Fig… CN Distribution at 7 m/s - Georgia Institute of Technology

advertisement

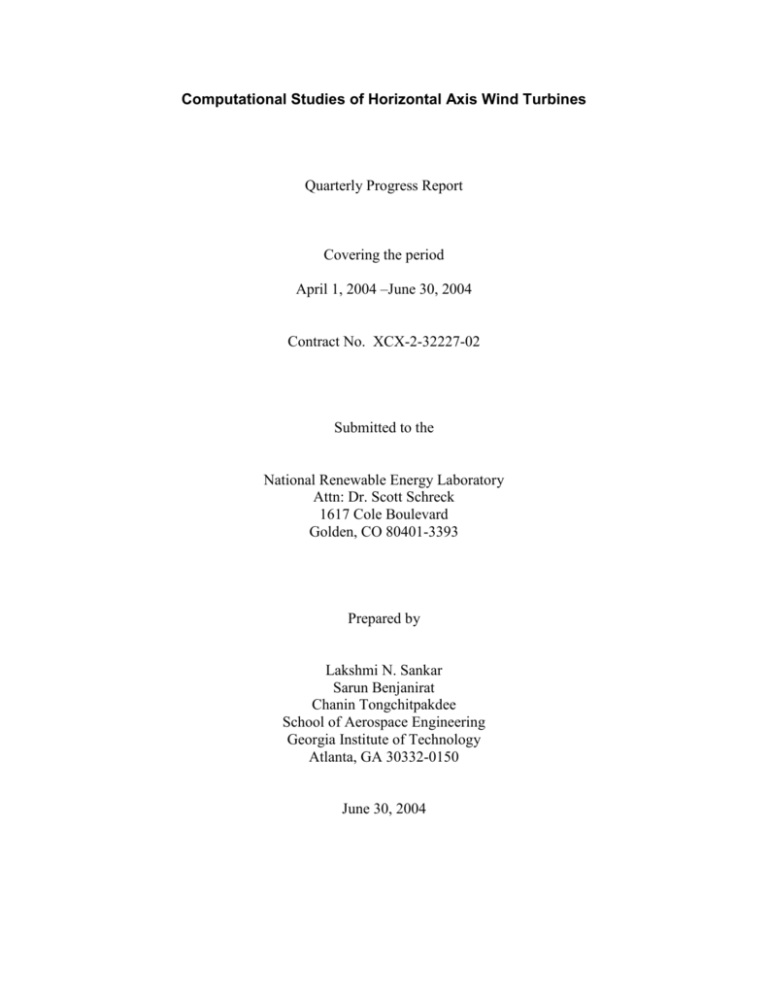

Computational Studies of Horizontal Axis Wind Turbines Quarterly Progress Report Covering the period April 1, 2004 –June 30, 2004 Contract No. XCX-2-32227-02 Submitted to the National Renewable Energy Laboratory Attn: Dr. Scott Schreck 1617 Cole Boulevard Golden, CO 80401-3393 Prepared by Lakshmi N. Sankar Sarun Benjanirat Chanin Tongchitpakdee School of Aerospace Engineering Georgia Institute of Technology Atlanta, GA 30332-0150 June 30, 2004 I. INTRODUCTION A computational research program is underway at Georgia Institute of Technology (Georgia Tech), Atlanta, Georgia, in the area of horizontal axis wind turbine (HAWT) aerodynamics. The research focuses on (a) improving and calibrating a hybrid solution methodology previously developed under NREL support for non-axial and non-uniform inflow, (b) improve the capabilities of a companion Navier-Stokes methodology, and apply it to a rotor-tower configuration for a range of downwind and yaw conditions, and (c) explore passive and active control concepts for extending the useful operating range of horizontal axis wind turbines. The mathematical and numerical formulation used in this study divides the flow field around a HAWT into three distinct entities: a thin viscous region surrounding the individual blades, a potential flow region that transfer the disturbances generated by the rotor to the far field, and a helical wake structure (vorticity) that includes the tip vortices shed by the rotor blades. The computational effort focuses on the extension of a three-dimensional (3-D) hybrid Navier-Stokes/Potential Flow solver that has been developed at Georgia Tech for helicopter rotor, propeller and HAWTs. In this approach, 3-D unsteady, compressible Navier-Stokes equations are solved in the thin viscous region on a body-fitted grid surrounding the rotor blade. Away from the blades in the potential flow region, the 3-D unsteady compressible potential flow equations shall be solved. The vorticity shed by the blades as a result of dynamic stall and spanwise and azimuthal variations of circulation are captured by vortex filaments that are freely convected by the local flow. Since the costly Navier-Stokes calculations are done only in regions close to the wind turbine blades, and because much of the vorticity is tracked using Lagrangean techniques, the method is an order of magnitude more efficient than the full blown Navier-Stokes methods. SUMMARY OF ACTIVITIES DURING THE RESEARCH PERIOD It may be recalled that the previous progress report (Jan 1, 2004 – March 31, 2004) described the development of a C-O grid topology based analysis, and preliminary results for axial flow conditions. In this report, we are summarizing additional work that has been done for yawed flow conditions. These calculations were done on a C-O grid. There were 140 points in the C- or wraparound direction, 95 points in radial direction