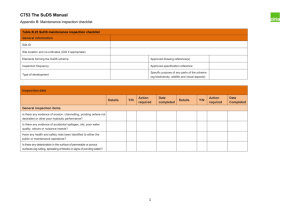

Inspection checklist - formatted

advertisement

Faculty of Natural Sciences Lab inspection checklist – May 2011 Laboratory/Workshop/Hazardous Area - identification list Purpose of checklist This form is for the use of those performing laboratory/workshop/hazardous area inspections. The inspection must be done in cooperation with the Principal Investigator or a nominated deputy. The individual leading the inspection and completing the checklist must have appropriate competence and training in lab inspection. The checklist is designed to identify and record good practice in these areas as well as identify areas for improvement. The questions listed in each section of the checklist are based on statutory requirements as well as Dept, Faculty and College policies. Scope of checklist Each section is based on a particular activity or hazard. If the activity or hazard is not present the corresponding section does not need to be completed. At the start of the inspection indicate the relevant sections in the table below. If a particular question within a relevant section is ‘not applicable’ indicate this in the actions section. If required contact the Faculty Safety Managers for guidance or advice on the questions. Section 1. Area environment 2. Fire 3. First aid 4. General personal protective equipment 5. General area safety 6. Electrical 7. Access control (College amber or red access system) 8. Chemicals 9. Naked flames 10. Clean rooms 11. Fume Cupboards 12. Biological safety 13. Home Office designated labs 14. Microbiological safety cabinets 15. Other local exhaust ventilation (small extraction units, HEPA filtration, dust extraction, snorkels etc) 16. Gases (cylinders & piped systems) and cryogenics 17. Equipment operating at high pressure 18. Centrifuges 19. Drugs, drug precursors and prescription only medicines 20. Isotopes – where possible this section needs to be completed with the relevant RPS 21. Sealed sources and X-ray generators – where possible this section needs to be completed with the relevant RPS Check box where appropriate Mandatory Mandatory Mandatory Mandatory Mandatory Mandatory 1 Faculty of Natural Sciences Lab inspection checklist – May 2011 22. Naturally occurring radioactive material 23. Ultraviolet light and other non ionising radiation 24. High powered (Class 3B and 4) lasers 25. Magnetic fields 26. Nanotechnology 27. Soldering 28. Machine tools 29. Heavy lifting equipment Actions and follow up Where required the individual leading the inspection will agree an appropriate action to reduce the risk from the identified activity or hazard. This will require a named individual to carry the action forward and an appropriate time frame for completion. The completed checklist and actions will be sent to the Principal Investigator as well as those who were present at the inspection. The completed checklist will need to be discussed at an appropriate research group meeting to ensure all those working in the area are made aware of any issues that have been raised and actions that are required. Progress on resolving required actions will be demonstrated at a follow up inspection (generally arranged 6 – 8 weeks after the original inspection). Note – any actions requiring immediate follow up must be dealt with appropriately to prevent significant harm or injury. Faculty of Natural Sciences Laboratory inspection checklist Location Dept Inspected by Principal Investigator Present at Inspection? Date of inspection Date for follow up inspection: 2 Faculty of Natural Sciences Lab inspection checklist – May 2011 Section 1 - Area Environment 1 Inspection point Yes No n/a Follow up inspection Action required / notes / action owner / time scale Complete 1.1 Ongoing Comment Is lighting in the area sufficient to allow people to work safely? Is the temperature in the area comfortable? 1.2 Is the area clean and tidy? 1.3 Is furniture appropriate for the type of work in the area? 1.4 Is the floor intact and level? 1.5 Are the walls and ceiling in good condition? 1.6 Is there any evidence of eating or drinking in the area? 1.7 1.8 Is personal clothing or items (e.g. bags, coats) in the area? Are noise levels in the area excessive? 1.9 Is the area overcrowded with equipment? 1.10 3 Faculty of Natural Sciences Lab inspection checklist – May 2011 Is the area overcrowded with people? 