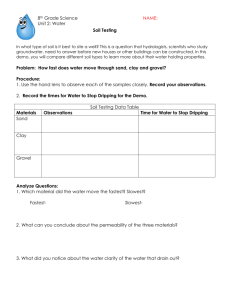

Soil_Testing[1]

advertisement

![Soil_Testing[1]](http://s3.studylib.net/store/data/007676733_2-ea91438a466ba4fcc89ad2d372a198b3-768x994.png)

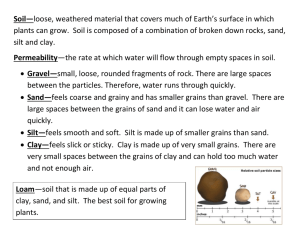

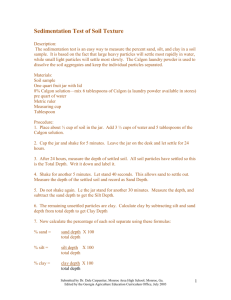

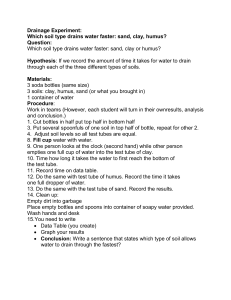

Soil Testing Purpose Almost any structure we build rests on the ground. Before we can design the structure or determine a site grading plan, we must understand the soil conditions. Soil is made up of many different size grains of broken-down rock (sand, silt, and clay). How much water a soil will hold, how easily water passes through the soil, and what happens to the soil as it dries depend on the combination of these materials in your particular soil. The regions climate and weather conditions and their affect on the soil must be considered. Before the design of a major project, such as a highway, building, bridge or dam, can begin, the ground underneath the proposed construction site must be tested to determine composition and other factors affecting its loadbearing capacity. On large projects, core samples are used. Engineers use a drill to remove samples of earth at prescribed intervals. Sometimes core samples are taken from a depth of one hundred feet or more. The samples are then brought to the surface for study. A geotechnical engineer, which is a type of civil engineer, collaborates with a surveyor to map grades, slopes and any modifications that may have been made to the site. The engineers will determine appropriate sites and depths for taking soil samples. Boring sites will include areas where filling and cutting may occur during construction. In addition, engineers will develop preliminary concepts for drainage structures that may be needed to direct water away. Not every project needs test borings. However, you must know the basic soil type before you can proceed. In this activity, you will be using some tests to quickly determine a soil type. By identifying the soil type and properties using a chart, you will be able to make some preliminary decisions regarding grading and load bearing characteristics. SOIL CATEGORIES Soil rarely exists in nature as sand alone, gravel alone, or any other single component. Usually, soil occurs as mixtures with varying proportions of particles of different sizes. The Unified Soil Classification System is based on the characteristics of the soil that indicate how it will behave as a construction material. There are many indicators and descriptors for soil. In the USCS, all soils are placed into one of three major categories. They are Coarse-grained. Fine-grained. Highly organic. The USCS further divides soils that have been classified into the major soil categories by letter symbols, such as S for sand. G for gravel. M for silt. C for clay. A soil that meets the criteria for a sandy clay would be designated (SC). There are cases of borderline soils that cannot be classified by a single dual symbol, such as GM for silty gravel. 15 What to look for Granular soils, fine sands Plastic (cohesive) soils, and silts clay Visual appearance and feel Coarse grains can be seen; feels gritty when rubbed between fingers Movement of water in the spaces Plasticity when moist Cohesion in dry state Grains cannot be seen by the naked eye; feels smooth and greasy when rubbed between fingers When a small quantity is When a small quantity is shaken in the palm of the shaken in the palm of the hand, water will appear on the hand, it shows no sign of surface of the sample. When water moving out of the shaking is stopped, water will voids. gradually disappear. Very little or no plasticity Plastic and sticky, sample can be rolled Little or no cohesive strength High dried strength, in dry state; will crumble crumbles with difficulty and readily disintegrates slowly in water Particle size Gravels range from about 3” down to the size of peas. Sands start just below this size and decrease until the individual grains are just distinguishable by the naked eye. The eye can normally see individual grains about 0.07 millimeter in