For Spent Fountain Solution Mixture

advertisement

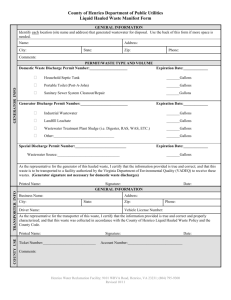

MASSACHUSETTS WATER RESOURCES AUTHORITY 2 Griffin Way Chelsea, MA 02150 Telephone: (617) 242-6000 Facsimile: (617) 371-1604 TO: FROM: DATE: SUBJECT: Holders of Group Permit for Photo Processing and Printing Operations Toxic Reduction and Control (TRAC) February 14, 2014 Annual Compliance Report for Photo Processing and Printing Operations Enclosed is your Annual Compliance Report for calendar year 2013. Please complete the report based upon your operations during calendar year 2013. It must be received in MWRA’s Toxic Reduction and Control by March 31, 2014. The mailing address is MWRA, TRAC, 2 Griffin Way, Chelsea, MA 02150. Important Reminders: Your lab must submit your silver sample result(s) electronically at http://websmr.mwra.com. This is a new website. MWRA will only accept sample results that are submitted electronically. Submit a paper copy of your silver sample result including the chain of custody form (attached to your G1 or C1 Permit) for samples taken in 2013. Your report must be signed by a responsible individual capable of certifying that the information submitted is true, accurate, and complete. Please review and update the information on Page 1. Completion and submittal of the report constitutes only partial compliance with your Group Permit for Photo Processing and Printing Operations (for instance, you must notify the MWRA in writing at least thirty days before you close or move your facility or substantially change your operations). On August 13, 2013, TRAC issued 2 Penalty Assessment Notices (PANs), totaling $1,000.00, to companies that failed to submit the annual Compliance Report or annual silver sample result (or both) as required by the Group Permit for Photo Processing and Printing Operations (Group Permit). The due date for filing the Compliance Report and silver sample was April 1, 2013. If you have any questions about completing the form, please contact your Industrial Coordinator. An electronic version of this form can be found on MWRA’s website @ www. mwra.com. http://websmr.mwra.com. MASSACHUSETTS WATER RESOURCES AUTHORITY/TRAC MUNICIPALITY 44 01 02 03 04 45 06 46 07 08 09 10 47 11 57 12 48 49 13 14 15 16 50 51 58 17 18 52 19 20 21 22 23 24 25 26 27 28 29 53 54 30 55 31 32 33 34 35 36 37 56 38 39 40 41 42 43 Allston Arlington Ashland Bedford Belmont Boston (downtown) Braintree Brighton Brookline Burlington Cambridge Canton Charlestown Chelsea Clinton Dedham Dorchester East Boston Everett Framingham Hingham Holbrook Hyde Park Jamaica Plain Lancaster Lexington Malden Mattapan Medford Melrose Milton Natick Needham Newton Norwood Quincy Randolph Reading Revere Roslindale Roxbury Somerville South Boston Stoneham Stoughton Wakefield Walpole Waltham Watertown Wellesley West Roxbury Westwood Weymouth Wilmington Winchester Winthrop Woburn ICLIST: July, 2013 INDUSTRIAL COORDINATOR John Norton Steve Buczko Lisa Chapman Lisa Chapman Dennis Capraro Steve Buczko Eric Renda Erika Samuels Keary Simmerman Lisa Chapman Walter Schultz Eric Renda Erika Samuels Ken Cunningham Tom Halloran Eric Renda Erika Samuels Tom Halloran Keary Simmerman Lisa Chapman Steve Buczko George Riley Erika Samuels Erika Samuels Tom Halloran Ken Cunningham Dennis Capraro John Norton Erika Samuels Dennis Capraro Steve Buczko Tom Halloran Eric Renda Keary Simmerman George Riley George Riley George Riley Steve Buczko Keary Simmerman John Norton John Norton Keary Simmerman John Norton Steve Buczko Eric Renda Steve Buczko Eric Renda Tom Halloran Ken Cunningham John Norton Erika Samuels Erika Samuels George Riley Ken Cunningham Keary Simmerman Steve Buczko Dennis Capraro PHONE 617-305-5656 617-305-5619 617-305-5622 617-305-5622 617-305-5620 617-305-5619 617-305-5662 617-305-5666 617-305-5638 617-305-5622 617-305-5665 617-305-5662 617-305-5666 617-305-5623 617-305-5679 617-305-5662 617-305-5666 617-305-5679 617-305-5638 617-305-5622 617-305-5619 617-305-5664 617-305-5666 617-305-5666 617-305-5679 617-305-5623 617-305-5620 617-305-5656 617-305-5666 617-305-5620 617-305-5619 617-305-5679 617-305-5662 617-305-5638 617-305-5664 617-305-5664 617-305-5664 617-305-5619 617-305-5638 617-305-5656 617-305-5656 617-305-5638 617-305-5656 617-305-5619 617-305-5662 617-305-5619 617-305-5662 617-305-5679 617-305-5623 617-305-5656 617-305-5666 617-305-5666 617-305-5664 617-305-5623 617-305-5638 617-305-5619 617-305-5620 MASSACHUSETTS WATER RESOURCES AUTHORITY GROUP PERMIT ANNUAL COMPLIANCE REPORT - (for calendar year 2013) Photo Processing and/or Printing Operations Due Date: March 31, 2014 Return Completed Form To: Massachusetts Water Resources Authority 2 Griffin Way Chelsea, MA 02150 ATTN: TRAC - G1 Permit Please complete this form to update information you reported in your last Group Permit Compliance Report. Answer all the questions. If a question does not apply, please indicate N/A. The signed report and supporting documentation must be received by the MWRA by March 31, 2014. If MWRA does not receive