1.11 4 Faculty of Natural Sciences Lab inspection checklist – May 2011 Section 2 - Fire 2 Inspection point Yes No n/a Follow up inspection Action required / notes / action owner / time scale Complete 2.1 2.2 2.3 2.4 Ongoing Comment Is fire equipment stored correctly? Is fire fighting equipment inspected annually? Are fire escape routes free from obstructions? Are fire action notices or local emergency procedures indicating assembly point present? Are fire doors propped open in the area? 2.5 2.6 Have new staff and PhD students attended the College fire safety and fire prevention at work course? 2.7 Are there named fire wardens appointed for the area? 5 Faculty of Natural Sciences Lab inspection checklist – May 2011 Section 3 - First Aid Follow up inspection 3 3.1 3.2 3.3 Inspection point Yes No n/a Action required / notes / action owner / time scale Complete Ongoing Comment Are first aid kits present or the nearest location displayed? Are first aid kits (and its contents) adequately stocked and within the expiry date? Is the accident and near miss reporting procedure known? 3.4 Are current first aid contact posters on display? 3.5 Are the eyewash / emergency showers present, accessible and maintained? 3.6 If yes: Is the weekly flush record being completed regularly? 6 Faculty of Natural Sciences Lab inspection checklist – May 2011 Section 4 – General personal protective equipment (PPE) 4 Inspection point Yes No n/a Follow up inspection Action required / notes / action owner / time scale Complete 4.1 Ongoing Comment Are lab coats / gowns / overalls or other appropriate protective clothing worn in the area? Is protective clothing clean? 4.2 4.3 Are sufficient storage areas for protective clothing in place? Is visitor protective clothing available? 4.4 4.5 Are safety glasses / eyewear available and worn as required? 4.6 Are disposable latex gloves in use (powdered or non powdered)? 4.7 Is respiratory protective equipment (RPE) required for any activity? 4.8 If yes: Have all those using the RPE had successful face fit testing of the masks? Is re-useable RPE maintained appropriately? 4.9 7 Faculty of Natural Sciences Lab inspection checklist – May 2011 Section 5 – General area safety 5 Inspection point Yes No n/a Follow up inspection Action required / notes / action owner / time scale Complete 5.1 Are appropriate warning signs on hazardous area doors and entry points? 5.2 Are inappropriate items stored in fridge, freezers or cold rooms? 5.3 5.4 5.5 5.6 5.7 5.8 5.9 5.10 Ongoing Comment Are heavy items stored inappropriately on or in high shelves, cupboards or other areas? Are shelves, cupboards and other fixings securely attached to the walls? Are waste bins overfilled or full bags not disposed of? Is benchkote (or similar lab bench covering) used appropriately and changed regularly where used? Are sharps used, stored and disposed of appropriately? Are trolley’s used for moving heavy or awkward objects? If yes: Is equipment it in good condition? Are ladders and folding steps registered with the Safety Dept? 8 Faculty of Natural Sciences Lab inspection checklist – May 2011 Are current risk assessments in place for use of 5.11 equipment in the area? 5.12 Are local induction records present for all Group members working in the area? 5.13 Are local training records present? 9 Faculty of Natural Sciences Lab inspection checklist – May 2011 Section 6 – Electrical 5 Inspection point Yes No n/a Follow up inspection Action required / notes / action owner / time scale Complete 6.1 Ongoing Comment Are arrangements for portable appliance testing (PAT) in place and up to date? Any leads or wires trailing on the floor? 6.2 6.3 6.4 6.5 6.6 6.7 6.8 6.9 Any fused extension leads or socket boards in use and located on floor or on benches? Any non fused multi point socket adapters or extension leads in use? Any electrical equipment located on the floor? Is high voltage equipment (over 240 volts) present? If yes: Is it commercially bought and designed to the appropriate British and European standards? Has any electrical equipment been designed and / or constructed ‘in house’ or by other third parties? If yes: Has it been inspected and tested by a competent electrical technician? Appropriate hazard signage in place? 