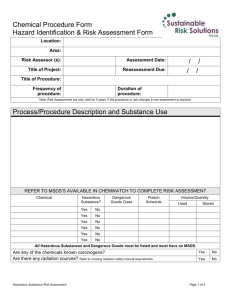

Hazard Communication part 1 - UA SafeState

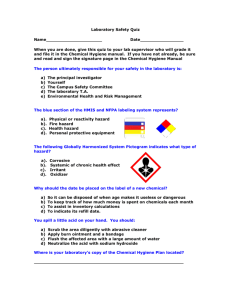

advertisement