your completed report by March 31, 2014, you may be subject to financial penalties and other enforcement action. If you have any questions about completing this form, please contact your Industrial Coordinator. (A list of Industrial Coordinator telephone numbers is enclosed) 1. General Information (please correct and complete this information directly on this form) MWRA Permit Number: Company Name: Facility Address: Facility Contact: Title: Telephone: Fax number: E-mail Address: Permit/Mailing Address: Permit Contact: Title: Telephone: Fax number: E-mail Address: Billing Address: Billing Contact: Title: Telephone: Fax number: E-mail Address: PAGE 1 Nature of Operations at Your Facility The following questions are designed to determine if your facility has the appropriate MWRA permit. Please answer all of the questions below. 2. What does your facility do? Printer: including lithography using presensitized plates, specifically from: 1) the offset lithographic plate making process, including direct to plate (DTP) and/or computer to plate (CTP) processes; 2) fountain solution mixture; 3) photo processing (as part of printer's operations); 4) cleaning operations; and 5) prepress operations, including proofing systems and image setting equipment. (Prepress houses and service bureaus are considered printers). Does your facility conduct direct to plate (DTP) or computer to plate (CTP) processes? Yes No Photo Processor: processing from color and black and white film, prints and slides, xrays, and negative microfilm. 2a. Does your facility conduct only digital photo processing on site? Yes No If yes, Did you stop discharging all wastewater from the facility to the sewer? Yes Did you stop discharging all spent fixer solution from the facility to the sewer? No. Yes No. Indicate the date you stopped discharging all wastewater and spent fixer solution to the sewer from the photo processing operation. Date: ____________________________ 3. Is your facility located in a residence? Yes No 4. Do you perform only hand tray processing? 5. On average, does your facility discharge 25,000 gallons or more per day of wastewater from photoprocessing or printing operations? Yes No 6. Indicate how your facility disposes of its fixer solution: Fixer solution is hauled from the facility. Fixer solution is treated and discharged to the sewer. Other (please describe) ________________________________________ Yes No Nature of Operations at Your Facility 7. For printing facilities that generate wastes from lithography using presensitized plates: (check the one, which applies) Fountain solution mixture is not used at the facility. Spent fountain solution mixture is hauled from the facility or evaporated and is not discharged to the sewer system. Spent fountain solution mixture is discharged from the facility to the sewer system at the following volume and frequency. (average gallons per month): _____________ NOTE: If you generate up to 55 gallons per month of spent fountain solution mixture, you may discharge that spent fountain solution to the sewer if you have an MWRA permit. If you generate more than 55 gallons per month of spent fountain solution mixture, you must request and receive advance written authorization from the MWRA to discharge any amount of spent fountain solution to the sewer. Make your request below by checking the “yes” box and completing the remainder of the requirement. Yes. My facility generates more than 55 gallons per month of spent fountain solution mixture and I request permission to discharge up to _________ gallons of spent fountain solution to the sewer system per month. (You must submit with your Compliance Report, monitoring results from an analytical laboratory showing the characteristics of your spent fountain solution). If you have received written authorization from the MWRA to discharge greater than 55 gallons per month of spent fountain solution, provide the date of the authorization here:_______________. You are not required to request authorization again unless the volume or characteristics of your discharge changes. To maintain MWRA authorization to discharge more than 55 gallons per month of sent fountain solution mixture to the sewer, you must have this discharge analyze each calendar year. The analytical results must be submitted annually with your Annual Compliance Report. For Spent Fountain Solution Mixture Sampling. The sampling and analysis shall be performed by a DEP certified independent laboratory that is fully certified for the pollutants being analyzed. Use the chain of custody form and sample location number provided with permit. The samples shall be analyzed as described in the permit. A copy of this form is attached to this Compliance Report for your use. Operations and Discharge Information The purpose of this section is to describe all discharges to the MWRA sewer system from your facility. (Check Yes or No for each discharge or activity listed below). 