6.10 10 Faculty of Natural Sciences Lab inspection checklist – May 2011 Section 7 – Access control Not applicable 7 Inspection point Yes No n/a Follow up inspection Action required / notes / action owner / time scale Complete 7.1 Does the area have an access control sticker displayed at the entrance? 7.2 If yes: Is the area designated as amber? Ongoing Comment Is the area designated as red? 7.3 7.4 If red or amber is there an up to date Code of Practice in place? 7.5 If red or amber, is the emergency response plan in place and displayed? 7.6 If red or amber is there an authorised users list on the entry door? 7.7 If yes: Is the list up to date? 11 Faculty of Natural Sciences Lab inspection checklist – May 2011 Section 8 – Chemicals Not applicable 8 Inspection point Yes No n/a Follow up inspection Action required / notes / action owner / time scale Complete 8.1 Are flammables stored correctly in dedicated cabinet with spill trays, etc? 8.2 Is appropriate hazard signage on the flammable storage cabinet? 8.3 Are non flammable chemicals stored in cabinet for flammable chemicals? 8.4 Are there less than 50 litres of flammable liquids stored in the area? 8.5 Ongoing Comment Are corrosives stored correctly in dedicated cabinet? 8.6 Is appropriate hazard signage on the corrosive storage cabinet? 8.7 Are non corrosive chemicals stored in the cabinet for corrosive chemicals? 8.8 Are toxic chemicals suitably segregated from other chemicals? 8.9 Are carriers for transportation of reagent / stock bottles available? 12 Faculty of Natural Sciences Lab inspection checklist – May 2011 Are reagent bottles correctly labelled with name (not 8.10 formula) and hazard label? 8.11 8.12 8.13 Are reagent bottles stored on low shelves or cupboards? Are there any containers of reagents (greater than 500mls) left on benches or in fume cupboards – i.e not stored correctly? Are containers of waste chemicals correctly labelled using College waste labels (yellow)? Is the balance area clean and tidy? 8.14 8.15 8.16 8.17 8.18 8.19 Is used glassware and apparatus appropriately dealt with? Are Local emergency procedures in place for dealing with chemical spillages? Is Hydrofluoric acid (HF) in use? If yes: Are the relevant HF first aid procedures displayed? Is HF antidote available? Are any poisons stored or used in the area? 8.20 8.21 If yes: Are they in locked storage with a sign out and in system in place? 13 Faculty of Natural Sciences Lab inspection checklist – May 2011 Section 9 – Naked flames Not applicable 9 Inspection point Yes No n/a Follow up inspection Action required / notes / action owner / time scale Complete 9.1 9.2 Ongoing Comment Are any Bunsen burners, spirit burners, butane gas burners or any other forms of naked flame used? Are naked flames located or used near flammable material? 9.3 Are naked flames used in a microbiological safety cabinet (MSC) or fume hood? 9.4 Is any flexible tubing used to supply gas to burner system? 9.5 If yes: Is it in good condition and securely attached? 14 Faculty of Natural Sciences Lab inspection checklist – May 2011 Section 10 – Clean room Not applicable 10 Inspection point Yes No n/a Follow up inspection Action required / notes / action owner / time scale Complete Ongoing Comment Is there an up to date Code of Practice? 10.1 10.2 Is there a current documented pre-entry induction / training process? 15 Faculty of Natural Sciences Lab inspection checklist – May 2011 Section 11 – Fume cupboards Not applicable 11 Inspection point Yes No n/a Follow up inspection Action required / notes / action owner / time scale Complete 11.1 Are fume cupboards in good working order and servicing in date (annual)? 11.2 Are items stored within fume cupboards that could disrupt the flow of air? Ongoing Comment Is the safe working height of the sash indicated? 11.3 Are the fume cupboard alarms operational? 11.4 11.5 Is the original commissioning data displayed on the fume cupboard? Are re-circulating fume hoods present? 11.6 11.7 11.8 11.9 If yes: Are they annually maintained (test sticker present)? Where appropriate, are filters changed and date for next change indicated? Is there a suitable and sufficient risk assessment for the use of the fume cupboard(s)? 