including 70 stations on the rotor blade, and 60 points in the normal direction. The first point of the wall was placed at 0.0005 chords. The baseline Baldwin-Lomax model was used in this study. A prescribed wake model was used to account for the inflow from the vortices that were not captured by the computations. Because many of the calculations involved extensive flow separation, Navier-Stokes equations were solved over the entire C-O grid, and no potential flow zone was used. These calculations were done in a time accurate manner. The computed loads were averaged over the last revolution. Figure 1 shows typical results for the instantaneous toque values over an entire rotor revolution, and comparison with measurements. On Figures 2 and 3 we show the radial variation of normal and chordwise pressure forces, at several wind speeds and yaw angles. The results were in reasonable agreement with experiments only at low wind speeds (~ 7 m/sec to 10 m/sec) and low yaw angles (below 30 degrees). At higher wind speeds and/or high yaw angles, where extensive flow separation was present, considerable discrepancies were found with this baseline grid, and baseline turbulence model. Sarun Benjanirat, a Ph D student working on this project is studying the effects of a higher order turbulence model (k-omega) on these simulations (for zero yaw conditions) while Chanin Tongchitpakdee, another student working on this project under school support is studying the effects of grid spacing on these simulations. Figure 4 shows the chordwise distribution of pressures for several wind and yaw conditions. At very low wind speeds, particularly near the inboard stations, the compressible flow formulation produced very high local pressure coefficients (higher than the expected value around 1). Because of the low prevalent dynamic pressures, this discrepancy did not affect the integrated loads (e.g. torque, bending moments, etc). A low Mach number (incompressible) formulation would help improve the predictions at these stations, but is not planned at this time. Figures 5 and 6 show the torque generated by the rotor, and the bending moments as a function of yaw angle at several wind speeds. As before, at lower wind speeds (7 m/sec and 10 m/sec) these values are in reasonable agreement with measurements. The agreement is good for these “integrated” loads even at high yaw angles even though the sectional loads and flow details differ somewhat from measurements, demonstrating that the algorithm preserves the global conservation of mass, momentum, and energy. An abstract based on these results has been submitted to the 2005 ASME Wind Energy Symposium, and has been accepted for publication. The next progress report will include a draft version of our paper, and results for the k-omega simulations. 