Gravimetric analysis

advertisement

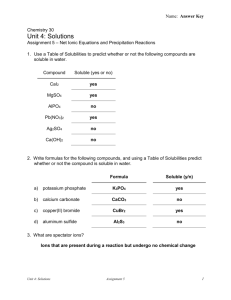

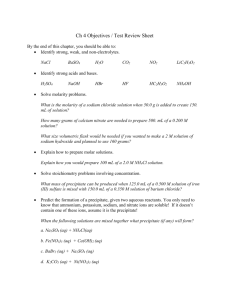

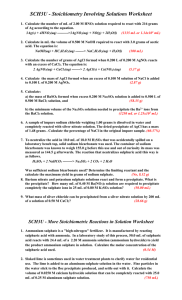

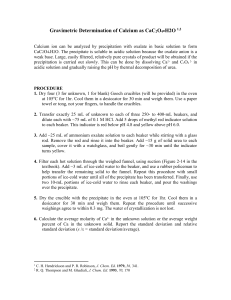

Gravimetric analysis Gravimetry is a general term applied to methods of analysis in which the determination are based upon measurements of weight. Gravimetric analysis is the process of isolating and weighing of the final product with known, pure, stable and definite chemical structure. The separation of the element or the compound containing it, may be done in a number of ways, the most important of which are: i) Separation by volatilization ii) Separation by extraction or partition iii) Separation by adsorption and ion exchange iv) Separation by precipitation. Our interest will be devoted to the separation by precipitation method. Gravimetry 106 Gravimetry by precipitation: Precipitation methods are based on precipitating the substance to be determined from solution as an insoluble compound of known chemical composition. The content of the component is then calculated from the weight of the resulting precipitate. The precipitate is often ignited before weighing, to decompose and convert it into a substance of a different composition, which is more suitable to be weighed. These processes are generally involved in any gravimetric determination: 1. Precipitation. 2. Filtration and washing 3. Drying or/and ignition. 1. Precipitation. The precipitation process takes place in three stages. In the first one, ions collide with each other in the supersaturated solution to form primary nuclei. Superimposition of ions on the primary nuclei to form colloidal particles is the second stage, and in the third stage colloidal particles aggregate to form visible precipitates which according to the concentration of the solutions used, rate of nuclei formation and the nature of Gravimetry 107 the precipitated material may be crystalline (as barium sulphate), curdy (as silver chloride) or gelatinous (as ferric hydroxide) Stage 1 ions in supersaturated solution Primary nuclei (non filterable) Stage 2 Colloidal particals Fine crystals Stage 3 Final form Coarse crystals e.g.PbSO4 Crystalline aggregate e.g. BaSO4 Stabilized Colloid Colloidal aggregate Gel (e.g. Fe(OH)3) Curd (e.g. AgCl) Choice of precipitant One of the important considerations in gravimetric analysis is the choice of the right precipitating agent. Specific reagents would react with one single species of compounds thus Gravimetry 108 preventing the precipitation of the other contaminant neither by true nor by co-precipitation. However the ideal of specific reagents for one substance has not been realized. Reagents are mostly selective, i.e. react with a group of compounds. However selectivity can be improved by adjusting the condition of the experiment: In some cases change of the oxidation number of some members of the selectivity. For example reduction of ferric ion to ferrous prevents its precipitation as hydroxide with ammonia. The masking effect of certain complexing agents may be also useful. Fundamental Requirements for the precipitation process. Three fundamental requirements must be fulfilled during precipitation process. 1. The substance to be determined must be precipitated quantitatively. In practice, this usually means that the quantity remaining in solution does not exceed the minimum detectable by the ordinary analytical balance, viz 0.1 mg 2. The precipitate must be pure not contaminated (this point will be discussed in detail later) 3. The precipitate must be in a physical form suitable for subsequent handling (e.g. rapid filtration and washing). Gravimetry 109 Precipitates of relatively large crystals are very convenient because: 1. They are retained readily by the filter paper, 2. Their surface is not extensive, accordingly, they do not readily adsorb impurities from the solution, and 3. They are easily washed. Precipitates consisting of very small crystals, such as BaSO4 or CaC2O4 are less convenient in this respect. Amorphous precipitates, especially if gelatinous, such as Al(OH)3, have extensive specific surface and therefore adsorb considerable amounts of impurities which are difficult to wash off. Requirements for the weighed form 1. Its composition should correspond exactly to its chemical formula. For example, the Fe(OH)3 formed in gravimetric determination of iron does not correspond exactly to the formula Fe(OH)3, but contains variable amounts of water and which are not known exactly. Therefore, it will be more correct to write its formula as (Fe2O3 n.H2O). When ferric hydroxide is ignited, all this water is removed and a compound of quite definite Gravimetry 110 composition is formed, exactly corresponding the formula Fe2O3. Moreover, when a precipitate is ignited the water and any volatile impurities retained by it, are completely removed. 2. The weighed form must have adequate chemical stability. For example, CaO precipitate readily absorbs H2O and CO2 from air; therefore it is sometimes converted into CaSO4 by treatment with sulphuric acid and excess acid is removed by evaporation. 3. Finally, the content of the element being determined in the precipitate should be as low as possible. The colloidal state: The colloidal state of matter is distinguished by a certain range of particle size (0.001 to 0.1) as a consequence of which certain characteristic properties become apparent. Ordinary filter papers will retain particles up to a diameter of 10, so the colloidal solutions in this respect behave like true solutions. Properties of colloids: 1. The solid is dispersed in the form of aggregates of the ions or molecules while in true solutions the dissolved solid is Gravimetry 111 homogeneously dispersed in the form of individual ions or molecules. 2. In contrast to the true solution, the solid present in a colloidal suspension has a negligible effect on such properties as freezing point, boiling point, and osmotic pressure. 3. The colloidal suspension have the tendency to scatter visible radiation. This when a light beam passes through a colloidal solution, its path can be readily seen (Tyndall effect) 4. Owing to the smallness of the size of the particles, the ratio of surface to weight is extremely large. Phenomena which depend upon the size of the surface, such as adsorption, will play therefore an important part with substances in the colloidal state. 5. Typical colloidal solutions may remain without forming a precipitate for a very long time. This clearly proves the existence of certain factors preventing cohesion of the colloidal particles. One of these factors, is the presence of like electric charges on the colloidal particles; this cause mutual repulsion of the particles, which are prevented from joining into large aggregates. We shall consider a case in which a colloidal arsenious sulphide is formed by the use of H2S in acid medium as a Gravimetry 112 precipitating agent. Here sulphide ions are primarily adsorbed (since every precipitate has a tendency to adsorb its own ions), and some hydrogen ions are secondarily adsorbed have been termed counter ions. Thus the so called electrical double layer is set up between the particles and the solution. Coagulation: If a small amount of electrolytes is added to a colloidal solution, the colloidal particles coagulate into larger aggregates that sink to the bottom of the vessel. The coagulation effect is explained simply with the assumption that the colloidal particles adsorb oppositely charged ions from electrolyte to these primarily adsorbed. Accordingly, the charges on the colloidal particles are decreased so much that they can join together. Thus coagulation effects of electrolytes increase rapidly with increasing the valency of the ions of the opposite charge to that on the colloidal particles. Peptisation: Upon washing the precipitate with water, part of the adsorbed electrolyte is removed. The electrolyte concentration in the supernatant liquid may fall below the coagulation value Gravimetry 113 (minimum amount of electrolyte necessary to cause flocculation), the precipitate may pass into colloidal solution again. The formation of amorphous precipitates: In this case addition of each portion of precipitant causes rapid formation of an enormous number of very minute crystalline nuclei in the liquid; these grow not by deposition of the substance on their surfaces but by joining to form larger aggregates which sink by gravity to the bottom of the vessel. Amorphous precipitates have: 1. Enormous surface area and therefore adsorb readily various extraneous substances from solutions. 