Procedure - Environmental Protection Department

advertisement

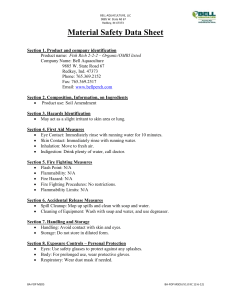

SHENZHEN ENVIRONMENTAL ELECTRICAL APPLIANCE COMPANY Environmental Instruction Handling and Storage of Chemicals (EI-09) Revision No. : 1 Date : 01-01-2006 Zhao Wei Prepared by : (EMR) Yu Fung Approved by : (General Manger) Revision History Revision Date 01-01-2006 Description First issue Sections Affected Revised By -- -- Approved By Yu Fung Handling and Storage of Chemicals SEEA 1.0 Instruction Number : EI-09 Revision Number : 1 Date : 01-01-2006 Purpose This instruction provides guidelines on the best practices to be adopted for preventing pollution through purchasing, transporting, consuming and disposing management to ensure the chemical materials of are being controlled properly and comply with legal and other requirements. 2.0 Scope This instruction is applicable to the management of the chemical materials (e.g. acids, alkaline, adhesives, paint and organic solvent, etc.) used by the factory. The issues covered in this technical instruction are categorised into: Information and labelling: Containers; Storage and Transportation; Handling and Spill Prevention; and Inspection and Maintenance Procedures for management of chemical waste are given in the EI-04 Waste Management. 3.0 Procedure 3.1 MSDS —Materials Safety Data Sheet 3.1.1 Production Manager should communicate with related department representatives to compile MSDS for the factory’s chemical materials according to the legal and other requirements and factory’s chemical consumption conditions. 3.1.2 MSDS should include the following: Name of chemical Chemical properties and atomic group Hazard Classification Reactivity Explosive properties Poisonous properties Caution remarks for transport and handling Emergency response methods Caution remarks for waste disposal management 3.1.3 All facilities that store and utilize chemical should have relevant MSDS for those chemicals available so that proper safety precautions can be taken according to the MSDS. 3.1.4 When a new chemical is introduced, the purchasing department is responsible for requesting the corresponding MSDS from the supplier, submit such MSDS to the Environmental Management Committee and provide a copy of the MSDS to the production department to determine where the chemical should be stored and which department would be using the chemical. The MSDS would then be added into the Page 2 SEEA Handling and Storage of Chemicals Instruction Number : EI-09 Revision Number : 1 Date : 01-01-2006 in-house MSDS list. 3.1.5 Production Manager should review in-house MSDS at least once every half a year to prevent omission of MSDS for new chemicals. 3.2 Purchasing Control 3.2.1 Purchasing department should request and maintain chemical production certificates for the chemicals from the supplier. 3.2.2 When a new chemical is used, Production Manager would conduct an open meeting and fill out the Environmental Assessment Meeting Minutes. The assessment would include: Chemical properties; Explosive properties; Health hazards and Disposing caution. The assessment should be reported to the EMR. 3.2.3 Each department could purchase chemicals after gaining permission from the EMR. 3.2.4 Environmental control from chemical suppliers should be followed in accordance to EP-02 Review of Legal and Other Environmental Requirements. 3.3 Chemical Material Label 3.3.1 All chemical containers should possess related labels and hazardous chemicals should contain the relevant hazard labels. 3.4 Chemical Storage Management 3.4.1 Production department should establish clear directives for the storage environment and management according to the legal and other requirements as well as the inhouse MSDS guidelines. Each chemical storage facility should establish and implement relevant Environmental Management Checklist. 3.4.2 Do not stack chemical containers directly on top of each other. 3.4.3 Each month the production department should prepare a Chemical Monthly Report based on the present chemical storage and usage status and submit a copy of this report to the Environmental Management Committee. 3.5 On-site Chemical Use Management 3.5.1 On-site chemical should be stored and used according to Production of On-site Chemical Storage and Usage Management Regulations. 3.5.2 Chemical use department should maintain a conserving spirit by stipulating strategies to effectively use chemical resources without interfering with the quality of production. 3.5.3 Production Manager should conduct routine checks at the premise of the storage facility by adopting “First in, First use” management principle while monitoring the chemical storage capacity to prevent chemicals expiring to occur. 3.6 Expired Chemical Management 3.6.1 Expired chemicals should be returned to the Production Department with original packaging so that the Purchasing Department could then return it to the supplier. Page 3 Handling and Storage of Chemicals SEEA 3.7 Instruction Number : EI-09 Revision Number : 1 Date : 01-01-2006 Emergency Response Management 3.7.1 Where nonconformity are identified corrective action measures are defined and implemented in accordance with EP-05 Environmental Emergency Preparedness and Response 4.0 Monitoring and Checking 4.1 Environmental Management Committee is responsible for monitoring chemicals handled by all departments. 4.2 A Chemical Monthly Report will be produced at the beginning of each month. Each procedure concerning the chemical handling situation should be analyzed in accordance with the Chemical Monthly Report and should be retained until the end of the year where these records would be submitted to the Environmental Management Representative. 4.3 When preparing the objectives and targets at the year-end review, determine the overall amount of chemical consumption reduction using previous performance levels as a guide and incorporate these reduction levels into the respective objectives and targets so that resource conservation could be achieved. 5.0 Records Record Location / Retention Responsibility Minimum Retention Time supplier’s Purchasing / Production Department 3 years Environmental Assessment Meeting Minutes (Refer to relevant Meeting Records) Production Department 3 years Environmental Management Checklist (Refer to relevant checklist records) Production Department 3 years Chemical Monthly (Refer to each chemical report) Report month’s Production Department 3 years Common Chemical Classification and Labels (Refer to relevant legal and related documents as well as in-house MSDS requirements) Production Department 3 years Record Description MSDS (Refer information) 6.0 to Appendix Nil Page 4