressed as a percentage. The quantity is dimensionless so has no units. Strain Rate How fast the strain increases. This should be a constant for tensile tests. Since strain is dimensionless, the strain rate has the curious unit of s -1. Pupils would find this curious and it could open a route to discussing units with a link to speed for revision purposes. Stress The Force per unit area – same as a reduction in pressure (negative pressure) – and has the effect of standardising the load to be comparable to specimens of any cross sectional area: again, this is a useful discussion point to discuss units – with a link to pressure for revision purposes. Compression would be the equivalent of an increase in positive pressure. Tough A material that resists cracking by absorbing a large amount of energy before it breaks. Ductile materials are tough. Opposite = Brittle True Stress If the stress at the site of necking is determined from in-situ measurements of cross sectional area, then the True Stress at that point would be known. As load decreases, the area decreases even faster, so that the True Stress continues to rise up to failure. Also see Stress and Engineering Stress UTS Tensile Strength (or Stress). This corresponds to the maximum (if there is one) of the test material. Yield Point / Yield Stress / Elastic Limit The point, just above the linear region of the stress v strain curve, at which plastic deformation results in permanent change in shape of the material. Table 3: Glossary of common terms 8 Blank Page 9 Stress-Strain Diagrams Recorded on a Tensometer The shape of the curves can be misleading due to a combination of the design of the Tensometer, which is designed to provide a constant strain rate, and the behaviour of the ductile specimen being tested. The following refers to specimen charts illustrated in the Excel file, Tensile Tests.xls, on the OxMAT CD ROM (Reprinted for reference in the Appendix). An overview of the properties of a ductile metal can be explained below. This is most closely represented by Copper in the data provided in the spreadsheet, but all ductile metals show some of these characteristics. Difference corresponding to carbon steel are considered later. In the case of the three metals shown in the chart, all follow the following general patterns:In the diagram (right) O = Initial origin OO1 = Permanent elongation A = Elastic limit OA = Linear region B = General point beyond A BO = Relaxation if stress removed (Note: O1B is parallel to OA) C = Maximum Strength AC = Region of plastic Deformation X = Failure CA = Plastic Flow (Note: This is the region where “necking” or localised thinning of the specimen takes place.) Engineering Stress (Nm-2) C B X A O O1 Strain (No dimensions) The overall shape (not values) of the curve would be the same for a plot of Force v length. However, plotting (Engineering) Stress v Strain standardises the curve to an initial cross sectional area of 1m2 by dividing by the initial cross sectional area. Problems: The plot assumes that the initial cross sectional area and length are constant throughout. This is not the case. The volume of material remains constant, therefore as the length increases, the cross sectional area decreases. This effect is minute and is generally ignored over the elastic region. Once necking takes place, however, reduction in the cross sectional area at that point becomes marked. This is not normally allowed for in these plots and can give rise to misleading observations. Since the Stress is determined by Load/Area, as localised area decreases, the stress will, in fact increase at this point. As the Tensometer cannot measure the decrease in cross sectional area, it is not actually measuring the “True stress”, but the stress assuming a constant cross-sectional area, referred to as the “Engineering stress”. Engineering stress is generally used for simplicity, since once this starts to happen, any safe loading has been exceeded by far, and few structures are designed to fail in such a precise way. Exceptions may include safety bolts that are designed to fail under dangerous loading conditions. 