Report - Indian Institute of Management, Ahmedabad

advertisement

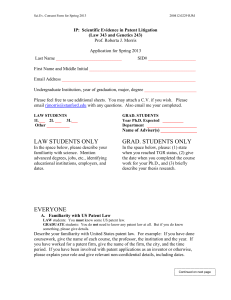

CINE Project Methods employed by R and D of various companies for screening ideas Submitted to: Prof. Anil Gupta On 25th February, 2007 By Ananda Chakraborty 1 Acknowledgement On the onset, I would like to thank Prof. Anil Gupta for providing this unique learning opportunity. For the successful completion of this project, I would like to express gratitude to Mr. Abhijit Sinha, Manager, R and D (Foundry), Tata Motors, Jamshedpur Plant and Mr. Vinod G. Kumar Manager, R and D (Foundry), Tata Motors, Jamshedpur Plant. I would also like to thank Mr. P. K. Mazumdar Director, Syngenta and Chairman, Croplife India, from whose guest the project has borrowed heavily. Ananda Chakraborty 2 TABLE OF CONTENTS Introduction .................................................................................................................. 4 Patent Law .................................................................................................................... 4 New Product Registration ........................................................................................... 7 The typical steps in product registration in India .................................................... 8 New Product development and screening of ideas in Agrochemical industry: ...... 9 R and D in manufacturing industries: ..................................................................... 11 Conclusion: ................................................................................................................. 14 References ................................................................................................................... 15 3 Introduction In today’s competitive scenario, Research and Development has assumed a very important role. For many large corporations, R and D is the source for competitive advantage. Some firms use innovative ideas to develop new products, molecules while others innovate to reduce cost or improve product/ service quality and some businesses are completely developed from an innovative idea. In this study, the functioning of R and D has been studied in two different roles, one of developing new products and second is of reactive research to improve a process. Agrochemicals and Pharmaceuticals are two such industries where the whole business thrives on how many new products a company can bring to the market. In other words, R and D is the most crucial function for them. But along with being innovative and creating new products, there is also another important concern about the Intellectual Property Rights which guarantees the return from R and D that these firms make. So it is necessary to understand the patents laws first to appreciate the methods of screening new ideas by these firms. Patent Law Any industry which is characterized by high R&D processes require intellectual property rights to protect its inventions and earn justifiable return on huge investments it has incurred for R&D. India followed process patent law till 2005. Under process patent law, protection is given to the process and not product. So it is quite possible for any other firm to make the same product through reverse engineering in which only different process is used to manufacture same product. This way any well performing product could be copied and launched by rival firm, thereby reducing the revenues for original inventor. So no organization would have any incentive to invest huge money in R&D to discover new pesticide molecules. Moreover onus of proving infringement was on patent holder. Such kind of regulatory environment discouraged any R&D efforts in India. Hence till 2005, India has major off patented products in market. 4 Development in 1995: India joined WTO in 1995 and hence obliged to follow TRIPS (Trade Related Intellectual Property Rights) agreement. Under TRIPS Agreement, fundamental rights of innovator are protected through patent protection. TRIPS agreements does not discriminate innovations as large or small, incremental or pioneering, but establishes a framework for judge the inventive quality of an invention. It has given general guidelines for judging the invention to be patentable. These guidelines are Process/product must be new Involves an inventive step Should have capability of industrial application Under Article 65.1 and 65.2 of TRIPS Agreement, developing countries had 5 years to comply with the TRIPS provisions. Under Article 65.4, a further 5 years were provided to comply with the requirement of granting product patents in areas where such protection was not granted. These provisions were made so that developing countries could develop their own system of strong patent law. India availed 10 years through these provisions. 1st amendment in 1/1/1995: First amendment was made as soon as India joined WTO. Under this amendment Government of India provided EMR (Exclusive Marketing Rights) and initiated Mail Box facility to accept product patent applications. EMR gives exclusivity to the innovator for marketing of the product embodying the innovation. This provision prevents any other manufacturer to sell the same product in the specified market. EMR was given subject to an applicant holding a process patent, market approval in other countries and the innovation pertaining to post January 1, 1995 period. 