2. Since the bonds between the individual crystal nuclei in the aggregates are relatively weak, the aggregates may break up again to give a colloidal solution. Substances of very low solubility form amorphous precipitate for example metal sulphides and hydroxides. Because of the very low solubility, the solubility product is greatly exceeded by addition of even small amounts of precipitant, and this favors the rapid formation of numerous crystal nuclei. The type of precipitate formed depends not only on the individual properties Gravimetry of substance but also on the precipitation 114 conditions. For example BaSO4 is precipitated in crystalline form out of dilute aqueous solution. However, if it is precipitated out of mixture of water with 30 - 60% of alcohol, which greatly reduces the solubility of BaSO4, a colloidal solution or an amorphous precipitate is formed. Homogeneous precipitation When a precipitant is added to a solution, even when the solution is dilute and well stirred, there will always be some local regions of high supersaturation, and impure precipitate forms. However, if the precipitant is added directly, but is rather generated slowly by homogeneous chemical reaction within the solution at a rate comparable to the rate of particle growth, the extent of supersaturation will not reach as high a value as could exist if the precipitant was added directly. This technique is called homogeneous precipitation, and its principal requirements are that the chemical used must not cause any reaction during its addition to the system, any that it can be made to from the precipitant by a slow reaction, often a hydrolysis reaction. That homogeneous formation of crystalline precipitates will lead to less occlusion than the classical methods seems reasonable when it is recalled that occlusion is believed to Gravimetry 115 result from envelopment of adsorbed ions and counter ions by the rapidly growing crystalline solid. But during homogeneous precipitation crystal growth occur slowly and there is, therefore, more time for the adsorbed ions to be replaced on the surface by the lattice ions. But contamination by isomorphic and nonisomorphic inclusion is not appreciably by homogenous precipitation. The best known example of homogeneous precipitation is the use of the hydrolysis of urea to generate hydroxyl ions for the precipitation of aluminium, ferric iron, and other heavy metal ions. The precipitant (hydroxyl ion) is formed by the following reaction which takes place by heating urea just below the boiling point of water until the pH of the solution rises to the desired value: (NH2)2 CO + 3 H2O CO2 + 2NH4+ + 2 OHThe homogeneous precipitated heavy metal hydroxide is superior to that precipitated by the classical method; in that it is much purer, and more dense, compact and easily filterable. Many applications of the above technique involves the homogeneous removal of hydrogen ion in order to increase the concentration of an anion acting as the precipitant for acid Gravimetry 116 soluble compounds such as calcium oxalate. Here, the calcium and oxalate ions are brought together in a solution that is sufficiently acidic to prevent formation of the solid. Precipitation is then induced through homogeneous neutralization of the acid by the ammonium hydroxide liberated by the hydrolysis of urea. Large crystals result, free from contamination with magnesium or phosphate after one precipitation. Homogeneous precipitation of sulphates, oxalates, phosphates and sulphides can be made by adding the corresponding alkyl ester and boiling to hydrolyse the ester into the inorganic anion, i.e., the precipitant. In this way, calcium and magnesium can be precipitated quantitatively as the oxalate, barium and strontium as the sulphate and aluminium and zinc as the phosphate. The generation reactions are represented by the following equation: (C2H5)2C2O4 + 2 H2 O 2 C2H5OH + H2C2O2 (CH3)2SO4 + 2 H2 O 2 CH3OH + 2 H+ + SO42- (C2H5)3PO4 + 3 H2 O 3 C2H5OH + H3PO4 CH3 CS NH2 + H2 O CH3CONH2 + H2S Cation-release method Each of the proceeding examples involves the slow generation Gravimetry 117 of an anion to unite with the sought-for cation forming a precipitate. Some methods of homogeneous precipitation entail the reverse procedure that is the slow generation of a cation for the precipitation of the desired anion. One well known example is the liberation of barium ion, in the presence of sulphate ion (the anion to be determined by precipitation), through the reaction between hydrogen peroxide and ethylenediamine tetra-acetic acid (EDTA). The barium-EDTA complex is soluble and is very stable, but the organic ligand is destructively oxidized by hydrogen peroxide, and barium ion, freed from the complex, is then able to react with the sulphate ion. 2. Filtration For separating the precipitate from the mother liquor, filtration is the most common operation. Essentially, filtration is effected by passing the slurry, through a porous medium. Its techniques involve the use of filter-paper or filter crucibles and the choice of one technique or the other is decided by the type of precipitate and the subsequent treatment it may need. A) Filtration on paper: Filter papers of various sizes and porosities are commercially Gravimetry 118 available. The porosity of the paper used is chosen according to the nature of the precipitate. Three grades are available in the fine precipitates as of barium sulphate. No 41 papers have wider pores and are suitable for gelatinous precipitates as hydrated ferric and aluminium oxides. The more open texture of whatman No. 40 papers makes them suitable for well crystallized precipitates as that of magnesium ammonium phosphate. Filter-paper used for gravimetric work is treated with hydrochloric and hydrofluoric acids to remove silicon and other minerals which cannot be volatilized during the subsequent ignition, so as to minimize the ash left after the paper has been burnt away. Such acid-treated papers are called ashless filterpapers; they usually leave, after incineration, not more than 1 gm. residue per paper. Paper pulp prepared by shaking ashless paper clippings with hot water can be used as a filtering medium for the rapid filtration of the most finely divided precipitates. B) Filtering crucibles: When the precipitate as to be weighed after drying only, or then it cannot be ignited in presence of paper, a filtering crucible is useful. Gravimetry 119 It also permits the use of suction to increase the speed filtration and the same crucible may be used for successive determinations. E.g Goch crucible and Sintered crucibles Gooch crucibles Sintered glass crucibles 3. Drying and ignition of precipitates Drying and ignition are nearly the same except for the temperature; drying is usually done at a temperature below 250oC. The crucible (or funnel) containing the precipitate is placed in a small beaker and covered with a watch glass, and heated in a drying oven at the prescribed temperature. In most cases, this operation merely evaporates the water or other volatile liquid, without causing any chemical change. A temperature Gravimetry 120 of 110o - 135o C is commonly used. When relatively unstable substances (e.g. hydrates) are dried for weighing, the drying temperature must be either low enough that no decomposition occurs, or high enough to give complete conversion to a stable decomposition product, (e.g. the anhydrous substance), so that the composition of the weighing form is exact and known. An initial drying period of 1 - 2 hours is used, then the precipitate is cooled in a desiccators and weighed. Heating for another half hour, cooling and weighing are repeated till constant weight is obtained. A precipitate is only dried if it has a definite chemical composition and is only heated to remove its water of hydration of crystallisation. Ignition at temperatures above 250oC is done in order to transfer a substance to a definite chemical composition; for example precipitated Fe(OH)3 is first dried at 100oC to get rid of the water adsorbed on the precipitate, then it is ignited to remove the elements of water leaving the pure dry Fe2O3. According to the nature of the precipitate, it may be incinerated together or apart from the filter paper: 1. Incineration of the precipitate apart from the filter paper is done for precipitates which are easily reducible by the Gravimetry 121 action of carbon produced on burning the filter paper, such as copper oxide which is reduced with carbon to metallic copper and BaSO4 which is reduced to BaS or Fe2O3 to Fe3O4, etc. For this the precipitate after drying in the oven at 100o 105oC, is separated from the filter paper by friction, the filter paper is first incinerated in a crucible until its carbon is completely burnt off and the precipitate then added to the crucible and incineration is completed until the crucible acquires a constant weight. Incineration of the precipitate and filter paper together: On the contrary of the previous case, some precipitates are very stable and unreducible by the carbon of the burnt filter paper, e.g. Al2O3. If this is the case, the filter paper and the precipitate are dried at 100o - 105oC, then the filter paper is folded down over the precipitate to enclose it completely, and the whole is placed in a tared crucible with the side having the three thickness uppermost. The whole are pressed to the bottom of the crucible without breaking the filter paper. The crucible is then placed in an inclined position on a triangle, the cover resting partly on the latter, and a small flame applied to slowly cabonise the filter paper. The evolved gases should not be allowed to catch fire, nor the paper, as this may causes mechanical expulsion of the fine particles of the precipitate owing