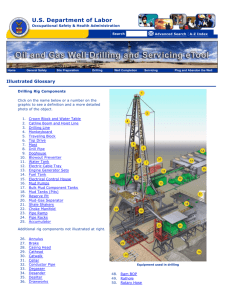

How the hole is drilled

advertisement

How the hole is drilled The hole for an oil well commence when the 20 inches or plus diameter surface hole is drilled. The bottom hole assembly (made up of drill pipes and drill collars with the bit) is attached to the kelly. The rotary table drives the kelly and hence the drilling bit the bottom is rotated. Surface hole is drilled until reaching the bedrock. Then the conductor pipe or the first casing is installed within the hole. Casing is very expensive. During running in casings, the drilling operation has to be stopped. Careful planning has to be done before running in the casings. Before running in casings, the drilling mud should be suitable in keeping in the bottom hole pressure. The thickness of the steel for casing should be appropriate so that certain logging operation can be carried out. 1 The casing is run in from the top of the hole. The purpose of the casing is to isolated the production zones. Casing and cementing The general functions of all casing strings are: 1. To furnish a permanent borehole of precisely known diameter through which subsequent drilling, completion and producing operations may be conducted. 2. To allow segregation of formations behind the pipe, which prevents interformational flow and permits production from a specific zone. 3. To afford a mean of attaching the necessary surface valves and connections to control and handle the produced fluids. The main purpose of primary cementing is as in (2) above, other purposes are: 1. To afford additional support for the casing, either by physical bracing or prevention of formation pressures being imposed on the pipe. 2 2. To retard corrosion by minimizing contact between the pipe and corrosive formation waters. Casing types and specifications Surface casings In hard rock areas, a single string of surface pipe set a few hundred feet deep is usually adequate to: 1. control caving and washing out of poorly consolidated surface beds 2. furnish a mean of handling the return follow of drilling mud. 3. protect fresh water sands from possible contamination by drilling mud, or oil, gas, and/or salt water from lower zones. 4. Allow attachment of blowout preventer. In soft rock areas, it is often necessary to set both a conductor string and a surface string to perform these functions. In such instances, the conductor pipe may be two 3 or three hundred feet long with the surface pipe extending to depth of two or three thousand feet. Intermediate casings The decision to use intermediate string is largely dependent on well depth and geologic conditions in a specific area. Wells of moderate depth may use no intermediate pipe, while deep wells may require one or more protective strings. The principal functions of the intermediate casins is to seal off troublesome zones which 1. contaminate the drilling fluid, making mud control difficult and expensive (salt, gypsum, heaving shales etc.) 2. jeopardize drilling progress with possible pipe sticking, excessive hole enlargement, or other fishing hazards. 4 Oil Strings or Production casings This is the last and deepest casing string run. It is set above, part way through, or completely through the lowermost pay zone, depending on the type of completion to be performed. It furnishes the means of segregating the pay section from all other zones and is the work shaft through which access to the producing zone is gained. Normally, the produced fluids flow through tubing; sometimes, however, the oil string may actually serve as the flow conduit. Cementing operation The casing has to be cemented to the well bore. The technique used is by pumping the cement through the casing into the annulus (the space between the casing and the wall of the borehole). The amount of cement to be calculated before the cementing begins, based on the size of the hole and the size 5 of the casing. Logs may be run prior to cementing to determine if the hole is in gauge. Also prior to the cementing operation, the cement is tested to determine how much time is available for pumping before the cement begins to set compressive strength. In any operation the hole is always filled with drilling mud. Even when casing is being run in. When the casing is run in and set in place at the top of the hole, the top of the casing is connected to the pump. A bottom plug is inserted into the casing, then the pump will pump cement behind the bottom plug. When enough cement (has been calculated) has been pumped, the top plug is inserted. The top plug is being pushed into the casing by pumping drilling mud. 6 When the bottom plug hit the float shoe of the casing, pressure will increase due to the continuous pumping of the drilling mud. It will come to a stage when the diaphragm of the bottom plug will break and through the shoe, the cement is pushed into the annular. The top plug will hit the bottom plug when the pumping pressure increases. Pumping will cease and the wellhead is secured while waiting-on cement (WOC) to set. 7 Fishing Operation The term fishing applies to all operation concerned with the retrieving of equipment or other objects from the hole. Portion of the drill string, bit, drill string accessories and inadvertently dropped hand tools are typical items which may require fishing. Stuck pipe Many fishing jobs start with the drill pipe becoming stuck during a trip. Some of the causes of stuck pipe are i. foreign objects or junk in the hole ii. sloughing formations (heaving shales, etc) iii. bit and drill collar balling iv. pressure diffrential sticking v. cuttings settling above the bit or drill collars All of the above are quite obvious except (iv) which requires further clarification. 8 Fishing tools i. Overshot tools: slip over the outside of the object and pull. ii. Tapered tap: the tap is run into the fish and rotated until sufficient threads are cut for a firm hold. iii. Spears: these devices pass inside the fish, grasping its inner wall with expanding slops, which can be set or released by rotating the pipe. iv. Washover pipe: this is a section of pipe having sufficient inside diameter to telescope outside the fish. v. Inside and outside cutters: 9