8. What does your facility discharge to MWRA Sewer? Types of Solutions Yes No Fixer Rinsewater Developer Activator Water from cleaning equipment Solvents Laboratory Waste Fountain Solution 8a. Does your facility discharge wastewater to the MWRA sewer from any of the following activities? (Please check Yes or No) Yes Types of Activities Processing Color film, prints or slides Processing negative microfilm Processing black and white film, prints or slides Processing x-rays Processing Motion Picture film Processing black and white slides or transparencies or positive microfilm using a reversal dichromate bleach processing solution Screen printing Flexographic or gravure/rotogravure printing process Plate developing using a petroleum-based additive process Engraving plate manufacturing The manufacture or distribution of photographic or printing chemicals. The recovery of materials from, of from the reprocessessing or recycling of, photo processing or printing wastes (except as part of your silver treatment of wastes generated from your own photo processing and printing operations. 9. How many film, paper, or slide processors are used at your facility? ___________ 10. On average, how many days per week does your facility discharge photo or printing wastewater? _________days/week 11. On average, how many hours per day do you discharge photo or printing wastewater? ____________hours/day 12. What was the average volume discharged from your photo processing and printing processes, including rinsewater, in gallons per day? ________gpd No 12a. How did you determine this flow? Water supply meter readings Manufacturers' processing specifications Wastewater flow meter readings Estimated (describe method)_____________ 13. Estimate the percentage of daily flow from your silver recovery unit(s):________% 14. Where is the wastewater from your photo processing and printing processes, including rinsewater, discharged? (check all that apply) Floor drain Sink 15. Standpipe Other_________________________________ For Calendar Year 2013, provide in the following table the average monthly volume of photo or printing chemicals and rinsewater used in processing per month: Chemistry (Solutions) Average Monthly Volumes (In Gallons) Check Here If Annual Sample Included This Solution Fixer Bleach-Fix Stabilizer (washless systems) Bleach Developer (photo and/or plate) Equipment Washdown Rinsewater (photo and/or plate) Conditioner Other (e.g., reversal, fountain solution, cleaner, etc.) TOTAL Hauled Wastes 16. If wastes were hauled from your facility during Calendar Year 2013, please provide the following information: Waste Type Estimated Quantity (include units) Name/Address Of Waste Hauler Fixer Developer Ink Silver Harvested from Silver Recovery Unit Other (describe) Hazardous Waste (describe) Provide your facility's Hazardous Waste Generator I.D. Number (if applicable):__________ Pretreatment Information 17. For Calendar Year 2013, indicate the silver recovery (pretreatment) used at your facility and the total treatment capacity of each unit (in volume, supplied from your manufacturer). (If None are used, indicate N/A in the Number of Units” column) Type of Unit Number of Units Treatment Capacity (gallons per day) Electrolytic Metallic Replacement (Steel Wool Canisters) Ion Exchange Evaporation/Distillation Self-contained automated chemical precipitation system (e.g., Kodak SR 2000) Other Chemical Precipitation EPAN Other: 18. If you use chemical precipitation silver recovery, list the manufacturer, brand name, and model of your system: If you use chemical precipitation silver recovery, is it in series with an electrolytic unit? yes No. If yes, describe the arrangement of your pretreatment equipment: If you use metallic replacement silver recovery, is it in series with an electrolytic unit? yes No 19. Did you install a new silver recovery system in 2013? If yes, date new system installed: ________________ yes No 20. Other Wastewater Pretreatment Systems used at your facility (other than silver recovery): (check all that apply) pH Neutralization by chemical addition (describe)________________ limestone chip tank Other (describe)_________________________________ Wastewater Sampling and Analysis Information Please enter the results of silver sample(s) taken during Calendar Year 2013. Sample Date / / / / / / Sample Location Number Silver Analysis Result Was the sample collected immediately after the silver recovery system? Yes No If yes, please read below carefully If: You took a sample only of the discharge from your silver recovery unit, AND The analytical result was > 2 mg/l Then: You must do a mathematical calculation to determine if your equipment is effectively removing silver to achieve compliance with the MWRA limit of 2 mg/l. The mathematical calculation is done in two steps: Step1: Determine the percentage that the silver recovery system is to the total discharge of fixer, rinsewater, developer, etc. Step 2: Multiply the result from Step 1 by the silver sample analytical result you received. Example: You took a sample only of your silver recovery system without rinsewater You discharge 