2nd amendment in 1/1/2000 Under 2nd amendment, companies were given “Uniform” patent term of 20 years for innovations in all areas, major efforts were put in rationalization of patent process and 5 tried to reduce the time required for grant of patent. Other features of this amendment were following: Same treatment was given to innovations made abroad as given to the innovations made in India Onus of patent violation was shifted on the infringer Safeguards for protection of public interest, nation security, bio-diversity, traditional knowledge etc were incorporated in the amendment. Patent (amendment) act 2005 On completion of 10 years joining WTO, India launched new patent law in 2005 with major breakthrough by shifting to product patent as obliged by TRIPS agreements. Though India has product patent now, there are lot of loop hole which are impeding the process. We will study some of them here. • Product patent to only “new chemical entities” (NCE): India patent law gives product patent to New Chemical Entities (NCE) only. But NCEs are beyond reach of many innovators as it takes lot of R&D budget and time. At the same time there are lots of innovators who does increment innovation and these innovations are not patentable. In Indian situation, many Indian companies, research institutions, scientists have huge potential for incremental innovations but patent law 2005 doesn’t support such innovations. But given that India need to comply with TRIPS agreement, which suggests patent protection to all innovation including incremental ones, have not included protection for incremental innovations. • TRIPS agreement has general guidelines criteria for innovation getting qualified for patenting. But Indian patent law has different definitions for criteria which has created lot of confusion among MNCs. Because there are • Law hasn’t made any provision to increase the protection period for mail box applicants. Because for mail box applicants, the rights and privileges are available from date of patent grant if they have filed application after 1/1/2005 whereas rights commence from date of publication of application. This reduced the protection period for 1995 mail box applicants. 6 • The provision for pre-grant opposition permits anyone to file opposition to patent claim by innovator, and in case if patent office accept such application, patent applicant does not have right of appeal. Besides, the time lines prescribed for filing of pre-grant opposition application i.e. 6 months after the date of publication or any time before the grant of patent can lead to substantial delays. • The amended Patent Act permits import of patented product without the authorization of the patentee. This could lead to import of products from a country where the product are off patent or patent is expired. • If an innovator from India wants to get a patent abroad, it needs the prior permission of authorities in India. Now such double process of getting permission in India first and then filing patent application lengthen the whole process. New Product Registration It is a regulatory process of evaluation and acceptance by the statutory authority of the claims made by the applicant in order to protect the health of people, animals, plants and environment and to ensure that pests are controlled in a safe and efficient manner. Registration of agrochemicals is handled at central Government level whereas issues regarding implementation of the Act including manufacturing license is done at the state level. It is a multidisciplinary endeavor including chemistry, bio-efficacy, toxicity and packaging. Types of registration • Provisional Registration u/s 9(3b) – For the new molecule introduced first time in India. Usually granted for a period of 2 years • Regular Registration u/s 9(3) – • Subject to the submission of complete data “Me-Too” Registration u/s 9(4) – After 9(3) registration of a molecule, any other person can apply for registration 7 The typical steps in product registration in India (The basic steps are same for agrochemical and Pharmaceutical industry) 2. CIB & RC, Ministry of Agriculture (Registration & Scrutiny) Submits application along with data 1. Applicant Deficiency report Admn Office Legal Chemistry Bioefficacy Registration Committee Packaging Toxicology 4. Ministry of Health (MRL Fixation) 3. ICAR 5. Central Insecticides Laboratory (Testing) For Products Manufactured in India SCPR studies data and recommend s the MRL Secretariat scrutinizes residue pro forma CCFS studies SCPR recommendati on and approves MRL Inspector visits site and collects the sample Sample analysis For Imported Technicals Submit samples Sample analysis Time required for obtaining Patent for different kind of Agrochemicals: Activity 9(4) – “Me Too” registration 9(3) and 9(3b) Fresh Registration Documentation and Form 1 and other documents verification by legal 0.5 month 1 month CIB&RC analysis, covering: 1-3 months 6-12 months Sample submission, collection & Analysis 2-6 months 2-6 months MRL Fixation (Ministry of Health) 1-2++ months 3-12 months Registration Certificate Issuance 2 months 2 months OVERALL PROCESS Minimum 6 months Minimum 12-36 months • • • • Chemistry Bioefficacy Toxicology Packaging 8 New Product development and screening of ideas in Agrochemical industry: The main contention in Agrochemical and Pharmaceutical industries is not only the fact that there is around 3 years lead time between a product is being applied for patent and it is actually out into the market. The lead time actually conceptualizing a product and finally selling it commercially is even more. For the last 10 years industry average, the lead time between a product being synthesized for the first time to the market is about 9.1 years (Ref: Mazumdar P. K. ( 2006, January 13) “R and D of new molecules” http://www.ficci.com/media-room/speeches-presentations/2006/jan/agrochem/ SessionIII/MrMazumdar.ppt ). For formulating one successful, unique product (Noble Product) of crop production, there is actually a screening of about 140,000 molecules and the whole process costs about $ 210 million from inception to consummation (Ref: Mazumdar P. K. ( 2006, January 13) “R and D of new molecules” http://www.ficci.com/media-room/speechespresentations/2006/jan/agrochem/ SessionIII/MrMazumdar.ppt ). So the main concern is to design a product looking ahead into a market of 10 years ahead. The R and D of an agrochemical company will have to assume the market conditions, prevailing