Sterile technique - Contra Costa College

advertisement

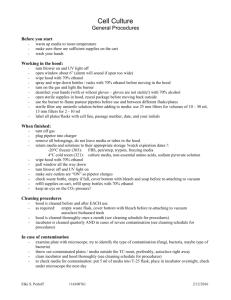

Three documents about sterile (aseptic) technique: 1. From MIT: (http://openwetware.org/index.php?title=BE.109) Hood Preparation 1) 2) 3) 4) 5) 6) 7) Wear gloves to protect yourself but also to prevent dry skin and microorganisms from contaminating your samples. Swab down the work surface liberally with 70% ethanol. Start from the back and proceed forward. Swab during work if necessary. Swab any instruments that will be used in the hood with 70% ethanol, particularly the pipettes, which will often be used above biological samples. Keep sterile pipette tips in “Hood Only” boxes that are opened only in a sterile environment. Swab the exterior of the box with 70% ethanol. Bottles should always be tightly capped when outside the hood (i.e., they should have been tightly capped the last time they were in the hood). Dry bottles thoroughly if they have been taken out of the water incubator. Swab them with 70% ethanol, especially at the neck and the bottom, and place them directly into the hood. Avoid shaking them vigorously during handling. Bring only the items you need for a particular procedure into the hood to prevent cluttering your working space. Having a clear working space will significantly reduce the chance of contamination! Ensure easy access to items in the hood and maintain plenty of clear space in the center of the hood to work in. Sterile Handling 1) 2) 3) 4) 5) 6) Spray gloves with 70% ethanol as often as necessary. The indicator stripes on the autoclave tape should turn black if an object has been properly autoclaved. Never block the negative pressure zone (also the frontal non-sterile area) of the vertical laminar flow hood with objects (i.e., notebooks, pipetteman handle). Avoid working too closely to the front, or the non-sterile area, of the hood. Keep working area at the center or towards the back. Keep the objects needed for the current procedure within reach; keep the others in the back. Avoid working above an open bottle or dish in vertical laminar flow. Always work around them unless they are capped or covered. Avoid leaving bottles, dishes, and flasks open when they are not in use. If the cap must be laid down, place it face-up/face-down towards the back of the hood where there is less traffic and less chance of being touched or crossed over. Correct cap placement has been debated. Having a cap facing up can potentially introduce airborne particles and drive non-sterile lid liquid onto the interior face of the cap, where contaminations can fall into the bottle upon recapping. If facedown placement is preferred, then make sure to swab the area specifically and thoroughly before the cap is placed down there. Conversely, if hood surface sterility cannot be absolutely guaranteed due to high traffic or cluttering, then 7) 8) 9) 10) 11) 12) 13) 14) 15) face-up is a better option. The best placement, however, is to place the cap on its side and towards the back of the hood. This way the interior is not in contact with the air flow or with the work surface. However, this is not possible with dishes. Therefore, exercise good judgment in light of individual operating style and the hood setup. Never pour from one sterile container to another. Pouring will generate a liquid path to introduce infection from the outside to the inside. Always pipette or use filters when transferring from one bottle to another. Mop up any spillage immediately and swab with 70% ethanol to avoid the chance of growth of micro-organisms. Withdraw a pipette from its wrappers at the center of the working area, tilt it such that the tip (bottom end) is pointing away from the frontal non-sterile area and away from other objects in the hood. Withdraw the pipette such that it slides through the sterile interior of the wrapper without touching the outside of the wrapper. Avoid contact between the tip of the pipette and the mouth of the bottle. The mouth and neck of the bottle (both inside and out) present a potential source of contamination. When working with Pasteur pipettes, do not remove pipettes directly from the box with fingers. Shake the tube gently to cause the pipettes to slide out slightly, and then withdraw a pipette with fingers without touching the other pipettes and the tube interior. To keep the hood from being cluttered, do not leave any trash in the hood. Immediately discard uncontaminated wrappers in the regular trash. Put all pipette tips and biologically contaminated sharps in the sharps biohazard waste container. Put all biologically contaminated tissue culture plates, flasks, and other nonsharps in the non-sharps biohazard waste container. However, an effort to minimize entry/exit from the hood should be made to minimize disturbances in the laminar flow at the entrance, which may create the potential to waft in contaminants. Handle the pipette with a steady hand. Avoid large motions and do not let the tip touch anything non-sterile. Keep the tip away from the front and far above the objects in the hood. Do not fill a dish/flask so full or swirl it such that the medium spills over the edge. This will introduce a path of infection via liquid and may cause crosscontamination. Cleaning up 1) Cap bottles tightly before removing them from the hood. 2) Swap down the work surface liberally with 70% ethanol. 