Summary of Tsumeb Mi..

advertisement

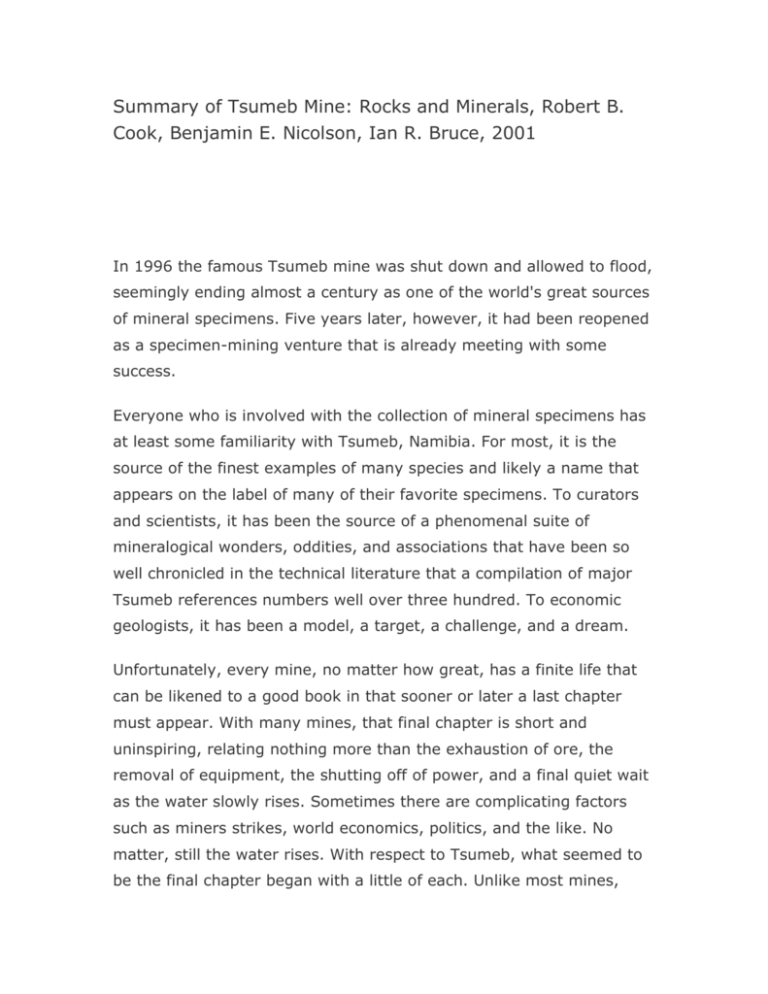

Summary of Tsumeb Mine: Rocks and Minerals, Robert B. Cook, Benjamin E. Nicolson, Ian R. Bruce, 2001 In 1996 the famous Tsumeb mine was shut down and allowed to flood, seemingly ending almost a century as one of the world's great sources of mineral specimens. Five years later, however, it had been reopened as a specimen-mining venture that is already meeting with some success. Everyone who is involved with the collection of mineral specimens has at least some familiarity with Tsumeb, Namibia. For most, it is the source of the finest examples of many species and likely a name that appears on the label of many of their favorite specimens. To curators and scientists, it has been the source of a phenomenal suite of mineralogical wonders, oddities, and associations that have been so well chronicled in the technical literature that a compilation of major Tsumeb references numbers well over three hundred. To economic geologists, it has been a model, a target, a challenge, and a dream. Unfortunately, every mine, no matter how great, has a finite life that can be likened to a good book in that sooner or later a last chapter must appear. With many mines, that final chapter is short and uninspiring, relating nothing more than the exhaustion of ore, the removal of equipment, the shutting off of power, and a final quiet wait as the water slowly rises. Sometimes there are complicating factors such as miners strikes, world economics, politics, and the like. No matter, still the water rises. With respect to Tsumeb, what seemed to be the final chapter began with a little of each. Unlike most mines, however, the importance of mineral specimens encountered here and the potential availability of additional valuable material in unmined parts of the upper workings have extended that final chapter. Had Tsumeb been the source of no specimens at all, it would still be famous as an incredibly valuable mineral deposit, having produced more than $5 billion in lead, zinc, copper, germanium, and other metals from a relatively small, though quite rich, deposit that was operated almost continuously for ninety-one years, ending in 1996 on level 48 at a depth of 1,650 meters (Gebhard 1999; Wilson 1977; Sohnge 1967). Thankfully, Tsumeb has been much more than a mere cash cow for a series of mining companies. Because of an unusually wide array of associated metals, the peculiar geologic history of the site of ore deposition, and, most important, the presence of three separate zones of oxidation, Tsumeb is one of the premier mineral localities in the world. From this mine, 247 mineral species have been identified, with 24 additional unknowns undergoing or awaiting study. It is the type locality for 52 species and remains the only known occurrence for 40 of these. Approximately 65 species are found here in well-crystallized specimens, the quality of most of which is unequaled in those from any other locality. At the time of its closure, Tsumeb was operated by Gold Fields Group of South Africa. Hundreds of miners worked each shift in myriad stopes and headings, a modern system of internal initial ore processing and decline access was in place, and a mill and smelter were working at full capacity, handling some 2,000 tons of ore and its concentrated products each day. Once the closure decision was made, most equipment was removed, and the pumps were shut off. Some ore was scavenged from pillars and other remnants higher in the mine as the waters rose. Ultimately the mill was shut down, the smelter was cut back to operate on ore from the nearby Kombat mine, and the assets were purchased by a local group, Ongopolo Mining and Smelting. After considering several proposals aimed at limited reopening of the mine for mineral specimen production, Ongopolo entered into an agreement with a new company, Tsumeb Specimen Mining (Pty) Ltd. Principals in this venture are Ian Bruce of Crystal Classics and mineral collectors Simon Brock and David Lloyd. An excellent review of the deposit's history and geology and a series of detailed informative news bulletins on Tsumeb Specimen Mining's progress can be found at their Web