16 Faculty of Natural Sciences Lab inspection checklist – May 2011 Section 12 – Biological safety Not applicable 12 Inspection point Yes No n/a Follow up inspection Action required / notes / action owner / time scale Complete 12.1 Does all deliberate work with non-genetically modified (NGM) human pathogens have an accompanying approved DP1 assessment form? 12.2 Does all work with NGM human tissue, fluids, cells etc have an accompanying approved DP2 assessment form? 12.3 Are approved risk assessments in place for all work involving genetically modified (GM) material? 12.4 Are SOPs in place and displayed for disposal of biological waste? 12.5 12.6 12.7 Ongoing Comment Are disinfectants in use validated for purpose? Is GM waste clearly segregated in autoclave bags/labelled bins? Is any plant health controlled material in use? 12.8 If yes: Are appropriate licenses and registrations in place? 12.9 Does all work with Plant Health Controlled Material have 17 Faculty of Natural Sciences Lab inspection checklist – May 2011 an accompanying approved DP3 assessment? 12.10 12.11 12.12 12.13 12.14 12.15 Is any other biological material (human / animal / insect) imported by the research group? If yes: Are appropriate licenses / registrations in place for imported or regulated biological material? Are all those working with hazard group 2 pathogens (GM or non GM) or unscreened human blood, serum or tissue at containment level 2 on Bioagents health screening? Have those using human material (fluids, tissue etc), started or received a Hep B vaccination? Are there warning labels present for hazardous biological material (containment level 2 or above) in areas where it is stored and used? Are staff and students involved with insect colony maintenance, or other work in breeding (CT) rooms where work will extend over a period of two months enrolled on Biomedical health surveillance? 12.16 Is there any work with biological toxins? 12.17 Any work with biological agents listed on Schedule 5 of the Anti Terrorism Crime Security Act? 12.18 If yes: Is the material registered with the safety dept? 12.19 Are any specified animal pathogens in use? 12.20 If yes: Is the appropriate DEFRA licence in place? 12.21 Do the research group transport diagnostic or hazardous biological material to other institutions or sites? 18 Faculty of Natural Sciences Lab inspection checklist – May 2011 12.22 If yes: Is the relevant Dangerous Goods Safety Advisor (DGSA) consulted before packaging? Name of DGSA: 19 Faculty of Natural Sciences Lab inspection checklist – May 2011 Section 13 – Home Office Designated Labs (DL) Not applicable 13 Inspection point Yes No n/a Follow up inspection Action required / notes / action owner / time scale Complete 13.1 13.2 Ongoing Comment Are all those working in the DL registered with Occupational Health? Are all designated labs registered with CBS and Safety Dept using the DL Form part A and B? Are SOPs available for use of animals within the DL? 13.3 13.4 Is there an approved SOP for transfer of animals from CBS to the DL? 13.5 Are correct containers used for transport (as specified in the SOP)? 13.6 Is an up to date list of those using the DL displayed in the lab? Is the DL used exclusively for animal work? 13.7 13.8 13.9 If no: Is there adequate segregation of animal from non-animal work? Is there segregated storage for ‘normal’ clothing outside of the DL? 20 Faculty of Natural Sciences Lab inspection checklist – May 2011 Is the DL work area screened from external view? 13.10 Is there dedicated PPE for animal work? 13.11 Are all animals in holding contained with IVCs? 13.12 13.13 Is all work with conscious animals carried out in a ventilated cabinet / downdraft bench / other LEV? 13.14 Is any work with unconscious animals done outside of any LEV (including dirty cage change and shaving)? 13.15 Is all LEV associated with controlling laboratory animal allergens (LAAs) tested and maintained appropriately? 13.16 Is the designated lab registered on the College access control system? 13.17 Is there an up to date code of practice for the designated lab? 13.18 Are appropriate transport boxes available for transport of animals? 13.19 Is all PPE associated with the designated lab stored appropriately? 13.20 Is waste from the designated lab disposed of regularly and appropriately? 13.21 Are prescription only medicines present and stored securely? 13.22 Are controlled drugs present and stored correctly? 