3) Turn off the vacuum, if used. 2. From http://www.hos.ufl.edu/mooreweb/TissueCulture/January%2011/Sterile%20Technique/Sterile%20Technique%202007.doc Sterile (Aseptic) Technique Aseptic technique is absolutely necessary for the successful establishment and maintenance of plant cell, tissue and organ cultures. The in vitro environment in which the plant material is grown is also ideal for the proliferation of microorganisms. In most cases the microorganisms outgrow the plant tissues, resulting in their death. Contamination can also spread from culture to culture. The purpose of aseptic technique is minimize the possibility that microorganisms remain in or enter the cultures. The environmental control of air is also of concern because room air may be highly contaminated. Example: Sneezing produces 100,000 - 200,000 aerosol droplets which can then attach to dust particles. These contaminated particles may be present in the air for weeks. (Have you ever viewed the air around you when you open the curtains on a sunny day?)...Air may also contain bacterial and fungal spores, as do we. I. Contaminants A. Bacteria, fungi, and insects 1. Bacteria Bacteria are the most frequent contaminants. They are usually introduced with the explant and may survive surface sterilization of the explant because they are in interior tissues. So, bacterial contamination can first become apparent long after a culture has been initiated (see below). Some bacterial spores can also survive the sterilization procedure even if they are on the tissue surface. Many kinds of bacteria have been found in plant tissue cultures including Agrobacterium, Bacillus, Corynebacterium, Enterobacter, Lactobacillus, Pseudomanas, Staphylococcus, and Xanthomonas. Bacteria can be recognized by a characteristic "ooze"; the ooze can be many colors including white, cream, pink, and yellow. There is also often a distinctive odor. 2. Fungi Fungi may enter cultures on explants or spores may be airborne. Fungi are frequently present as plant pathogens and in soil. They may be recognized by their "fuzzy" appearance, and occur in a multitude of colors. 3. Yeast Yeast is a common contaminant of plant cultures. Yeasts live on the external surfaces of plants and are often present in the air. 4. Viruses, etc. Viruses, mycoplasma-like organisms, spiroplasmas, and rickettsias are extremely small organisms that are not easily detected. Thus, plant culture is not necessarily pathogen-free even if microorganisms are not detected, and this can influence culture success. Special measures such as meristem culture are often necessary to eradicate such contaminants. 5. Insects The insects that are most troublesome in plant cultures include ants, thrips, and mites. Thrips often enter cultures as eggs present on the explants. Ants and mites, however, usually infest already established cultures. Mites feed on fungus and mite infestations are often first detected by observing lines of fungal infection that lead from the edge of the culture vessel to the plant tissue, having been introduced by the insect. It is very difficult to eradicate insect infestations. Careful lab practices and cleanliness should prevent most infestations. B. Initial Contaminants Most contamination is introduced with the explant because of inadequate sterilization or just very dirty material. It can be fungal or bacterial. This kind of contamination can be a very difficult problem when the plant explant material is harvested from the field or greenhouse. Initial contamination is obvious within a few days after cultures are initiated. Bacteria produce “ooze” on solid medium and turbidity in liquid cultures. Fungi look “furry” on solid medium and often accumulate in little balls in liquid medium. C. Latent Contamination This kind of contamination is usually bacterial and is often observed long after cultures are initiated. Apparently the bacteria are present endogenously in the initial plant material and are not obviously pathogenic in situ. Once in vitro, however, they increase in titer and overrun the cultures. Latent contamination is particularly dangerous because it can easily be transferred among cultures. D. Introduced Contamination Contamination can also occur as a result of poor sterile technique or dirty lab conditions. This kind of contamination is largely preventable with proper care. E. Detection of Contaminants Contamination is usually detected by the "eyeball" method in research labs. However, indexing is possible, and is frequently done in commercial settings. This involves taking a part of the plant tissue and culturing it in media that are specific for bacteria and fungi. Media that have been used for this purpose include PDA (potato dextrose agar) and NB broth (with salts, yeast extract and glucose). This is the most reliable method for detecting bacteria and fungi, but, as indicated above, there may be infecting organisms that won’t be detected. II. The Transfer Hood Laminar airflow hoods are used in commercial and research tissue culture settings. A horizontal laminar flow unit is designed to remove particles from the air. Room air is pulled into the unit and pushed through a HEPA (High Energy Particle Air) filter with a uniform velocity of 90 ft/min across the work surface. The air is filtered by a HEPA (high efficiency particulate air) filter so nothing larger than 0.3 micrometer, which includes bacterial and fungal spores, can pass through. This renders the air sterile. The positive pressure of the air flow from the unit also discourages any fungal spores or bacteria from