SHY 145 MAT - Sivil Havacılık Genel Müdürlüğü

advertisement

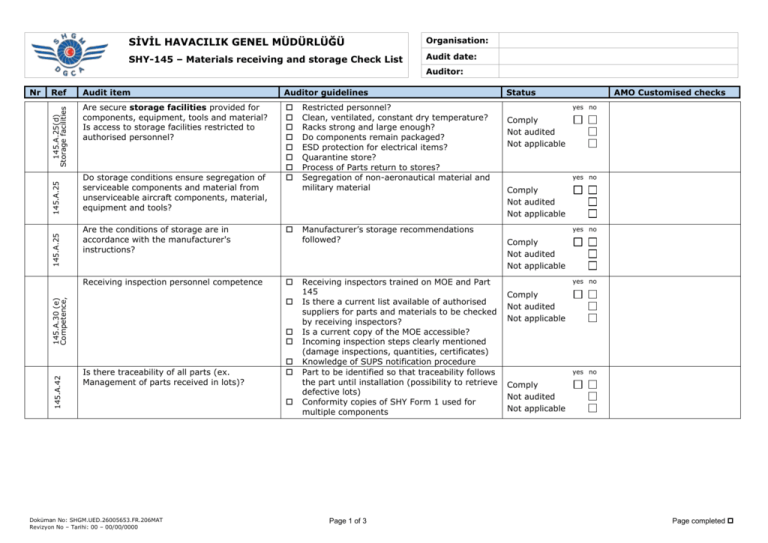

SİVİL HAVACILIK GENEL MÜDÜRLÜĞÜ Organisation: SHY-145 – Materials receiving and storage Check List Audit date: Auditor: Ref Audit item Auditor guidelines Are secure storage facilities provided for components, equipment, tools and material? Is access to storage facilities restricted to authorised personnel? Do storage conditions ensure segregation of serviceable components and material from unserviceable aircraft components, material, equipment and tools? Are the conditions of storage are in accordance with the manufacturer's instructions? Receiving inspection personnel competence 145.A.42 145.A.30 (e) Competence, 145.A.25 145.A.25 145.A.25(d) Storage facilities Nr Is there traceability of all parts (ex. Management of parts received in lots)? Doküman No: SHGM.UED.26005653.FR.206MAT Revizyon No – Tarihi: 00 – 00/00/0000 Restricted personnel? Clean, ventilated, constant dry temperature? Racks strong and large enough? Do components remain packaged? ESD protection for electrical items? Quarantine store? Process of Parts return to stores? Segregation of non-aeronautical material and military material Manufacturer’s storage recommendations followed? Receiving inspectors trained on MOE and Part 145 Is there a current list available of authorised suppliers for parts and materials to be checked by receiving inspectors? Is a current copy of the MOE accessible? Incoming inspection steps clearly mentioned (damage inspections, quantities, certificates) Knowledge of SUPS notification procedure Part to be identified so that traceability follows the part until installation (possibility to retrieve defective lots) Conformity copies of SHY Form 1 used for multiple components Page 1 of 3 Status AMO Customised checks yes no Comply Not audited Not applicable yes no Comply Not audited Not applicable yes no Comply Not audited Not applicable yes no Comply Not audited Not applicable yes no Comply Not audited Not applicable Page completed SİVİL HAVACILIK GENEL MÜDÜRLÜĞÜ Organisation: SHY-145 – Materials receiving and storage Check List Audit date: Auditor: Nr Ref Audit item Auditor guidelines Acceptance of Components. Are all components classified? 145.A.42 (a) 145.A.42 Information system for materials management Doküman No: SHGM.UED.26005653.FR.206MAT Revizyon No – Tarihi: 00 – 00/00/0000 Is receiving inspection formalised (serviceable tag) Is SHY Form 1 accompanying the items Verify that aircraft parts (bolts etc.) are received with an SHY Form 1 Is there an understanding on the alternatives to SHY Form 1s? Components classified/segregated as serviceable, unserviceable, unsalvageable, standard parts, raw and consumable materials Receiving inspection of life limited parts (back to birth traceability available, installation on different a/c type where relevant) System in place for receiving inspection of ESD components (ESD bracelets tested before use) Fasteners accompanied by records confirming integrity (chemical/physical properties) Availability of flammability test reports where applicable System to avoid Incoming parts from military or subjected to extreme stress/heat Check alternate PP/NN information iaw approved data System in place to printout list of expired materials and to segregate it from serviceable Sample cross check PP/NN and quantities and location of parts Page 2 of 3 Status AMO Customised checks yes no Comply Not audited Not applicable yes no Comply Not audited Not applicable Page completed SİVİL HAVACILIK GENEL MÜDÜRLÜĞÜ Organisation: SHY-145 – Materials receiving and storage Check List Audit date: Auditor: Nr Ref Audit item Auditor guidelines Storage racks sample inspection 145.A.42 Doküman No: SHGM.UED.26005653.FR.206MAT Revizyon No – Tarihi: 00 – 00/00/0000 Can each part, carton or package be linked to its certification and/or test records by some unique identifier Is batch segregation utilized for aircraft fasteners, materials requiring flammability testing, and other material requiring batch control. Inspect aircraft components for proper documentation Standard parts for proper documentation Aircraft components stored with plags and caps where applicable standard parts (cross check quantities in the envelope with system) Sample check of tyres stores (lighting system, manufacturer recommendations followed) Sample check of consumables materials for expiration date and temperature conditions (orings, sealants) Systems in place to store components requiring very low temperatures (prepreg material) – records of cycles outside the fridge Page 3 of 3 Status AMO Customised checks yes no Comply Not audited Not applicable Page completed