site, www.MineralMining.com, to which the reader is referred. A detailed review of the deposit's geology is available in Lombaard et al. (1986). It is one thing for a few miners out of hundreds to periodically recover specimens in a mine from which thousands of tons of rock are removed daily. A lot of mineralized rock is available to many eyes, and there is a significant infrastructure in place: There is water for drilling, compressed air at each heading, adequate ventilation, an internal communications and electrical network, a technical support staff, and ready access through a complex system of shafts, raises, and decline entries. It is a completely different matter for a few enthusiastic individuals thousands of miles from home to confront a flooded mine into which mill tailings and related surface debris have flowed for half a decade, with the primary objective of economically recovering mineral specimens. There were problems, both those that were anticipated and those that could not have been foreseen. If anything, Tsumeb is a wet mine. Drill-core records, stope maps, and recollections of former employees indicated that the most likely target areas for good azurite, malachite, wulfenite, cerussite, and arsenate minerals were between levels 5 and 8, some 100-150 meters below the normal water table. A big pump would be required. Consequently, a pump and supposedly seamless high-pressure piping were lowered through shaft No. 1 to level 12, with the intention of initially pulling the water level down to level 8. Did lightning strike the headframe, shorting out the pump's electrical system and requiring that it be removed, rewired, and reinstalled back down on 12? Yes, it did. Was the supposedly seamless pipe really seamless, or did it burst when confronted with hundreds of meters of hydraulic head? Burst it did. Finally, however, the weather cleared, the pipe held, the pump did its job, and access from the surface to level 8 was achieved after the removal of more than 800 million gallons of water. The pump continues to run at a rate of 1,800 gallons per minute. The mine was accessible now, or was it? Access could only be achieved through the decline, an inclined, spiral ramp of sorts with turnouts at each level. Rubber-tired equipment would allow quick work of muck removal and the transport of miners and equipment. The decline had partially filled with tailings and other debris while underwater, necessitating significant rehabilitation. After a great deal of work, there was, at last, clear access down to level 5, but there were no water and air lines, no ventilation, and no safe electrical system for blasting. These were installed, and mining was set to commence based on a plan to drive drifts into areas of remaining pillars and other mineralized zones, generally on the periphery of the orebody. Two two-man mining crews were employed along with a scooptram operator. A foreman, former Tsumeb shift boss Kieviet Rust, would oversee mining, with Ian Bruce in charge of the day-to-day operation. A former Cornish miner, Vitek Urbanski, and Australian geologist Ben Nicolson were added to complement the surface and underground staff. Cool lubricating water flowed to the drills, voltage and amps were there aplenty, ventilation was perfection itself, but the absolutely necessary, consistent supply of compressed air to run the drills was not there. There was a problem with the main compressor station at the smelter, the only available source of compressed air. This was a situation that could not be easily overcome and in the end required the purchase of a compressor dedicated to the mining venture. Once the new compressor was in place, the final mechanical hurdle had been cleared, and the operation fell into a routine of drilling, loading, blasting, mucking, and, periodically, removing specimens. In early 2001, Tsumeb was back in operation. In order to understand the targets of the current Tsumeb effort, it is necessary to first appreciate the geometry of the deposit itself. It is a somewhat sinuously plunging, pipelike body of relatively small crosssectional area. Prior to mining, it cropped out as a green, malachiterich hill some 150 x 50 meters in area. The