entering. Depending on the design of the hood, the filters are located at the back or in the top of the box. III. Sterilization and Use of Supplies and Equipment: A. Sterilizing tools, media, vessels etc. 1. Autoclaving Autoclaving is the method most often used for sterilizing heat-resistant items and our usual method for sterilizing items. In order to be sterilized, the item must be held at 121C, 15 psi, for at least 15 minutes. It is important that items reach this temperature before timing begins. Therefore time in the autoclave will vary, depending on volume in individual vessels and number of vessels in the autoclave. Most autoclaves automatically adjust time when temperature and psi are set, and include time in the cycle for a slow decrease in pressure. There are tape indicators that can be affixed to vessels, but they may not reflect the temperature of liquid within them. There are also “test kits” of microorganisms that can be run through the autoclave cycle and then cultured. Empty vessels, beakers, graduated cylinders, etc., should be closed with a cap or aluminum foil. Tools should also be wrapped in foil or paper or put in a covered sterilization tray. It is critical that the steam penetrate the items in order for sterilization to be successful. 2. Autoclaving and Fiter-sterilizing Media and Other Liquids Two methods (autoclaving and membrane filtration under positive pressure) are commonly used to sterilize culture media. Culture media, distilled water, and other heat stable mixtures can be autoclaved in glass containers that are sealed with cotton plugs, aluminum foil, or plastic closures. However, solutions that contain heat-labile components must be filter-sterilized. For small volumes of liquids (100 ml or less), the time required for autoclaving is 15-20 min, but for larger quantities (2-4 liter), 30-40 min is required to complete the cycle. The pressure should not exceed 20 psi, as higher pressures may lead to the decomposition of carbohydrates and other components of a medium. Too high temperatures or too long cycles can also result in changes in properties of the medium. Organic compounds such as some growth regulators, amino acids, and vitamins may be degraded during autoclaving. These compounds require filter sterilization through a 0.22 µm membrane. Several manufacturers make nitrocellulose membranes that can be sterilized by autoclaving. They are placed between sections of a filter unit and sterilized as one piece. Other filters (the kind we use) come pre-sterilized. Larger ones can be set over a sterile flask and a vacuum is applied to pull the compound dissolved in liquid through the membrane and into the sterile flask. Smaller membranes fit on the end of a sterile syringe and liquid is pushed through by depressing the top of the syringe. The size of the filter selected depends on the volume of the solution to be sterilized and the components of the solution. Nutrient media that contain thermo labile components are typically prepared in several steps. A solution of the heat-stable components is sterilized in the usual way by autoclaving and then cooled to 35°-50° C under sterile conditions. Solutions of the thermo labile components are filter-sterilized. The sterilized solutions are then combined under aseptic conditions to give the complete medium. In spite of possible degradation, however, some compounds that are thought to be heat labile are generally autoclaved if results are found to be reliable and reproducible. These compounds include ABA, IAA, IBA, kinetin, pyridoxine, 2-ip and thiamine are usually autoclaved. 3. Ethylene Oxide Gas Plastic containers that cannot be heated are sterilized commercially by ethylene oxide gas. These items are sold already sterile and cannot be resterilized. Examples of such items are plastic petri dishes, plastic centrifuge tubes etc. 4. UV Radiation It is possible to use germicidal lamps to sterilize items in the transfer hood when no one is working there. We do not do this. UV lamps should not be used when people are present because the light is damaging to eyes and skin. Plants left under UV lamps will die. 5. Microwave It is also possible to sterilize items in the microwave; we do not do this. 6. More Comments Know which of your implements, flasks, etc. are sterile and which are not. Sterile things will have been autoclaved and should be wrapped with some kind of protective covering, e.g. foil, for transport from the autoclave to the hood. Our usual autoclave time of 20 minutes is intended for relatively small volumes. Large flasks of media, water, etc. may require longer autoclaving periods. It is preferable to put no more than one liter of liquid in a container to be autoclaved. Also, be sure to leave enough room in the container so that the liquid does not boil over. Sterilized items should be used within a short time (a few days at most). Items that come packaged sterile, e.g. plastic petri plates, should be examined carefully for damage before use. If part of a package is used, seal up the remainder and date and label. Use up these items unless there is some question about their sterility; they are expensive. IV. Working in the Transfer Hood: The hood should remain on continuously. If for some reason it has been turned off, turn it on and let it run for at least 15 minutes before using. Make sure that everything needed for the work is in the hood and all unnecessary things are removed. As few things as possible should be