21 Faculty of Natural Sciences Lab inspection checklist – May 2011 Section 14 – Microbiological Safety Cabinets (MSCs) Not applicable 14 Inspection point Yes No n/a Follow up inspection Action required / notes / action owner / time scale Complete Ongoing Comment Are any of the MSCs ducted? 14.1 Are any of the MSCs re-circulating? 14.2 Are MSCs cluttered, dirty or damaged? 14.3 Are MSC alarms operational? 14.4 14.5 Is original commissioning data displayed? 14.6 Are MSCs maintained as required by College code of practice? 14.7 14.8 14.9 Is the appropriate signage clearly visible on MSCs (as described in College code of practice)? Are any MSCs used to control exposure risks at containment level 2 and over? If yes: Has annual KI operator protection factor test been completed and recorded? 22 Faculty of Natural Sciences Lab inspection checklist – May 2011 14.10 Are monthly airflow tests carried out on MSCs used for work requiring containment level 2 or above? 14.11 If yes: Is the anemometer calibrated annually? 14.12 Is there an SOP for fumigation of the MSC? 14.13 Is there a suitable and sufficient risk assessment for use of the MSCs? 23 Faculty of Natural Sciences Lab inspection checklist – May 2011 Section 15 – Other Local Exhaust Ventilation (wet benches, down flow hoods, capture hoods, snorkels, weighing enclosures, anaerobic cabinets, chemical work stations, ventilated cabinets etc) Not applicable 15 Inspection point Yes No n/a Follow up inspection Action required / notes / action owner / time scale Complete 15.1 Ongoing Comment Is equipment maintained and inspected as per manufacturer’s instructions? Is LEV examined and tested every 14 months? 15.2 Is commissioning data available? 15.3 15.4 Is there a means of determining that the LEV is working (e.g. manometer, airflow indicator)? Is there a low airflow indicator / alarm? 15.5 15.6 Are any filters present changed regularly according to recommended guidelines? 15.7 Is there an SOP for safely changing and disposing of contaminated filters? 15.8 Is there a suitable and sufficient risk assessment for use of the LEV? 24 Faculty of Natural Sciences Lab inspection checklist – May 2011 Section 16 – Gases and Cryogenics Not applicable 16 Inspection point Yes No n/a Follow up inspection Action required / notes / action owner / time scale Complete Ongoing Comment Are gas cylinders present? 16.1 Are they appropriately secured? 16.2 16.3 16.4 Are they sited away from escape routes? Are the regulators appropriate for the type of gas? 16.5 Have all gas regulators been statutorily inspected by BOC in the last year? 16.6 Are any ‘failed’ regulators still in use? 16.7 Do users carry out routine inspections and leak tests of regulators and tubing? Are cylinder trolleys in good condition? 16.8 16.9 Any cylinders of flammable gas? 25 Faculty of Natural Sciences Lab inspection checklist – May 2011 16.10 If yes: Are cylinders of flammable gasses fitted with a flash back arrestor? Any cylinders of toxic gas? 16.11 Any cylinders of corrosive gas? 16.12 16.13 16.14 16.15 16.16 16.17 16.18 16.19 16.20 Are current emergency procedures displayed for toxic, flammable and corrosive gases? Are there any gas monitors or alarms present? If yes: Is there a record of the alarm being tested and the date it needs to be replaced? Has a risk assessment been completed for each type of gas present? Are connections and tubing from gas cylinders to equipment appropriate and properly secured? Are fixed lab gas pipelines on the College insurance register and subject to annual insurance inspection? Are fixed manifolds maintained and inspected annually (this needs to be specifically arranged with BOC by the research group)? Have those using cylinders attended appropriate gas safety training? Are cryogenic liquids in use? 16.21 16.22 If yes: Are the Storage vessels for these liquids in a good state of 26 Faculty of Natural Sciences Lab inspection checklist – May 2011 repair? 16.23 Are pressure vessels for cryogenic liquids inspected by BOC (annually)? 16.24 Is appropriate PPE available to wear when using cryogenic liquids? 16.25 16.26 16.27 Are areas where asphyxiants (e.g. liquid nitrogen) being used adequately ventilated? Is there a dedicated cryogenic filling point? Are cryogenic filling points segregated and identified appropriately? 