upper 50 meters or so of the deposit were mined by surface methods that gave way to a succession of deeper and deeper shafts. Relatively late in its history, equipment and personnel access from the surface to level 12 was changed from shaft to decline, a spiral rampway put down primarily in the hanging wall of the deposit. Drifts were run off the decline at appropriate intervals to allow access to those levels already established. For engineering and geologic purposes, the mine was divided into levels numbered relative to depth, and on each level relative to position either east or west of the center of the deposit. So, a position in the mine given as level 5, West-5 would be a stope or other entry that would be in the fifth segment of the mine west of its center and on the 5th level below the surface. This coordinate system was critical in the understanding both of records for drill holes that intersected vuggy, secondary mineralization and also of the detailed initial specimen reconnaissance conducted primarily by David Lloyd. This information pointed to prospective areas located on level 5 at West-4, West-5, and East-5. These areas have received the greatest attention. Current mining follows a careful plan in which crosscuts are run at discrete intervals off of the main level 5 access drift toward areas of potentially productive ground. If specimen-bearing zones are encountered, then mining is modified, based on the characteristics of that zone. Normally, short 4-foot rounds are drilled and shot. An initial inspection of muck (broken rock produced by the blast) and of the new face resulting from each blast is made and any specimen material recovered. Then muck is removed from the face and stockpiled underground with the scooptram for possible future recovery as lowgrade ore. Five areas that are currently producing specimen-grade or, in the case of nodular azurite, cutting material have been encountered. One of these contains nodular and crystalline azurite in discontinuous clay seams, a second has vuggy zones that locally contain cerussite crystals on crystalline dolomite, a third is a zone of vuggy mottramite, a fourth contains vugs of crystalline malachite in massive chalcocite, and a fifth contains floater groups of reticulated cerussite. The occurrences of specific mineral species within these areas are described below. Minerals Aragonite, Ca(C[O.sub.3]). In the West-5 area of level 5, a short distance from the mottramite-rich zone described below, is a vertical water-bearing zone within which pale blue aragonite is precipitating as botryoidal masses and crusts. The material is relatively abundant, and platelike specimens to 25 cm across have been collected. Azurite, [Cu.sub.3][(C[O.sub.3]).sub.2][(OH).sub.2], and Malachite, [Cu.sub.2][(C[O.sub.3]).sub.2][(OH).sub.2]. Nodular and, less frequently, rosettelike azurite crystal groups occur on level 5 in clay seams that vary in width up to about 40 cm and appear to occupy late jointlike fractures that dip from about 30-60 degrees, The azurite content of clay seams can vary up to 50 percent azurite by volume, with the largest nodules about 5 kilograms and 15 cm across. Some are highly irregular to kidney shaped; others are almost spherical. The most common nodules are pure azurite in radially fibrous masses that exhibit a peculiar satiny sheen or chatoyancy on broken surfaces. Others contain cores of malachite that constitute up to about 30 percent of the nodule. In the largest, the associated malachite is velvety and contains irregular central vugs. The largest of these compound nodules is about 10 cm in diameter. All or parts of the surfaces of some nodules are bounded by flat crystal faces reflecting terminations of radially arranged tabular crystals, whereas on others azurite occurs in groups of tabular, well-developed crystals that have grown roughly tangential to the nodule surface. Locally within the clay seams are attractive groups of medium-to-dark blue, etchedappearing azurite crystals to 8 x 6 cm with individual flat blades to 5 cm long. These crystals are commonly in a somewhat crude radial arrangement, show only minor replacement by malachite, are often deeply striated, and contain