stored in the hood. Check the bottom of the hood to make sure there is no paper or other debris blocking air intake. Remove watches, etc., roll up long sleeves, and wash hands thoroughly with soap (preferably bactericidal) and water. Spray or wipe the inside of the transfer hood (bottom and sides, not directly on the filters) with 70% EtOH. Others use disinfectants such as Lysol®. Wipe the work area and let the spray dry. Wipe hands and lower arms with 70% EtOH. It is not necessary to flame them (This is a joke.). Spray everything going into the sterile area with 70% ethanol. For example, spray bags of petri dishes with 70 % alcohol before you open them and place the desired number of unopened dishes in the sterile area. Work well back in the transfer hood (behind the line). Especially keep all flasks as far back to the back of the hood as possible. Movements in the hood should be contained to small areas. A line drawn across the distance behind which one should work is a useful reminder. Make sure that materials in use are to the side of your work area, so that airflow from the hood is not blocked. Don’t touch any surface that is supposed to remain sterile with your hands. Use forceps, etc. Instruments (scalpels, forceps) can be sterilized by flaming - dipping them in 95% EtOH and then immediately placing them in the flame of an alcohol lamp or gas burner. This can be dangerous if the vessel holding the alcohol tips over and an alcohol fire results. A fairly deep container, like a coplin-staining jar, should be used to hold the ethanol. Use enough ethanol to submerge the business ends of the instruments but not so much that you burn your hands. Some people wear gloves in the hood for certain procedures. If you do this, be very careful not to get them near the flame. Other methods of sterilization that do not require alcohol are with a bacticinerator or glass bead sterilizer. There is not as much risk from fire with these, but the instruments can still get extremely hot, causing burns. Arrange tools and other items in the hood so that your hands do not have to cross over each other while working. For a right-handed person, it is best that the flame, alcohol for flaming, and tools be placed on the right. The plant material should be placed to the left. All other items in the hood should be arranged so that your work area is directly in front of you, and between 8 and 10 inches in from the front edge. No materials should be placed between the actual work area and the filter. Keep as little in the hood as possible. Plant material should be placed on a sterile surface when manipulating it in the hood. Sterile petri dishes (expensive), sterile paper towels, or sterile paper plates work fine. Pre-sterilized plastic dishes have two sterile surfacesthe inside top and inside bottom. Sterilize your instruments often, especially in between individual petri plates, flasks, etc. The tools should be placed on a holder in the hood to cool or should be cooled by dipping in sterile water or medium before handling plant tissues. Wipe up any spills quickly; use 70% EtOH for cleaning. Clean hood surface periodically while working. Use of glass or plastic pipettes: Glass pipettes are put into containers or wrapped and then autoclaved. Plastic pipettes are purchased presterilized in individual wrappers. To use a pipette, remove it from its wrapper or container by the end opposite the tip. Do not touch the lower two-thirds of the pipette. Do not allow the pipette to touch any laboratory surface. Insert only the untouched lower portion of the pipette into a sterile container. Sterilize culture tubes with lids or caps on. When you open a sterile tube, touch only the outside of the cap, and do not set the cap on any laboratory surface. Instead, hold the cap with one or two fingers while you complete the operation, and then replace it on the tube. This technique usually requires some practice, especially if you are simultaneously opening tubes and operating a sterile pipette. After you remove the cap from the test tube, pass the mouth of the tube through a flame. If possible, hold the open tube at an angle. Put only sterile objects into the tube. Complete the operation as quickly as you reasonably can, and then flame the mouth of the tube again. Replace the lid. Inoculating loops and needles are the primary tools for transferring microbial cultures. We use plastic ones that come sterile. If you are moving organisms from an agar plate, touch an isolated colony with the transfer loop. Replace the plate lid. Open and flame the culture tube, and inoculate the medium in it by stirring the end of the transfer tool in the medium. If you are removing cells from a liquid culture, insert the loop into the culture. Even if you cannot see any liquid in the loop, there will be enough cells there to inoculate a plate or a new liquid culture. If you don't have to be careful about the volume you transfer, a pure culture or sterile solution can be transferred to a sterile container or new sterile medium by pouring. For example, we do not measure a specific volume of medium when we pour culture plates, although after you have done it for a while, you become pretty consistent. Remove the cap or lid from the solution to be transferred. Thoroughly flame the mouth of the container, holding it at an angle as you do so. Remove the lid from the target container. Hold the container at an angle. Quickly and neatly pour the contents from the first