FIIO Color shift diagnosis_Tubing Flush and INK LOW

advertisement

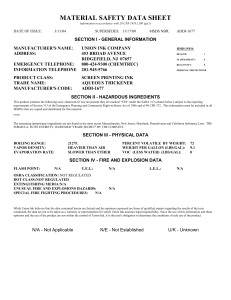

Falcon II Outdoor color shift Diagnosing and Correcting the 'wicking' or mixed inks issue The problem could be presented in this way: We have a color shift in one of the heads. By that I mean, bay 3 is wicking ink from bay 4. I have run all of the proper tests and procedures (nozzle check/ 2X powerful clean) and the problem persists. What is wrong with our machine? Is there some other process that I can do? There are two possible issues of which you should be aware; Fact: Ink can only ‘mix’ as the head sits on the capping unit. 1) Ink can sit in the capping unit for a prolonged period and allow one color to wick up into the other color in the same printhead. New firmware will perform a flush of the waste system just prior to 'shut down’ or whenever you will not be using the printer for 10 min at a time. This process will rinse out the capping unit, pumps and waste tubing so that solvent waste doesn't sit in those parts. The new firmware will add a menu item that you may select at anytime but it will perform this process just before shutdown. The new process is called 'Tubing Flush', takes just a few seconds to perform and does NOT use any more ink than the printer currently uses. 2) The second issue has been mentioned briefly and is related to the two colors that are in the same printhead. Fact: The INK STATUS menu works for you only if you never remove a cartridge unless you are replacing it. The counter is reset to 100 each time you remove a cartridge so if you remove a partial cartridge and replace it in the printer there is no way to tell how much ink is actually in the cartridge until the INK LOW (Near End) indicator pops out with approximately 6 to 9 percent ink left. Pair up the Colors in the check nozzle pattern to see which colors are in the same Printheads. From right to left the K8YCMMCYK1 are actually cartridges in the opposite order K1YCMMCYK8. Whenever the printer displays the INK LOW (Near End) message it includes a number which indicates the cartridge that is low. INK LOW 2 would be the second cartridge from the left. What is important is that when the INK LOW 2 is displayed, ink cartridge 1 needs to be checked to insure that it is also not ‘Near End’. When the INK LOW 2 message is displayed check the INK STATUS menu to see how much ink is left in cartridge 1 since it shares the same capping position as #2. If #1 is also in the low teens or single digit percentage then that cartridge should be replaced at the same time as #2. If it is a higher percentage in the high teens or higher then it could be left in until such time as it displays INK LOW 1. We have found that customers who do not watch the 'pairs' will experience 'mixed' colors on a frequent basis. This simply wastes ink and should be avoided. Once inks are mixed it is important that you: Update your firmware to version 2.08 immediately. It might be possible to perform 2 Powerful cleanings back to back to clean out the ‘mixed colors’. It may be required to perform an INK LOAD in order to flush out the mixed inks from the other ink color circuit. 106749046