to the rapid escape of the products of combustion. If Gravimetry 122 they inflame, the crucible should be covered to put out the flame. When the paper is completely charred and no gases evolve, the crucible is heated to red hot at the bottom, the flame being kept away from the crucible’s mouth otherwise air currents set up might sweep out particles of light precipitates; also the reducing gases may reduce the precipitate. When all carbon has been oxidised, the flame is adjusted to give the required temperature of ignition of the particular precipitate and heating is continued to constant weight. Pyrolysis Curves: Many precipitates of analytical interest decompose on heating to give stable weighable forms, which can be weighed while it actually in a furnace. A special balance designed for the purpose is called thermobalance; it is sensitive to 0.2 mg. and can be measure the temperature of the furnace to within about 1oC, between room temperature and 110oC. The graph recording the weight of the precipitate against the temperature is called “pyrolysis curve”. It is evident that the precipitate should be ignited in a temperature range where the curve is flat, i.e. where the weight is constant over a wide temperature range. Gravimetry 123 The pyrolysis curves of calcium oxalate and magnesium oxalate are particularly interesting. The momohydrate CaC2O4, H2O is stable at 100oC, then loses water up to about 226oC, forming CaC2O4 which is stable up to 398oC, and then the oxalate loses carbon monoxide abruptly to form CaCO3. The carbonate is stable in the range of about 420 to 600oC, and the dissociation to calcium oxide commences. The weight finally becomes constant at about 850oC. Magnesium oxalate differs in its behavior in that it loses carbon monoxide and dioxide simultaneously, forming magnesium oxide directly with no intermediate carbonate. Burners of various types are used for burning or igniting the Gravimetry 124 precipitates. The more usually used is the blowpipe in which a strong supply of air, in addition to the gas, in admitted from an external air supply under pressure; the temperature available by a blowpipe is from 1000 - 1200oC. A sharp temperature for burning (400 - 1000oC) may be arrived at by using an electrically heated “muffle furnace” Desicators are intended for two purposes in gravimetric analysis: storage of samples from which moisture has been removed, and provision of a dry place in which samples, and especially crucibles, may be to cool to room temperature after heating or ignition and prior to weighing. Weighing is the most important operation in both gravimetric and volumetric analyses. In the latter, standard solutions are prepared by dissolving a known weight in a known volume. For gravimetric analysis the saught for material, or a derivative thereof, is isolated from a known weight of sample and then the pure material is weighed. The analytical balance, is probably the most important tool in this respect and it must be sensitive, accurate and reproducible. A part from the usual analytical balances, damped balances are now commonly used. A balance is said to be damped if it is subjected to some force Gravimetry 125 which restrains its motion and decreases the frequency of its swings. Damping is induced by attaching to the beam either large light pistons which move loosely in larger cylinder, or a small aluminium plate which mover between the poles of a powerful magnet. In the first case damping is due to friction of the piston with the air inside the cylinder and the balance is, therefore, called “Air-Damped”. In the other case, damping is induced magnetically and the balance is the so-called “Magnetically Damped”. Calculation in gravimetric analyses: In many gravimetric analyses the sought for material is isolated free from other admixed ingredients and then weighed. From the weight so obtained the percentage of the material can be established. It is more common, however, not to isolate the saught for material itself, but a compound or a derivative containing it which is stable, easily weighable and having a definite composition. Here the calculation of the amount of the saught for material needs the application of our general knowledge of the reactions taking place and the laws of chemical combination. For example, for the estimation of sodium sulphate in a sample of impure salt or in a medicament etc., an aliquot is weighed out, dissolved in water and the sulphate precipitated as barium Gravimetry 126 sulphate which is filtered off, ignited and weight. Now the reactions involved are : Na2SO4 + BaCl2 = BaSO4 + 2 NaCl. BaSO4 is not altered by ignition. That is, one molecule of barium sulphate is obtained from one molecule of sodium sulphate, then the weight of sodium sulphate present in sample can be calculated from the equation. wt.BaSO4 wt.Na2 SO4 Mol.wt. BaSo4 Mol.wt. Na2 So 4 or Wt. Na2SO4 = Wt. BaSO4 x wt. Na2 SO 4 Mol.wt. BaSo4 The ratio of the molecular weights of the materials involved, i.e. wt. Na2 SO 4 , is called the gravimetric conversion factor. Mol.wt. BaSo4 If, instead of sodium sulphate, aluminium sulphate is the material to be estimated, then the reaction will be: Al2(SO4)3 + 3 BaSO4 = 3 BaSO4 + 2 AlCl3 That is, one molecule of aluminium sulphate gives three of Gravimetry 127 barium sulphate and the conversion factor will be: wt. Al2 SO4 3 x Mol.wt. BaSo4 It can be concluded that the molecular weight of the substance sought appear in the numerator of the substance weighed appears in the denumerator each multiplied by the number of its molecules involved in the reactions. If in the above examples the amount of an element only is to be determined such as Na, Fe or S the atomic weight of such elements replaces the molecular weight of the sought compound in the numerator. The factor for sulphur in the above estimation will be At. wt. S Mol.wt. BaSo4 Gravimetric conversion factors have been calculated for most of the common analyses and extensive tables may be found in most had books of chemical analysis. Contamination of gravimetric precipitates One of the most difficult problems that faces the pharmaceutical analytical chemist in employing precipitation Gravimetry 128 as a means of separation and gravimetric determination is obtaining the precipitate in a high degree of purity. However, a precipitate formed in solution by the combination of suitable reagents is almost invariably contaminated by the other ions present during precipitation. It is necessary to investigate the ways in which a precipitate can become contaminated and what conditions can be employed to minimize contamination and the methods can be used to increase the purity of the precipitate after precipitation has been effected. Contamination may be divided into two classes, according to the mechanisms by which they associate with the precipitate. A) Contamination by true precipitation 1. Simultaneous precipitation: This occurs when the solubility product of the impurity is exceeded during the addition of the precipitating agent, so that both the impurity and the desired precipitate deposit about the same time, for example, when silver chloride is formed from a solution containing bromide ion as impurity, both silver chloride and silver bromide precipitate. Ordinarily, simultaneous precipitation is not of great importance as a source of error in gravimetric analysis. It is Gravimetry 129 possible to predict its occurrence by a knowledge of the composition of the solution in which precipitation is carried out. Moreover, it is possible to avoid such contamination, by removing the impurity through actual separation or complexing. But the common methods of washing, digestion and reprecipitation are seldom effective. 2. Conatmination by postprecipitation Here, the contamination is introduced by the precipitation of the impurity, sometime after the precipitate containing the desired constituent has formed. This delayed precipitation is not attributed to any great difference in solubilities between the precipitate and impurity, but rather to a difference in rates of crystallization. Moreover, postprecipitation is closely associated with surface adsorption. The Ks for calcium oxalate is 2.6 x 10-9 and Ks for magnesium oxalate is 1 x 10-8, yet the latter does not form in the absence of the former. This suggests that the surface of the calcium oxalate must be a major factors, probably in the following way. Oxalate ion is present in excess in the solution and therefore, comprises the adsorbed ion layer. This effectively produces a relatively high concentration of oxalate ion localized on the calcium oxalate surface to the extent of providing a local state of supersaturation with respect to magnesium oxalate, so that precipitation of the latter Gravimetry 130 ensues. Contamination by postprecipitation is apparently increased by digestion, so that it is necessary to filter the saught for precipitate as soon as its precipitation is complete, without leaving it in contact with the mother liquor. In certain cases, a water-miscible liquid may be added as soon as the primary precipitation is complete in order to coat the precipitate particles in such a way that their surfaces are no longer in direct contact with the mother liquor. The organic material used for coating must, of course, be volatile upon subsequent ignition of the precipitate. B) Contamination by coprecipitation Some of the soluble materials contaminate the precipitate and, if they cannot be removed by washing, are said to be coprecipitated. Several types of coprecipitation are recognized; which of these predominates in a given case, depends upon the particle size of the precipitate as well as the chemical composition of both the precipitate and the solution. The demarcation among these type is not sharp and, furthermore, any real case of coprecipitation may involve more than one type. Gravimetry 131 1. Coprecipitation by isomorphic inclusion: Two compounds are said to be “isomorphic” if they possess: 1. The same type of formula. 