10 Line OA: The line is linear and the material follows Hooke’s Law. Relieving stress returns the specimen to its original, unstretched length. Beyond A: the stress is such that dislocations (later) in the crystal start to move. This changes the spatial arrangement of some of the atoms relative to each other, hence a permanent change in length is observed and the line is no longer linear. Relaxing the specimen of all stress at this point allows the Stress v Strain line to follow a path parallel to the line OA, as the slope is a property of the material (Young’s Modulus = Stress/Strain), but returns to point O1 where OO1 indicates the permanent extension resulting from the movement of dislocations. Carbon Steels The above applies to carbon steels also, but the alloying element carbon affects the behaviour of the dislocations. Carbon atoms are small compared to iron and tend to fit between iron atoms in the crystal lattice (interstitial alloy), as opposed to occupying the site of an iron atom in the crystal as happens with metal-metal alloys (substitutional alloys). The position of carbon atoms increases the local stress (same dimensions as pressure) in the crystal. If the atoms could be positioned in a region where the crystal lattice is imperfect, and greater gaps between iron atoms are found, then the stress will be reduced. Placing the interstitial atoms in these spaces (see dislocations, later) forms a lower energy situation than having the carbon distributed within a perfect crystal lattice. Such imperfections occur at grain boundaries (where crystals of different orientation meet) and at dislocations. Natural systems adjust from high to low energy systems, therefore, to minimise the energy of the system, carbon atoms diffuse to these sites – that is, grain boundaries and dislocations. Carbon atoms occupy the larger than usual gap at a dislocation. This prevents the dislocation from moving and is said to “pin” the dislocation. If the dislocations in iron are pinned, then they cannot move, preventing plastic deformation at stress values that would otherwise result in plastic deformation. This extends the useful range of the iron by extending the elastic region of the stress v strain curve. There is a limit, however, and once it is reached, the dislocation is forced past the carbon atom that has been pinning it. This results in a slight relaxation and an initial peak at the end of the elastic region. More dislocations are pinned, preventing further deformation, hence the line rises again. This stress and relaxation pattern repeats a number of times giving the series of peaks observed in the graph. Stress C Steel Pure Iron NOT TO SCALE Strain 11 Dislocations …occur when an otherwise perfect region of a crystal has an “extra” plane of atoms inserted. The extra plane displaces adjacent planes, increasing local stress. Bonds between metal atoms are strained and therefore of higher energy than those within the bulk of the perfect crystal and can, therefore, break more easily. Note: in diagrams a. and b., the three shaded atoms represent a plane of atoms perpendicular to the plane of the paper. The “extra space” forms a low energy “tunnel” into which carbon atoms can diffuse. Under the influence of a stress (tensile or compressive), metallic bonds between the metal atoms become strained and break, reforming with atoms of the adjacent “extra” plane (figure c.). Effectively, the dislocation moves, disturbing the arrangement of atoms and giving rise to a permanent change of shape (ringed in figure d.) Consider crystal planes, viewed edge-on, so they appear as straight lines… a. A perfect crystal 1 b. A dislocation 2 3 4 1 2 3 4 1 2 E 3 4 1 2 E 3 4 c. Under stress, bonds “flip” Insertion of a low concentration of 1 2 3 4 interstitial atoms, such as carbon, into the dislocation makes “bond flipping” more 1 2 3 4 difficult simply because the carbon “gets in the way”. Greater energy is needed to make the dislocation move past the carbon E 1 2 3 4 atoms. Once the dislocation has moved, the material continues to deform until held 1 2 E 3 4 back by more pinned dislocations, resulting in greater resistance to plastic d. The dislocation “moves” changing the deformation: this is indicated by further spatial arrangement of the atoms around it: rising of the curve. The process repeats that is a slight, permanent change of shape several times resulting in a series of peaks occurs. before all dislocations have become unpinned. At higher concentrations, more dislocations are pinned simultaneously, so the material resists slip until a greater energy: a higher proportion of dislocations fail simultaneously, so progressively fewer peaks and troughs (Luders bands) are seen. Please note. This is a simplified explanation of the influence of carbon, or other interstitial alloy elements on the behaviour of dislocations in steel. The whole process is also affected by heat treatments (which can produce a variety of different microstructures and crystal allotropes within the steel), other alloy materials and actual strain rates of the test. However, it should be more than detailed enough for any A-Level treatment of the subject. 