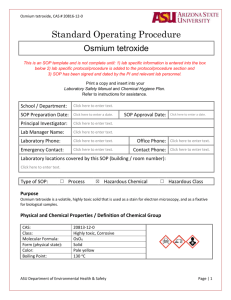

Osmium Tetroxide SOP Template

advertisement

Standard Operating Procedure for Highly Hazardous Chemicals: Osmium Tetroxide Principal Investigator: Department: Lab Safety Coordinator/Lab Manager: Lab Phone: Office Phone: 24-hour Emergency Contact: Date SOP was written and approved by PI: Date of last SOP revision by PI: Click here to enter text Click here to enter text Click here to enter text Click here to enter text Click here to enter text Click here to enter text Click here to enter text Click here to enter text Section 1 – Hazardous Chemicals Chemical Name Click here to enter text Click here to enter text CAS Number Quantity Stored: Click here to enter text Quantity and units Click here to enter text Quantity and units Section 2 – Potential Hazards Osmium tetroxide or osmic acid anhydride is a pale yellow or colorless crystalline solid with a pungent odor. Osmium tetroxide is volatile and readily sublimates at room temperature (and does so significantly even when refrigerated). Osmium tetroxide is mainly used as a fixative or as a histological stain for fat in electron microscopy. It acts as a catalyst for chlorate peroxide, and periodate oxidation reactions, and as an oxidizing agent in the conversion of olefins to glycols. Osmium tetroxide is a strong oxidizer and can react with easily oxidized organic materials to cause fires or explosions. Osmium tetroxide in contact with hydrochloric acid will cause formation of poisonous chlorine gas. The acute toxicity of osmium tetroxide is high and it is a severe irritant of the eyes and respiratory tract. Exposure to osmium tetroxide via inhalation, skin contact, or ingestion can lead to systemic toxic effects involving liver and kidney damage. Chronic exposure to osmium tetroxide can result in an accumulation of osmium compounds in the liver and kidney and damage to these organs. Osmium tetroxide has been reported to cause reproductive toxicity in animals; this substance has not been shown to be carcinogenic or to show reproductive or developmental toxicity in humans. Exposure to osmium tetroxide vapor can damage the cornea of the eye. Irritation is generally the initial symptom of exposure to low concentrations of osmium tetroxide vapor, and lacrimation, a gritty feeling in the eyes, the eyes can temporarily cloud, and the appearance of rings around lights may also be noted. In most cases, recovery occurs in a few days. Concentrations of vapor that do not cause immediate irritation can have an insidious cumulative effect; symptoms may not be noted until several hours after exposure. Contact of the eyes with concentrated solutions of this substance can cause severe damage and possible blindness. Inhalation can cause headache, coughing, dizziness, lung damage, difficult breathing and may be fatal. Contact of the vapor with skin can cause dermatitis, and direct contact with the solid can lead to severe irritation and burns. Exposure to osmium tetroxide via ingestion can lead to systemic toxic effects involving liver and kidney damage. Section 3 – Trainings/Approvals Required PI or designee must provide training to the laboratory personnel specific to the hazards involved in working with hazardous chemicals, work area decontamination, and emergency procedures. The laboratory personnel should attend the trainings, review this SOP and SDS and complete the documentation of training. The trainings should be provided prior to work with hazardous chemicals and annual refresher thereafter. Section 4 – Designated Area Storage & Use Location: Enter Building and Room Number(s) Enter Storage Conditions. (For example: room temperature, refrigerator, inert atmosphere, glove Storage Conditions: box. Please refer to Section 7 for more information on choosing appropriate storage conditions) Section 5 – Engineering Controls / Emergency Safety Equipment Engineering Controls All handling and use of osmium tetroxide must be performed inside a certified chemical fume hood and with the sash at the lowest possible height for safe usage of reagent. Emergency Safety Equipment An eyewash, safety shower, and ABC fire extinguisher must be available within the work area for immediate emergency use. Prior to use, review the Safety Data Sheet for the proper fire extinguisher to use with the given material. Section 6 – Personal Protective Equipment Eye Protection Fully enclosed goggles or a face shield are recommended for work with these chemicals as they offer greater facial protection than safety glasses. NOTE: Safety glasses DO NOT offer adequate protection from osmium tetroxide vapors. Hand Protection Gloves must be worn when handling osmium tetroxide. Disposable nitrile gloves should be adequate for handling most of these in general laboratory settings. If direct or prolonged contact is anticipated, appropriate chemical-resistant gloves should be used. A Safety Data Sheet (SDS) should be reviewed if handling may involve extended or high exposure to lab personnel to ensure adequate skin protection is provided. Skin and Body Protection Protection equipment against chemicals such as lab coats is required. Full-length pants or equivalent as well as closed toe shoes must be worn. Long-sleeved clothing, lab coat or apron is advised if more than normal handling operations could be expected. Section 7 – Special Handling Procedures and Storage Requirements Precautions for safe handling Do not work alone when working with highly hazardous chemicals. All colleagues in the area should be made aware of the hazards with the project. Avoid contact with skin and eyes. Avoid formation of dust and aerosols. Inform others in the laboratory about your usage of highly hazardous chemicals. Provide appropriate exhaust ventilation at places where dust is formed. Always work with osmium tetroxide in a chemical fume hood – never on an open benchtop. Use of a Biological Safety Cabinet for working with osmium tetroxide is not appropriate because it sublimes and the BSC is not designed to prevent exposure to vapors. If weighing osmium tetroxide powder and the balance cannot be located in a chemical fume hood, tare a container then add the powdered osmium tetroxide