2000 Torque variation (10 m/s, 100 yaw) NREL Code 1800 1600 Torque (Nm) 1400 1200 1000 800 600 400 200 0 0 90 180 270 360 Azimuth (deg) Figure 1. The variation of the torque as a function of time (azimuth) for 10 m/s with 100 yaw 1.4 1.2 CN Distribution (7 m/s, 10o yaw) CN Distribution (7 m/s, 30o yaw) NREL Code 1.2 NREL Code 1 1 0.8 CN CN 0.8 0.6 0.6 0.4 0.4 0.2 0.2 0 0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 0 0.1 0.2 0.3 0.4 r/R 1 0.5 0.6 0.7 0.8 0.9 1 r/R 0.6 CN Distribution (7 m/s, 45o yaw) CN Distribution (7 m/s, 60o yaw) NREL Code 0.9 NREL Code 0.5 0.8 0.7 0.4 CN CN 0.6 0.5 0.3 0.4 0.2 0.3 0.2 0.1 0.1 0 0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 0 0.1 0.2 0.3 0.4 r/R 0.5 r/R Figure 2a. CN Distribution at 7 m/s under several yaw conditions 0.6 0.7 0.8 0.9 1 2 1.8 CN Distribution (10 m/s, 10o yaw) CN Distribution (10 m/s, 30o yaw) NREL Code 1.8 NREL Code 1.6 1.6 1.4 1.4 1.2 1.2 CN CN 1 1 0.8 0.8 0.6 0.6 0.4 0.4 0.2 0.2 0 0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 0 1 0.1 0.2 0.3 0.4 r/R 1.4 0.5 0.6 0.7 0.8 0.9 1 r/R 1 CN Distribution (10 m/s, 45o yaw) CN Distribution (10 m/s, 60o yaw) NREL Code NREL Code 0.9 1.2 0.8 1 0.7 0.6 CN CN 0.8 0.5 0.6 0.4 0.3 0.4 0.2 0.2 0.1 0 0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 0 0.1 0.2 0.3 0.4 r/R 0.5 r/R Figure 2b. CN Distribution at 10 m/s under several yaw conditions 0.6 0.7 0.8 0.9 1 2.5 2.5 CN Distribution (13 m/s, 10o yaw) CN Distribution (13 m/s, 30o yaw) NREL Code 2 1.5 1.5 CN CN 2 NREL Code 1 1 0.5 0.5 0 0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 0 0.1 0.2 0.3 0.4 r/R Figure 2c. CN Distribution at 13 m/s under 100 and 300 yaw conditions 0.5 r/R 0.6 0.7 0.8 0.9 1 3 2.5 CN Distribution (15 m/s, 10o yaw) CN Distribution (15 m/s, 30o yaw) NREL Code NREL Code 2.5 2 2 CN CN 1.5 1.5 1 1 0.5 0.5 0 0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 0 0.1 0.2 0.3 0.4 0.5 r/R 2 0.6 0.7 0.8 0.9 1 r/R 1.8 CN Distribution (15 m/s, 45o yaw) CN Distribution (15 m/s, 60o yaw) NREL Code 1.8 NREL Code 1.6 1.6 1.4 1.4 1.2 1.2 CN CN 1 1 0.8 0.8 0.6 0.6 0.4 0.4 0.2 0.2 0 0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 0 0.1 0.2 0.3 0.4 r/R 0.5 r/R Figure 2d. CN Distribution at 15 m/s under several yaw conditions 0.6 0.7 0.8 0.9 1 0.14 0.12 CT Distribution (7 m/s, 10o yaw) CT Distribution (7 m/s, 30o yaw) NREL Code NREL Code 0.12 0.1 0.1 0.08 CT CT 0.08 0.06 0.06 0.04 0.04 0.02 0.02 0 0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 0 0.1 0.2 0.3 0.4 r/R 0.5 0.6 0.7 0.8 0.9 1 r/R 0.08 0.05 CT Distribution (7 m/s, 45o yaw) CT Distribution (7 m/s, 60o yaw) NREL Code NREL Code 0.07 0.04 0.06 0.03 0.04 CT CT 0.05 0.02 0.03 0.01 0.02 0 0.01 0 0.1 0.2 0.3 0.4 0.5 0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 -0.01 r/R r/R Figure 3a. CT Distribution at 7 m/s under several yaw conditions 0.6 0.7 0.8 0.9 1 0.3 0.25 CT Distribution (10 m/s, 10o yaw) CT Distribution (10 m/s, 30o yaw) NREL Code NREL Code 0.25 0.2 0.2 CT CT 0.15 0.15 0.1 0.1 0.05 0.05 0 0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 0 1 0.1 0.2 0.3 0.4 0.5 r/R 0.16 0.6 0.7 0.8 0.9 1 r/R 0.12 CT Distribution (10 m/s, 45o yaw) CT Distribution (10 m/s, 60o yaw) NREL Code NREL Code 0.14 0.1 0.12 0.08 CT