multiple, somewhat skeletal terminations. Locally, however, these azurite groups are completely replaced by malachite or have discrete masses of velvety malachite as a final crystallization product on their surface. Once out of the mine, nodular azurite is separated into three grades: "A", "B", and "C". A-grade consists of competent nodules with no, or only a small percentage of, inclusions other than malachite. B-grade also is competent azurite with a somewhat higher clay content and porosity. C-grade is generally country rock containing dense networks of azurite-filled or healed fractures with more or less accompanying malachite. A-and B-grades are weighed and laid out to dry. The adhering clay cracks and separates as it contracts upon drying. Once dry, the individual nodules are immersed in water, causing much of the clay to fall away. The remainder is then removed easily with a water jet. The nodules are then air-dried and resorted. A-and some Bgrade azurite that has no specimen potential is stored for shipment to cutting houses. C-grade is retained for carving and lesser-quality lapidary projects. The best mining day relative to nodular azurite was 29 March, when 95 kilograms of A-grade and 36 kilograms of B-grade were recovered. On other good days, 69, 49, and 45 kilograms of Agrade material were recovered. Fine azurite particles are stored for a potential pigment market. Only a few sharp, perfectly formed azurite crystals of the sort for which Tsumeb is so well known have been found to date. These occur in fractures and small pockets in intensely brecciated, iron- and copper-stained dolomite that locally contains nearby azurite-bearing clay seams. Most of these are very sharp, dark inky-blue, flattened crystals of Roman-sword habit, with the longest about 2 cm. Typically only isolated crystals or small clusters occur in these pockets, with individuals generally in the 1-cm range. Partial to complete alteration of these crystals to velvety malachite is conspicuous in some pockets. Other minerals of collector interest are generally absent, and many such pockets are devoid even of azurite. Only a handful of high-quality azurite in equant blocky crystals to 4 cm have been found in these pockets so far. Not all specimen-grade azurite occurs in or adjacent to clay seams. Early in 2001, approximately 900 kilograms of botryoidal, cauliflowershaped azurite and malachite masses to about 30 cm across were encountered in an iron-oxide-rich, crystalline cerussite-bearing zone encountered on level 5 at West-4. These were carefully mined by hand and, along with several hundred thumbnail to small cabinet-sized azurite crystal specimens found in the general area of clay-seam azurite mineralization, were shipped to London for cleaning, preparation, and pricing. A cursory examination of accessible areas between levels 2 and 5 indicates that additional azurite and malachite of potential specimen grade remains in some stopes. Malachite is ubiquitous in most of the accessible workings, occurring as seams and as cavity and fracture fillings and coatings, commonly associated with subordinate azurite. Malachite occurs with azurite in clay seams as a local replacement in discrete, generally concentric zones as well as in irregular portions of azurite nodules. In some specimens, it occurs as a velvety replacement of the last phase of azurite crystallization on the surfaces of associated rosettelike azurite aggregates. Relatively sharp, elongate tabular azurite crystals completely replaced by somewhat dull greenish-gray malachite occur in fractures a short distance above and below the nodular azuritebearing clay seams. Pseudomorphs to about 8 cm have been recovered, with most specimens having only one or two isolated crystals, although a few nice groups with crystals to about 3 cm long have been found. A single cavity in the clay-seam area contained pale beige 8-mm wulfenite crystals on which were perched malachite pseudomorphs after azurite to 5 mm long. The approximately 5 x 7 x 10-cm cavity was in relatively dense dolomitic limestone, suggesting that recovery of undamaged specimens could present a problem. In some fractures bordering the clay seams, azurite and