STGCL.SWP.91.1_RNA Extraction from blood or cells

advertisement

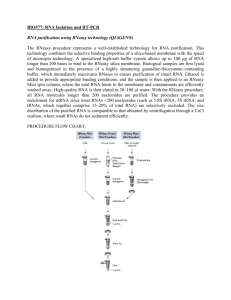

OHS026 Safe Work Procedure Faculty/Division School/ Divisional Unit Medicine Document number Initial Issue date STGCL.SWP.91.1 07/05/2010 STG- Radiation Oncology Current Version Issue date 07/05/2010 Current version 1.0 Next review date May 2012 The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form. Safe Work Procedure Title and basic description Title: RNA extraction from blood or cells using RNeasy Kit from Qiagen (handbook found at www.qiagen.com) Description: This Safe Work Procedure describes the extraction of RNA from blood, tissue or cells using extraction kit from Qiagen Associated risk assessment title and location: STGCL.RA.91.1 Describe the activity or process This SWP describes the protocols for isolating RNA from blood, cell isolates and cultures. These procedures are performed in the PC-2 facility following the OGTR guidelines. PC-2 induction must be carried out before these methods are undertaken. These protocols involve the use of hazardous substances. The attached Risk Assessment and all relevant MSDSs must be accessed and read before the work is commenced. In addition, this document references: “Broths and buffers for molecular biology” and “Preparation of lymphocytes from fresh blood”; be aware that the hazards associated with the procedures described in those documents will not be detailed here. Furthermore, all persons carrying out these protocols must also be familiar with STGCL.SWP.2.1, which describe the correct procedures to be followed when disposing of PC-2 waste. NB: - in this document, preparation of RNA using commercial kits will be described. Using a kit is quicker, and involves less exposure to hazardous substances. These methods are described in the singular, however more than one preparation is undertaken at any one time! Even numbers make centrifuging simpler. Step 1. Harvest cells according to step 1a or 1b. 1a. Cells from blood or grown in suspension (do not use more than 1 x 107 cells): Determine the number of cells. Pellet the appropriate number of cells by centrifuging for 5 min at 300 x g in a centrifuge tube (not supplied). Carefully remove all supernatant by aspiration, and proceed to step 2. Note: Incomplete removal of cell-culture medium will inhibit lysis and dilute the lysate, affecting the conditions for binding of RNA to the RNeasy membrane. Both effects may reduce RNA yield. 1b. Cells grown in a monolayer (do not use more than 1 x 107 cells): Cells can be either lysed directly in the cell-culture vessel (up to 10 cm diameter) or trypsinized and collected as a cell pellet prior to lysis. Cells grown in cell-culture flasks should always be trypsinized. To lyse cells directly: Determine the number of cells. Completely aspirate the cell-culture medium, and proceed immediately to step 2. ANote: Incomplete removal of cell-culture medium will inhibit lysis and dilute the lysate, affecting the conditions for binding of RNA to the RNeasy membrane. Both effects may reduce RNA yield. To trypsinize and collect cells: Determine the number of cells. Aspirate the medium, and wash the cells with PBS. Aspirate the PBS, and add 0.1–0.25% trypsin in PBS. After the cells detach from the dish or flask, add medium (containing serum to inactivate the trypsin), transfer the cells to an RNase-free glass or polypropylene centrifuge tube (not supplied), and centrifuge at 300 x g for 5 min. Completely aspirate the supernatant, and proceed to step 2. Step 2. Disrupt the cells by adding Buffer RLT: For pelleted cells, loosen the cell pellet thoroughly by flicking the tube. Add the appropriate volume of Buffer RLT (see Table 5). Vortex or pipet to mix, and proceed to step 3. Step 3. Homogenize the lysate according to step 3a, 3b, or 3c: See “Disrupting and homogenizing starting material”, pages 20–23, for more details on homogenization. If processing _1 x 105 cells, homogenize by vortexing for 1 min. After homogenization, proceed to step 4. Note: Incomplete homogenization leads to significantly reduced RNA yields 3a. Pipet the lysate directly into a QIAshredder spin column placed in a 2 ml collection tube, and centrifuge for 2 min at full speed. Proceed to step 4. 