4 gallons of rinsewater and developer for each 1 gallon you discharge from silver recovery. Silver sample analytical result received = 5.0 mg/l Step 1: 1 (silver recovery discharge in gallons per day ÷ 5 (total of rinsewater + developer + silver recovery discharge in gallons per day) = .20 Step 2: .20 (result from Step 1) x 5.0 mg/l (silver sample analytical result received) = 1.00 mg/l. Result is in compliance with the silver discharge limit of 2.0 mg/l. Please complete the following for your facility: Step 1: (silver recovery discharge in gallons per day) ÷ + silver recovery discharge in gallons per Step 2: (result from Step 1)X (total of rinsewater + developer d day)= (silver sample analytical result received) = mg/l. The following questions have been added from the Massachusetts Department of Environmental Protection’s (DEP’s) Compliance Certification for Photo Processors. Is your photo processing operation directly piped to the silver recovery system? [] yes []no If no, please answer the following: Are you in compliance with the basic requirements for storing untreated wastewater in appropriate tanks and containers as defined in DEP’s Workbook: []yes []no Please refer to DEP’s Photo Processor Environmental Certification Workbook. How many gallons of silver bearing wastewater did you treat through your silver recovery system? ____________gallons/year (2013) What Should You Submit With Your Compliance Report? 1) Silver Sample Result Please attach a paper copy of your silver sample result(s) to your completed Compliance Report. Your result(s) must include a completed sample chain of custody form (a copy of the chain of custody form is attached to your G1or C1 Permit). Important Reminder: Your lab must submit your silver sample result(s) electronically over the Internet at http://websmr.mwra.com. If your result(s) are not submitted electronically, MWRA will consider the report as not submitted. Missing reports are subject to enforcement action. 2) Copy of the Maintenance and Sample Log For your log to be considered complete it should include the following information: 3) Sampling dates and results of the annual silver sample If your silver sample result was greater than 2 mg/l, the log must include a description of the steps you took to return to compliance. For example, the log should indicate when you changed your equipment or took other steps to return the equipment to its effectiveness. The log should also contain analytical results of a silver sample taken to demonstrate that the steps you took to return to compliance were successful. Dates of installation and replacement of metallic replacement cartridges, silver harvesting dates, and cleaning and servicing dates. The amount of spent fountain solution mixture discharged each month. (This requirement applies to printing facilities) Sample Analyses and Reporting Certification Form (Attached to Compliance Report) All G1or C1 permit holders complete the attached form and return it to MWRA along with your Compliance Report. 4) A list of catalog numbers, brand names, and product descriptions of all photo chemicals used in your facility for the first time. 5) Copies of water bills. (Only if you discharge an average of at least 10,000 gallons per day) 6) Copy of pH Logs. (Only if you discharge from a DTP or CTP process). A copy of the pH Log Form is attached to your G1 Permit. Who May Sign This Compliance Report? Certification Form/Authorized Representative The permittee shall submit the Sample Analyses and Reporting Certification Form required by this permit. Each certification form shall be signed and dated by an Authorized Representative of the permittee. An Authorized Representative is a: (a) Responsible corporate officer, if the permittee is a corporation. For the purpose of this requirement, a responsible corporate officer means a president, secretary, treasurer, or vice president of the corporation in charge of a principal business function, or any other person who performs similar policy or decision-making functions for the corporation, or the manager of one or more manufacturing, production, or operating facilities, provided, the manager is authorized to make management decisions which govern the operation of the regulated facility including having the explicit or implicit duty of making major capital investment recommendations, and initiate and direct other comprehensive measures to assure long-term environmental compliance with environmental laws and regulations; can ensure that the necessary systems are established or actions taken to gather complete and accurate information for the permit requirements; and where authority to sign documents has been assigned or delegated to the manager in accordance with corporate procedures. (b) General partner or proprietor if the permittee is a partnership or sole proprietorship respectively. (c) Duly authorized representative of the individual designated in (a) or (b) of this section if: i) the authorization is made in writing by the individual described in (a) or (b); ii) the