行政院國家科學委員會專題研究計畫成果報告

advertisement

Stress Effect on the Reaction Kinetics of Metal/Silicon

systems

計畫編號:甲-91-E-FA04-1-4

執行期限:94 年 4 月 1 日至 95 年 3 月 31 日

主持人:C.J. Tsai

計畫參與人員:W.C. Lin, Y.C. Chu, and L.H. Wu

Department of Materials Science and Engineering, National Tsing Hua University,

Hsinchu, Taiwan, ROC

Ⅰ. Abstract

device7. In our previous experiments, the

external stress we exert using a mechanical

From

the

results

of

previous

experiments, the stress effect on silicidation

process only can be observed in the Ni/Ti/Si

system. In the TiN/Ti/Si system, although the

transformation temperature of silicide does

not change with a tensile stress induced by

the TiN layer existing on the Ti/Si interface,

the Ti-Si intermixing layer is thicker in the

sample with a larger tensile stress. These

results indicate that the external stress we

method having a maximum magnitude about

300MPa seems to have no influence on the

silicidation process in the Ni/Si and Ti/Si

system. In the Ni/Ti/Si system, a result of

tensile (compressive) strss retards (enhances)

the silicidation process is observed. It implies

that the thin Ti interlayer in the Ni/Ti/Si

system is a key point to let the external stress

have the ability to influence the phase

transformation temperature. In the TiN/Ti/Si

exert in these experiments could influence

the mobility of atoms during the annealing

process but does not have enough energy to

change

the

temperature

of

phase

transformation. It is the reason that the

activation energy of the phase transformation

is usually larger than the activation energy of

the mobility. Besides, the stress field

distribution of the periodic nano-scale-pattern

NiSi2 templates which we fabricate using

system, a tensile stress forms on the Ti/Si

interface due to the large compressive stress

in the TiN layer. The results of the TiN/Ti/Si

system show that the tensile stress obviously

enhances the mobility of Si but does not

change

the

temperature

of

phase

transformation during the annealing process.

So we conjecture that the external stress we

exert is only enough to influence the mobility

of atoms because the activation energy of the

polystyrene nanosphere lithography

simulated using a finite element method.

mobility is usually smaller than the activation

energy of the phase transformation. Therefore,

the tensile stress retards the silicidation

process observed in the Ni/Ti/Si system

might be due to the tensile stress let more Si

mix with Ti interlayer at low temperature,

and the formation of Ni silicide become more

difficult because more Ti atoms must be

segregate from the Si during the phase

is

Ⅱ. Introduction

Stress is found to influence the rate of

chemical reaction1,2, the formation and

stability of phase3,4, the nucleation site of

epitaxial growth5,6, and even the property of

1

transformation process.

Using the finite element method to

simulate the stress field of Ge islands on Si

substrate has shown a good agreement with

the measurement results8-10, and it indicate

that this method is reliable to calculate the

stress filed in a nano-scale structure

especially when the structure with a epitaxial

relation with the substrate. The lattice

mismatch between the NiSi2 and the Si

substrate is -0.46% at room temperature and

100

90

F/W (N/m)

80

70

60

50

40

30

20

5

10

15

20

25

Thickness of TiN (nm)

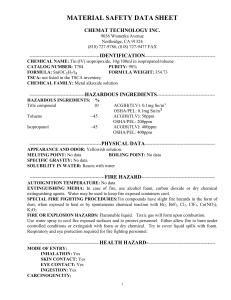

Fig. 1. The F/W for TiN/Ti/Si system with TiN layer

this mismatch is smaller than the different

between the Ge and Si. For this reason, the

elastic condition used to simulate the stress

field in the Ge islands should be proper to

from 5nm to 25nm. At thickness above 20 nm, the

use in the periodic nano-scale-pattern NiSi2

templates which we fabricate previously. The

stress field of the standard epitaxial structure

of NiSi2/Si(100) is simulated using a finite

element analysis software, FEMLAB 3.1, in

this experiment.

increasing convex with increasing thickness

of the TiN layers, which causes an tensile

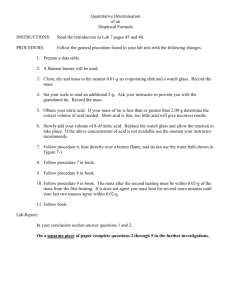

stress on the Ti/Si interface. The TEM

images for the samples with 5 and 25nm TiN

layer after annealing at 300℃ are shown in

F/W saturated.

It can be seen clearly that the sample is

Fig. 2 (a), and (b). Ti-Si intermixing layers

are found to grow thicker between the Ti

layer and the Si substrate in both samples and

the thickness of intermixing layer is 2.2nm in

Fig. 2 (a) and 3.5nm in Fig. 2 (b). The

intermixing layer would grow as the

annealing temperatures increase but at the

same annealing temperature the intermixing

layers are always thicker in samples with

thicker TiN thickness. The diffusion behavior

Ⅲ. Results and Discussion

The TiN/Ti/Si structure was deposited

using a sputter system at a base pressure of 1

×10-8 torr. The TiN layer usually has a large

compressive stress11 and it will exert a tensile

stress on the interface of Ti and Si. The

magnitude of the tensile stress on the

TiN(5nm)/Ti/Si

interface of Ti and Si can be controlled by

modify the thickness of the TiN layer. In this

experiment, the range of the TiN thickness is

from 5nm to 25nm and the thickness of Ti

layer is 25nm for all samples. The initial F/W

which is proportional to curvature for the

TiN/Ti/Si as a function of TiN layer

thickness

is

shown

in

Fig.