CT 0.1 0.08 0.06 0.06 0.04 0.04 0.02 0.02 0 0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 0 0.1 0.2 0.3 0.4 r/R 0.5 r/R Figure 3b. CT Distribution at 10 m/s under several yaw conditions 0.6 0.7 0.8 0.9 1 0.5 0.5 CT Distribution (13 m/s, 10o yaw) CT Distribution (13 m/s, 30o yaw) NREL Code NREL Code 0.4 0.4 0.3 CT CT 0.3 0.2 0.2 0.1 0.1 0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 0 0 -0.1 0.1 0.2 0.3 0.4 r/R Figure 3c. CT Distribution at 13 m/s under 100 and 300 yaw conditions 0.5 r/R 0.6 0.7 0.8 0.9 1 0.5 0.5 CT Distribution (15 m/s, 10o yaw) CT Distribution (15 m/s, 30o yaw) NREL Code NREL Code 0.4 0.4 0.3 CT CT 0.3 0.2 0.2 0.1 0.1 0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 0 -0.1 0 0.1 0.2 0.3 0.4 r/R 0.5 0.6 0.7 0.8 0.9 1 r/R 0.3 0.2 CT Distribution (15 m/s, 45o yaw) CT Distribution (15 m/s, 60o yaw) NREL Code NREL Code 0.25 0.15 CT CT 0.2 0.15 0.1 0.1 0.05 0.05 0 0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 0 0.1 0.2 0.3 0.4 r/R 0.5 r/R Figure 3d CT Distribution at 15 m/s under several yaw conditions 0.6 0.7 0.8 0.9 1 -4 -4 Cp Distribution at r/R=0.30 Cp Distribution at r/R=0.47 NREL Code NREL Code -3 -3 -2 -2 -1 Cp Cp -1 0 0 1 1 2 2 3 3 4 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 0 1 0.1 0.2 0.3 0.4 x/C 0.5 0.6 0.7 0.8 0.9 1 x/C -4 -2.5 Cp Distribution at r/R=0.63 Cp Distribution at r/R=0.80 NREL Code NREL Code -2 -3 -1.5 -2 -1 Cp Cp -0.5 -1 0 0 0.5 1 1 1.5 2 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 x/C 0 0.1 0.2 0.3 0.4 0.5 0.6 x/C -1.5 Cp Distribution at r/R=0.95 NREL Code -1 Cp -0.5 0 0.5 1 1.5 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 x/C Figure4a. Cp Distribution at 7 m/s with 100 yaw angle on several span wise stations 0.7 0.8 0.9 1 -2.5 -3 Cp Distribution at r/R=0.30 Cp Distribution at r/R=0.47 NREL Code -2 NREL Code -2.5 -2 -1 -1.5 -0.5 -1 0 -0.5 Cp Cp -1.5 0.5 0 1 0.5 1.5 1 2 1.5 2.5 2 3 2.5 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 0 0.1 0.2 0.3 0.4 x/C 0.5 0.6 0.7 0.8 0.9 1 x/C -2.5 -2 Cp Distribution at r/R=0.63 Cp Distribution at r/R=0.80 NREL Code -2 NREL Code -1.5 -1.5 -1 -1 -0.5 Cp Cp -0.5 0 0 0.5 0.5 1 1 1.5 1.5 2 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 x/C 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 x/C -1.5 Cp Distribution at r/R=0.95 NREL Code -1 Cp -0.5 0 0.5 1 1.5 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 x/C Figure 4b. Cp Distribution at 7 m/s with 300 yaw angle on several span wise stations 0.8 0.9 1 -1.5 -1.5 Cp Distribution at r/R=0.30 Cp Distribution at r/R=0.47 NREL Code NREL Code -1 -1 -0.5 -0.5 0 Cp Cp 0 0.5 0.5 1 1 1.5 1.5 2 2.5 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 0 0.1 0.2 0.3 0.4 x/C 0.5 0.6 0.7 0.8 0.9 1 x/C -1.5 -1.5 Cp Distribution at r/R=0.63 Cp Distribution at r/R=0.80 NREL Code -1 -0.5 -0.5 0 0 Cp Cp -1 NREL Code 0.5 0.5 1 1 1.5 1.5 2 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 x/C 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 x/C -1.5 Cp Distribution at r/R=0.95 