malachite occur as masses of alternating, crudely parallel bands. Although bands of both minerals consist of crystal aggregates, malachite appears to have replaced bands originally consisting of the most sharply crystallized azurite. These bands are made up almost entirely of subparallel malachite pseudomorphs after azurite, arranged perpendicular to the band edge, and range to 2 cm thick. Individual specimens to 8 x 14 cm across have been recovered in which plates of malachite pseudomorphs commonly rest on, or occur with, irregular masses or flat plates of blue, unreplaced azurite, making a striking contrast. On level 5 in the West-5 access drift is an area rich in massive chalcocite that contains cavities to 3 cm from which project mats of sparkling, apparently nonpseudomorphic malachite crystals. The occurrence is in coarsely brecciated dolomite at the margin of a previously mined-out area in pillars and on the walls of a stope where the early work had ended. Vuggy malachite-rich rock occurs locally within the open pit, particularly in rubble along the north wall. Here velvety pseudomorphs after crudely developed azurite crystals to 2 cm have been found. Associated minerals are rosasite, mottramite, and minor smithsonite. Cerussite, PbC[O.sub.3]. Good cerussite specimens have been recovered from level 5 in the West-4 stope area. The occurrence is in heavily oxidized, coarse dolomitic limestone breccia penetrated in a heading that had been abandoned by one of the early operators. In this zone of relatively bad ground (fig. 6), the surfaces of broken limestone fragments are locally coated by sharp dolomite rhombohedra to about 1 cm, among which are scattered cyclic cerussite twins that range to about 2 cm across. The cerussite crystals are bright and glassy and range from colorless to pale gray. Although most are undamaged, some show points of contact with adjacent breccia fragments, resulting in incompletely formed crystals. Breccia fragments are loosely cemented by iron oxides and lesser secondary copper minerals and have individual crystal-coated surfaces to 5 x 20 cm. A pale blue-green mineral tentatively identified as rosasite occurs with the cerussite as botryoidal and stalactitic masses. About fifty cerussite specimens have been collected. Good masses of botryoidal malachite and azurite were collected from this zone when it was first encountered (see above). A second cerussite occurrence encountered on East-5 produced about forty floater specimens of reticulated crystals in groups to 5 x 2.5 cm. Chalcocite, [Cu.sub.2]S. Only massive chalcocite has been encountered. Locally it occurs in rich masses that cement coarse dolomitic limestone breccia, most commonly in remnant pillars near the margin of the orebody in the West-5 area of level 5. Within these zones occur irregular masses of acicular to somewhat tabular malachite crystals that locally incompletely fill cavities in massive chalcocite, producing vuggy specimens. Most such malachite pockets are rimed by white calcite that separates the inner malachite from the bright gray metallic chalcocite, resulting in attractive specimens. Cuprite, [Cu.sub.2]O. Although Tsumeb is well known for fine cuprite specimens, none have been found since the mine's reopening. However, in the West-5 segment of level 5, massive fine-grained cuprite ("tile ore") occurs in fractured dolomite in the vicinity of chalcocite-cemented breccia. Some cuprite masses and veinlets are up to 1 cm across and in a matrix that locally contains cavities lined with sparkling calcite crystals, suggesting good specimen potential for that area. Duftite, PbCu(As[O.sub.4])(OH). Pale green to lime-green masses of botryoidal duftite occur in local abundance in the East-5 access drift with late crystalline calcite and in vuggy late quartz. The material is similar to that found in the well-known dioptase occurrence at levels 30-32 of the mine. Somewhat earthy duftite occurs locally in parts of the open pit characterized by relatively abundant malachite and rosasite. Two of three green unknowns identified by X-ray diffraction analysis of specimens collected since the mine reopened were duftite. Mottramite, PbCu(V[O.sub.4])(OH). In the West-5 