Sodium Dodecyl Sulfate: 1.5g

DEPARTMENT OF CHEMISTRY

TEACHING LAB EXPERIMENT RISK ASSESSMENT FORM

This form must be completed jointly by the Lab Officer in charge and the Lecturer in charge. A hardcopy of the completed form should be kept in a file together with the Project Risk

Assessment.

Name of Lecturer in Charge Name of Lab Officer in Charge Module / Expt No.

A/P Jaenicke Stephan

Activity being assessed:

Tan Lay San CM 2264/Expt 3

Emulsion Polymerization

Preparation of polystyrene by emulsion polymerisation & determine its molecular weight by viscosity measurements.

Known or expected hazards associated with the activity:

Hazards of reagents, solvents and known reaction products.

State each substance and the approximate amounts to be used/produced.

List of activities involved in this experiment which inevitably entail risks. The following are the activities being use:

1) Glass Apparatus. Refer to prepared risk assessment on Use of Glassware

2) Heating Mantle, Oven. Refer to prepared risk assessment on Use of Laboratory Heating

Equipment

3) Thermometer. Refer to prepared risk assessment on Use, Handling and Clean-Up

Procedures for Mercury

4) Electricity, Mechanical Stirrer. Refer to prepared risk assessment on Electricity. Refer to prepared risk assessment on Use of Standard Electrical Equipment

5) Fumehood. Refer to prepared risk assessment on Use of Fume Hoods.

6) Waste disposal: All organic waste have to be disposed of in the appropriately labelled waste container placed in a secondary containment housed under the designated fume hood.

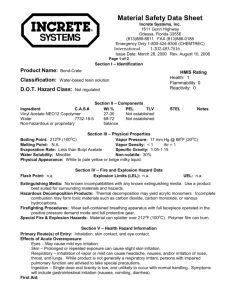

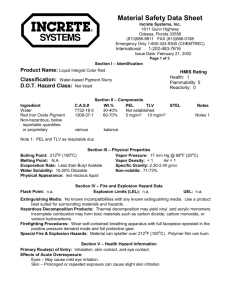

Sodium Dodecyl Sulfate: 1.5g

Harmful if inhaled or swallowed. Causes eye and skin irritation. May be harmful if absorbed through skin. May cause allergic reaction. Contains material which causes damage to the following organs: Skin, eyes.

Potassium Persulfate: 0.3g

Oxidizer. Contain with other material may cause fire. Causes respiratory tract, eye and skin irritation. May be harmful if swallowed.

Isopropyl Alcohol: 420ml

Flammable liquid and vapor. Vapor may cause flash fire. Harmful if inhaled or swallowed.

Causes severe eye irritation. Causes damage to the following organs: Respiratory tract, skin,

Page 1 of 8

Printed on: 17 April 2020

central nervous system, eye lens or cornea. May cause skin irritation.

Distilled Styrene: 37g

Flammable liquid and vapor. Harmful if swallowed, inhaled or absorbed through skin.

Causes irritation to skin, eyes and respiratory tract. Affects CNS, liver and reproductive system.

Nitrogen gas:

A harmful concentration of this gas in the air will be reached very quickly on loss of containment.

On loss of containment this gas can cause suffocation by lowering the oxygen content of the air in confined areas. See Notes in Reference website.

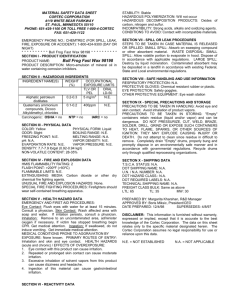

Toluene: 100mL

Flammable liquid and vapour. Vapor may cause flash fire. May be fatal if swallowed. Harmful if inhaled. Causes respiratory tract, eye and skin irritation. Causes damage to the following organs: Kidneys, liver, respiratory tract, skin, central nervous system, eye, lens or cornea.

* Above amount stated are computed for the whole experiment .

Incompatible materials (special precautions):

Sodium Dodecyl Sulfate:

Highly reactive with oxidizing agents, acids.

Potassium Persulfate:

Reactive with reducing agents, combustible materials, metals, acids, alkalis.

Isopropyl Alcohol:

Highly reactive with oxidizing agents.

Distilled Styrene:

Vapor is explosive when exposed to heat or flame; reacts with oxygen above 40C (104F) to form a heat-sensitive explosive peroxide. On exposure to light and air, styrene slowly undergoes polymerization and oxidation with formation of peroxides. Violent polymerization may be initiated by alkali metal-graphite composites, butyllithium, dibenzoyl peroxide, azoisobutyronitrile or ditert-butyl peroxide. Styrene reacts violently with chlorosulfonic acid, oleum, sulfuric acid, chlorine + iron(II)chloride and can react vigorously with oxidizing materials. Dissolves rubber.

Corrosive to copper and copper alloys. Incompatible with peroxides, aluminum chloride, strong acids, metallic salts, halogens, polymerization catalysts and accelerators.

Conditions to Avoid: Heat, flame, ignition sources, air, light.

Nitrogen gas:

Page 2 of 8

Printed on: 17 April 2020

Reacts with oxygen and hydrogen on sparking forming nitric oxide and ammonia.

