SECTION 14220

RESIDENTIAL ELEVATORS

Display hidden notes to specifier. (Don't know how? Click Here)

Copyright 2013 ARCAT, Inc. - All rights reserved

PART 1 GENERAL

1.1

1.2

1.3

SECTION INCLUDES

A.

Residential electric winding drum elevators.

B.

Residential hydraulic elevators.

RELATED SECTIONS

A.

Section 04810 - Unit Masonry Assemblies: Hoistway construction.

B.

Section 05500 - Metal Fabrications: Guide rail mounting supports.

C.

Section 06100 - Rough Carpentry: Hoistway construction.

D.

Section 06200 - Finish Carpentry: Hoistway doors and frames.

E.

Section 08114 - Custom Steel Doors: Hoistway doors.

F.

Section 08115 - Custom Steel Frames: Hoistway frames.

G.

Section 08211 - Flush Wood Doors: Hoistway doors and frames.

H.

Section 09260 - Gypsum Board Assemblies: Hoistway finish.

I.

Division 16 - Electrical service.

1.

Power supply of 240 volts, single phase, 60 hertz.

2.

Power supply of 208 volts, single phase, 60 hertz.

3.

Manually operated, fused line, 3-pole lockable disconnect located in the

machine area.

4.

115 volt light source in hoistway.

5.

Phone line to central telephone exchange.

J.

Section _____ - _________________________________.

REFERENCES

14220-1

1.4

A.

ANSI A17.1 - Safety Code for Elevators and Escalators.

B.

NFPA 70 - National Electrical Code.

SYSTEM DESCRIPTION

A.

1.5

1.6

SUBMITTALS

A.

Submit under provisions of Section 01300.

B.

[ Product Data ]: Manufacturer's data sheets on each product to be used, including:

1.

Preparation instructions and recommendations.

2.

Storage and handling requirements and recommendations.

3.

Installation methods.

C.

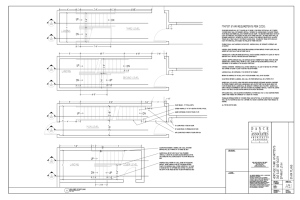

Shop Drawings: Include detailed dimensions of components, including locations of

connections to other work, load reactions at points of support, and arrangement of

equipment.

D.

Selection Samples: For each finish product specified, two complete sets of color

chips representing manufacturer's full range of available colors and patterns.

E.

Verification Samples: Selected cab finishes, not less than 6 by 6 inches (150 by

150 mm).

F.

Operating and Maintenance Data: Installation, operating, and maintenance

instructions, parts lists and wiring diagrams.

QUALITY ASSURANCE

A.

1.7

1.9

Installer Qualifications: Authorized elevator contractor specializing in installing

equipment of the type specified and approved by dumbwaiter manufacturer.

REGULATORY REQUIREMENTS

A.

1.8

System Characteristics:

1.

Capacity: _____ lbs (_____ kg).

2.

Size of car: _____ wide, _____ deep, _____ high.

3.

Travel distance: _____ ft, ____ in (____ m).

4.

Speed: _____ feet per minute (_____ m per minute).

5.

Number of stops: _____.

Comply with ________ building code for manufacture and installation of dumbwaiter

system.

DELIVERY, STORAGE, AND HANDLING

A.

Store products in manufacturer's unopened packaging until ready for installation.

B.

Store equipment undercover and in accordance with the manufacturers

recommendations.

WARRANTY

A.

Provide Manufacturers limited warranty on materials and workmanship.

PART 2 PRODUCTS

2.1

MANUFACTURERS

14220-2

2.2

A.

Acceptable Manufacturer: Waupaca Elevator Company, 1nc., 1726 N. Appleton, WI

54911. ASD. Tel: (800)238-8739. Fax: (920) 991-9086. Email:

crs@waupacaelevator.com, www.waupacaelevator.com.

B.

Substitutions: Not permitted.

C.

Requests for substitutions will be considered in accordance with provisions of

Section 01600.

D.

Provide electric elevators of a single manufacturer.

RESIDENTIAL ELECTRIC ELEVATORS

A.

Cab Design: "The Designer."

B.

Cab Design: "The Contemporary."

C.

Cab Design: "The Estate."

D.

Cab Design: "The Traditional."

E.

Guide Rail: Specially formed 3/16 inch (4.7 mm) thick, 8 inch (203 mm) wide steel

channel with rail brackets at 30 inch (762 mm) intervals.

1.

Provide heavy-duty splice bolts at all matched, ground, and numbered rail

splices.

F.