authorization specifies either an individual or a position having responsibility for the overall operation of the facility from which the industrial discharge originates, such as the position of plant manager, operator of a well, or well field superintendent, or a position of equivalent responsibility, or having overall responsibility for environmental matters for the company; iii) the written authorization is submitted to the MWRA If an authorization is no longer accurate because a different individual or position has responsibility for the overall operation of the facility, or overall responsibility for environmental matters for the permittee, a new authorization satisfying the requirements of this section must be submitted to the MWRA prior to or together with the next report required of the permittee. Certification I certify under penalty of law that this document and all attachments were prepared under my direction or supervision in accordance with a system designed to assure that qualified personnel properly gather and evaluate the information submitted. Based on my inquiry of the person or persons who manage the system, or those persons directly responsible for gathering the information, the information submitted is to the best of my knowledge and belief, true, accurate, and complete. I am aware that there are significant penalties for submitting false information, including the possibility of fine and imprisonment for knowing violations. Signature: ____________________________________ Print the name of the person whose signature is above: _________________________________ Title: _________________________________________ Date: _________________________________________ SAMPLE ANALYSES AND REPORTING CERTIFICATION FORM FOR SUBMISSION DIRECTLY FROM THE LABORATORY The permittee must have a current signed and dated copy of this form on file with the MWRA. Industry Name: Permit I hereby certify that I have engaged an independent laboratory (which is certified by the Massachusetts Department of Environmental Protection to perform wastewater analyses) to submit to the MWRA, via its Pretreatment Information Management System Web Self-Monitoring Report (Web SMR) available at http://websmr.mwra.com/, the reports of the analyses of sampling required by the MWRA. I certify under penalty of law that the information submitted through the MWRA’s web-based program, and accompanying chain of custody forms, provided to the MWRA by the laboratory, were prepared under my direction or supervision in accordance with a system designed to assure that qualified personnel gather and evaluate the information submitted. Based on my inquiry of the person or persons who manage the system, or those persons directly responsible for gathering the information, the information to be submitted by the laboratory will be, to the best of my knowledge and belief, true, accurate, and complete. I am aware that there are significant penalties for submitting false information, including the possibility of fine and imprisonment for knowing violations. I certify that I have instructed the laboratory to provide me with a copy of each report it submits to the MWRA on my behalf, no later than the day it submits the report to the MWRA. I understand that I am responsible to assure that such reports are timely submitted to me and to the MWRA. I understand that this certification applies to the laboratory I now use and to any laboratory, I may use in the future. _______________________________________ Signature of Authorized Representative ____________ Date ___________________________________________________ (Print name and title of Authorized Representative) (Print name and title of Authorized Representative) __________________________________________ ___________________ Signature of Authorized Representative Date __________________________________________________________ Please make copies of this blank form for use with your permit. Updated: 8/15/2007 GROUP PERMIT FOR PHOTO PROCESSING AND PRINTING OPERATIONS Request to Discharge Spent Fountain Solution Mixture Form For Offset Lithographic Printers Only If you generate more than 55 gallons per month of spent fountain solution mixture, you must request and receive advance written authorization from the MWRA to discharge any amount of spent fountain solution to the sewer. To request authorization, you must complete and submit this Form, have your fountain solution mixture analyzed, and submit the analytical results to the MWRA. Also, please use the Chain of Custody/Field Form provided in the back of the permit. A copy of this Form is attached to this Compliance Report for your use. FACILITY NAME: __________________________________ PERMIT NO: _____________________ FACILITY ADDRESS: _________________________________________________________________________ 1 What is the average volume (gallons) of spent fountain solution you discharge to the sewer per month? ______________________________ 2. How many days per month do you discharge the spent fountain solution? _______________________________ 3. Do you discharge any other industrial wastewater to the sewer? [ ] yes [ ] no If yes, specify the type of waste: _______________________________________________________________ (If your answer to question #3 above is no, skip questions #4, #5, and #6.) 