PIMS 3515 Brazil SUCRE-FSP PRODOC- Part 1

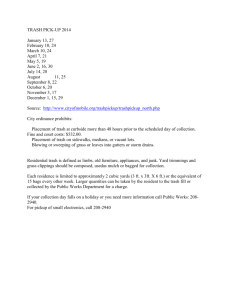

advertisement