area of level 5, approximately 50 meters along strike from the broken, oxide-rich cerussite-bearing zone, a relatively large area of vuggy, dark greenishgray, botryoidal mottramite was encountered. The material forms irregular masses to 30 cm that fill cavities in dark, oxide-rich clayey fault gouge. Much of the mottramite exhibits satiny to sparkling drusy surfaces that are attractive though quite fragile. Unusual associated minerals have not been encountered with the mottramite. Minium, [Pb.sub.3][O.sub.4]. Minium as orange fracture coatings was recovered from boulders on the stockpiled low-grade ore near the decline entrance. Rosasite, [(Cu,Zn).sub.2](C[O.sub.3])[(OH).sub.2]. Pale-to-medium blue mammillary rosasite aggregates occur with malachite in oxidized rock fallen from the north face of the open pit near the decline access drift. Specimens reminiscent of those characteristic of some Arizona localities have been recovered. Minor rosasite occurs sparingly as isolated spherical aggregates in the vuggy, cerussite-bearing zone in the West-4 area of level 5. Smithsonite, ZnC[O.sub.3]. Although famous for its phenomenally variable smithsonite specimens, none have been found in the mine since its reopening. However, core-drilling records indicate the potential for vuggy smithsonite in an area of West-5 yet to be reached. Masses of pale green botryoidal smithsonite in cavities to 5 cm have been found in ore stockpiled on the dump immediately east of the decline portal. Rosasite and an earthy yellow unknown are locally associated. Although the current venture is meeting with some success, specimens equal to the best material for which the deposit is famous are yet to be unearthed. Still, the promise of great things to be discovered in the upper oxidized zone is certainly there, and despite the best efforts of everyone involved in geology, engineering, and careful mining, the impact of Lady Luck will surely be felt one way or the other during the next year or so. This author (R. B. C.) is confident that he speaks for collectors and mineralogists the world over in wishing everyone involved all the best. This small enthusiastic group is to be congratulated for undertaking a financially and rather physically daunting series of tasks so that the rest of us might have a continued supply of good Tsumeb specimens. ACKNOWLEDGMENTS The manuscript was improved considerably by the critical reviews of Bob Ramik of the Royal Ontario Museum, Toronto, and John S. White of Kustos, Stewartstown, Pennsylvania. Financial support for the site visit was borne by Tsumeb Specimen Mining and is gratefully acknowledged, as are the organizational skills of Simon Brock. REFERENCES Gebhard, G. 1999. Tsumeb: A unique mineral locality. Grossenseifen, Germany: G. G. Publishing. Lombaard, A. F., A. Gunzel, J. Innes, and T. L. Kruger. 1986. The Tsumeb lead-copper-zinc-silver deposit, South West Africa/Namibia. In Mineral deposits of southern Africa, ed. by C. R. Anhaeusser and S. Maske, 1761-87. Geological Society of South Africa. Sohnge, G. 1967. Tsumeb: A historical sketch. South West Africa Scientific Society. Wilson, W. E., ed. 1977. Tsumeb! The world's greatest mineral locality. Mineralogical Record 8:1-128. Dr. Robert B. Cook, an executive editor of Rocks & Minerals, is a professor of geology and head of the Department of Geology and Geography at Auburn University. He writes the Connoisseur's Choice column for Rocks & Minerals. Benjamin E. Nicolson, a geologist from Australia, has about ten years' experience in the gold mines of Western Australia. He is a mineral collector, successful electronic gold prospector, and owner of several pegmatitic rare-earth mineral occurrences. Ian R. Bruce is the owner of Crystal Classics, a well-known mineral dealership in the United Kingdom. ROBERT B. COOK Department of Geology and Geography Auburn University Auburn, Alabama 36849 cookrob@auburn.edu BENJAMIN E. NICOLSON Tsumeb Specimen Mining Ltd. P.O. Box 344 Tsumeb, Namibia b_nicolson@hotmail.com IAN R. BRUCE Crystal Classics The Old Linhay, Woodcoxhayes Halberton Road Willand, Devon, EX15 2QF United Kingdom azurite@iafrica.com.na COPYRIGHT 2002 Heldref Publications COPYRIGHT 2002 Gale Group