27 Faculty of Natural Sciences Lab inspection checklist – May 2011 Section 17 - Equipment operating at high pressure (contains steam at any pressure, or exerts a pressure in excess of 0.5 bar above atmospheric pressure and contains gas or fluids, or some mixture of them) Not applicable 17 Inspection point Yes No n/a Follow up inspection Action required / notes / action owner / time scale Complete 17.1 Comment Is high pressure equipment registered with Facilities Management (FM)? 17.3 If yes: Does the equipment have an annual insurance inspection tag and a Written Scheme of Examination? Are any autoclaves present and are they maintained as per manufacturer’s instructions and registered with FM? 17.4 Is there a suitable and sufficient risk assessment for the equipment? 17.2 Ongoing 28 Faculty of Natural Sciences Lab inspection checklist – May 2011 Section 18 – Centrifuges Not applicable 18 Inspection point Yes No n/a Follow up inspection Action required / notes / action owner / time scale Complete 18.1 Ongoing Comment Are centrifuges maintained as per manufacturer’s instructions? Are centrifuge rotors maintained and inspected? 18.2 18.3 18.4 Is there a log book in use for high, super and ultra speed centrifuges? Are the centrifuges, rotors and buckets clean? 18.5 Are any centrifuges used for hazardous material? 18.6 If yes: Are emergency procedures displayed? 18.7 Is there a suitable and sufficient risk assessment for use of centrifuges? 29 Faculty of Natural Sciences Lab inspection checklist – May 2011 Section 19 - Drugs, Drug Precursors and Prescription Only Medicines Not applicable 19 Inspection point Yes No n/a Follow up inspection Action required / notes / action owner / time scale Complete 19.1 Do you hold / use Category 1 Drug Precursors? 19.2 If yes: Do you hold a Home Office License? 19.3 Who is the Responsible Person for your department? 19.5 Do you use controlled drugs (CDs) and / or prescription only medicines (POMs)? 19.6 If yes: Do you hold a Home Office License? 19.8 19.9 Comment Are the drug precursors stored under lock and key? 19.4 19.7 Ongoing Give name of responsible person: Are the CDs / POMs stored under lock and key? Is there a log book for use of CDs? Who is the Responsible Person for these? Give name of responsible person: 30 Faculty of Natural Sciences Lab inspection checklist – May 2011 Section 20 – Isotopes (where possible this section to be completed with the relevant RPS) Not applicable 20 Inspection point Yes No n/a Follow up inspection Action required / notes / action owner / time scale Complete 20.1 20.2 Ongoing Comment Has all work been registered with the Safety Dept? Have all users of material registered with the Safety Dept and attended mandatory training? Are local rules in place and on display? 20.3 20.4 Are local radiation induction records available for all workers? 20.5 Has the radiation protection supervisor been appointed in writing by the HoD? Is appropriate lab designation signage in place? 20.6 Are TAD sheets present and completed? 20.7 20.8 20.9 Is the work area suitable including locked storage for radioisotopes? Are monitor sheets for work area present and completed? 31 Faculty of Natural Sciences Lab inspection checklist – May 2011 Are disposal records (bins and sinks) used and up to 20.10 date? 20.11 20.12 20.13 20.14 Are bins used for waste disposal emptied regularly? Is there a spill / decontamination kit available for isotopes? Are the correct contamination monitors present and testing in date? Are workers wearing personal monitors (if applicable)? 20.15 Is there any equipment or other items under sink designated for radioactive work? 20.16 Is the work area for using ionising radiation neat and tidy? 20.17 Are appropriate records to demonstrate regular monitoring of lab area for radiation contamination available? 32 Faculty of Natural Sciences Lab inspection checklist – May 2011 Section 21 - Sealed sources including X-ray Generators (where possible this section to be completed with the relevant RPS) Not applicable 21 Inspection point Yes No n/a Follow up inspection Action required / notes / action owner / time scale Complete Ongoing Comment Are local rules in place and on display? 21.1 Is a area code of practice available? 21.2 Is appropriate hazard signage in place? 