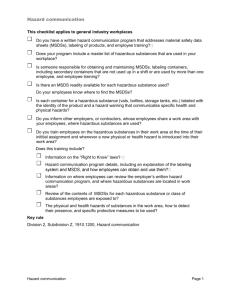

MIOSHA Agency Instruction STD 04-1

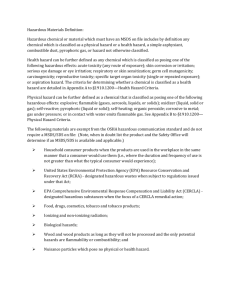

advertisement