NREL Code -1 -0.5 Cp 0 0.5 1 1.5 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 x/C Figure 4c. Cp Distribution at 7 m/s with 450 yaw angle on several span wise stations 0.8 0.9 1 -1.5 -1.5 Cp Distribution at r/R=0.30 Cp Distribution at r/R=0.47 NREL Code -1 -0.5 -0.5 0 0 NREL Code Cp Cp -1 0.5 0.5 1 1 1.5 1.5 2 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 0 1 0.1 0.2 0.3 0.4 x/C 0.5 0.6 0.7 0.8 0.9 1 x/C -1.5 -1.5 Cp Distribution at r/R=0.63 Cp Distribution at r/R=0.80 NREL Code NREL Code -0.5 -0.5 0 0 Cp -1 Cp -1 0.5 0.5 1 1 1.5 1.5 2 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 x/C 0 0.1 0.2 0.3 0.4 0.5 0.6 x/C -1.5 Cp Distribution at r/R=0.95 NREL Code -1 -0.5 Cp 0 0.5 1 1.5 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 x/C Figure 4d. Cp Distribution at 7 m/s with 600 yaw angle on several span wise stations 0.7 0.8 0.9 1 -7 -7 Cp Distribution at r/R=0.30 Cp Distribution at r/R=0.47 NREL Code -6 NREL Code -6 -5 -5 -4 -4 -3 Cp Cp -3 -2 -2 -1 -1 0 0 1 1 2 3 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 0 0.1 0.2 0.3 0.4 x/C 0.5 0.6 0.7 0.8 0.9 1 x/C -7 -7 Cp Distribution at r/R=0.63 Cp Distribution at r/R=0.80 NREL Code -6 NREL Code -6 -4 -4 -3 -3 Cp -5 Cp -5 -2 -2 -1 -1 0 0 1 1 2 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 r/R 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 x/C -7 Cp Distribution at r/R=0.95 NREL Code -6 -5 -4 Cp -3 -2 -1 0 1 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 x/C Figure 4e. Cp Distribution at 10 m/s with 100 yaw angle on several span wise stations 0.8 0.9 1 -6 -6 Cp Distribution at r/R=0.30 Cp Distribution at r/R=0.47 NREL Code -5 NREL Code -5 -4 -3 -3 -2 -2 Cp Cp -4 -1 -1 0 0 1 1 2 2 3 3 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 0 0.1 0.2 0.3 0.4 x/C 0.5 0.6 0.7 0.8 0.9 1 x/C -6 -6 Cp Distribution at r/R=0.63 Cp Distribution at r/R=0.80 NREL Code -5 NREL Code -5 -4 -3 -3 -2 -2 Cp Cp -4 -1 -1 0 0 1 1 2 2 3 3 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 x/C x/C -6 Cp Distribution at r/R=0.95 NREL Code -5 -4 -3 Cp -2 -1 0 1 2 3 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 x/C Figure 4f. Cp Distribution at 10 m/s with 300 yaw angle on several span wise stations 0.8 0.9 1 -4 -4 Cp Distribution at r/R=0.30 Cp Distribution at r/R=0.47 NREL Code NREL Code -3 -2 -2 -1 -1 Cp Cp -3 0 0 1 1 2 2 3 3 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 0 0.1 0.2 0.3 0.4 x/C 0.5 0.6 0.7 0.8 0.9 1 x/C -4 -4 Cp Distribution at r/R=0.63 Cp Distribution at r/R=0.80 NREL Code NREL Code -3 -2 -2 -1 -1 Cp Cp -3 0 0 1 1 2 2 3 3 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 x/C x/C -4 Cp Distribution at r/R=0.95 NREL Code -3 -2 Cp -1 0 1 2 3 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 x/C Figure 4g. Cp Distribution at 10 m/s with 450 yaw angle on several span wise stations 0.8 0.9 1 -2 -2 Cp Distribution at r/R=0.30 Cp Distribution at r/R=0.47 NREL Code NREL Code -1.5 -1 -1 -0.5 -0.5 Cp Cp -1.5 0 0 0.5 0.5 1 1 1.5 1.5 2 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 