size, or about the size of the No. 200 sieve. Silt and clay particles, which are smaller than sands, are indistinguishable as individual particles. Size Group Cobbles Gravels Sands Fines (clay or silt) Sieve Size Passing Retained On No maximum size 3 inches No. 4 No. 200 3 inches No. 4 No. 200 No minimum size Procedure These test methods provide information about the size of the soil particles, the amounts of the various sizes, and the characteristics of the very fine grains. See Table 1 for a summary of the test results and the USCS soil types. Simple Grain Size Analysis 1. Divide the soil sample into approximately two equal portions. Set aside one portion for later testing. 2. Dry one soil sample in an oven. Check soil occasionally and stir. 3. While soil is drying, weigh glass containers, sieves, and bottom sieve pan. 4. Remove soil from oven and place in mortar and pestle and pulverize the soil. 5. Stack sieves with No 4 on top, then the No 40 sieve below that, and then the bottom pan. 6. Place soil in No 4 sieve, place cover on top and shake vigorously. 7. Pull the cover off of the No 4 sieve and inspect contents to be sure that small dirt clumps do NOT exist on the No. 4 sieve. Manually break up small dirt clumps and sift again. 16 8. Remove the No 4 sieve from the stack with its soil contents and weigh them. 9. Record and subtract the weight of the No 4 sieve only (i.e., without the soil sample). The difference is the GRAVEL fraction in the soil sample. 10. Repeat steps 7 and 8 for the No 40 sieve. The difference is the coarse and medium grained SAND fraction in the soil sample. 11. Weigh the bottom pan and its contents. Record and subtract the weight of the empty pan. The difference is the fine SAND, SILT, and CLAY fraction of the soil sample. 12. Pour the contents of the bottom pan into the Mason jar. Weigh and record this weight. 13. Add water to the jar so that ¾ of the jar is filled. 14. Shake the Mason jar, allow the fine sand to settle for 5 to 10 seconds, remove the top, and pour off the dirty water into a 5-gallon pail. Be careful not to spill any of the soil that has settled to the bottom of the jar into the 5 gallon pail. 15. Repeat until water is clear. The material remaining in the Mason jar is the fine grained SAND. SILT, and CLAY that has been removed from the soil sample. 16. Place the Mason jar, without top, and contents into the oven and dry. 17. Remove the jar, being careful, as the glass jar will be hot. 18. Weigh the jar and contents. Record the weight and subtract the weight of the empty jar. The difference is the fine grained SAND fraction in the soil sample. 19. Determine the weight of SILT and CLAY in the soil sample. Record and present the results in a table similar to the sample table provided. Item No 4 sieve No 40 sieve Bottom Pan Mason Jar Item Mason jar and soil Soil in mason jar Mason jar and fine SAND Fine SAND in mason jar SILT and CLAY in mason jar Fine SAND in pan SILT and CLAY in pan Weight, grams Weight, grams Item No 4 sieve and retained soil GRAVEL Fraction in mason jar Soil Sample wgt, grams Weight, grams Soil Sample wgt, grams No 40 sieve and retained soil Med. and coarse SAND Bottom pan and soil Fine SAND, SILT and CLAY Presentation of results Item GRAVEL Med. and coarse SAND Fine SAND Soil Sample wgt, grams Percent in soil sample Total SAND, % SILT and CLAY 17 USCS Class. Technique for Coarse-Grained Soils & Fine-Grained Soils COARSEGRAINED SOILS (GRANULAR) More than 50% GRAVEL and SAND Gravelly Soils More than 50% GRAVEL Sandy soils More than 50% coarse, medium, and fine grained SAND FINEGRAINED SOILS (COHESIVE) More than 50% of the soil is SILT and CLAY Highly Organic Soils Dry Crushing Strength None to slight Medium to high Table 1 GW. Well-graded GRAVEL. Clean Gravels will not leave a Various sizes of gravel in sample. stain on a wet GP. Poorly graded GRAVEL. palm. One size of gravel in sample. Uniform. GM. Silty GRAVEL. Non-plastic Dirty Gravels will leave a fines. See ML below to identify. stain on a wet GC. Clayey GRAVEL. Plastic palm. fines. See CL below to identify. SW. Well-graded SAND. Various