2. The same type of crystal structure. 3. The same type of bonding, and 4. Almost the same type of crystal lattice spacing. Thus, if the precipitate and an impurity are isomorphic, one ion within the crystal of the precipitate is replaced (during the precipitation) right in the crystal lattice by an ion of the impurity which actually becomes incorporated permanently into the crystal lattice of the precipitate. The impurity is distributed throughout the host crystal of the precipitate, sometime uniformly, and sometimes non-uniformly, for example, BaSO4 and PbSO4 , are isomorphic, they have the same type of formula, the same type of crystal structure, the same type of bonding (both divalent salts) and almost the same type of crystal lattice spacing (ionic diameters of Ba2+ and Pb2+ are 5 Å, respectively (the angstrom, Å is 10-8 cm). If SO4- is added to a solution containing Ba2+ and traces of Pb2+ in concentrations not sufficient to exceed the solubility product of PbSO4, contamination of the precipitate with lead sulphate occurs despite the fact that the solubility product of the lead compound is not exceeded. The lead ions replace some of the barium ions in a random fashion throughout the crystal lattice, Gravimetry 132 causing no appreciable distortion of the barium sulphate crystals. This coprecipitation, resulting in mixed crystal formation, cannot be appreciably diminished by the ordinary methods of reducing coprecipitation, viz., digestion, and washing. The only real way to eliminate this type of coprecipitation error, is to remove the contaminating ion beforehand, or to dissolve the contaminated precipitate and to carry out reprecipitation under more favorable conditions. 2. Coprecipitation by non-isomorphic inclusion. When two substances are not completely isomorphic to be miscible in all proportions, they may still be soluble to some extent in each other. Such may be the case when two compounds have the same type of formula, the same crystal structure; but different bonding and different crystal lattice spacing. This may be illustrated by the contamination of barium sulphate with potassium ion. The first is a divalent salt, while, the latter is a monovalent salt. the ionic diameters for Ba2+ and K+ are 5Å and 3Å, respectively. Barium sulphate may to lerate limited amounts of potassium without sufficient distortion to lose its characteristic crystal symmetry and structure. In small amounts, the contaminate may be distributed throughout the Gravimetry 133 host in a manner similar to isomorphic inclusion. It should be noted, however, that the replacement of one barium ion with one potassium ion must be complained by some other modification of the crystal lattice in order to maintain electrical neutrality. Space considerations would certainly not permit two potassium ions to occupy the lattice site of a single barium ion. However, a hydrogen sulphate ion, HSO4-, is similar to a sulphate ion, so electrical neutrality is preserved if a hydrogen sulphate anion replaces a sulphate ion every time a potassium ion replaces a barium ion. That this must occur, is indicated by the observation that coprecipitation of potassium ion is almost negligible where very few hydrogen sulphate ions are present (at pH 5); but coprecipitation of potassium ions is appreciable at pH 1, where that of the sulphate exist as hydrogen sulphate. 3. Coprecipitation by surface adsorption: As already described ions are adsorbed from the mother liquor into the surface of precipitated particles. This adsorption involves a primary adsorbed-ion layer held very tightly, and a counter-ion layer held more or less loosely. These ions are carried down and distributed over the particle surfaces of the precipitate. As the case with gelatinous precipitate and, to some extent with curdy precipitates, it is seldom important for coarsely crystalline precipitates. Where surface adsorption is Gravimetry 134 the predominant mechanism, the bulk of impurity may be removed by simple washing. 4. Coprecipitation by occlusion: An adsorbed, nonisomorphic impurity never fits as well into a crystal structure as the host substance itself. Hence even through the impurity may be temporality adsorbed on the surface of a crystal, it tends to be pushed out and replaced by the host substance as the crystal grows, so that the interior of the crystal is uncontaminated the impurity long restricted only to the surface of the particle. However, if the crystal grows rapidly, the impurity does not have time to be deebed, it may be covered over and entrapped within the rapidly growing crystal. Such enclosed impurities are said to be occluded or internally adsorbed. This type of impurity differ from isomorphic in: 1. The extent of occlusion may not follow any particular laws, but may be very variable and highly dependent upon the mode of formation of the precipitate. 2. The occluded impurity may be discontinuously distributed throughout the precipitate. 3. It is possible to remove the occluded impurity by washing, if the wash liquid can reach it. Hence digestion Gravimetry 135 and reprecipitation are often effective in removing occluded impurities. In another mode of occlusion, impurities are entrapped in the spaces between the particles in aggregates. These voids may trap not only impurities adsorbed on the surface of the void, but also mother liquor with its impurities, whether they are adsorbable or not. Reduction of contamination Measures taken to diminish the contamination, and hence the error, include: elimination of contamination digestion of the precipitate reprecipitation and Washing. 1. Elimination of contamination The contamination may be eliminated by actual separation before precipitation; or by changing it chemically to a less objectionable form without actual separation, by employing complxing reactions, redox reactions, ...etc. For example, ferrous iron is adsorbed much less than ferric iron to a precipitate of barium sulphate. Therefore, in the determination Gravimetry 136 of barium by precipitation as barium sulphate, any iron present should be reduced before to the ferrous condition. 2. Digestion: Digestion, i.e. allowing the precipitate to stand in contact with the mother liquor for some time before filtration, is often an effective method in lowering the degree of contamination of crystalline precipitates. Several processes take place during digestion. a) A freshly-formed precipitate contains micro and macro crystals, the former are usually more soluble than the latter. This render the mother liquor supersaturated with respect to the larger crystals, and in order to establish equilibrium, additional material leave solution and enter the solid phase depositing on the large crystals, causing them to grow even larger. The impurities which were held by the micro crystals are not adsorbed appreciably by the large crystals. This process is called Ostwald ripening process. The net result is the disappearance of small impure crystals, and the growth of purer and more perfect larger crystals. b) Another process, internal ripening, brings about an internal perfection of the precipitate crystals. Thus, a freshly form Gravimetry 137 precipitate has a rather irregular form and contains many imperfections. On standing in contact with its mother liquor, ions from the lattice enter the body of solution and are replaced by ions from the solution. This is attributed to the fact that ions form the protruding point at the corners and edges of the crystal lattice dissolve more readily than others, while ions replacing them enter the recesses and ore vices in the lattice in an orderly fashion. The net result is a general perfection of the crystal lattice. During this time, occluded and adsorbed impurities may be expelled, and since the number of surface ions has decreased, the amount of readsorbed impurities decreases also, and a general purification of the precipitates. c) For coagulation colloidal precipitates, digestion -as a means of purification- is of little value due to the very large surface area contamination of the is rather precipitate of the particles, where surface-adsorbed the type. Moreover, the solubility of soft substances of low surface tension is independent of the particle size. Therefore the micro crystals will not dissolve to be replaced on larger crystals, leaving back their impurities. However, for some