Intensive Animal Housing with Liquid Waste Management

advertisement

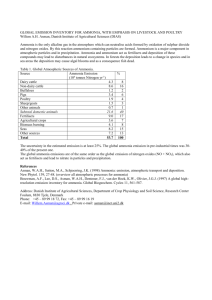

Intensive Animal Housing with Liquid Waste Management Summary Dwaine Bundy, PhD., PE Ag and Biosystems Engineering Dept Iowa State University Ammonia emission from swine building utilizing liquid managed manure storage systems is primarily emitted from the excretion of the feces and urine. The ammonia emission from the building is less dependent upon the manure management system than the overall management of the facility. Removal of the liquid manure from the building has less effect of the total ammonia emission than the management of the facility. Studies show deep pits, shallow pits with frequent removal of manure, and under floor separation of feces and urine will not significantly alter ammonia emission from the building. The flooring system is a significant factor in the amount of ammonia emission from the building. Manure on the feeding floor results in higher ammonia emission. It has been shown that partially slatted floors normally will have a higher ammonia emission level than totally slatted floors. Overall good hygiene such as keeping the slats dry and reducing water wastage that keeps the floors wet. Proper ventilation will also reduce manure on the floors. Feed additives have been found to reduce ammonia by reducing pH; however, if reduced significantly may result in higher hydrogen sulfide. Reducing the crude protein level of the pig diet can also reduce ammonia concentrations. Manure additives can help reduce ammonia emissions. Pit additives have been found to reduce ammonia off the liquid manure surface as much as 40 %; however since most of the ammonia comes from the feeding floor the overall effectiveness is minimized. Bio-filters have been effective in removing ammonia from the exhaust air of mechanically ventilated swine buildings. Even though it has been shown to be effective, the relatively high cost and maintenance of the system has limited its adoption.