container into the second. Replace the lid. If you must transfer an exact volume of liquid, use a sterile pipette or a sterile graduated cylinder. When using a sterile graduated cylinder, complete the transfer as quickly as you reasonably can to minimize the time the sterile liquid is exposed to the air. Remove items from the hood as soon as they are no longer needed. All cultures must be sealed before leaving the hood. When transferring plant cultures, do contaminated cultures last. Situate the cultures so that the contaminated part is closest to the front of the hood. Place waste in the proper containers: Empty (e.g. after transfer) or old petri plates used in transformation experiments go in the big bag to be autoclaved, as do other disposable that were in contact with recombinant bacterial or plant material. All needles go in the sharps box, needles used with bacteria get autoclaved. Small bags used in the hood for waste go in the big bag to be autoclaved; do not overfill the small bags or leave full bags in or on the hood for someone else to dispose of. Glassware that comes in contact with bacteria is placed in a separate pan to be autoclaved. When finished in the hood, clean up after yourself. Remove all unnecessary materials and wipe the hood down with 70% EtOH. Be sure when you are finished that you turn off the gas to the burner! It is pointless to practice good sterile technique in a dirty lab. Special problems are contaminated cultures, dirty dishes and solutions where microorganisms can grow. Store cultures in a sequestered area. We will discuss this area later. Check cultures every 3-5 days for contamination. V. Surface-sterilizing Plant Material 1. Preparation of Stock Plants Prior good care of stock plants may lessen the amount of contamination that is present on explants. Plants grown in the field are typically more “dirty” than those grown in a greenhouse or growth chamber, particularly in humid areas like Florida. Overhead watering increases contamination of initial explants. Likewise, splashing soil on the plant during watering will increase initial contamination. Treatment of stock plants with fungicides and/or bacteriocides is sometimes helpful. It is sometimes possible to harvest shoots and force buds from them in clean conditions. The forced shoots may then be free of contaminants when surface-sterilized in a normal manner. Seeds may be sterilized and germinated in vitro to provide clean material. Covering growing shoots for several days or weeks prior to harvesting tissue for culture may supply cleaner material. Explants or material from which material will be cut can be washed in soapy water and then placed under running water for 1 to 2 hours. 2. Ethanol (or Isopropyl Alcohol) Ethanol is a powerful sterilizing agent but also extremely phytotoxic. Therefore, plant material is typically exposed to it for only seconds or minutes. The more tender the tissue, the more it will be damaged by alcohol. Tissues such as dormant buds, seeds, or unopened flower buds can be treated for longer periods of time since the tissue that will be explanted or that will develop is actually within the structure that is being surface-sterilized. Generally 70% ethanol is used prior to treatment with other compounds. 3. Sodium Hypochlorite Sodium hypochlorite, usually purchased as laundry bleach, is the most frequent choice for surface sterilization. It is readily available and can be diluted to proper concentrations. Commercial laundry bleach is 5.25% sodium hypochlorite. It is usually diluted to 10% - 20% of the original concentration, resulting in a final concentration of 0.5 - 1.0% sodium hypchlorite. Plant material is usually immersed in this solution for 10 - 20 minutes. A balance between concentration and time must be determined empirically for each type of explant, because of phytotoxicity. 4. Calcium Hypochlorite Calcium hypochlorite is used more in Europe than in the U.S. It is obtained as a powder and must be dissolved in water. The concentration that is generally used is 3.25 %. The solution must be filtered prior to use since not all of the compound goes into solution. Calcium hypochlorite may be less injurious to plant tissues than sodium hypochlorite. 5. Mercuric Chloride Mercuric chloride is used only as a last resort in the U.S. It is extremely toxic to both plants and humans and must be disposed of with care. Since mercury is so phytotoxic, it is critical that many rinses be used to remove all traces of the mineral from the plant material. 6. Hydrogen Peroxide The concentration of hydrogen peroxide used for surface sterilization of plant material is 30%, ten times stronger than that obtained in a pharmacy. Some researchers have found that hydrogen peroxide is useful for surface-sterilizing material while in the field. 7. Enhancing Effectiveness of Sterilization Procedure Surfactant (e.g.Tween 20) is frequently added to the sodium hypochlorite. A mild vacuum may be used during the procedure. The solutions that the explants are in are often shaken or continuously stirred. 8. Rinsing After plant material is sterilized with one of the above compounds, it must be rinsed thoroughly with sterile water. Typically three to four separate rinses are done. 9. Use of Antibiotics and Fungicides in Vitro We have found that the use of antibiotics and fungicides in vitro is not very effective in eliminating microorganisms and these compounds are often quite phytotoxic. 