curdy precipitates, such as silver chloride, digestion causes a decrease in the total surface area and a corresponding decrease in the amount of contamination, but with no growth in size; except that the tiny Gravimetry 138 colloidal particles may form loose agglomerates by sharing their water jackets. d) For gelatinous precipitates, however, digestion is not recommenced, it may render the precipitate slimy and thus impairs its filterability. e) The stable form of the precipitate may be attained during digestion. Often, the precipitate first formed may be an allotropic modification of the saught- for precipitate. Such forms are often amorphous, and consequently impure or unfilterable. Being less stable, however, they have higher solubilities than the stable form during digestion. In the recrystallisation process, impurities are returned to the mother liquor, and the stable form is usually purer. f) Reprecipitation. In a reprecipitation, a sought-for precipitate is washed, dissolved in pure solution and repreprcipitated. This method is satisfactory in decreasing the surface-adsorbed and occluded impurities, it may also improve the purity of precipitates suffering from postprecipitation. During the second precipitation, the amount of contaminant adsorbed will be lower since its concentration in the solution is less. As a result, less will be enclosed within the crystalline structure of the precipitate Gravimetry 139 when it is again formed. But reprecipitation is of little value in dealing with contaminants carried precipitation or by isomorphic inclusion. by simultaneous Reprecipitation is also unsatisfactory whenever the contamination arises from the reagent used for precipitation process itself. g) Thus, contamination of hydroxides with basic salts formed during the precipitation process cannot be greatly reduced just by reprecipitation. h) Because reprecipitation requires much time and extra manipulation which increase the probability of error, and because the procedure is in application wherever no simple methods of dissolution are available, reprecipitation is not generally desirable. i) Washing. Washing a precipitate serves to remove surface adsorbed impurities, and impurities in the mother liquor held mechanically by the precipitate. Simple washing is ineffective for other kinds of contamination. Certain precautions must be taken in choosing a wash liquid : 1. It should not dissolve any considerable amount of the precipitate. 2. It should not peptize the precipitate. 3. It should neither metathesize the precipitate nor cause further Gravimetry precipitation of impurities. For example 140 MgNH4PO4 tends to hydrolyze to MgHPO4 when washed with water, and must be washed with dilute NH3 to prevent such hydrolysis. Hydrolysable metal salts, such as those of Fe3+ and Al3+, cannot simply be washed away from a sought-for precipitate with water, for they hydrolyze and contaminate the precipitate. Dilute nitric acid may be used to prevent such hydrolysis. Using several small portions of wash liquid are more effective than washing with few larger portions. Washing crystalline precipitate may be done with water, and if the precipitate is somewhat soluble, a saturated solution of the precipitate may be used as the wash liquid. Washing can also done with organic solvent, like alcohol and ether, if the precipitate can be dried at a low temperature. Coagulated colloidal precipitates require care in washing. Thus curdy precipitates with their large surface area are more liable to contamination than crystalline precipitates, and are therefore prone to peptization if washed with water. For this purpose, a solution of a strong electrolyte such as nitric acid is used for washing. The ions of the electrolyte replace the adsorbed contaminant ions, and at the same time prevent Gravimetry 141 peptization of the precipitate. The electrolyte chosen should be volatile so that it will be removed during subsequent drying or ignition of the precipitate. In case of gelatinous precipitates, made up of very small particles with huge surface area, the changes on the particles are controlled by the pH of the wash solution; and are usually ashed with an electrolyte solution such as ammonium nitrate. This prevents peptization of the precipitate, and the ions adsorbed are largely replaced by the volatile ions of ammonium nitrate. Organic precipitants Certain types of organic compounds produce precipitates with metal ions with a high degree of selectivity. The precipitates formed are usually crystalline and pure, they are easily filtered and washed, and contain a low metal ion to precipitate ratio. Furthermore, their selective action can often be improved by pH control and the use of masking. Most organic precipitants combine with cations to form chelate rings (non-ionic complexes). Other organic precipitants form salt-like precipitates with metal ions. 1. Precipitants forming chelate compounds: Most of the organic precipitants which form chelate compounds with cations, contain both an acidic and a basic Gravimetry 142 coordinating (electron-donating) functional group. The metal, interacting with both of these groups, becomes itself one member of a heterocyclic ring. From the strain theory of organic chemistry, it is expected that rings of this type would be mainly five- and six- membered. Hence, the acidic and basic functional groups in the organic molecule must be situated in positions with respect to each other which permit the closure of such rings. Insofar as the chalets are non-polar, they will have low solubility in water and high solubility in organic solvents. Chelating precipitants are weak acids: therefore in forming the insoluble complex salts, the usual equilibrium principles of ionisation constants and solubility product constants apply, for example, if: H.Chel represents the organic precipitant. Mn+ represents a cation of valence number “n” Then; H.Chel H+ + Chel- Ka = [H ][Chel ] and K a [H.Chel] Also; n.Chel- + Mn+ M [Chel]n and Ks = [Chel-]n [Mn+] The overall reaction can be represented thus: Gravimetry 143 n H.Chel + Mn+ nH+ + M(Chel)n A neutral chelate compound of the type M(Chel)n is essentially organic in nature. The metal ion becomes simply one of the members of an organic ring structure, and its usual properties and reactions are no longer readily demonstrable. The following are some of the acidic, and coordinating groups commonly found in organic chelating agents; note that the oxime group appears in both categories. Acidic groups Coordinating groups - COOH (carboxyl) -NH2 (amino) -OH (hydroxyl) -NO (nitroso) -NH (imine) =N- (cyclic nitrogen) = N-OH (oxime) = N-OH (oxime) -SO3H (sulphonic) = O (carbonyl oxygen) In order to form a chelate with a given organic precipitant, the metal ion must be of appropriate size, oxidation number, and coordination number. In many cases, the chelate compounds formed are suitable weighing forms for gravimetric analysis. When this is the case, the gravimetric factor for calculation to the metal is very favorable, because the metal constitutes only a small part of the heavy chelate molecule. If the precipitate is not a suitable weighing form, it can be ignited Gravimetry 144 to the metal oxide for weighing. 2. Precipitants forming salt-like compounds: Some organic precipitants produce slightly soluble salt-like compounds (rather than chalets) in which the bond with the species precipitated is primarily ionic in character. Sodium tetraphenylboron: This compound has the formula Na+B(C6H5)4- and is a specific precipitating agent for potassium and ammonium ions in cold mineral acid solution. Under these conditions, only mercuric mercury, rubidium, and cesium interfere, and must be removed before treatment. Benzidine. This compound is used primarily for the precipitation of sulphate ion from a slightly acid medium. Gravimetry 145 The solubility of the precipitate increases rapidly with temperature and with the acidity of the environment; both of these variables must be carefully controlled. The precipitate is a satisfactory weighing form. Substituted arsonic acids Substituted arsonic acids have the structure. Where, R is an organic group, especially phenyl, p-hydroxyphenyl, and n-propyl. These acids precipitate quadrivalent metal ions such as tin, thorium, and zirconium from acid media. The precipitate generally contains two moles of the acid per mole of quadrivalent cation. The nature of the organic portion of the molecule (R) determines, to some extent, the cations that form precipitates as well as the conditions under which they are formed. Because these precipitates are difficult to dry without decomposition, metallic aresonates are ignited to their respective oxides before weighing. Application of gravimetric analysis An important consideration in gravimetric analysis is the specificity of the reagent used for the formation of the precipitate. Ideally, a single element in the periodic table would precipitate with a given reagent under a given set of the Gravimetry 146 reaction conditions. In fact however, very few of the reactions available even approach such specific behavior. Most reagents, at best, are selective, i.e. they precipitate several