Capacity: 500 pounds (227 kg).

G.

Speed: 30 feet per minute (9.144 m per minute).

H.

Travel Distance:

I.

Wire Rope: Two 1/4 inch (6.3 mm) 8x19 improved plow steel ropes.

J.

seq level2 ALPHABETICA. Pit Depth: _____ inches (_____ mm).

K.

Machine: Utilizing high ratio gearbox with direct mounted and coupled motor;

include single drum with outboard bearing for support and slack-cable devices.

L.

Brake: Spring-applied, electrically-released only when drive motor is energized.

M.

Motor: Two horsepower, single speed reversing type, constant NEMA rated.

N.

Cab Truck: Running on four Hi-Density Synthetic guides and four Hi-Density

Synthetic rollers; twin instantaneous safeties applied by a retained compression

spring.

1.

Minimum Height: 49-1/4 inches (1.251 m).

O.

Controls: Momentary contact, fully automatic.

1.

Cab Control: Include landing buttons, cab light switch, alarm button, and

emergency stop switch.

2.

Limit Switches: Provided at all landings to automatically stop car with 1/4

inch (6.3 mm) of landing level; provide final limit at top landing.

P.

Electrical Overload Protection: Fused.

Q.

Signal System:

1.

Standard momentary-contact hall push button stations with in-use lights.

2.

Wall-mount phone jack.

_____ feet (_____ m).

14220-3

3.

4.

5.

6.

2.3

Alarm bell.

Emergency cab lighting.

Car-here lights

Flush phone box.

R.

Hoistway Door Interlocks: Preventing elevator operation unless doors are closed

and preventing accidental opening of any door unless cab is at designated landing;

include door latches.

1.

Self closures.

S.

Number of openings: ____ as follows:

1.

_______ front.

2.

_______ back.

3.

_______ left side.

4.

_______ right side.

RESIDENTIAL HYDRAULIC ELEVATORS

A.

Model: "CUSTOM-RYDE."

B.

Cab Design: "The Designer."

C.

Cab Design: "The Contemporary."

D.

Cab Design: "The Estate."

E.

Cab Design: "The Traditional."

F.

seq level2 ALPHABETICB. Guide Rail: 8 pound (3.6 kg) tee planed steel.

G.

Capacity: _____ pounds (_____ kg), roped 2:1.

H.

Speed: 30 feet per minute (9.144 m per minute).

I.

Speed: 36 feet per minute (10.973 m per minute).

J.

Travel Distance: _____ feet (_____ m).

K.

Wire Rope: Two or three 3/8 inch (9.5 mm) diameter traction steel ropes.

L.

Pit Depth: _____ inches (_____ mm).

M.

Operation: Two speed, extremely gentle starts and stops.

N.

Power Unit: Constant displacement rotary screw-pump, oil reservoir, hydraulic

control unit, and oil level gage; include safety descent.

O.

Motor: 2 horsepower.

P.

Motor: 2-1/2 horsepower.

Q.

Controller: UL Certified-Automatic PLC Based.

R.

Electrical Overload Protection:

S.

Car Operating Panel, Car Top Box: Include alarm, emergency cab lighting,

momentary-contact landing buttons, cab light switch, and stop switch.

T.

Signal System:

Fused and thermal overload protection.

14220-4

1.

2.

3.

Standard momentary-contact hall push button stations with call/in-use lighted

buttons and car-here lights.

Wall-mount phone jack.

Flush phone box.

U.

Hoistway Door Interlocks: Preventing elevator operation unless doors are closed

and preventing accidental opening of any door unless cab is at designated landing;

include door latches.

1.

Self closures.

V.

Power Gate Opener.

W.

Number of openings: ____ as follows:

1.

_______ front.

2.

_______ back.

3.

_______ left side.

4.

_______ right side.

PART 3 EXECUTION

3.1

3.2

3.3

EXAMINATION

A.

Verify that hoistways are plumb and square; confirm dimensions before beginning

installation.

B.

Verify electrical power is available and of correct characteristics.

C.

If hoistway preparation is the responsibility of another installer, notify Architect of

unsatisfactory conditions before proceeding.

INSTALLATION

A.

Install in accordance with manufacturer's instructions provided and in compliance

with requirements of the National Electrical Code, ANSI A17.1 Code, and applicable

State and local building codes.

B.

Adjust for smooth acceleration and deceleration of car and for consistent stopping at

each landing.

PROTECTION

A.

Protect installed products until completion of project.

B.

Touch-up, repair or replace damaged products before Substantial Completion.

END OF SECTION

14220-5