12 Engineering and True Stress / Strain In tensile testing, the load cell in the tensometer detects load only. The tensometer is designed to test specimens of fixed dimensions and hence of fixed and constant cross sectional area and original length. Using these pre-defined values, output is read in terms of stress and strain. F , where F and a are the applied load (N) and cross sectional area (m2) a e Strain is defined as , where e and l are the linear extension (m) and original length (m) l Stress is defined as As the test proceeds and the elastic limit is exceeded, the specimen necks and permanent extension takes place, hence both the cross sectional area and “original” length of the specimen change. The tensometer cannot take these changing values into account and continues to assume the initial values, resulting in error values of the absolute stress and strain. In the absence of any cost effective way of correcting this defect in the experimental design, the output is accepted, but is qualified by referring to “Engineering” stress and strain. If the true stress and true strain could be plotted, the lines of the charts would continue to rise, as the stress in the region of necking continues to rise as a result of decreasing cross sectional area. Please Note: The value of Young’s modulus CANNOT be derived from the linear slope at the start of the stress-strain diagram as obtained from a tensometer. This is due to the fact that the load cell, to which the specimen is attached to measure the load acting on it, moves slightly. The movement of the load cell gives a larger than reality value to extension and hence to strain. Furthermore, although the tensometer is designed to be rigid, there can be some flexing of the frame which, in turn, can result in an error in measurement. Load measurements should be accurate and diagrams are self-consistent. As the purpose of the instrument is to measure loads ( hence engineering stress) and to examine the shape of the diagram, then the fact that Young’s modulus cannot be measured is not important. The non-linear shape at the start of the diagram is also due to extension in the load cell which works on a lever principle. 13 Elastic Limit and Limit of Proportionality – A Closer Look In the detail of a stress strain diagram… EL = Elastic Limit LP = Limit of Proportionality Stress EL From origin to LP, the metal obeys Hooke’s Law. That is:Stress Strain LP Furthermore, extension is not permanent, and removing the load will return the metal to its original size and shape Beyond the point LP, but NOT coincident with it, is a point at which plastic flow starts to occur, EL. Beyond EL, there are two components to the extension, such that if the load is removed and elastic component will result in the material trying to regain its original size and shape, but also there will be a plastic deformation, resulting in a permanent increase in length. Path taken on unloading BEFORE EL Path taken on unloading AFTER EL Strain The region BETWEEN LP and EL is also purely elastic, with full recovery on the unloading of the metal, but is NOT linear. To explain this feature, we need to consider the Potential Energy between metal atoms as the separation of the atoms changes. As the atoms approach, the PE changes:1. 2. 14 Decreases (-) due to electronic / bonding effects (inverse square law). a. Over relatively large distances, the attractive force dominates. b. Approaching from infinity (moving right to left in figure 2a on the next page), the PE increases to a large negative value (- for attraction) as the extent of electronic / orbital overlap increases. c. The PE increases as the square of the distance. Increases (+) due to repulsive forces between nuclei (inverse cubic). a. Over very short distances, the repulsive force dominates b. As the nuclei approach (moving right to left), electrostatic repulsion increases the PE (+ for repulsion) between the atoms c. The PE varies as the cube of the distance. 3. There is an equilibrium position where the forces balance and the PE is at a minimum value referred to as the Potential Energy well illustrated in Fig 2b on the next page. This corresponds to the bond length, or lattice parameter in the case of a cubic metal crystal. 4. The PE well is not symmetrical. To the left, repulsive forces (varied as 1/distance cubed) dominate and to the right, attractive forces (varied as 1/distance squared) dominate. 