ions at the same time. In some cases, improved selectivity can be obtained by oxidation or reduction of some of the ions present, by control of the pH of the solution, or by the use of masking agents. For example, the precipitation of chromic chromium along with ferric iron as hydroxides on the addition of ammonium hydroxide does not occur if the chromium is first oxidized to chromate. The use of pH control to increase the selectivity of metal sulphides and metal hydroxide precipitation is well known. Similarly, the precipitation of aluminium along with ferric iron as hydroxides can be prevented by increasing the pH of the solution to form aluminate. So also masking agents may be used to inhibit certain precipitations and enhance selectivity. Familiar examples are the use of tartaric acid to prevent the precipitation of iron as iron hydroxide and prevent precipitation of copper as hydroxide (in Fehling solution); and the use of ammonia to prevent the precipitation of chloride as silver chloride. Selected gravimetric methods Several specific determinations, in each of which the final quantitative measurement is that of weight, are discussed in Gravimetry 147 this chapter. One involves a quantitative separation by volatilisation, and each of the other includes a quantitative precipitation process. The determinations have been selected to encompass a variety of precipitates, procedures, and principles. Considerable emphasis is placed on a description sources of error; these are discussed in terms of the following requirements: 1. The unknown constituent must be precipitated quantitatively 2. The precipitate must be quantitatively pure or of known purity at the time of final measurement, and 3. The precipitate must be in a physical form suitable for subsequent handing. 1. Determination of chloride The determination of chloride as silver chloride involves all those operations necessary for precipitating a fairly insoluble, curdy precipitate which is easily washed free of impurities. The chloride content of a soluble salt can be determined by precipitation as silver salt. Ag+ + Cl- AgCl Gravimetry 148 The precipitate is collected in a filtering crucible, washed, and brought to constant weight by drying at 110oC. Completeness of precipitation: The solubility of silver chloride increases on heating, therefore the precipitate should always be washed and filtered at room temperature. A slight excess of silver nitrate should be added to reduce the solubility of silver chloride (common ion effect). A dilute nitric acid medium is required to hasten and to maintain flocculation any solubility loses. Cations which form soluble chloro- complexes, e.g. mercuric ions which give soluble HgCl42, should be removed prior to precipitation. Purity of the precipitate; The specificity of the precipitating agent for chloride ion is much improved in the presence of nitric acid. Most of the anions of weak acids, e.g. phosphate, carbonate, ..etc., which form insoluble silver salts in neutral medium only, will not, interfere. However, even in dilute nitric acid, bromide, iodide, and thiocyanate ions still yield insoluble precipitates with silver ions, and these ions must be removed beforehand. Cations which hydrolyse on boiling the solution to give insoluble oxychlorides, e.g. bismuth, antimony, and ferric ions: Gravimetry 149 Bi3+ + H2O + Cl 2 H+ + BiOCl must be removed in advance. It is apparent from the above hydrolytic equilibrium equation that hydrogen ion (in the form of nitric acid in this case) would displace the eqilibrium system by dissolving the insoluble oxychloride. But this needs high concentration of acid and would introduce error through oxidation of the chloride ion: 2Cl- + 2 NO3- + 4 H+ Cl2 + 2 NO2 + 2 H2O Silver halides are decomposed into their constituent elements on exposure to light specially during the early stages of the precipitation when the milky suspension presents an enormous surface for photochemical reaction. The mechanism of this decomposition is apparently complex, but may be represented for simplicity as follows: 2 AgCl 2 Ag + Cl2 The precipitate acquires a violet colour due to the accumulation of finely divided silver. Agents which reduce silver salts into metallic silver, e.g. Gravimetry 150 formation, sulphur dioxide, reducing ions, etc., must be absent. Filtration: The precipitate should be filtered through filter crucibles. If filter paper is used, it will largely reduce the precipitate adhering to it during heating in the drying operation. In such a case, the filter paper is burnt, the ash treated with nitric acid to dissolve any reduced silver, then hydrochloric acid is added to convert it back to silver chloride. Washing and drying: To suppress peptization, the precipitate is washed with a volatilisable electrolyte, e.g. very dilute nitric acid. the precipitate may finally be washed with ethanol to remove much of the water and, being more volatile than water, assists in the drying process. However, the precipitate should not be dried rapidly, otherwise it would shrink and trap water that cannot be completely removed except on heating to melting point of the precipitate, but then decomposition begins. 2. Determination of Iron The gravimetric determination of iron is almost invariably made by oxidising it (if necessary) to the ferric state, and precipitating it with ammonia as ferric hydroxide, filtered on paper, washed Gravimetry 151 again dried, and ignited to the oxide and weighed: 2 Fe3+ + 6 NH3 + (x+3) H2O Fe2O3 . x H2O + 6NH4+ Fe2O3 . x H2O Fe2O3 + H2O Completeness of precipitation: The precipitation of iron as hydrous ferric oxide is not complete if the iron is not entirely in the ferric state at the time of precipitation. Any ferrous iron must be oxidised beforehand, by means of bromine, or nitric acid, or hydrogen peroxide. 2Fe2+ + Br2 2 Fe3+ + 2 Br- 3 Fe2+ + NO3- + 4 H+ 3 Fe3+ + NO + 2 H2O 2 Fe2+ + H2O2 + 2 H+ 2Fe3+ + 2 H2O The latter oxidant is preferable, because its reduction product is water, and because any excess peroxide easily decomposes by boiling the solution briefly. 2 H2O2 2 H2O + O2 The primary particles of the precipitate are extremely minute, and their enormous surface development is conductive to extensive contamination by adsorption. Gravimetry 152 Purity of the precipitate: Nearly every metallic ion other than alkali metal ions can form a hydroxide, hydrous oxide, or basic salt in alkaline solution, and so all may interfere and impair the purity of the precipitate of ferric hydroxide. Careful control of the hydroxyl ion concentration is necessary to provide the required selectivity. Buffers , as well as weak bases (as the may be ) are to be used in limiting the hydroxyl ion concentration to the predetermined value; through complications often ensure by momentary local excesses of hydroxyl ions where the drops of added reagent enter the solution inn the precipitation vessel. This particular source of difficulty is eliminated in the method of precipitation from homogeneous solution. Dispositive ions such as Zn3+ and Cu2+ which form soluble amino complexes, nevertheless, cause serious interference. Thus during the precipitation process, when the ammonia concentration is low, the hydroxide, which obstructs them from the solvent action of excess ammonia, and even if these hydroxides are completely r-dissolved, the amino complexation (M(NH3)4)2+ are quite strongly adsorbed on and carried down with the iron hydroxide in alkaline solution. Tri- and tetra-positive cations such as Al3+, Cr3+ and Mn4+ are Gravimetry 153 precipitated as their hydrous oxides along with the ferric iron. Although Mn2+ is not quantitatively precipitated by ammonia in presence of high concentration of ammonium ion, yet Mn2+ in the original solution is oxidised along with ferrous iron if bromine is used as the oxidising agent, and is quite easily air-oxidised and precipitated as Mn4+ hydrous oxide in the alkaline solution. therefore, these cations must be removed before precipitating iron in the course of its gravimetric determination. Repecipitation is often necessary in order to obtain proper precipitate of ferric hydroxide. But if the precipitate is highly impure, it is preferable to use a fairly specific or organic precipitant. Filtration and washing: Ferric hydroxide as all gelatinous precipitates, retains within the solid phase a quantity of the mother liquor. The precipitate tends to clog the pores of the filter and therefore filter crucibles cannot be used for filtration. A coarse filter paper should be employed, and nearly all of the washing operation should be accomplished in the precipitation vessel by decantation prior to transfer of the main body of precipitate to the filter. Filter paper can be added to the solution and upon which the Gravimetry 154 precipitate gathers, as a means to effectively increase the bulkiness and consequently the ease of handling this gelatinous precipitate. As wash liquid, a hot dilute solution of an electrolyte such as ammonium nitrate is generally used, the electrolyte serving to prevent peptization. After transferring the precipitate to the filter, washing must be continued without interruption. If the gelatinous precipitate is allowed to dry, it shrinks and cracks in the paper, and any wash liquid poured on such a precipitate runs through the channels and does not accomplish much in washing out the soluble impurities. Upon drying the precipitate, a high temperature must be used to remove all traces of water. A final ignition temperature of about 1000oC. is suitable. If this temperature is exceeded, some of the ferric oxide may be reduced to the magnetic oxide by loss of oxygen. red . 