4. What is the average volume of the other industrial wastewater you discharge to the sewer per month? _________ gallons per month. 5. How many days per month do you discharge the other industrial wastewater? __________________________ 6. List process(es) resulting in the other industrial wastewater discharge(s): __________________________________________________________________________________________ __________________________________________________________________________________________ 7. How is the spent fountain solution discharged to the sewer? [ ] Hard Pipe [ ] Sink [ ] Floor Drain [ ] Stand Pipe [ ] Other (specify) _________________________________ 8. Please have an independent DEP certified laboratory collect a grab sample of your spent fountain solution, representing the spent fountain solution you are discharging, and have the sample analyzed for the following, using EPA Methods approved in 40 C.F.R. Part 136: EPA Test Method 200.7: Antimony (total); Arsenic (total); Cadmium (total); Chromium (total); Copper (total); Lead (total); Nickel (total); Selenium (total); Silver (total); Zinc (total). EPA Test Method 245.1: Mercury (total). EPA Test Method 150.1: pH. EPA Test Method 625: Extractable Organics, and Flow. In addition, if you use an alcohol-based fountain solution, please have the sample analyzed for closed-cup flash point. 9. You must provide the results of the analysis for the spent fountain solution grab sample to the MWRA. Please make copies of this blank form for use with your permit. Updated: 8/15/2007 10. What colors of ink and their brand names were in contact with the analyzed spent fountain solution? 11. Certification: I certify under penalty of law that this document was prepared under my direction or supervision in accordance with a system designed to assure that qualified personnel properly gathered and evaluated the information submitted. Based on my inquiry of the person or persons who manage the system, or those persons directly responsible for gathering the information, the information submitted is to the best of my knowledge and belief, true, accurate, and complete. I am aware that there are significant penalties for submitting false information, including the possibility of fine and imprisonment for knowing violations. Name: __________________________ Signature: ________________________________ Title of Responsible Person: ___________________________Date: ___________________ 12. Return this form to the MWRA: Massachusetts Water Resources Authority Toxic Reduction and Control Chelsea Facility Two Griffin Way Chelsea, MA 02150-3334 Attention: G1 Permits Please make copies of this blank form for use with your permit. Updated: 8/15/2007 MWRA Industrial User Sampling Chain of Custody/Field Form SAMPLE TYPE: GRAB For Spent Fountain Solution Mixture Sampling Only Industry Name: ____________________________________________________ MWRA Permit Number: ________________ Facility Address: _______________________________________________________________________________________ Sampling Location Number: Description: 7001 Spent fountain solution discharge stream . Briefly describe the process(es) discharging during sample time: DISCHARGE TYPE ( ) BATCH or FLOW on sampling day: ( ) CONTINUOUS GPD The FLOW was: ( ) MEASURED ( ) ESTIMATED Method used to measure/estimate flow: FIELD pH: ______ s.u.(pH must be measured on-site) FIELD TEMPERATURE:________________ FIELD COLOR:_______________ FIELD ODOR: ____________________ SAMPLE Date (mm/dd/yy): __ __/__ __/__ __ SAMPLE Time (military, hh:mm): __ __/__ __/__ __ GRAB PARAMETERS Sampled: ( )ABN (Extractables Organics) Type of Preservative Added Preserved to What pH? When Was Preservative Added? * Comments: (Y=Yes, N=No) Cl2 Detected? Amt Na2S203 Added: ( ) Metals** **List Metals: * Preserved=P Field Preserved=F Preserved When Sample Delivered to Lab=L SAMPLED BY (print name): (sign name): Sampling Company Name: RELINQUISHED BY: COMPANY NAME: DATE: TIME: RECEIVED BY: COMPANY NAME: DATE: TIME: RELINQUISHED BY: OMPANY NAME: TO BE COMPLETED BY LABORATORY: NAME AND TITLE OF THE PERSON RECEIVING THE SAMPLE: NAME: _______________________TITLE:_________________ SIGANTURE OF PERSON RECEIVING SAMPLE: ________________________________________________________________ DATE AND TIME RECEIVED BY LABORATORY: DATE: __________________________ TIME: __________________________ DATE ANALYSIS PERFORMED: ______________________________________________________________________________ LABORATORY NAME: __________________________________________ LABORATORY DEP ID #: ______________________ Please make copies of this blank form for use with your permit. Updated: 8/15/2007 Please make copies of this blank form for use with your permit. Updated: 8/15/2007