SWP -80C Freezer Defrost

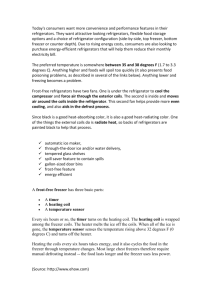

advertisement

OHS026 Safe Work Procedure Faculty/Division Medicine Document number School/ Divisional Unit Initial Issue date 11 October 2011 SoMS Current version 2 Current Version 11 October 2011 Next review date 11 October 2012 The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form. Safe Work Procedure Title and basic description Title: -80C Freezer Defrost Description: Procedure for removing built up ice from a -80C freezer. Associated risk assessment title and location: -80C Freezer Defrost Risk Assessment Describe the activity or process Identify Hazards Freezer should be labeled with hazardous signage, contact person and contact details. Do not store any food or drink or flammable liquids within the -80 freezer. All items in the -80 freezer should be labeled with the following details (Owners Name, Contents, Date). Notify all users and research support staff of freezer defrost and cleaning. Identify any hazardous substances stored or spilled within freezer. Ice Removal If non-hazardous spills in freezer, small amounts of ice can be routinely removed from door seal area by operator wearing PPE using a plastic ice scraper and a non-absorbent container to collect waste ice and water. If hazardous spill within PC2 freezer. PC2 spill procedure should be followed. All collected ice should be transported in a sealed container within a second non-absorbent container to PC2 facility, thawed, and sterilized or decontaminated before disposal. Freezer Defrost Notify security if freezer connected to alarm system. Remove all freezer contents by operator wearing PPE in non-absorbent low temperature containers. Relocate samples to another low temperature freezer storage. If PC2, use PC2 transport procedure. Dispose of any expired samples. Disconnect the electrical supply before commencing cleaning. Place a “slippery surface” sign nearby. Follow the PC2 spill procedure for any spilled hazardous substance. Remove loose ice from door seal area and freezer using a plastic ice scraper and a non-absorbent container to collect waste ice and water. Place absorbent towels inside the freezer and on the surrounding floor to soak up the water. Disinfect inside of thawed freezer and allow to dry. Dispose of all waste ice and water. If PC2, use PC2 waste procedure. Check the floor and area around the freezer that it is dry, clean if necessary. Reconnect electrical supply and wait until freezer temperature has stabilized before reconnecting alarm. Replace samples from temporary storage to freezer by operator wearing PPE and monitor freezer temperature. Notify security that freezer is reconnected to alarm system. List all resources required including plant, chemicals, personal protective clothing and equipment, etc PPE - low temperature gloves, surgical gloves, gown, fully enclosed shoes and splash eye protection. Equipment – temporary freezer storage, plastic ice scraper, absorbent towels, sealable waste container, non-absorbent low temperature containers, “Slippery surface” signage, mop and bucket, PC2 spill kit. Chemicals – suitable disinfectant solution (bleach, viroclean) List potential hazards and risk controls including specific precautions required Electric shock Disconnect the electrical supply before commencing full defrosting and cleaning. Exposure to hazardous substances Wear appropriate PPE (low temperature gloves and surgical gloves, gown and splash eye protection). All items double-contained when stored and transported. Collect all ice and liquid in containers and bag wet towels in biohazard bag in bin. ______________________________________________________________________________________________________________________ Page 1 of 2 Safe Work Procedure Uncontrolled document when printed Date Effective: 01/01/2007 Current Version: 1.2, 15/08/2007 When thawed, disinfect internal surface of freezer. Slipping on wet floor Place towels on the surrounding floor and place inside the freezer to soak up the water. Place a “Slippery Surface” sign at the area to notify people of the possible hazard. Frost burns to skin and eyes Wear appropriate PPE at all times (low temperature gloves and surgical gloves, gown and splash eye protection). List emergency shutdown instructions If the freezer is still close to set temperature, return power to the freezer, place samples back in the freezer and lock it. Alternatively, secure the samples in another working -80 freezer. List clean up and waste disposal requirements Equipment – temporary freezer storage, plastic ice scraper, absorbent towels, sealable waste container, non-absorbent low temperature containers, “Slippery surface” signage, mop and bucket, PC2 spill kit. If PC2 freezer dispose of absorbent towels using PC2 waste procedure. List legislation, standards and codes of practice used in the development of the SWP AS 2243.3:2010: Safety in Laboratories – Microbiological safety and containment OGTR Guidelines for Certification of a Physical Containment Level 2 Laboratory (Version 3.1– Effective 1 July 2007) Supervisory approval, training, and review Supervisor: Mark Hill Signature: Plant custodian: Mark Hill Signature List competency required – qualifications, certificates, licencing, training - eg course or instruction: If PC2 freezer, PC2 laboratory training. SWP review date: 11 October 2012 Responsibility for SWP review: Mark Hill ______________________________________________________________________________________________________________________ Page 2 of 2 Safe Work Procedure Uncontrolled document when printed Date Effective: 01/01/2007 Current Version: 1.2, 15/08/2007