to the container in a chemical fume hood (NOT a Biological Safety Cabinet) and seal the container before returning to the balance to weigh the powder. Set up a designated area for work with osmium tetroxide. If appropriate for long-term experimental usage, post signage for osmium tetroxide and display it in conspicuous locations during the experiments. Line work surfaces with plastic-backed absorbent pads to ensure containment of any spills. Keep containers closed as much as possible. When osmium tetroxide is freshly prepared and active, it is colorless to pale yellow in color. When the material reacts and causes oxidation, it turns black. This is helpful to know especially in the event of a splash or spill or inadvertent dermal exposure (black dots on skin). Change gloves regularly (at least every two hours) and wash hands at the time of the glove change. Wash hands thoroughly immediately after working with any concentration of osmium tetroxide. Storage requirements Keep container tightly closed in a dry and well-ventilated place and in secondary containment. Due to high vapor pressure, store reagent in a secondary container in a refrigerator. Osmium tetroxide vapors can penetrate plastics; therefore osmium tetroxide should be stored in sealed glass containers (e.g. desiccator) with unbreakable secondary containment. Refrigeration of the product can reduce sublimation; however this product should not be stored with other chemicals inside a refrigerator (use desiccator). Label all containers, including secondary containment, with the chemical name and hazard warning. NOTE: A refrigerator containing osmium tetroxide must be labeled with a caution sign noting the presence of osmium tetroxide and its hazards. Do not remove osmium tetroxide from secondary container until it is fully in the fume hood. Keep corn oil on hand to use for decontamination and in case of a spill – it deactivates osmium tetroxide. Do not store reagent with strong reducing agents, organic materials, or powdered metals. Contact with hydrochloric acid will cause formation of poisonous chlorine gas. Consider purchasing reagent in liquid form to avoid particulate exposure from the powdered form. Purchase only the smallest amounts necessary for your work, and discard old materials promptly. Reagents should be periodically examined to ensure containers are in good condition. Storage requirements will depend on the specific chemical being stored. Check Safety Data Sheets for incompatibilities when storing chemicals. Avoid storing the material by exits. Transport requirements Transportation of hazardous chemicals should follow the guidelines for chemicals as described in the BU Chemical Hygiene Plan. For bulk transport, chemicals should be transported using a clean cart. The materials themselves must be in sealed containers, clearly labeled with the contents name and applicable hazard classification(s). Section 8 – Spill and Accident Procedures Emergency procedures for chemical exposure Remove any contaminated clothing as quickly as possible. Flush any exposed skin or hair with water for at least 15 minutes. Do not hesitate in activating a safety shower. For chemical exposure to the eye, flush with water for at least 15 minutes at an emergency eyewash station. Hold eyelids open while flushing. Seek appropriate medical assistance. If transported to hospital, bring a Safety Data Sheet (SDS) for the material you were exposed to, if able. Emergency procedures for chemical spill or accident Remove personnel from the immediate area. Do not attempt to handle a large spill/reaction/fire, or one in which you are not trained or equipped for. Turn off all ignition sources if this can be done safely, vacate the area, and call for assistance. Follow the reporting procedures on the Emergency Flip Chart. Small Spills Inside Fume Hood (<2mL) Ensure appropriate PPE is worn (see Section 6 above) Cover the spill with corn oil. Oil will turn black when it reacts with the OsO4. Absorb the corn oil/OsO4 solution with absorbent from spill kit. Scoop up and place in double plastic bag. Attach appropriate waste tag and submit waste request online. Clean area with detergent solution to remove residual corn oil. Larger spills (>2mL) and spills outside of the fume hood Alert other personnel in the immediate area Evacuate area, closing all doors to the laboratory Telephone EHS for assistance Telephone 353-2121 on CRC and 414-4444 on BUMC if an injury or fire has occurred as a result of the spill Keep others from entering the area until EHS confirms area is safe for occupancy Section 9 – Waste Disposal Decontamination Contaminated containers and equipment may be decontaminated by dipping in corn oil before removing from the hood. The corn oil will turn black. Paper soaked with corn oil may be used to test if the osmium tetroxide is fully neutralized – if the paper blackens, osmium tetroxide is still present and more corn oil should be added. Contaminated work surfaces may be decontaminated with corn oil or an aqueous solution of sodium sulfite, followed by a cleaning with detergent and water. Waste disposal Osmium tetroxide is an Environmental Protection Agency (EPA) P-Listed (acutely toxic) material. Empty containers that held P-listed chemicals must also be disposed of as hazardous waste. The containers are not allowed to be washed or re-used. All waste and contaminated disposables (pipette tips, ampoules etc.) should be disposed of as hazardous waste, including labeling as hazardous waste and use of secondary containment. Waste disposal requests should be directed to EHS at http://www.bu.edu/ehs/services/waste/chemical-waste/ Section 10 – Lab Specific Changes Laboratory-Specific Procedures: Describe any deviation from the recommended practices in the SOP Documentation of Training Print this page (multiple copies as needed) and insert into your Chemical Safety Logbook, under the Personnel and User Certification section. The laboratory personnel should attend annual training sessions, review this SOP and SDS, and sign the training form. Signature of all users is required. I have read and understand the content of the referenced SOP: Name (please print) Signature Date