0 0.1 0.2 0.3 0.4 x/C -2 0.6 0.7 0.9 1 Cp Distribution at r/R=0.80 NREL Code -1.5 NREL Code -1.5 -1 -0.5 -0.5 Cp -1 0 0 0.5 0.5 1 1 1.5 1.5 2 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 x/C 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 x/C -2 Cp Distribution at r/R=0.95 NREL Code -1.5 -1 -0.5 Cp 0.8 -2 Cp Distribution at r/R=0.63 Cp 0.5 x/C 0 0.5 1 1.5 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 x/C Figure 4h. Cp Distribution at 10 m/s with 600 yaw angle on several span wise stations 0.8 0.9 1 -12 -12 Cp Distribution at r/R=0.30 Cp Distribution at r/R=0.47 NREL Code NREL Code -10 -8 -8 -6 -6 Cp Cp -10 -4 -4 -2 -2 0 0 2 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 0 1 0.1 0.2 0.3 0.4 x/C 0.5 0.6 0.7 0.8 0.9 1 x/C -12 -12 Cp Distribution at r/R=0.63 Cp Distribution at r/R=0.80 NREL Code NREL Code -10 -8 -8 -6 -6 Cp Cp -10 -4 -4 -2 -2 0 0 2 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 x/C 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 x/C -12 Cp Distribution at r/R=0.95 NREL Code -10 -8 Cp -6 -4 -2 0 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 x/C Figure 4i. Cp Distribution at 13 m/s with 100 yaw angle on several span wise stations 0.8 0.9 1 -10 -10 Cp Distribution at r/R=0.30 Cp Distribution at r/R=0.47 NREL Code -8 -8 -6 -6 Cp Cp NREL Code -4 -4 -2 -2 0 0 2 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 0 0.1 0.2 0.3 0.4 x/C 0.5 0.6 0.7 0.8 0.9 -10 -10 Cp Distribution at r/R=0.63 Cp Distribution at r/R=0.80 NREL Code -8 -8 -6 -6 Cp Cp NREL Code -4 -4 -2 -2 0 0 2 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 x/C 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 x/C -10 Cp Distribution at r/R=0.95 NREL Code -8 -6 Cp 1 x/C -4 -2 0 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 x/C Figure 4j. Cp Distribution at 13 m/s with 300 yaw angle on several span wise stations 0.8 0.9 1 -14 -10 Cp Distribution at r/R=0.30 Cp Distribution at r/R=0.47 NREL Code NREL Code -12 -8 -10 -6 Cp Cp -8 -6 -4 -4 -2 -2 0 0 2 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 0 0.1 0.2 0.3 0.4 x/C 0.5 0.6 0.7 0.8 0.9 -10 -10 Cp Distribution at r/R=0.80 Cp Distribution at r/R=0.63 NREL Code -8 -8 -6 -6 Cp Cp NREL Code -4 -4 -2 -2 0 0 2 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 x/C 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 x/C -10 Cp Distribution at r/R=0.95 NREL Code -8 -6 Cp 1 x/C -4 -2 0 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 x/C Figure 4k. Cp Distribution at 15 m/s with 100 yaw angle on several span wise stations 0.8 0.9 1 -10 -10 Cp Distribution at r/R=0.30 Cp Distribution at r/R=0.47 NREL Code -8 -8 -6 -6 Cp Cp NREL Code -4 -4 -2 -2 0 0 2 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 0 0.1 0.2 0.3 0.4 x/C 0.5 0.6 0.7 0.8 0.9 -10 -10 Cp Distribution at r/R=0.63 Cp Distribution at r/R=0.80 NREL Code -8 -8 -6 -6 Cp Cp NREL Code -4 -4 -2 -2 0 0 2 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 x/C 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 