Clean Sands will not leave a sizes of sand in sample. stain on a wet SP. Poorly graded SAND. One palm. size of sand in sample. Uniform. Dirty Sands will SM. Silty SAND. Non-plastic leave a stain on fines. See ML below to identify. a wet palm. SC. Clayey SAND. Plastic fines. See CL below to identify. Dilatancy Toughness Rapid Low ML None to very slow Slow to none Medium to high CL Slight to Medium medium High to very none High high Readily identifiable by color, odor, spongy feel, and frequently by fibrous texture MH CH OL, OH, and Pt Well-Graded Soils. A well-graded soil is defined as having a good representation of all particle sizes from the largest to the smallest. Poorly-Graded Soils. There are two types of poorly-graded soils. A uniformly graded soil consists primarily of particles of nearly the same size. A gap-graded soil contains both large and small particles, but the gradation continuity is broken by the absence of some particle sizes. USCS Classification Technique for Fine-Grained Soils 1) Use half of the original soil sample that was set aside to complete: a) Dry sample in oven b) Sift soil though No 40 sieve c) Use the soil retained in the bottom pan for the 3 tests described below. 2) Dry Strength (Crushing characteristics) 3) Dilatancy (Reaction to Shaking) 4) Toughness 5) Smear Test 18 Soil Types and Properties Division Letter code Color Gravel and Gravelly Soils GW Red GP GM Sand and Sandy Soils Soil Description Well-Graded Gravel or gravel sand mixture, little or no fines Red Poorly-graded gravel or gravel sand mixture, little or no fines Yellow Silty gravels, gravel sand silt mixture GC Yellow Clayey gravels; gravel clay sand mixture SW Red SP SM SC Well-graded sands or gravelly sands, little or no fines Red Poorly-graded sands or gravelly sands, little or no fines Yellow Silty sands, sand silt mixtures Yellow Clayey sands, sand clay mixture Value for Embankments Very stable, pervious shells of dikes and dams Reasonably stable, pervious shells of dikes and dams Reasonably stable, not particularly suited to shells but may be used for impervious cores or blankets Fairly stable, may be used for impervious cores Very stable, pervious sections, slope protection required Reasonably stable, may be used in dike section with flat slopes Fairly stable, not suited to shells but may be used for impervious cores or dikes Fairly stable, may be used for impervious core for flood control structures Value as a Foundation Material Excellent Frost Action Drainage Maximum Gradient None Excellent 2.5:1 Good None Excellent 2.5:1 Good Slight Poor 2:1 Good Slight Poor 1.75:1 Good None Excellent 3:1 Fair None Excellent 3:1 Fair Slight Fair 2.5:1 Fair Medium Poor 2.5:1 19 Division Letter code Color Soil Description Value for Embankments Silts and Clays Liquid Limit <50% (plasticity level) ML Green Poor stability, may be used for embankments with proper control CL Green OL Green MH Blue CH Blue Inorganic silts, rock flour, silty or clayey fine sands or clayey silts with slight plasticity Inorganic clays of low to medium plasticity, gravelly clays, silty clays, lean clays Organic silt clays of low plasticity Inorganic silts, micaceous or diatomaceous fine sandy or silty soils, elastic silts Inorganic clays of high plasticity, fat clays OH Blue Silts and Clays Liquid Limit >50% Highly Organic soils Pt Organic clays of medium to high plasticity, organic silts Orange Peat and other highly organic soils Value as a Foundation Material Fair Frost Action Drainage Maximum Gradient Very High Poor 1.25:1 Stable impervious cores and blankets Fair Medium Impervious 1.25:1 Not suitable for embankments Poor stability, core of hydraulic fill dam, not desirable in rolled fill construction Poor High Impervious 1.5:1 Poor Very High Poor Fair stability with flat slopes, thin cores, blankets and dike sections Not suitable for embankments Very Poor Medium Impervious 5:1 Very Poor Medium Impervious 5:1 Not used Not suitable Slight Poor 5:1 2.5:1 Source: U.S. Army Corps of Engineers. (1953). The unified soil classification system. U.S. Army Technical Memorandum, No.3-357. 20