Beam properties

advertisement

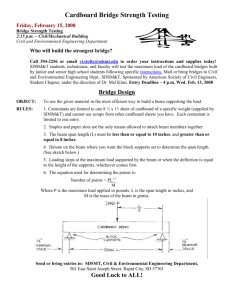

Beam properties The illustration depicts a board supported at each end on its narrow face and bending under a load [i.e. acting as an elastic beam]. The application of the load causes bending stresses, the fibers in the upper edge of the beam are resisting compression while those on the lower edge are resisting separation i.e. the lower part of the beam is experiencing tensile stress (the strain will tend to extension in beam length) while the upper part is experiencing compressive stress (the strain will tend to contraction in length) and there is shear stress around a neutral axis – where length doesn't change – but the axis moves lower as the load increases. The distribution of the tensile, compressive and shear stresses have application in engineering beam theory for the design of wing spars and other structural members, leading to the use of more complex, but lighter, beams in place of solid beams. The theory applies to metal and composite beams and is also applied in sandwich construction where high strength materials are used for the outer layers with a lower density material as the core. The core material separates the load carrying layers but still binds them together so that the load forces are properly distributed. The mechanics: let's say the cross-section dimensions of the beam shown are 100 mm in depth by 30 mm thick, the 'clear span' is 1000 mm, the depth/span ratio is 100/1000 = 0.1 and the load is a constant value. If the thickness of the beam is doubled [to 60 mm] the deflection distance under the load will be halved, whereas if instead the depth of the beam is doubled [to 200 mm], the deflection will be reduced to just one-eighth of that shown. Increasing the depth to 200 mm will double the depth/span ratio to 0.2. Similarly if the thickness is doubled the beam will carry double the load, but if the depth is doubled it will carry four times the load – with the same span between the supports. (Of course there is a limit to the amount the depth can be increased before other factors become significant.) Mr. Banks April 2007 Conversely if the supports are moved closer together so that the distance spanned is halved (the depth/span ratio is doubled) then stiffness is increased eight-fold and the beam will carry double the load. So the breaking strength of a beam is: • directly proportional to the width • but proportional to the depth squared • and inversely proportional to the span. While the stiffness of a beam is: • directly proportional to the width • but proportional to the depth cubed • inversely proportional to the span cubed. Thus whether the depth or width of a solid beam is doubled the mass is the same but the strength/stiffness/weight ratios for a beam are very much better with increased depth rather than increased thickness. Mr. Banks April 2007