Abstract Tert-butyl alcohol (TBA), as a high value-added fine

advertisement

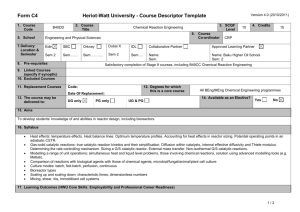

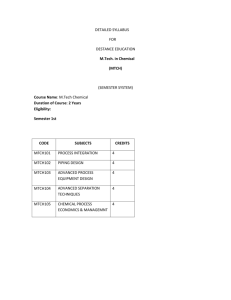

Catalytic Distillation for the Synthesis of tert-Butyl Alcohol with Structured Catalytic Packing Yang Yang, Zhigang Lei*, Qunsheng Li, Biaohua Chen State Key Laboratory of Chemical Resource Engineering, Beijing University of Chemical Technology, Box 35, Beijing, 100029, China Abstract Tert-butyl alcohol (TBA), as a high value-added fine chemical, can also serve as an excellent alternative fuel and has a virtually limitless potential for growth because it is synthesized by hydratation of cheap isobutene from the C4 mixture. The catalytic distillation for the synthesis of TBA has many advantages over conventional sequential processes, for instance, a fixed-bed reactor followed by a distillation column in which the bottom of reaction mixture is recycled to the reactor inlet. The equilibrium-controlled conversion limitation (up to 70% isobutene conversion at most in fixed-bed reactor) is eliminated by continuous removal of TBA from the reaction zone in the catalytic distillation column. Undoubtedly, how to design the hardware containing catalyst is crucial for catalytic distillation. In this work a new-type structured catalytic packing was constructed, which consists of corrugated wire gauze sheets and separate porous catalytic bags containing an acidic ion-exchange resin (supplied by Qilu Petrochemical Corporation) assembled in alternative sequence. The reaction kinetics of liquid catalytic hydratation of isobutene over ion-exchange resin embedded with and without catalytic bags has been determined in a batch stirred reactor, respectively. The experimental data are described well by a Langmuir-Hinshelwood type kinetic expression in the temperature range 50 - 75℃, and for catalyst without catalytic bags are given as follows: 10576 a TBA 6604 .4 a IB rTBA 4.667 10 6 exp 9.739 10 10 exp( ) 2 T T a H 2O a H 2O where ai is the activity of components in liquid phase. The effective factor η of catalyst bag in which catalyst was embedded was expressed as exp( 801 2.217 ) . The kinetic equation and effective factor T were incorporated into the mathematical model of catalytic distillation process with the combination of fixed-bed reactor and catalytic distillation column. It was found that high conversion of isobutene can be achieved and energy consumption per amount of TBA is reduced. Keywords: Catalytic distillation, TBA, Structured packing, effective factor, Mathematical model Correspondence: Prof. Dr. Zhigang Lei (leizhg@mail.buct.edu.cn), State Key Laboratory of Chemical Resource Engineering, Beijing University of Chemical Technology, Box 35, Beijing, 100029, China.