Supplementary data Journal title: Journal of Radioanalytical and

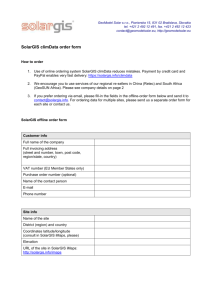

advertisement

Supplementary data Journal title: Journal of Radioanalytical and Nuclear Chemistry Article Title: Reactor production of 32P for medical applications: A comparative assessment of 32S(n,p)32P and 31P(n,)32P methods K.V. Vimalnath, Priyalata Shetty, A. Rajeswari, Viju Chirayil, Sudipta Chakraborty, Ashutosh Dash* Isotope Applications & Radiopharmaceuticals Division, Bhabha Atomic Research Centre, Trombay, Mumbai, India 400 085. *Corresponding Author: adash@barc.gov.in Materials and Methods Irradiated target processing facility Processing of the neutron irradiated target was carried out in a leak tight isotope processing facility consisting of stainless steel boxes [ 1.8 ×1.8 × 0.9 m3] with 100 mm lead shielding wall all-around and equipped with remote handling tongs, lead viewing windows and other associated remote accessories. Movement of material and equipment throughout the facility was carried out by an electric motor powered trolley mounted on stainless steel rail. The trolley runs through the entire length of the box and ends at a tunnel. In order to simplify operation in a remotely operated shielded facility, gadgets such as irradiation can cutting unit, remote vial crimping and decrimping etc. were specially made and installed inside the shielded facility. Equipments inside the cell were manipulated with remote handling tongs. All operations were performed according to prescribed radioactive work procedure in a shielded facility. All processing equipments including quartz distillation assembly for the distillation of neutron irradiated sulfur, receiver, ion exchange column, evaporating flask and storage container, were designed and fabricated in house and installed inside the shielded facility. Experimental Radiological safety In view of radioactive nature of 32 P safe and approved radioactive procedures were adopted during the irradiated target processing procedures. All the plant operations were carried out after thorough planning in order to achieve ‘ALARA’. The personnel involved in this work were monitored for radiation exposure levels by TLD dosimeters. Continuous air sampling of work area was performed to monitor levels of airborne radioactivity and to maintain safe levels of radiological safety. Results 32S(n,p)32P production process Target Natural S atom consists of 32S (95.02%), 33S (0.75%), 34S (4.21%) and 36S (0.02%). When sulfur undergoes irradiation in a reactor, it is imperative to consider all the radionuclides produced both by thermal and fast neutrons. Table S1 depicts the nuclear reactions taking place when natural sulfur undergoes irradiation with thermal and fast neutrons in a nuclear reactor. It is seen from the Table. S1 that among all the possible radionuclides formed by natural S neutron irradiation, only 35 S (T1/2 = 87.2 d) and 33 P (T1/2 = 25.3 d) are of concern and could be radiochemical impurities of the final product 32P (T1/2 = 14.28 d). Concern due to 35S is least as it will remain with cold S during chemical separation. The contribution 33P is a point of concern as it is neither possible to separate nor feasible to reduce by cooling owing to its longer half life than 32 P. Experimentally it was observed that the ratio between the 32 P and 33 P activities produced in the same irradiation conditions is about 7000, because the much lower isotopic abundance and poor fast neutron cross section of 33S target as well as longer half life of 33P. Processing of neutron irradiated sulfur In view of the need to isolate 32 P formed during the neutron irradiation of target, radiochemical processing of irradiated sulfur target is necessary and a wide range of wet chemical extraction process such as liquid-liquid extraction technique, precipitation and dry distillation methods have been successfully used [1]. The wet extraction method consists of dissolution of irradiated powdered sulfur in boiling water in the presence of strong and weak acids to extract the phosphorus nuclide from the sulfur target using 2-octanol [2,3]. One of the major impediments of this wet chemical extraction method is the dependence of extraction yield with the particle size of the irradiated sulfur target and is significantly decreased when the target is melted or solidified due to the exothermal