6Fe2O3 O2 + 4 Fe3O4 Reduction of the ferric oxide to magnetic iron or even to metallic iron may occur by the carbon of the filter paper, or by the reducing gases from the flame if allowed to envelop the crucible containing the precipitate during ignition. Gravimetry 155 Another source of error occurs if the precipitate contains much ammonium chloride if the latter has been used incorrectly as wash liquid, whereby ferric chloride may form and volatilise during ignition; Fe(OH)2 + 3 NH4Cl 3 NH2 + 3 H2O + FeCl3 But if ammonium nitrate has been used as the wash liquid, no such error occurs, because the ferric nitrate formed will decompose on ignition giving ferric oxide: 4 Fe(NO2)3 12 NO2 + 2 Fe2O3 + 3 O2 3. Determination of Aluminium. This is another gelatinous precipitate; aluminium is precipitated as its hydrous oxide and ignited to the oxide. It is subject to the same coprecipitation errors that were discussed under the precipitation of iron. However, the separation of aluminium is complicated by the fast that aluminium hydroxide is amphoteric which limits the pH range over which it may be completely precipitated. The precipitation of aluminum hydroxide begins at pH of about 3 and is complete near the neutral point,, but is re-dissolve at a pH of about 9. Gravimetry 156 Aluminium hydroxide ionises as either a base or an acid: Al(OH)3 Al3+ + 3OHAl(OH)3 H+ + H2AlO3Consequently, aluminium hydroxide dissolves in strong acid, and in excess alkali. There is some pH at which aluminium solubility; this isoelectric point, as calculated from the above two equations, is pH 5.3. Two washed precipitate is dried, and ignited briefly above 1200oC to expel moisture completely, and to convert it to a different crystal modification which is not hygroscopic. Aluminium may also be quantitatively precipitated by oxime (8-hydroxy quinoline) from an acetic acid-acetate buffer solution. The precipitate is crystalline, little contaminated by adsorption of other ions from solution, and is easy to filter and wash. The precipitate is suitable form weighing as such, after oven-drying at about 130oC. If the aluminium solution contains cations that precipitate under the condition of experiment, it is advisable to separate the aluminum of the experiment, it is advisable to separate the Gravimetry 157 aluminum by precipitation. Thus, if cations of nickel, cobalt, manganese, zinc, magnesium, etc. are present, the solution is first neutralised, and then reacted with ammonium acetate and boiled. Aluminum precipitates as the basic acetate, Al(OH)2(CH2COO), which is filtered, washed, dissolved in acid, and then precipitated from the now pure solution as hydroxide. On the other hand, if the interfering ions are alkaline earth ions, the aluminum solution is treated with acetic acid and phosphoric acid in order to precipitate the aluminum phosphate AlPO3. This is filtered, washed, dissolved in acid and precipitated as above. 4. Determination of sulphate. Sulphate ion solution is determined by precipitation with barium chloride from a hot solution slightly acidified with hydrochloric acid. The precipitate is digested, washed, ignited and weighed. The determination centers on the reaction: Ba2+ + SO42- BaSO4 Barium sulphate is classified as a crystalline precipitate, the individual crystals are much larger than they are in a curdy precipitate such as silver chloride. Gravimetry 158 Completeness of precipitation. The solubility of barium sulphate at room temperature (about 3 mg. per liter) is sharply diminished by the presence of excess barium ion is the mother liquor; and is increased somewhat at elevated temperatures. Barium sulphate is markedly more soluble in acid media than in pure water. The second ionisation of sulphuric acid is slight, K s = 3 x 10-2 ; hence hydrogen ion can lower the sulphate ion concentration to some extent and thus increase the solubility of barium sulphate: BaSO4 + H+ Ba2+ + HSO4By precipitating barium sulphate in hot dilute solution and in the presence of some hydrochloric acid, the relative supersaturation is decreased somewhat, so that a better precipitate is obtained., The acidity contributes to the purity of the precipitate as will be shown. Purity of the precipirtate: Barium ion forms insoluble precipitates with a variety of anions other than sulphate ion, including carbonate, phosphate, Gravimetry 159 chromate, arsenate, oxalate, etc. which simultaneously precipitate with the sulphate. Yet most of them are anions of weak acids so that their barium salts are soluble in acid media. The only anion which remains insoluble under these conditions (of acidity) is the fluoride ion, it is removed by volatilisation as hydrofluoric acid, or by complexation with boric acid. Some anions, such as nitrate and chlorate, are coprecipitated as their barium salts to such an extent as to introduce very large errors. Nitrate and/or chlorate in the original sample can be removed by repeated evaporation with hydrochloric acid: 2 NO3- + ClO3- 6 Cl- + 8 H+ 2 NO + 3 Cl2 + 4 H2O + 5 Cl- + 6 H+ 3 Cl2 + 3 H2O The more common cations which simultaneously precipitate as sulphate along with barium sulphate, are lead, calcium, and strontium. Lead may be removed by complexation with acetate, while calcium and strontium are removed by fusing the sample with sodium carbonate. The melt is extracted with water, and the calcium and strontium (now present as insoluble carbonates) are removed by filtration. The filtarte, containing the pure sulphate, is acidified boiled to remove carbon dioxide prior to precipitation as barium sulphate. Gravimetry 160 Several heavy metals, whose sulphate are soluble, tend to coprecipitate with barium sulphate; the higher the oxidation number of the cation, the greater the coprecipitation. Metallic reducing agents will reduce the oxidation number of many cations such as ferric iron; and will also remove cations of inactive elements such as copper, antimony by reducing them to the elemental state. Alkali metals may also coprecipitate as sulphate along with the barium sulphate. Ammonium salts, if coprecipitated, cause serious error and must be removed before precipitating barium sulphate. The removal is done by evaporation with nitric acid: NH4+ + NO3- N2O + 2 H2O then the nitrate ion is removed by evaporation with hydrochloric acid. Barium sulphates not sufficiently soluble in any reagent to permit dissolution and reprecipitation as a means of decreasing contamination. The behavior on ignition of substances coprecipitated with barium sulphate and their influence on the results of analysis are mentioned in the following. The coprecipitation of anions as nitrate and chlorate leads to Gravimetry 161 positive error, i.e. high result. Thus, barium nitrate ignites to the oxide, and barium chlorate ignites to chloride, and these residues add to the weight of the barium sulphate. The coprecipitation of cations leads to either positive or negative errors. Thus, coprecipitation of ammonium sulphate gives negative error, because of the complete volatilisation on ignition: (NH4)2SO4 2 NH3 + SO3 + H2O The coprecipitated sulphates of heavy metals undergo decomposition during ignition, losing sulphur trioxide and leaving a residue of the metal oxide. Whether the error is negative or positive depends upon the relative weights of the sulphur trioxide volatillised and of the metal oxide remaining as residue. Of the cations commonly encountered ferric iron is noteworthy. In this case, the precipitate is partially ferric sulphate which is decomposed upon ignition to ferric oxide. Each sulphate ion should account for one barium sulphate molecule (molecular weight 233) in the final precipitate, but since each sulphate ion involved in the coprecipitation of iron accounts for only one third of a ferric oxide molecule (molecular weight 159.69, one third being only 53.23), the precipitate is too light, and the result for sulphate comes out Gravimetry 162 low; i.e., the error is negative. Coprecipitation of other cations leads to a similar conclusion weighs less than the barium ion itself, and vice versa. Physical form of the precipitate: Although barium sulphate is crystalline precipitate, yet it exhibits a tendency to “creep”, i.e. the fine clumps of precipitate, supported on a liquid surface and moving over it through the action of surface tension, distribute over the entire wetted surface of the containing vessel, even surfaces are wet. Thus, the particles of the precipitate can climb up a wetted filter paper into the side of the glass funnel, if the latter is wet, and may be lost. In such cases, the filter paper must be filled to the rim. Digestion helps decrease creeping of the precipitate. To remove moisture completely from the washed