3b. Homogenize the lysate for 30 s using a rotor–stator homogenizer. Proceed to step 4. 3c. Pass the lysate at least 5 times through a blunt 20-gauge needle (0.9 mm diameter) fitted to an RNase-free syringe. Proceed to step 4. ___________________________________________________________________________________________________________ ___________ Page 1 of 3 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 Describe the activity or process Step 4. Add 1 volume of 70% ethanol to the homogenized lysate, and mix well by pipetting. Do not centrifuge. Note: The volume of lysate may be less than 350 μl or 600 μl due to loss during homogenization. Note: When purifying RNA from certain cell lines, precipitates may be visible after addition of ethanol. This does not affect the procedure. Step 5. Transfer up to 700 μl of the sample, including any precipitate that may have formed, to an RNeasy spin column placed in a 2 ml collection tube (supplied). Close the lid gently, and centrifuge for 15 s at _8000 x g (_10,000 rpm). Discard the flow-through. Reuse the collection tube in step 6. If the sample volume exceeds 700 μl, centrifuge successive aliquots in the same RNeasy spin column. Discard the flow-through after each centrifugation.* Optional: If performing optional on-column DNase digestion (see “Eliminating genomic DNA contamination”, page 23), follow steps D1–D4 (page 69) after performing this step. Step 6. Add 700 μl Buffer RW1 to the RNeasy spin column. Close the lid gently, and centrifuge for 15 s at _8000 x g (10,000 rpm) to wash the spin column membrane. Discard the flow-through. Reuse the collection tube in step 7. * Flow-through contains Buffer RLT or Buffer RW1 and is therefore not compatible with bleach. See page 8 for safety information. Note: After centrifugation, carefully remove the RNeasy spin column from the collection tube so that the column does not contact the flow-through. Be sure to empty the collection tube completely. Skip this step if performing optional on-column DNase digestion (page 69 RNeasy Handbook at www.Qiagen.com). 7. Add 500 μl Buffer RPE to the RNeasy spin column. Close the lid gently, and centrifuge for 15 s at _8000 x g (10,000 rpm) to wash the spin column membrane. Discard the flow-through. Reuse the collection tube in step 8. Note: Buffer RPE is supplied as a concentrate. Ensure that ethanol is added to Buffer RPE before use (see “Things to do before starting”). 8. Add 500 μl Buffer RPE to the RNeasy spin column. Close the lid gently, and centrifuge for 2 min at _8000 x g (10,000 rpm) to wash the spin column membrane. Note: After centrifugation, carefully remove the RNeasy spin column from the collection tube so that the column does not contact the flow-through. Otherwise, carry-over of ethanol will occur. 9. Optional: Place the RNeasy spin column in a new 2 ml collection tube (supplied), and discard the old collection tube with the flow-through. Close the lid gently, and centrifuge at full speed for 1 min. Perform this step to eliminate any possible carryover of Buffer RPE, or if residual flow-through remains on the outside of the RNeasy spin column after step 8. 10. Place the RNeasy spin column in a new 1.5 ml collection tube (supplied). Add 30–50 μl RNase-free water directly to the spin column membrane. Close the lid gently, and centrifuge for 1 min at 8000 x g (10,000 rpm) to elute the RNA. 11. If the expected RNA yield is >30 μg, repeat step 10 using another 30–50 μl RNasefree water, or using the eluate from step 10 (if high RNA concentration is required). Reuse the collection tube from step 10. List all resources required including plant, chemicals, personal protective clothing and equipment, etc Chemicals L-broth (LB) TE buffer DNAse 95% and 70% v/v ethanol (NB: - this is a hazardous and flammable substance) Isopropanol (NB: - this is a hazardous and flammable