5. Compressing the material is, therefore harder than extending the material. 6. In extending the material, the atomic distance is increased. Over a short period of time, this approximates to a linear relationship. 7. Larger distances reduce the attraction between neighbouring atoms making it easier for bonds to break and reform, e.g. at a dislocation, where a strained bond breaks but reforms with a closer neighbour. Hence we get plastic deformation. 8. Between the linear, elastic region and the onset of plastic deformation is a region in which a. The relationship between force and distance is NOT linear, but… b. The attractive forces do not allow for bonds to break, hence… c. A non-linear, elastic region is recognised. Rapid rise in repulsive PE – hence compression is very difficult PE between atoms PE due to Attractive forces PE due to Repulsive forces PE due to Combined forces i.e the above two lines added together. Beyond recovery, some bonds break and new ones form between neighbouring atoms. (Dislocations move) Elastic, but non-linear Inter-atomic distance Relatively linear over a short region. (Up to LP on - plot) Equilibrium condition The Bond Length 2b: Linking the energy well to the Stress-Strain plot 2a: Potential Energy well for adjacent atoms in a metal crystal. NOT drawn to scale During Plastic Deformation – an extension and “worked” example Dislocations provide the energy for strained bonds to break, but these bonds reform in a less strained position. Other bonds become strained etc. as the dislocation moves through the metal. It should be noted at this point that work is being done, since effectively, planes of atoms are moving through the crystal under the influence of an applied force. Doing work generates heat, hence the metal warms up. This is illustrated clearly by… 1. Straighten out a trombone paper clip. 2. Place against the lips to notice the temperature. (This may not be necessary) 3. Take the clip away from your lips and bend back and forth rapidly until the clip breaks. 4. Place against the lips – and notice the very large rise in temperature. This may be noticeable through the fingers, but the lips are more temperature sensitive. Furthermore, the clip bends easily at first, but it soon gets harder to bend. This is due to 1. The generation and movement of many dislocations. The dislocations are limited to sliding along specific crystal planes. 2. Bottlenecks of dislocations jam up the crystal planes used by the dislocations. 3. In turn this restricts / prevents dislocations from moving and hence limits plastic flow / ductile behaviour. 4. The material is hardened, as steel is with carbon, by the pinning of dislocations but via a different mechanism. 5. This mechanism is referred to as “Work hardening”. 15 Acknowledgements Thanks to Dr. Richard Todd who checked the script for accuracy and also made some useful suggestions. Thanks also to David Hutton and Vanessa Cheel for their suggestions and corrections in proof reading. There is a saying that there is “nothing new under the sun”. The plasticine / sand experiment is not a new idea in itself, but hopefully is presented in a novel way with ideas for using it more widely within the school curriculum. I would like to thank the person, whose name I do not know, for the original idea. Figure 1: Properties of Engineering Materials R. A. Higgins 2nd Edition ISBN 0 340 60033 0 Butterworths 16 Appendix Images of plasticine / sand experiments. Plasticine test specimens showing amount of sand and the extent of necking. A close up of each of the test specimens showing the fracture surfaces. 17 18 0.00E+00 0.00E+00 1.00E+02 2.00E+02 3.00E+02 4.00E+02 5.00E+02 6.00E+02 7.00E+02 8.00E+02 9.00E+02 1.00E+03 5.00E-02 1.00E-01 0.02% C 1.50E-01 0.18% C 2.00E-01 0.41% C Strain 2.50E-01 0.54% C 0.8%C 3.00E-01 3%C 3.50E-01 Stress-Strain Plots for Different Carbon Contents 4.00E-01 4.50E-01 5.00E-01 Variation of Stress-Strain charts with increasing carbon content Millions Stress / Pa Steel Samples Compared Medium Carbon Steel A medium carbon steel (top) compared to a high carbon steel (below). Note the relatively large extent of necking and permanent increase in length of the medium carbon specimen compared to that of the high carbon specimen. Both steels are compared with an untested original specimen to allow for relative measurements to be made. High Carbon Steel Low Carbon Steel Fracture Surface. Note the dimpled interior structure indicating ductile failure and a surrounding smoother “shell” which denotes a brittle failure across crystal planes. Most metals will exhibit this mixed failure pattern in varying degrees. 