10. Plant Preservative Mixture PPM™ is a proprietary broad-spectrum biocide, which can be used to control contamination in plant cell cultures, either during the sterilization procedure, or as a medium component. PPM™ comes in an acidic liquid solution (pH 3.8). The recommended dose is 0.5–2.0 mL of PPM™ per liter of medium. Higher doses are required to treat endogenous contamination and for Agrobacterium. Its makers say that PPM™ has several advantages over antibiotics: It is effective against fungi as well as bacteria, thus it can be substituted for a cocktail of antibiotics and fungicides. PPM™ is less expensive than antibiotics, which makes it affordable for wide and routine use. The formation of resistant mutants toward PPM™ is very unlikely because it targets and inhibits multiple enzymes. Many antibiotics adversely affect plant materials. If used as recommended, PPM™ does not adversely affect in vitro seed germination, callous proliferation, or callous regeneration. Seeds and explants with endogenous contamination can be sterilized at doses of 5-20 mL/L of PPM™. This is useful when routine surface sterilization is insufficient. 3. Lauffenburger Tissue Culture SOP Rev: 03/06/07 http://openwetware.org/images/6/68/DALLAB_TC.doc Background: Tissue culture refers to the three-dimensional culture of tissue and/or a culture derived from dispersed cells taken from original tissue. Investigations of intracellular activity, intracellular flux, environmental interaction, cell-cell interaction, genetics, and cell products and secretion can be performed through tissue culture. The two major advantages of tissue culture are control of the physiochemical environment and the ability to maintain constant physiological conditions. Limitations of tissue culture include the need for a high level of expertise, the need for stringent environmental control, genetic and phenotypic instability, and differences in cell behavior in vitro. There are three main methods of initiating a culture: 1) organ culture, 2) primary explant culture, 3) and cell culture. This protocol describes techniques to be used for tissue culture in the Lauffenburger lab (56-378). These guidelines must be followed- failure to do so can result in damage to your and the experiments of others. To protect the overall lab, you (and any collaborators you work with in our facilities) will need to be certified by the Tissue Culture Czars before beginning work. In addition, repeated failures to follow the guidelines can result in loss of privileges. Lab Setup: You will be assigned a space in a tissue culture incubator. It is best to keep all of your work in one room, so use the hoods in the room you were assigned. The only exception to this rule is for lab members who use the 2nd floor tissue culture area – they may use either hood and backup incubator on occasions where they need to do an experiment on the 3rd floor. If you need space in the liquid nitrogen container for archival of cell lines, contact Megan Palmer. The doors to the tissue culture rooms are to be kept shut at all times. When in the tissue culture room, you can wear a disposable lab coat. This coat MUST NOT be used for general lab work; conversely, your general lab or radiation lab coats can not be used in the tissue culture room. Dealing with Biohazards: Although most cell lines are reasonably safe to work with, be aware that you are working with or around potentially dangerous materials (you should have already taken Blood Borne Pathogen training since we use human lines in our facilities). To protect everyone’s safety, follow these guidelines: 1) Label EVERYTHING. Minimal labeling includes your initials, the date, and the cell line nomenclature. For cell passages, it is usually best to include passage # and split ratio for your own information. 2) For long term experiments update the plate with the last date you changed media, etc. In general, cells that haven’t been observed in several days should be disposed of to minimize contamination risks. 3) If you have a lot of tubes, etc that are not for long term use (e.g. ViCell vials, falcon tubes), you can avoid labeling them all, but ONLY IF you dispose of properly immediately after you are done. At no time can you leave unlabeled materials in the lab when you are not in the lab. 4) Anything that has touched cells should be bleached and placed in autoclave waste, not general waste. Media/serum that has not been used on cells can be disposed of in the sink. Aseptic Technique: Contamination by microorganisms is a major problem in tissue culture. Bacteria, mycoplasma, yeast, and fungal spores may be introduced via the operator, the atmosphere, work surfaces, solutions and many other sources. Proper aseptic technique seeks to eliminate these contaminants. It is important to establish and maintain aseptic techniques particularly given the importance of cell culture to everyone’s experiments in the lab. Contamination can be minor and confined to one or two cultures, can spread among several cultures and infect a whole experiment, or can be widespread and wipe out your entire stock. Catastrophes can be minimized if 1) cultures are checked carefully under a microscope, 2) cultures are maintained without antibiotics for at least part of the time to reveal cryptic contaminations, 3) reagents are checked for sterility, 4) bottles of media are not shared with other people, and 5) the standard of sterile technique is kept high at all times. All materials that will come into direct contact with the culture must be sterile. Aseptic technique is a combination of procedures designed to reduce the probability of infection. Most cell culture work is done in a laminar flow hood. General Rules: 1. 