21.3 21.4 Has a critical examination been done in consultation with the College RPA? 21.6 Are service and maintenance records available (involving the checking of interlocks, secure keys, area alarms and e-stops etc)? Are leak test records available (held for a minimum of 2 years)? 21.7 Are dose rate instruments available, calibrated and copies of calibration certificates for x-ray set facilities? 21.8 Are count rate monitoring records available for leakage through x-ray shielding? 21.9 Are sealed source records from the manufacturer and a current list of sources available? 21.5 33 Faculty of Natural Sciences Lab inspection checklist – May 2011 Are suitable barriers in place to restrict access to other 21.10 users when x-ray beam alignments are being carried out? Is adequate shielding available for x-rays sets? 21.11 21.12 Are the statutory notices on display and contact details current and compliant with College guidance? 34 Faculty of Natural Sciences Lab inspection checklist – May 2011 Section 22 - Naturally Occurring Radioactive Material (NORM) inc geological samples and uranium & thorium compounds Not applicable 22 Inspection point Yes No n/a Follow up inspection Action required / notes / action owner / time scale Complete 22.1 22.2 Have all workers with NORM received local induction training? 22.4 Is there access to a contamination monitor in case of a spillage or emergency of NORM? 22.5 If yes: Has the monitor been calibrated within the last year? 22.6 Is each pot of uranium and thorium salts marked with TAD number and a TAD sheet available? 22.8 Comment Has work with NORM been registered with the Safety Department? Have all stocks of NORM been notified to the Safety Department? 22.3 22.7 Ongoing Is stock material stored in a secure location? Are the records of use of NORM updated on the TAD sheet? 35 Faculty of Natural Sciences Lab inspection checklist – May 2011 Section 23 – Ultraviolet (UV) and other non ionising radiation Not applicable 23 Inspection point Yes No n/a Follow up inspection Action required / notes / action owner / time scale Complete Ongoing Comment Is there a UV warning sign and mandatory visor sign? 23.1 23.2 Do all polycarbonate visors used for protection from UV have the CE mark: BS EN 170:2002 Are visor(s) stored appropriately and in clean condition? 23.3 Is there a disposal route for UV tubes (contain mercury)? 23.4 36 Faculty of Natural Sciences Lab inspection checklist – May 2011 Section 24 – Laser Safety Not applicable 24 Inspection point Yes No n/a Follow up inspection Action required / notes / action owner / time scale Complete 24.1 Is a current list of authorised laser users displayed on the lab entry door? 24.3 Do all laser sources have the appropriate classification and UK warning label(s)? 24.4 Is the laser warning light at the entrance interlocked to the laser(s)? 24.6 Comment Do all lasers have a registration sticker located on them? 24.2 24.5 Ongoing Does the laser warning light give a true indication of beam emission when it is showing “ON”? Is the entrance door interlocked to the laser(s)? Is entrance to the laser lab restricted? 24.7 24.8 If different accessible wavelengths in the area, is information on the current laser hazard clearly displayed at each point of access to the laser area? 24.9 Is there a curtain or barrier blocking the view of the laser user area from the lab entrance? 37 Faculty of Natural Sciences Lab inspection checklist – May 2011 Have you supplied a copy of your current laser 24.10 assessment(s) and code of practice to the Dept laser safety officer? Is there a current code of practice for use of the lasers? 24.11 Is the laser system completely enclosed? 24.12 24.13 24.14 24.15 Is suitable screening in place around the laser table? Are all beam path components that generate errant beams locally enclosed? Does the beam cross walkways between optical benches? 24.16 If yes: Is the beam path completely enclosed by a tube or other enclosure? 24.17 Is a detection device that controls a safety shutter to block the beam in place? 