Isothermal kinetic evaluation of methyl ethyl ketone peroxide mixed

advertisement

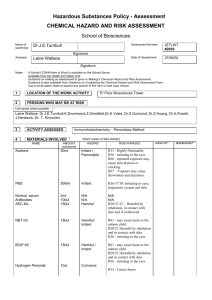

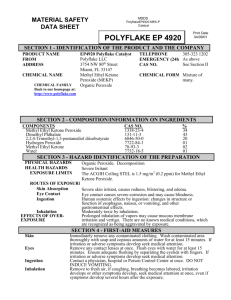

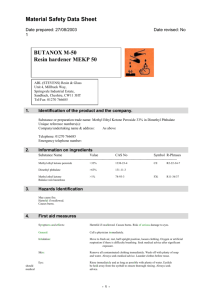

ISOTHERMAL KINETIC EVALUATION OF METHYL ETHYL KETONE PEROXIDE MIXED WITH ACETONE BY TAM III TESTS Mei-Li You1,2, Jo-Ming Tseng1, Ming-Yang Liu2, Tsung-Chih Wu3, Chi-Min Shu1,4* 1 Doctoral Program, Graduate School of Engineering Science and Technology, National Yunlin University of Science and Technology (NYUST), 123, University Rd., Sec. 3, Douliou, Yunlin, Taiwan 64002, ROC 2 Department of General Education Center, Chienkuo Technology University, 1, Chieh Shou N. Rd., Changhua, Taiwan 50094, ROC 3 Department of Safety, Health and Environmental Engineering, Hungkuang University, 34, Chung-Chie Rd., Shalu, Taichung County, Taiwan 43302, ROC 4 Process Safety and Disaster Prevention Laboratory, Department of Safety, Health, and Environmental Engineering, NYUST, 123, University Rd., Sec. 3, Douliou, Yunlin, Taiwan 64002, ROC * E-mail address: shucm@yuntech.edu.tw Abstract Methyl ethyl ketone peroxide (MEKPO), the topic material, has been extensively applied as an initiator and cross–linker during polymerization, but it has also induced many severe accidents on a global scale. The innovative objective of an isothermal kinetic evaluation was to determine the basic characteristics of reactive chemicals to prevent serious runaway accidents. Therefore, we endeavored to demonstrate the reaction model and kinetic parameters, such as activation energy (Ea), and frequency factor (A), by the thermal activity monitor III (TAM III) under three isothermal situations of 70, 80, and 90°C, in terms of 31 mass% MEKPO and with 99 mass% acetone. The results showed that MEKPO could liberate a great quantity of heat during an exothermic reaction. In addition, acetone could alleviate the degree of exothermic runaway while being added with MEKPO. Keywords: methyl ethyl ketone peroxide (MEKPO), isothermal kinetic evaluation, runaway accidents, thermal activity monitor III (TAM III), acetone