2. 3. 4. 5. 6. 7. Wear gloves – but note that these are to protect you, and are not inherently clean! Keep the work surface clean (clean with 70% ethanol and keep the work area clear enough to allow work without reaching over an item and preventing inadvertent brushing of a sterile tip against another object.) Use sterile reagents and media and work to keep them that way (do not reuse tips, clean the outside of reagent bottles with 70% ethanol, autoclave or sterile filter as appropriate) Keep bottles, flasks and tubes covered as much as possible. Remove liquid from containers at an angle. Clean with 70% ethanol often (surfaces and gloves). Remember that it is the inside of containers (autoclaved bottles, centrifuge tubes, etc) that is sterile.. treat the outside as dirty and clean with EtOH. The major advantage of working in a laminar flow hood is that the working environment is protected from contamination by a constant flow of filtered air. A vertical flow hood is where air blows down from the top of the hood onto the work surface. Follow these guidelines when using the laminar flow hood. Keep this direction of flow in mind when setting up your work area. Start-up in the hood 1) The hood must be operating correctly to be used- be sure UV light is OFF, turn on regular light if needed. Sash should be opened to upper tape mark (approximately 8 inches of clearance). Hood blowers are not to be turned off- if they were turned off for any reason, allow to run for 15-20 minutes to clean the air in the hood. 2) Remember that everything that goes INTO the hood must be cleaned with 70% EtOH. This includes your hands. Spray them down before starting. 3) Swab down the work surface liberally with 70% EtOH. Wipe with a Kimwipe, starting from the back of the hood and moving forward. Wipe off anything you intend to use in the hood (pipettor, vacuum line/valve, Pasteur pipet box, etc). 4) Bring stuff into the hood that you intend to use – pipets, tips, etc. Each of these items needs to be cleaned with 70% EtOH. In addition, if you plan to use tips or microcentrifuge tubes, be sure to keep an autoclaved stock that is kept for hood use only. 5) Dry media bottles thoroughly if they have been taken out of the water bath (this water is a great source of contamination). Swab with 70% EtOH, especially at the neck and bottom before placing in hood. 6) Ironically, the greatest source for contamination comes from the cell culture flask itself. If you notice that you have dripped media onto a flask, either replace the lid or carefully wipe down with 70% EtOH before returning to the incubator. Working in the Hood 1) As stated above, everything that goes into the hood must be wiped with 70% EtOH before putting it onto the bench in the hood. This means your hands, new boxes of tips, new beakers of tubes, the exterior of bottle-top filter units, etc. Everything. 2) Keep the air intake (the vent in the bottom of sash, underneath your elbows) clear of all items at all times. If this vent is blocked, it allows room air to enter the hood, which is great source of contamination! Also, keep items from directly blocking the vent in the back of the hood. 3) Bring only the items you need for a particular procedure into the hood to prevent cluttering your working space. Having a clear working space will significantly reduce the chance of contamination! Ensure easy access to items in the hood and maintain plenty of clear space in the center of the hood to work in. 4) This is a vertical laminar flow hood, which means that air flows straight down from the top of the hood. Do not work directly over any open vessels, or contaminants from your hands could be blown into your vessel. Always work at an angle, off to one side. 5) Watch what you are pipetting! The replaceable filters in the air pipettors are expensive. Ensure that you don’t suck fluid up inside them. Especially watch the 1 mL pipettes...they fill really fast! 6) If you spill anything in the hood, clean up immediately to prevent cross-contamination and damage to working surface. Stop what you are doing and wipe up the spill – salts in particular can corrode the metal if left. Wipe the area with 70% EtOH before returning to work. 7) Styrofoam is not recommended in the hood – it often flakes and is difficult to keep out of the vents. Use plastic racks instead (if you need more racks, be sure to clean with EtOH before putting into the hood). Incubators and Microscope These are shared equipment, so they present a great method to spread contamination! 1) Before using the microscope, spray a Kimwipe with 70% EtOH and wipe down the stage. Do this also when you are done to prevent media spills from spreading between plates. 2) If you need counter space to set plates down on by the microscope, clean area with 70% EtOH. 3) The incubators are not technically sterile- however, every effort must be made to maintain their cleanliness to prevent contamination from spreading. If media has spilled in the incubator, clean the spill with EtOH. Spills into the water bath MUST be immediately taken care of- talk to either the lab manager or the tissue culture czars. 