x/C -10 Cp Distribution at r/R=0.95 NREL Code -8 -6 Cp 1 x/C -4 -2 0 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 x/C Figure 4l. Cp Distribution at 15 m/s with 300 yaw angle on several span wise stations 0.8 0.9 1 -7 -7 Cp Distribution at r/R=0.30 Cp Distribution at r/R=0.47 NREL Code -6 NREL Code -6 -5 -4 -4 -3 -3 Cp Cp -5 -2 -2 -1 -1 0 0 1 1 2 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 0 0.1 0.2 0.3 0.4 x/C 0.5 0.6 0.7 0.8 0.9 1 x/C -7 -7 Cp Distribution at r/R=0.63 Cp Distribution at r/R=0.80 NREL Code -6 NREL Code -6 -4 -4 -3 -3 Cp -5 Cp -5 -2 -2 -1 -1 0 0 1 1 2 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 x/C 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 x/C -7 Cp Distribution at r/R=0.95 NREL Code -6 -5 -4 Cp -3 -2 -1 0 1 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 x/C Figure 4m. Cp Distribution at 15 m/s with 450 yaw angle on several span wise stations 0.8 0.9 1 -4 -4 Cp Distribution at r/R=0.30 Cp Distribution at r/R=0.47 NREL Code -3 -3 -2 -2 Cp Cp NREL Code -1 -1 0 0 1 1 2 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 0 0.1 0.2 0.3 0.4 x/C 0.5 0.6 0.7 0.8 0.9 -4 -4 Cp Distribution at r/R=0.63 Cp Distribution at r/R=0.80 NREL Code -3 -3 -2 -2 Cp Cp NREL Code -1 -1 0 0 1 1 2 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 x/C 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 x/C -4 Cp Distribution at r/R=0.95 NREL Code -3 -2 Cp 1 x/C -1 0 1 2 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 x/C Figure 4n. Cp Distribution at 15 m/s with 600 yaw angle on several span wise stations 0.8 0.9 1 1000 2000 Torque variation with yaw angle (7 m/s) Torque variation with yaw angle (10 m/s) NREL Code NREL Code 1800 800 1600 700 1400 600 1200 Torque (Nm) Torque (Nm) 900 500 400 1000 800 300 600 200 400 100 200 0 0 0 10 20 30 40 50 60 70 0 10 20 Yaw Angle (deg) 30 40 50 60 3000 3000 Torque variation with yaw angle (13 m/s) Torque variation with yaw angle (15 m/s) NREL Code NREL Code 2500 2500 2000 2000 Torque (Nm) Torque (Nm) 70 Yaw Angle (deg) 1500 1500 1000 1000 500 500 0 0 0 10 20 30 40 Yaw Angle (deg) 50 60 70 0 10 20 30 40 50 60 70 Yaw Angle (deg) Figure 5a. The variation of the torque generated by the rotor as a function of yaw angle at several wind speeds 3000 4000 Root bending moment variation with yaw angle (7 m/s) Root bending moment variation with yaw angle (10 m/s) NREL Code NREL Code 3500 3000 Root Bending Moment (Nm) Root Bending Moment (Nm) 2500 2000 1500 1000 2500 2000 1500 1000 500 500 0 0 0 10 20 30 40 50 60 70 0 10 20 Yaw Angle (deg) 5000 40 50 60 70 5000 Root bending moment variation with yaw angle (13 m/s) Root bending moment variation with yaw angle (15 m/s) NREL Code NREL Code 4000 4000 Root Bending Moment (Nm) Root Bending Moment (Nm) 30 Yaw Angle (deg) 3000 2000 1000 3000 2000 1000 0 0 0 10 20 30 40 Yaw Angle (deg) 50 60 70 0 10 20 30 40 50 60 Yaw Angle (deg) Figure 6. The variation of the root bending moment as a function of yaw angle at several wind speeds 70