24.18 24.19 24.20 24.21 24.22 Is access to the beam path restricted by retractable tape or a barrier? Are users required to wear protective eyewear? Do you have hazardous beam transference between adjacent rooms If yes: Does the current risk assessment and local rules in the ‘receiving’ room address the possibility of a beam injury caused by the unanticipated release of a beam from the ‘transmitting’ room? Is there a safety shutter in the ‘receiving room’ under the 38 Faculty of Natural Sciences Lab inspection checklist – May 2011 control of the user in that area? 24.23 24.24 24.25 24.26 Is there a safety shutter in the ‘transmitting’ room which when opened energises a light in the ‘receiving’ room to indicate the availability of the beam? Are there any upwardly directed laser beams in your system If yes: Is the bottom mirror orientation fixed at 45-degrees (no adjustment possible) Is the top mirror’s angular adjustment restricted? 24.27 Is there a suitable and sufficient beam stop above the top mirror? 24.28 Is the upward beam shielded to prevent access to head and tools? 24.29 Is there a clear indication as to the correct eyewear to be worn for the lasers? 24.30 Is there a log recording inspections of laser safety eyewear for defects? 24.31 Are appropriate cleaning materials for the eyewear available? 39 Faculty of Natural Sciences Lab inspection checklist – May 2011 Section 25 – Magnetic Fields Not applicable Inspection point 25 Yes No n/a Follow up inspection Action required / notes / action owner / time scale Complete 25.1 Is an NMR present? 25.2 Is there any other equipment generating or using magnetic fields in place 25.3 Is there a code of practice for the area? 25.4 Is the emergency response plan displayed? 25.5 Are risk assessments in place? 25.6 Are Gauss lines present and clearly marked? 25.7 Ongoing Comment Is there appropriate hazard signage on doors etc? 40 Faculty of Natural Sciences Lab inspection checklist – May 2011 Section 26 – Nanotechnology Not applicable 26 Inspection point Yes No n/a Follow inspection Action required / notes / action owner / time scale Complete 26.1 Is a risk assessment completed and available? 26.2 Is local exhaust ventilation (LEV) employed as a control measure? 26.3 If yes: What type of LEV is in use? 26.4 Is LEV HEPA filtered? 26.5 Is suitable respiratory and personal protective equipment available? 26.6 Are emergency procedures defined? 26.7 Is monitoring of airborne nanoparticles in the workplace carried out? 26.8 Is health surveillance of workers carried out? 26.9 Are waste disposal procedures for nano material and contaminated material defined? Ongoing Comment Describe: 41 Faculty of Natural Sciences Lab inspection checklist – May 2011 Section 27 – Soldering Not applicable 27 Inspection point Yes No n/a Follow inspection Action required / notes / action owner / time scale Complete 27.1 27.2 27.3 Ongoing Comment Is non colophony or lead free solder in use? If colophony or lead solder in use are users registered with Occupational Health? Is appropriate extraction ventilation in use for soldering work? 27.4 If yes: Is it maintained as per manufacturer’s instructions? 27.5 Is there a suitable and sufficient risk assessment in place for soldering activities? 42 Faculty of Natural Sciences Lab inspection checklist – May 2011 Section 28 – Machine Tools Not applicable 29 Inspection point Yes No n/a Follow inspection Action required / notes / action owner / time scale Complete 29.1 Ongoing Comment Are the machine tools located within a non workshop area (e.g. teaching or research lab)? 29.2 If yes: Are those using machine tools appropriately trained and training records available? 29.3 Are all machine tools locked off when not in use? 28.4 Has the use of each machine tool been appropriately assessed in the last year? Name of keyholder / controller: Is ventilation / dust control present and suitable? 28.5 28.6 Are interlocking safety devices and guards in place in all equipment? Are all emergency stop buttons easily accessible? 28.7 43 Faculty of Natural Sciences Lab inspection checklist – May 2011 Section 29 – Heavy Lifting Equipment Not applicable 29 Inspection point Yes No n/a Follow inspection Action required / notes / action owner / time scale Complete 29.1 Is heavy lifting equipment registered with Facilities Management and subject to annual insurance inspection? 29.2 If yes: Does it have the correct coloured tag? 29.3 29.4 29.5 Ongoing Comment Have all users been on the appropriate College training course (slings, hoists and lifting equipment)? Are all uses of this equipment assessed and signed off by competent Dept Heavy and Mechanical Lifting Advisors (DHMLA)? Is a current list of authorised users of heavy lifting equipment displayed? 44