problems and regulations 10-12 years ahead and then design a new product. The process of new product development starts from collecting new leads or ideas. The new leads may come from existing products or problems in the market. Sometimes new leads come from combinatorial chemistry i.e. combining the active ingredients or functional groups of some existing products. Sometimes leads may come from natural products or by discovering the properties of some new molecule. Then these ideas are thoroughly screened and infeasible ideas are eliminated to get some workable leads. After the workable leads are identified, then starts an iterative process of implementing it by actually synthesizing the chemical, screening the properties of the new compound on actual samples. Then based on the shortcomings of the compound, a new molecule is generated, then again it is screened and again a new molecule is generated. This process continues until a noble product is obtained. The main parameters for screening are: 9 Action: how much active will the new compound be on the target pest/ insect? Selectivity: Will the new compound be active only on the target pest or it will harm the whole ecosystem? The laws regarding non-selective chemicals are becoming more and harsher every year. Residual toxicity: will the residual toxicity be within the permissible limits? The regulations on residual toxicity are being more stringent, so will the compound will be permissible after 10 – 12 years? Soil toxicity: the users are becoming very sensitive to after effects on soil. So how quickly the soil will be free from all toxic effects? Patentability: Will the new product be patentable or it is very similar to some existing product? Is some company working on the same direction and had it made any significant progress so that they can file a patent before? Thus based on these parameters and projecting them for a market of 10 years down the line, this iterative process is continued until a satisfactory product is obtained. Synthesize target New lead Screen Think of a new Target Compound Evaluate results Noble Product Screening process for innovating new chemicals in agrochemical industry The priorities for different judging criteria are as follows: • Activity & Selectivity – 1st Consideration (Performance Parameters) 10 • Properties of the chemical, Residual toxicity and Soil toxicity – 2nd Consideration (mainly environmental parameters) • Patentability, Cost of manufacturing and others – 3rd Consideration (mainly commercial parameters) Data Protection: Thus we see that the research of a new agrochemical requires generating a large database of the chemical nature of the molecule, its action selectivity, residual toxicity etc. This involves huge efforts as the applicant has to conduct studies and generate data to demonstrate the safety and efficacy of the product. For a new chemical, the cost is about US$ 150 million and is almost the same as the expenses incurred on innovation. The whole process may take 8-10 years. The data generated has considerable value. It is in no way different from a tangible asset (such as land, plant & machinery) that a person acquires by spending money and effort. This data will also be very useful for the development of other products along the same lines and competitors getting access to this data will have significant advantage especially for developing a me-too kind of product. Presently in India, there is no provision for protecting the data once the application for patent is filed. In many other countries, there is a data protection period of 1-3 years to reward the efforts of the developer. This absence of data protection is also a major concern in the agrochemical industry. R and D in manufacturing industries: Apart from being used in developing new products, R and D assume another equally important role of process improvement. In this section, R and D is viewed in a context of process improvement and modifying rather than actually creating new ideas. In manufacturing industries, when a new product comes to market, it stays there for a long time and a series of improvements and add-ons are made to that product. So the R and D is bifurcated into two streams. One concentrates on developing new product, while the deals with improving the existing products and processes. We can take the example of Tata Motors, a premier motor manufacturer in India. For new product development, there is a separate department “Engineering Research Centre” (ERC) which is separate from the plants R and D department. ERC develops new models, 11 tests them, evaluate the results, make necessary changes and hand them over to the plant for manufacturing. However, each of the three plants of Tata Motors have an independent R and D department which works for improvement of the products being manufactured by that plant. In this perspective, these in plant are more interesting. The R and D dept. of each plant is divided into two parts. One part of R and D deals with overall process development and the second part deals with product improvement, like improving the design of a spare part or a sub-assembly. We first look into the product improvement part. Its work mainly comprises of some reverse engineering and minor alterations of the parts. The triggers for product improvement come mainly from two places: Dealers: The dealers are most aware about the market conditions. Sometimes they give input to the company that one of the competitors model is doing better than Tata’s cars in some parameters. Then this division try to analyse the competitors model and try to pin point the causes for its better performance. If there are some minor changes in some components of the model, they try to make those alterations in the Tata’s model provided they do not any major parameter in the manufacturing process. Service Persons: They often report the recurring problem in the Tata’s models. In that case