Combines directly with lithium and at red heat with calcium, strontium and barium to form nitrides. Forms cyanides when heated with carbon in presence of alkalis or barium oxides.

Toluene:

Reactive with oxidizing agents, acids.

The risk of injury and its severity likely to arise from these hazards:

Sodium Dodecyl Sulfate, Potassium Persulfate & Isopropyl Alcohol:

Eye Contact: Hazardous in case of eye contact (irritant). Inflammation of the eye is characterized by redness, watering, and itching.

Skin Contact: Hazardous in case of skin contact (irritant). Skin inflammation is characterized by itching, scaling, reddening, or, occasionally, blistering. May be hazardous in case of skin contact

(permeator for Sodium Dodecyl Sulfate).

Inhalation: Hazardous in case of inhalation.

Ingestion: Hazardous in case of ingestion.

Highly reactive with oxidizing agents.

Distilled Styrene:

Inhalation: Causes irritation to the respiratory tract. Symptoms may include coughing, shortness of breath. A central nervous system depressant. Higher exposures can cause a build-up of fluid in the lungs (pulmonary edema), a medical emergency.

Ingestion: May cause irritation to the gastrointestinal tract. Symptoms may include nausea, vomiting and diarrhea. May cause central nervous system depression. Symptoms may include lethargy, drowsiness, staggering and sleepiness. May cause possible convulsions and risk of pulmonary edema.

Skin Contact: Causes irritation to skin. Symptoms include redness, itching, and pain. May produce blisters. May be absorbed through the skin.

Eye Contact: May cause irritation, redness, pain, and corneal damage. Chronic Exposure:

Repeated exposure may cause nausea, vomiting, appetite loss, a sensation of drunkenness, general weakness, and functional disorders of the nervous system and liver. May cause dermatitis. Women may experience ovulation and menstrual disorders. May cause mutagenic and teratogenic effects. Aggravation of Pre-existing Conditions: Persons with pre-existing skin disorders, eye problems, liver disease, central nervous system disorders, or impaired respiratory function may be more susceptible to the effects of the substance.

Nitrogen gas:

Overexposure by inhalation may lead to unconsciousness, weakness, death.

Page 3 of 8

Printed on: 17 April 2020

Toluene:

Eye Contact: Hazardous in case of eye contact (irritant). Inflammation of the eye is characterized by redness, watering, and itching.

Skin Contact: Hazardous in case of skin contact (irritant). Skin inflammation is characterized by itching, scaling, reddening, or, occasionally, blistering.

Inhalation: Hazardous in case of inhalation (lung irritant).

Ingestion: Extremely hazardous in case of ingestion. May be fatal if swallowed.

Who is at risk?

Persons handling the chemicals as well as those in the vicinity.

Measure to be taken to reduce the level of risk:

Proper laboratory attire and safety measures must always be used in order to reduce the level of risk. Wash hands thoroughly after handling. Do not take internally. Eye wash and safety equipment should be readily available. Styrene should be handled in a fume hood.

Eye protection: Chemical safety goggles.

Hand protection: Gloves.

Please refer to PSSO Safety Information Centre website on safety measures: http://www.chemistry.nus.edu.sg/PSSO/index.htm#undergrad

Training prerequisites:

This assessment should be read by everyone who will be using the above mentioned chemicals. Please refer to Completed Risk Assessment on Common Activities: http://www.chemistry.nus.edu.sg/PSSO/safety/risk/risk.htm#Common

Level of risk remaining:

The level of risk is low although constant vigilance is necessary to avoid injury.

Emergency action if :

Spill:

Sodium Dodecyl Sulfate:

Small Spill: Use appropriate tools to put the spilled solid in a convenient waste disposal container.

Large Spill: Stop leak if without risk. Do not get water inside container. Do not touch spilled material. Prevent entry into sinks or drainages. Call for assistance on disposal.

Potassium Persulfate:

Small Spill: Use appropriate tools to put the spilled solid in a convenient waste disposal container.

Page 4 of 8

Printed on: 17 April 2020

Large Spill: Stop leak if without risk. Avoid contact with a combustible material (wood, paper, oil, clothing...). Keep substance damp using water spray. Do not touch spilled material. Prevent entry into sinks or drainages. Eliminate all ignition sources. Call for assistance on disposal.

Isopropyl Alcohol:

Small Spill: Dilute with water and mop up, or absorb with an inert dry material and place in an appropriate waste disposal container.

Large Spill: Keep away from heat. Keep away from sources of ignition. Stop leak if without risk.

Cover with DRY earth, DRY sand or other non-combustible material. Do not get water inside container. Do not touch spilled material. Prevent entry into sinks or drainages. Call for assistance on disposal.

Styrene:

Ventilate area of leak or spill. Remove all sources of ignition. Keep unnecessary and unprotected personnel from entering. Contain and recover liquid when possible. Use nonsparking tools and equipment. Collect liquid in an appropriate container or absorb with an inert material (e. g., vermiculite, dry sand, earth), and place in a chemical waste container. Do not use combustible materials, such as saw dust. Do not flush to sinks! If a leak or spill has not ignited, use water spray to disperse the vapors, to protect personnel attempting to stop leak, and to flush spills away from exposures.