substance) Buffer RPE Buffer RW1 Buffer RLT Personal Protective Clothing: Wear suitable protective clothing (i.e. long-sleeve gown), latex gloves, and eye protection. Plant: Class I Biohazard Safety Cabinet Centrifuge Hermle Z 513 K Conical Flask Minispin Eppendorf Centrifuge Orbital Shaking Incubator ___________________________________________________________________________________________________________ ___________ Page 2 of 3 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 List potential hazards and risk controls including specific precautions required Hazards: Addition of antibiotics to Lauria Broth (LB) broth culture where the antibiotics are hazardous substances Risk Controls: MSDSs are available. Wear suitable protective clothing, goggles and gloves. Hazards: Handling of cells/cultures outside of a Class II Biohazard Safety Cabinet risks generating aerosol particles which may be inhaled or ingested. Risk Controls: An SWP has been prepared. External and internal PC-2 training is compulsory. Wear suitable protective clothing, goggles and gloves. Hazards: Handling of 70% ethanol and 95% ethanol which is highly flammable and irritant to eyes. Risk Controls: MSDSs are available. Wear suitable protective clothing, goggles and gloves. Keep away from sources of ignition. Do not breath vapour. Keep container tightly closed. Hazards: Handling of isopropanol which is highly flammable, irritant to eyes. Vapours cause drowsiness and dizziness. Risk Controls: MSDSs are available. Wear suitable protective clothing, goggles and gloves. Keep away from sources of ignition. Do not breath vapour, mist or gas. Keep container tightly closed. Hazards: Handling of Wash Buffer (Buffer RPE) which are irritant to skin and eyes Risk Controls: MSDSs are available. Wear suitable protective clothing, goggles and gloves. Hazards: Handling of Elution Buffer (Buffer RW1) which are irritant to skin and eyes Risk Controls: MSDSs are available. Wear suitable protective clothing, goggles and gloves. Hazards: Handling of Cell Lysis Solution (Buffer RLT) which is an irritant to skin and eyes Risk Controls: MSDSs are available. Wear suitable protective clothing, goggles and gloves. Hazards: Handling of DNAse which are harmful, irritant to skin and respiratory system Risk Controls: MSDSs are available. Wear suitable protective clothing, goggles and gloves.. List emergency shutdown instructions After inhalation: In case of unconsciousness place patient stably in side position for transportation. After skin contact: Immediately wash with soap, water and rinse thoroughly. After eye contact: Rinse opened eye for several minutes under running water. After swallowing: If symptoms persist consult doctor. List clean up and waste disposal requirements Isopropanol, ethanol waste has to be collected separately and collected as chemical waste. All waste must be collected, treated if required and disposed as chemical waste. Recommended cleansing agents:80% (v/v) of ethanol, if necessary together with cleansing agents. List legislation, standards and codes of practice used in the development of the SWP Manual for Qiagen RNeasy Handbook found at www.Qiagen.com Australian/New Zealand Standard, Safety in Laboratories Part 3: Microbiological aspects and containment facilities 2002 (AS/NZS 2243.3:2002) Supervisory approval, training, and review Supervisor: Dr Raymond Clarke Signature: Supervisor: Signature: Supervisor: Signature: Supervisor: Signature: Supervisor: Signature: Plant custodian: Dr Raymond Clarke Signature List competency required – qualifications, certificates, licencing, training - eg course or instruction: UNSW PC-2 Training UNSW OGTR Induction STGCL PC-2 Induction SWP review date: Responsibility for SWP review: ___________________________________________________________________________________________________________ ___________ Page 3 of 3 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007

![DNA/RNA Isolation Protocol [doc]](http://s3.studylib.net/store/data/006911113_1-8ce76fa1eed4bb9be7586444f49e73dc-300x300.png)