During oil production, it is ususal proctice to inject water into the well

advertisement

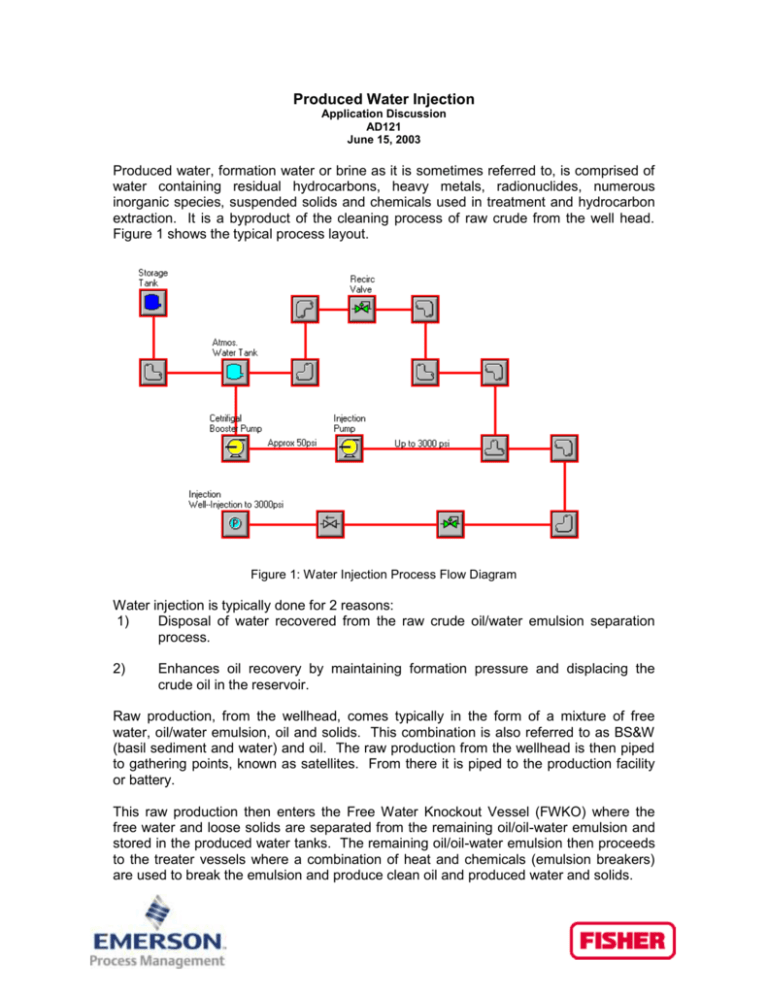

Produced Water Injection Application Discussion AD121 June 15, 2003 Produced water, formation water or brine as it is sometimes referred to, is comprised of water containing residual hydrocarbons, heavy metals, radionuclides, numerous inorganic species, suspended solids and chemicals used in treatment and hydrocarbon extraction. It is a byproduct of the cleaning process of raw crude from the well head. Figure 1 shows the typical process layout. Figure 1: Water Injection Process Flow Diagram Water injection is typically done for 2 reasons: 1) Disposal of water recovered from the raw crude oil/water emulsion separation process. 2) Enhances oil recovery by maintaining formation pressure and displacing the crude oil in the reservoir. Raw production, from the wellhead, comes typically in the form of a mixture of free water, oil/water emulsion, oil and solids. This combination is also referred to as BS&W (basil sediment and water) and oil. The raw production from the wellhead is then piped to gathering points, known as satellites. From there it is piped to the production facility or battery. This raw production then enters the Free Water Knockout Vessel (FWKO) where the free water and loose solids are separated from the remaining oil/oil-water emulsion and stored in the produced water tanks. The remaining oil/oil-water emulsion then proceeds to the treater vessels where a combination of heat and chemicals (emulsion breakers) are used to break the emulsion and produce clean oil and produced water and solids. Clean oil then proceeds to storage or shipping. The produced water from the treaters is transferred to tanks to hold for disposal. Depending on residence time in the tanks, some of the solids may settle out of the water and residual oil in the water floats to the surface. This oil layer is skimmed off the top and recycled through the plant to recover this additional oil. In smaller production facilities, this water may be disposed of directly from the tanks. In larger facilities, there is often an additional water treatment vessel known as a dissolved air flotation (DAF) unit that further cleans the water. After the DAF unit, the water is either sent through filters, which are usually sand or multimedia filters or through hydrocyclones to remove the last traces of oil. After final filtration, the water is used for steam generation, discharged to agricultural canals or rivers or re-injected downhole. As oil wells mature, the ratio of water to oil increases. This is because the formation “waters out” due to the water injection process. Water becomes a significant byproduct of oil and gas production. For example more than 7m3 of water is produced for every cubic meter of oil or gas equivalent (10bbl water/bbl oil) obtained from gas and oil wells in the continental U.S. The produced water is disposed of by either re-injection or by discharge into the environment. Subsurface injection is the primary method for disposal of produced water for land-based oil and gas operations. Produced water may be re-injected for disposal to shallower saltwater formations, or re-injected to older, depleted producing formations. By injecting the water into the producing formation, (Water Flood) well pressure and product flow is maintained by displacing the produced oil. The valves used in this process will generally see cavitation involving high-pressure drops and erosion damage caused by the sand and other particulate present during separation. Small holed trim and stacked disk designs have been tried in the past but have failed due to the holes clogging. Figure 2 shows a trim set that eventually failed due to severe plugging in this application. Figure 2: Plugged and Damaged Trim Set The ultimate solution is to use an anti-cavitation type trim that uses large holes such as the Fisher DST (Dirty Service Trim). A properly sized and selected DST will eliminate damaging cavitation, noise and vibration. It accomplishes this by staging the pressure drops across the properly determined number of stages. It will also allow for particulate from ¼” to pass through the trim without plugging in the smallest valve size to ¾” in the largest while providing cavitation protection for pressure drops up to 4500 psid. As the application varies greatly in pressures and pressure classes, temperature and particulate content, it may be possible to utilize other types of valves. Solutions may include D or DA bodies, 461, angle bodies and Cavitrol III type trims. These types of trims should only be utilized after fully scrutinizing all process conditions and factors.