Nitrogen gas:

Ventilation (extra personal protection: self-contained breathing apparatus).

Toluene:

Small Spill: Absorb with an inert material and put the spilled material in an appropriate waste disposal.

Large Spill: Keep away from heat. Keep away from sources of ignition. Stop leak if without risk.

Absorb with DRY earth, sand or other non-combustible material. Do not get water inside container. Do not touch spilled material. Use water spray to reduce vapors. Prevent entry sinks or drainages. Call for assistance on disposal.

Fire:

Sodium Dodecyl Sulfate:

Use dry chemical or CO

2

.

Potassium Persulfate:

Use oxidizing material. Do not use water jet. Use flooding quantities of water. Avoid contact with organic materials.

Page 5 of 8

Printed on: 17 April 2020

Isopropyl Alcohol:

Small Fire: Use DRY chemical powder.

Large Fire: Use alcohol foam, water spray or fog. Cool containing vessels with water jet in order to prevent pressure build-up, autoignition or explosion.

Styrene:

Explosion: Sealed containers may rupture when heated. Above the flash point, explosive vaporair mixtures may be formed. Vapors can flow along surfaces to distant ignition source and flash back. Sensitive to static discharge.

Fire Extinguishing Media: Water spray, dry chemical, alcohol foam, or carbon dioxide. Material floats on water and may travel back to an ignition source and spread fire. Water spray may be used to keep fire exposed containers cool. Do not allow water runoff to enter sinks or drainages.

Nitrogen gas:

Fire extinguishing materials: Non-flammable, inert gas. Use extinguishing media appropriate for surrounding fire.

Unusual fire and explosion hazards: Nitrogen does not burn; however, containers, when involved in fire, may rupture or burst in the heat of the fire.

Explosion: In case of fire: keep cylinder cool by spraying with water.

Toluene:

Flammable in presence of open flames, sparks and static discharge, of shocks, of heat, of oxidizing materials.

Small Fire: Use DRY chemical powder.

Large Fire: Use water spray or fog. Cool containing vessels with water jet in order to prevent pressure build-up, autoignition or explosion.

Is the experiment suitable for out-of-hours operation ? Yes No

References if any:

Sodium Dodecyl Sulfate: http://www.sciencelab.com/msds.php?msdsId=9925002

Isopropyl Alcohol: http://www.ee.iitb.ac.in/~nanoe/msds/ipa.pdf

Styrene: http://www.sciencelab.com/msds.php?msdsId=9925112

Nitrogen gas: http://www.airgas.com/documents/pdf/001040.pdf

Toluene: http://www.sciencelab.com/msds.php?msdsId=9927301

Page 6 of 8

Printed on: 17 April 2020

Signature of Lab Officer in Charge :………………………………………………………………..

Date :…………………………

Signature of Lecturer in Charge: ………… ……………………………………..

Date: … ……………………..

Prepared Risks Assessments for standard equipment and operation are with the kind permission of Dr. Ken MacNeil,

School of Chemistry, University of Bristol.

Page 7 of 8

Printed on: 17 April 2020

Activity being assessed:

Note any activity to be used which entail risk (e.g. use of glass vacuum apparatus, high pressures, high voltage, radiation, high temperatures). Give reference to any special protocols to be followed, and if appropriate attach copies to the risk assessment form. State any additional precautions taken to minimise risk.

Known or expected hazards associated with the activity:

FOR EACH CHEMICAL, read the MSDS and note:- a) Particular hazards (e.g. highly toxic, carcinogenic, corrosive, flammable, pyrophoric, explosive, volatile, dust hazard). Note any dangerous combinations of properties (e.g. volatile and toxic). b) Requirements for safe handling (e.g. fume cupboard, inert atmosphere, low temperature). c) How to dispose of residuals

Dispose to drain, with water dilution

Neutralise, then to drain with suitable dilution

To flammable liquid waste receptacle

To non-flammable liquid waste receptacle

Keep for recovery/recycling

Keep for special disposal later (e.g. heavy metals)

Double bag and dispose to dry waste

Special procedure (specify)

Incompatible materials (special precautions)

Note any dangerously incompatible materials and hazards arising from contact of any reagents and substances used with common materials such as paper, benches, hoses, etc.

Measures to be taken to reduce the level of risk

Include hazards of previously unknown products.

Location of work – laboratory, open bench, fume cupboard

Level of risk remaining:

Likelihood and consequences of any accident or unforeseen events whilst carrying out the activity. When this has been done, choose the appropriate procedure:- a) Close supervision and/or attendance of trained first-aider needed. b) Specific approval of supervisor needed. c) Training is needed prior-to or during the operations specified. d) Training is complete and only general laboratory competence required. e) No risk perceived.

Emergency action: a) Any special requirements to deal with accidental spillage or leakage. b) What to do in the event of accidental exposure (skin contact, inhalation, etc.).

Page 8 of 8

Printed on: 17 April 2020