the product improvement team tries to find out the cause of the problem. In general the problem could be either of two kinds: wrong usage by the end user like not using clean water in the radiator, or there could be manufacturing flaws. In case of wrong usage the message is given to the sales department. In case of manufacturing faults, product improvement team tries to make minor alterations in the manufacturing process or they refer it to the process improvement team. The process improvement team’s task is to improve the manufacturing process of the plant. They either may react to the triggers mentioned above or if sometimes some process goes completely out of control of the shop floor workers or the cost of manufacturing needs to be reduced to retain the profitability, then process improvement team is called for rescue. So this team generally starts working with a major problem in hand. Then their next task is to explore the probable causes of the problem. Sometimes when the cause is not very obvious from the visual inspection, a 12 brainstorming session is arranged to find out the probable causes. Then, after some working hypotheses are formed, these persons go into the shopfloor and find out the critical parameters that affect the manufacturing process of the concerned part/ assembly. Then they test their hypotheses and come up with some recommendations. If the changes needed to be made are very drastic and the entire assembly line is to be changed significantly, then they refer the problem to ERC. Product Improvement In Plant R and D Process Improvement R and D in Tata Motor ERC (central level) Research and Development Structure at Tata motor So, the in plant R and D of Tata Motors plants can be classified more as a reactive research than a proactive one. The basic criteria for selecting or rejecting an idea in the in plant R and D are effectiveness of the idea on the cause, its ease of implementation i.e. the disruption to the manufacturing process should be minimum possible and cost effectiveness. Here an optimum combination of Effectiveness & Ease of implementation is desired first and then cost effectiveness is the distinguishing factor. Apart from the ideas generated by the R and D dept., Tata Motors also encourage new and innovative ideas generated by the shop floor level employees. R and D screen these ideas and reward the workable ones. They also hand out handsome reward to the shop floor workers up to Rs. 30,000. The ideas generated by the shopfloor workers are also a very significant source of improvement for the Tata Motors plants. 13 Conclusion: Based on the above observations, a few conclusions can be made about how companies contemplate R and D and how they vary from context to context. Consideration of the market: it is very important to keep in mind the market conditions of the time when the idea will be actually marketable. For instance, in pharmacological or agrochemical industry, the lead time is very high and so they have to consider the customer demands, regulations etc. of 10 – 12 years ahead and not of the present. The same is with ERC of Tata motors, they will have to consider the changed customer preferences but only the lead time to market is not that long. Hence all new ideas should be developed by looking into the future market. If a company wants to launch a really good product which should stay very long time in market, then they should look even ahead than the time it will be in market. Difference in judging criteria: there is a huge difference in the judging criteria used for proactive research and reactive, improvement based research. In the earlier case, the success of the idea is the main criterion while in the latter case, the main consideration is that the idea should be effective and creative, but it must gel with the existing process causing the minimum possible disruption. So, when a company is designing a new process for manufacturing a new product this should be kept in mind. It implies that once a process is established, it is not going have many major changes until the process is shelved. So during the first designing, as many contingencies as possible should be taken into account. Difference in new product vis-à-vis improvement based research: these two aspects of R and D are completely different from each other. New product design is an aggregate level business decision, while the later one is a functional research. These two should be kept separately as their functioning is entirely different. Tata Motors duly appreciates this fact and thus ERC there is centrally controlled while the functional research is controlled by each individual plant. 14 References Mazumdar P. K. ( 2006, January 13) “R and D of new molecules” http://www.ficci.com/media-room/speechespresentations/2006/jan/agrochem/SessionIII/MrMazumdar.ppt Gupta.U. .( 2006, January 13).”Encouraging Innovation in Crop Protection Industry Indian Laws vs TRIPS Agreement” www.ficci.com/media- room/speeches presentations/2006/jan/agrochem/SessionII/Uttam.Gupta.ppt Kumar.A.( 2006, January 13). “Agrochemical Global View”. Molecules Registration:A www.ficci.com/media-room/speeches- presentations/2006/jan/agrochem/SessionII/Ajay.kumar.ppt Madan U.S. (2006, January 12). “Challenges and Problems Faced by Indian Pesticide Industry”. www.ficci.com/media-room/speeches- presentations/2006/jan/agrochem/SessionII/U.S.Madan.ppt MNCs outsourcing pesticides production, research to India. (2005, April 23). http://onlypunjab.com/fullstory2k5-insight-news-status-25-newsID-2119.html Nair M.D. (2004, February 18). First & Second Amendment to IPA 1970: Balancing TRIPS obligations and safeguarding Indian interests. http://www.pharmabiz.com/article/detnews.asp?articleid=20499&sectionid=4 6 Ramachandran. R. (2006, January 12) Impact of TRIPS on Agrochemical Industry in India. from www.ficci.com/media-room/speeches- resentations/2006/jan/agrochem/SessionVIII/MrRamchdran.ppt 15