1..

TiN(25nm)/Ti/Si

TiN

TiN

Ti

Ti

Ti+Si mixing layer

Ti+Si mixing layer

Si

Si

(a)

(b)

Fig. 2. TEM images of samples after annealed at 300

℃. The thickness of TiN layer is 5nm in (a) and 25nm

in (b).

2

Peak Height of Si (a.u.)

1.0x10

6

8.0x10

5

6.0x10

5

4.0x10

5

2.0x10

5

and

the

stress

TiN 5nm

TiN 25nm

0.0

z

0

100

200

300

400

500

600

Sputtering Time (sec)

y

(a)

x

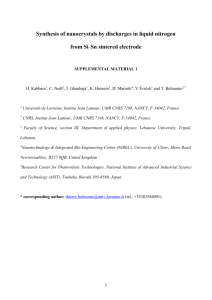

Fig. 3. The AES depth profile of Si atoms for

y

TiN(5nm)/Ti/Si and TiN(5nm)/Ti/Si system after

x

annealed at 300℃.

of Si atoms for the samples shown in Fig. 2 is

detected by AES (Fig. 3). From the result of

distribution of Si shown in Fig. 3, it can

confirm that the mobility of Si is enhanced at

a in-plane tensile stress state. The phase

transformation temperatures of Ti silicide do

not change for samples with different TiN

thickness from the results of XRD (not show

(b)

(c)

(d)

(e)

here). Compare with the results in the Ni/Si

and Ti/Si system, the phase transformation

temperature of silicide might be difficult to

change under a stress below 300MPa.

The stress field of the Si capped layer

upon the standard epitaxial structure,

trough-shape protuberance of NiSi2 into Si

boundary by {111} planes12,13, of

NiSi2/Si(100) is simulated using the finite

element method. Fig. 4 (a) shows the

Fig. 4. (a) The structure used to simulate the stress

structure used to simulate the stress field. Fig.

4 (b) is the x direction normal stress field on

the surface of the Si capped layer and Fig. 4

(c) is the x direction normal stress variation

along the x direction. The stress is tensile

outside the area projected by the NiSi2 dot,

and gradually change to compressive as the

center of NiSi2 dots approached. Fig. 4 (d)

and (e) is the x direction normal stress field

NiSi2 dot. The controllable nano-scale stress

field shown in Fig. 4 (b) is potential for

future application.

field. (b) The x direction normal stress field and (c)

the x direction normal stress variation along the x

direction, on the surface of the Si capped layer. (d)

The x direction normal stress field and (e) the x

direction normal stress variation along the x direction,

on the plane of NiSi2 surface..

variation on the plane of the NiSi2 surface.

The stress is highly tensile in the interior of

Ⅳ. Self-evaluation

From the result of stress effect in the

Ti/Si, Ni/Si, Ni/Ti/Si, and TiN/Ti/Si system,

3

the stress we exert using a mechanical

[11] A. J.Perry, J. N. Matossian, S. J. Bull, D.

method only can influence the mobility of

atom. But if a thin interlayer exists in a

system, it might have the ability to influence

the formation temperature of silicide

indirectly. The stress distribution of the

periodic nano-scale-pattern NiSi2 templates

has been simulated using a finite element

method. It can help us to predict the stress

state in a nano-scale structure which is

difficult to measurement in experiment.

I. Proskurovsky, and etc. Metallurgical

and Materials Transactions A. 30 2931

(1999).

[12] J. P. Sillivan, R. T. Tung, and F. Schery,

J. Appl. Phys., Vol. 72, 478, (1992).

[13] R. T. Tung, J. M. Gibson, J. M. Poate,

Phys. Rev. Lett., Vol. 50, 429, (1983).

Ⅴ. Reference

[1] J. Tersoff, Yuhai Tu, and G. Grinstein,

Appl. Phys. Lett, 73, 2328 (1998).

[2] K. S. Kim, J. A. Hurtado, and H. Tan,

Phys. Rev. Lett, 83, 3872 (1999).

[3] E. M. Schaller, B. I. Boyanov, S. English,

and R. J. Nemanich, J. Appl. Phys. 85,

3614 (1999).

[4] S. L. Cheng, H. M. Lo, L. W. Cheng, and

L.J. Chen, Thin Solid Films, 424, 33

(2003).

[5] S. Y. Shiryaev, F. Jensen, J. L. Hansen,1

J. W. Petersen, and A. N. Larsen, Phys.

Rev. Lett, 78, 503 (1997).

[6] G. Jin, J. L. Liu, S. G. Thomas, Y. H. Luo,

and K. L. Wang. Appl. Phys. Lett. 75,

2752 (1999).

[7] A. K. Fung, L. Cong, J. D. Albrecht, M. I.

Nathan, P. P. Ruden, and H. Shtrikman, J.

Appl. Phys. 81, 502 (1997).

[8] S. Christiansen, M. Albrecht, H. P.

Strunk, and H. J. Maier, Appl. Phys. Lett.

64, 3617 (1994).

[9] A. E. Romanov, G. E. Beltz, W. T.

Fischer, P. M. Petroff, and J. S. Speck, J.

Appl. Phys. 89, 4523 (2001).

[10] Q. X. Pei, C. Lu, and Y. Y. Wang, J.

Appl. Phys. 93, 1487 (2003).

4