dried barium sulphate precipitate, it must be ignited at a temperature of 500oC. or above. The barium sulphate itself is stable well above this temperature, but if oxidising conditions to hot prevail during ignition, it may be reduced by the carbon of the filter paper or by the carbon monoxide of the flame if the latter completely envelops the precipitate: Gravimetry 163 BaSO4 + 2 C BaS + 2 CO2 BaSO4 + 4 CO BaS + 4 CO2 If reduction occurs, the results are too low, but the error can be corrected either by heating with good access air: BaS + 2 O2 BaSO4 or by moistening the residue with one or two drops of concentrated sulphuric acid: BaS + H2SO4 BaSO4 + H2S Volatilisation of the excess sulpuric acid must be done very carefully to avoid loss by spattering; evaporation over a free flame will almost certainly result in mechanical loss, therefore use of a radiator or air bath is required. Applicability: Almost any form of sulphur can be determined by first converting it to sulphate and then precipitating as barium sulphate. Sulphur, sulphides, and sulphites are oxidised to sulphate; while peroxydisulphates (persulphates) are reduced to sulphate. Gravimetry 164 Of the official substances, cited in the Pharmacopoeias, the following are worth mentioning. Paromomycine sulphate, sodium sulphate and ichthammol. Ichthammol consists of the ammonium salts of certain sulphonic acids together with ammonium sulphate. It is analysed for both organically combined sulphur and for sulphate: a) For sulphate, the ichthammol sulphonic acids are removed by shaking with cupric chloride solution and filtrating off the precipitated cupric salts. The free sulphate, which is present in the filtrate, is determined by precipitating as barium sulphate. b) For organically combined sulphur, the ichthammol is heated with copper nitrate and sodium carbonate. The mixture is acidified with hydrochloric acid to convert the organically combined sulphur into sulphate; which is precipitated and determined as barium sulphate in the usual manner. From the percentage of total sulphur thus obtained, the percentage of sulphur in the form of sulphate is subtracted to give the percentage of the organically combined sulphur. Barium, strontium and lead may be determined by adding an Gravimetry 165 excess sulphate ion, just the reverse of the sulphate procedure. Coprecipitation errors again may be serious; anion coprecipitation leads to low results, and cation coprecipitation gives high results- just opposite to the situation in sulphate determinations. The solubilities of strontium and lead sulphates are too great for good quantitative work, but are rendered less soluble in a mixed solvent of alcohol and water. 5. Determination of calcium. Calcium ion is precipitated as the oxalate monohydrate and weighed as such: Ca2+ + C2O42- + H2O Ca2C2O4. H2O Other weighing forms are the carbonate, the oxide (obtained by heating the oxalate to the proper temperature) or the sulphate. The latter is obtained by treating the oxalate with sulphuric acid, and igniting to convert it into calcium sulphate: CaC2O4. H2O + H2SO4 CaSO4 + CO + CO2 + 2 H2O Calcium oxalate is soluble in strong acids, due to lowering of the oxalate ion concentration by formation of bioxalate ion, HC2O4-. Calculations from Ksp of calcium oxalate and K2 of Gravimetry 166 oxalic acid show that the solubility of calcium oxalate in solution of pH 5 or 4 is only slightly greater than in neutral solution. The solubility in slightly acidic solution is decreased by the common ion effect of excess precipitant. Most of the common metals, except the alkali metals, form sparingly soluble oxalates and must be removed before the calcium is precipitated. Magnesium oxalate, however, is only moderately soluble in water, and tends to form stable supersaturated solutions. the solubility of magnesium oxalate is increased by adding excess of oxalate ion, due to formation of oxalate decreases the solubility of calcium oxalate, due to the common ion effect. Use in made of the above two properties of calcium oxalate in the precipitation process to obtain crystalline, large particles precipitate without digestion (which would increases the danger of post precipitation of magnesium oxalate). Thus, the solution of the sample of calcium salt is acidified with hydrochloric acid, heated, and ammonium oxalate is added. The acidity, which prevents the precipitation of calcium oxalate, is neutralised homogeneously by adding an excess of urea which undergoes slow hydrolysis, and the ammonia liberated reacts with the bi-oxalate ion and thereby increases the oxalate ion concentration and effecting precipitation of Gravimetry 167 the calcium oxalate. The precipitate is digested for an hour, then filtered promptly. Longer digestion may result in considerable contamination by postprecipitation of magnesium oxalate. The precipitate is washed with electrolyte solution, e.g. ammonium oxalate, then dried at about 100 oC., to remove the moisture. Then the filter paper is charred, and ignited till all the carbon has been burnt off. The cold residue is moistened with a mixture of sulphuric acid and ethanol, heated, to remove the acid; and the process is repeated until constant weight is attained. 6. Determination of magnesium The determination depends upon the addition of phosphate ions and ammonia to precipitate the magnesium ions as crystalline hydrated magnesium ammonium phosphate which is then ignited to the pyrophosphate and weighed: Mg2+ + NH4+ + PO43- + 6 H2O MgNH4PO4. 6H2O 2MgNH4PO4. 6H2O Mg2P2O7 + 2NH3 + 13 H2O Precipitation is carried out at room temperature. The precipitate is fairly soluble in water, but much less so in the presence of ammonia. It forms slowly and therefore the Gravimetry 168 precipitate must be allowed to stand for several hours before filtration. There is a tendency for the precipitate to be contaminated with other phosphates if much potassium, sodium, or ammonia ions are present in solution, e.g. MgKPO4, MgNaPO4, and Mg3(PO4)2 all of which are unchanged on ignition thus leading to negative error; and Mg(NH4)4(PO4)2 which gives magnesium metaphosphate on ignition leading to high results: Mg(NH4)4(PO4)2 Mg(PO3)2 + 4 NH3 + 2 H2O Therefore, the excess ammonium salts must be removed before precipitation of the magnesium. Reprecipitation may also be resorted to, especially if excess potassium and sodium ions are also present. The magnesium ammonium phosphate is allowed to stand with the mother liquor several hours in the cold, filtered and washed with cold dilute ammonium hydroxide to minimise solubility loss, and dried. The filter paper is charred, and burned off at the lowest possible temperature until all carbon is destroyed. The precipitate is then ignited at about 1000oC, to convert it to the weighing form; magnesium pyrophosphate. Prolonged heating at 1200oC results in slow loss of phosphorus pentoxide. The ignited precipitate is not hygroscopic, and offers no difficulty in Gravimetry 169 weighing. Magnesium may also be determined by precipitation with oxime (8-hydroxyquinoline). The precipitate forms rapidly in ammonical medium; contamination by coprecipitation of other inorganic components of the solution is negligible, through some of the reagent may be coprecipitated. Weighing can be made of the dihydrate, Mg(C3H5OH)2. 2H2O, after ovendrying at 105oC. It is usually better to dry at about 140oC to remove all the water of hydration as well as any coprecipitated reagent. 7. Analysis of mixture A) Analysis of mixture of magnesium and calcium: The calcium is precipitated as oxalate, using excess oxalate to keep the magnesium in solution. The calcium oxalate is filtered rapidly, reprecipitated, and determined as explained. The filtrate, containing the magnesium oxalate complex, is treated with nitric acid to oxidise the excess oxalate: C2O42- + 2 NO3- + 4 H+ 2 CO2 + 2 H2O + 2 NO2 The magnesium is then determined as the pyroposphate, or as the oxinate. Gravimetry 170 B) Analysis of mixture of aluminum and magnesium Aluminium can be precipitated with 8-hydroxyquinoline from acetic acid- acetate buffer mixture; leaving magnesium in solution. From solution countering alkali tartrate to complex the aluminium, magnesium is precipitated as the quinolinate from sodium hydroxide solution. C) Analysis of mixture of aluminium and iron: The iron is oxidised to the ferric state, then sodium hydroxide is added in excess to precipitate iron as ferric hydroxide and convert aluiminium into soluble aluminate, AlO2-. The precipitate is filtered, washed, dissolved in nitric acid and reprecipitated to obtain a purer precipitate of ferric hydroxide and determined as under iron. The filtrate is acidified, and the resulting aluminium salt is determined. D) Analysis of mixture of iron and chromium: The iron is first oxidised to the ferric state, and the chromium is oxidised to the chromate state with sodium peroxide. The precipitated reprecipitated ferric hydroxide before being is filtered, determined. washed, The and filtrate, containing the chromate, is acidified with acetic acid, and treated with barium chloride. the precipitated barium chromate is filtered, washed, dried, and weighed. Gravimetry 171