19 Microstructures of steel samples – Approx. 0.02% Carbon showing the ferrite structure of very low carbon steel. 100μ 50μ 20 Microstructures of steel samples – Approx. 0.20% Carbon showing the white areas of ferrite and darker areas of pearlite. 100μ 20μ 21 Microstructures of steel samples – Approx. 0.40% Carbon. The greater carbon content results in greater amounts of pearlite forming. 20μ 20μ 22 Microstructures of steel samples – Approx. 0.54% Carbon. Lamellar structures due to pearlite formation are more evident. Remaining ferrite indicates the outline of original austenite grains. 100μ 20μ 23 Microstructures of steel samples – Approx. 0.80% Carbon. Spacing between pearlite Lamellae are due to the surface orientation of the grain resulting in spacings being “spread out”. 20μ 20μ 24 Glossary of Metallurgical terms used There are different structures that occur depending on the amount of carbon present and the heat treatment that the steel has been subjected to. The different structures are readily identified by observing the microstructure. The terms used to explain these images are explained briefly, below. The explanations relate to the text of this resource and should not be considered to be exhaustive. Austenite: Gamma (γ) iron (not magnetic). Austenite is a face-centred-cubic (fcc) lattice of iron which is the thermodynamically stable form of steel at high temperatures. Carbon can dissolve in austenite interstitially. On cooling, transformations to other phases take place, the exact structure (and hence properties) being dependent on cooling rate. Cementite: Iron carbide (Fe3C). Orthorhombic crystalline structure which forms in low carbon steel as lamellae in pearlite. As carbon content increases, the amount of ferrite decreases and the amount of pearlite increases. At ~0.80 to ~0.85%C all of the microstructure is pearlite but once the carbon content exceeds ~0.85%C cementite forms as a distinct phase with no ferrite present (other than that within the pearlite). Ferrite and cementite look very similar in micrographs and experience is needed to identify them in a steel of unknown carbon content. Ferrite: Alpha (α) iron (magnetic). For most practical purposes, ferrite can be considered as ‘pure’ iron, being soft, ductile and of relatively low strength. Ferrite typically contains a maximum of 0.03% carbon. The iron forms a body-centred cubic lattice with carbon atoms dispersed interstitially. The magnetic properties of iron are due essentially to ferrite. Normalise: This is a preliminary heat treatment in order to allow all carbon to dissolve interstitially and relieve internal stresses from working etc. The temperature is raised to 860˚C for one hour before allowing the steel to cool in still air. Pearlite: This is found in all slowly cooled structures of carbon steels and consists of alternate layers of ferrite and cementite. As the carbon content of the steel increases, the amount of pearlite increases with a consequent reduction of ferrite content. At appropriate magnification the pearlite structure has a fingerprint-like appearance. When etched, a striped appearance is given to the microstructure. The separation of lamellae depends on the angle with which the crystal strikes the surface. At small angles, the lamellae can behave as a diffraction grating and produce a “mother of pearl” impression in white light - hence the term pearlite. Lamellae viewed from above Surface of the steel Lamellae approaching the surface at different angles Work: In the context of applying a force which brings about a mechanical change, Work is done to move dislocations, induce internal stress, cause fractures etc. 25 Summary of the microstructures %C Low Mag High Mag 0.02 Very low Carbon. Little or no pearlite. 0.18 Once the iron is “saturated”, pearlite starts to appear. 0.40 Increasing carbon content results in increasing pearlite formation. 0.54 Pearlite is easily resolved in the optical microscope. 0.80 More pearlite forms with increasing C content. Pearlite is clearly visible as “zebra” stripes within a grain. 26 For further information about class experiments, school visits and courses (pupils and teachers), please contact: Martin Carr (Schools Liaison Officer) Department of Materials University of Oxford Parks Road Oxford OX1 3PH T. 01865 273 710 F. 01865 273 789 E. Martin.Carr@materials.ox.ac.uk W. http://www.materials.ox.ac.uk/undergraduate/schools.html 27