heat during neutron irradiation. Additionally, the use of mineral acid is a major deterrent as it induces impurities and leaves solid waste behind, which not only complicates the extraction but also requires additional purification step to achieve required purity. The requirement of multi-stage processes results in poor recovery yields. Owing to these drawbacks, assessing the potential of dry distillation technique in not only an interesting prospect, but viewed as a necessity. (n, ) 32P method of production In light of the perceived need to obtain 32P having desirable specific activity and yield, a thorough and systematic optimization of irradiation parameters and radiochemical procedures was consider worthwhile investigating. Target Stable phosphorus is mononuclidic 31 P (abundance: 100%), there is no direct competing reactions due to other isotopes of phosphorus. While the use of elemental phosphorus in (n,γ) 32P production method is the obvious choice in terms of productivity and simplicity in target processing, selection of the allotropic form of P constitute one of the most important criterion as it has three main allotropes including white, red and black and each one of them exhibit different properties. The option of using white phosphorus is precluded as it is toxic, volatile (melting point 44.2oC), thermodynamically unstable and can spontaneously ignite when it comes in contact with air. In this context, the scope of using red phosphorus seems to be the ideal choice as it is far more stable than the white allotrope and does not catch fire in air at temperatures below 240°C.Red phosphorus is formed after heating white phosphorus to 250°C (482°F) or by exposing white phosphorus to sunlight. Neutron Irradiation Nuclear reaction leading to production of 32P by radiative neutron capture is = 172 mb 31 P(n,) 32P The yield and specific activity of 32 P produced via (n,γ) route of production is mostly governed by the neutron flux and irradiation time. The variation of specific activity of 32 P produced at the end of neutron irradiation as a function of irradiation time at different thermal neutron fluxes has been calculated and the results are shown in Fig. S1. It is evident from the Fig. S1 that higher the thermal neutron flux of the reactor, shorter will be the time of irradiation for attaining the required specific activity. Although, the specific activity of 32 P produced at higher duration of irradiation at a given thermal neutron flux is significantly high, due to reasons concerning availability of neutron flux in Dhruva research reactor of our institute, irradiation at neutron flux higher than 7.5×1013 n.cm-2.s-1 could not be availed. Therefore our subsequent efforts were confined to this flux for production of 32 P. The 32 P activity produced at end of neutron irradiation as a function of irradiation time at flux of 7.5×1013 n.cm-2.s-1 available in Dhruva research reactor has been calculated and the results are shown in Fig S2. As evident from Fig S2, specific activity of 32 P increases exponentially with increasing irradiation time and reaches a value of 6.6 mCi 32P per mg P on 60th day of irradiation. Increase in specific activity of 32P is marginal beyond 60 days of irradiation. Irradiation time upto 4 half life of 32P was thus chosen to achieve practically maximum specific activity for subsequent studies and production. Chemical processing The choice of an appropriate reagent to dissolve neutron irradiated red phosphorous target is a critical issue. The use of nonoxidizing acids such as hydrochloric acid was found to be futile as it does not cause oxidation of red phosphorous. It transpires that oxidising acids are best suited for this applications, and conc. HNO3 seems to be the obvious choice. The most striking feature of HNO3 is its ability to dissolve red phosphorous and ease of use. About 9 mL conc. HNO3 was found to effective for the dissolution of 350 mg of red phosphorus by gentle heating. Quality control of 32P Specific activity Colorimetric method was used for determination of total PO43- content of the obtained 32P solution in the radioactive solution owing to the absence of interfering ions such as Fe, Al etc in the final product. Concentration of P was calculated making use of calibration curve constructed using measurements of absorbance of solutions having known concentration of