4) Put plates carefully into incubator- be sure not to bump other people’s plates, minimize stacking as much as possible, and keep your own plates set up to allow you easy access to what you need next. When You Are Finished 1) Trash must be disposed of properly- sharps/pipettes in the sharps waste bins, non-sharps that have contacted cells must be bleached and disposed of in autoclave bins, and all other non-sharp/nonbiohazard waste goes in regular trash. 2) Remove all of your media/solution bottles (tightly capped), tubes, etc from the hood. 3) Be sure the pipet-aid is returned to its rack to turn off pump. Close the vacuum line. 4) Restock Pasteur pipettes if empty with a new container of autoclaved pipettes– remember to clean the container with EtOH before putting in hood. 5) Wipe down the bench with 70% EtOH. 6) Check serological pipettes and restock if necessary. 7) All waste media and/or cell cultures should be bleached. Add bleach to a final concentration of 10% and let stand for 20 minutes. Then discard down the sink and put plates, etc into biohazard bins. ALL BIOHAZARD WASTE MUST BE PROPERLY DISPOSED OF BEFORE YOU LEAVE FOR THE DAY! Detailed Aseptic Technique There are tons of ways to contaminate your cells, and this list is not exhaustive but includes many general guidelines. Don’t worry- this will quickly become second nature.. 16) 17) 18) Solids (tips, etc) are autoclaved by the lab helpers. The indicator stripes on the autoclave tape should turn black if an object has been properly autoclaved. Sterile filter liquids in the tissue culture hood into an autoclaved bottle. Parafilm may be used to cover the outside of small media bottles before warming in the water bath (to help prevent water seepage into your media). When removing, clean with EtOH first, then remove the parafilm and EtOH treat as normal. 19) 20) 21) 22) 23) 24) 25) 26) 27) 28) 29) 30) Bottles should always be tightly capped when outside the hood (i.e., they should have been tightly capped the last time they were in the hood). Never pour from one sterile container to another. Pouring will generate a liquid path to introduce infection from the outside to the inside. Always pipette or use filters when transferring from one bottle to another. Do not fill a dish/flask so full or swirl it such that the medium spills over the edge. This will introduce a path of infection via liquid and may cause cross-contamination. Avoid working too closely to the front, or the non-sterile area, of the hood. Keep working area at the center or towards the back. Keep the objects needed for the current procedure within reach; keep the others in the back. Avoid working above an open bottle or dish in vertical laminar flow. Always work around them unless they are capped or covered. Avoid leaving bottles, dishes, and flasks open when they are not in use. If the cap must be laid down, place it face-up/face-down towards the back of the hood where there is less traffic and less chance of being touched or crossed over. Correct cap placement has been debated. Having a cap facing up can potentially introduce airborne particles and drive non-sterile lid liquid onto the interior face of the cap, where contaminations can fall into the bottle upon recapping. If face-down placement is preferred, then make sure to swab the area specifically and thoroughly before the cap is placed down there. Conversely, if hood surface sterility cannot be absolutely guaranteed due to high traffic or cluttering, then face-up is a better option. The best placement, however, is to place the cap on its side and towards the back of the hood. This way the interior is not in contact with the air flow or with the work surface. However, this is not possible with dishes. Therefore, exercise good judgment in light of individual operating style and the hood setup. Withdraw a pipettes from wrappers in the center of the working area, attaching directly to pipet-aid. Ensure that the tip does not come into contact with anything (including the outside of the wrapper). Dispose of wrapper immediately. Avoid contact between the tip of the pipette and the mouth of the bottle. The mouth and neck of the bottle (both inside and out) present a potential source of contamination. When working with Pasteur pipettes, do not remove pipettes directly from the tube with fingers. Shake the tube gently to cause the pipettes to slide out slightly, and then withdraw a pipette with fingers without touching the other pipettes and the tube interior. Handle the pipette with a steady hand. Avoid large motions and do not let the tip touch anything non-sterile. Keep the tip away from the front and far above the objects in the hood. To keep the hood from being cluttered, do not leave any trash in the hood. Immediately discard uncontaminated wrappers in the regular trash. Put all pipette tips and biologically contaminated sharps in the sharps biohazard waste container. Put all biologically contaminated tissue culture plates, flasks, and other non-sharps in the non-sharps biohazard waste container (after bleaching). However, an effort to minimize entry/exit from the hood should be made to minimize disturbances in the laminar flow at the entrance, which may create the potential to waft in contaminants. New cell lines are a potential danger to the lab stocks- they should be kept in the designated incubator until you have ascertained that they are free of bacteria, yeast, fungi, and mycoplasma contamination. After you have done that, move cells to your incubator space the next time you passage rather than moving the old plates.