PO43- ions. Radionuclidic (RN) purity Table S2 depicts the nuclear reactions taking place in a nuclear reactor during irradiation that leads to the concomitant formation of radionuclide impurities. The impurities of 76 As,122Sb,124Sb possibly arising from the presence of trace concentration of As and Sb in P target due to their identical chemistry with P. Experimentally it was observed that co-produced radionuclide impurities were present to the extent of 0.3 µCi 76As, 0.03 µCi 122Sb, 0.01 µCi 124Sb per mCi of 32 P at end of irradiation, which works out to a radionuclide impurity content of 0.034%. Radiochemical (RC) purity Radiochemical purity determination is an important parameter to ascertain that product radiochemical has 32 P as phosphate ion, which is the desirable form. Radiochemical purity is important in radiopharmacy since it is the radiochemical form which determines the biodistribution of the radiopharmaceutical. Radiochemical impurities will have different patterns of biodistribution which may irradiate the non-targeted organ and render the therapy meaningless. The radiochemical purities of typical batches of 32P obtained from 32S(n,p)32P and (n,) 32P routes of production as determined by paper chromatography are shown in Fig S3 (a) and (b) which indicate >98% of 32P as orthophosphate ion. Figure captions Fig. S1. Specific activity of 32 P produced at the end of neutron irradiation as a function of irradiation time at different thermal neutron fluxes during the neutron irradiation of red P. Fig S2. Specific activity of 32 P produced at the end of neutron irradiation as a function of irradiation time at thermal neutron flux of 7.5 ×1013 n.cm-2.s-1. Fig. S3. Paper chromatographic pattern of 32P in isopropyl alcohol, water, 50% trichloroacetic acid and 25% NH4OH solvent system (a) 32S(n,p)32P route and (b) 31P(n,γ)32P route Table S1. Radionuclide production by natural sulfur irradiation with thermal and fast neutrons Isotope of S Isotopic abundance (%) Activation products formed Fast neutrons irradiation Nuclear Half Life Reaction Thermal neutrons irradiation Nuclear Half Life Reaction 32 95.02 32 14.26 d 32 Stable 33 0.75 33 25.3 d 33 Stable 34 4.21 34 14.4 s 34 87.2 d 36 0.02 36 5.9 s 36 5.05 m S S S S S(n,p)32P S(n,p)33P S(n,p)34P S(n,p)36P S(n,)33S S(n,)34S S(n,)35S S(n,)37S Table S2. Production of radionuclide impurities during the neutron irradiation of red phosphorous Radionuclide 76 As 122 124 Sb Sb T1/2 1.09 d 2.7 d 60.2 d Eβmax energy used for assay keV % - - - - - - γ peaks used for assay Method of formation of the radionuclides keV % Nuclear reaction 559.1 45 75 657.1 6.2 564 70 692.9 3.82 602.7 97.8 722.8 10.9 % natural abundance As(n,γ) 100 Reaction cross section 4.5 b 121 Sb(n,γ) 57.21 5.9 b 123 Sb(n,γ) 42.79 4.1 b Specific Actiivty 32 P (mCi/mg) 8 7 13 = 7.5x10 th 6 13 5 = 5.5x10 4 = 4.5x10 3 = 3.5x10 th 13 th 13 th 13 = 2.5x10 2 th 13 = 1.5x10 th 1 0 0 20 40 60 80 100 120 Irradiation time (days) Fig. S1. Specific activity of 32 P produced at the end of neutron irradiation as a function of irradiation time at different thermal neutron fluxes during the neutron irradiation of red P. 32P Specific Activity build up (mCi/mg) 8 6 4 2 0 20 40 60 80 100 120 Irradiation time (days) Fig S2. Specific activity of 32 P produced at the end of neutron irradiation as a function of irradiation time at thermal neutron flux of 7.5 ×1013 n.cm-2.s-1. 30000 25000 Activity (cps) 20000 3PO4 15000 10000 5000 4P2O7 polyphosphate 0 0 5 10 15 20 25 30 Migration from the point of spotting (Cm) (a) 40000 35000 PO4 Activity (cps) 30000 3- 25000 20000 15000 10000 5000 P 2O 7 polyphosphate 4- 0 0 5 10 15 20 25 Migration from the point of spotting (Cm) 30 (b) Fig. S3. Paper chromatographic pattern of 32P in isopropyl alcohol, water, 50% trichloroacetic acid and 25% NH4OH solvent system (a) 32S(n,p)32P route and (b) 31P(n,γ)32P route References 1. Han HS , Park UJ, Shin HY, Yoo KM., (2007) Method for distillation of sulfur for the preparing radioactive phosphorous nuclide. US Patent No. 7,266,173 B2. 2. Samsah K, (1958) The Jener method for the extraction of pure 32 P from neutron- irradiated sulfur. Atompraxis. 4 (14): 14-17. 3. Razbash AA, Nerozin NA, Panarin MV, Sevast'yanov YG, Polyakov ON, Podsoblyaev DV, Smetanin EY, Dubinkina TA, Nikulin MP.( 1991). Winning 32P in the BR-10 Reactor, Atomnaya Energiya. 70 (4):260-262.