Two-pass, Strip-till Farming for Row Crops on Clay Soils

advertisement

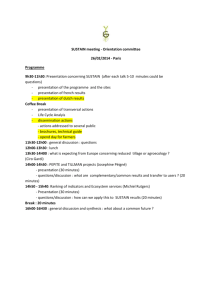

1 2002 Temple, Texas USA TWO-PASS, STRIP-TILL FARMING FOR ROW CROPS on CLAY SOILS John Morrison, USDA-ARS, Temple,TX Jerry Lemunyon, USDA-NRCS, Ft. Worth, TX Tom Gerik, TAES-BRC, Temple, TX Wyatte Harman, TAES-BRC, Temple, TX Mike Chandler, TX A&M Univ.-TAES, College Station, TX Joaquin Sanabria, TAES-BRC, Temple, TX Disclaimer: Materials and illustrations vary in format as taken from referenced published manuscripts. This is a technical summary; readers should go to referenced literature for details of research methods and extended discussion of results and conclusions. ______________________________________________________________________________ “Strip-till” is one of the newest twists on conservation tillage for the production of row crops, such as corn, sorghum, cotton, soybeans, tomatoes, cabbage, and possibly many more. Its appeal is that the use of Strip-till is immediately adopted and does not require the long learning curve often associated with No-till production techniques and management. Strip-till requires minimal planter modifications, using conventional row crop planters. Planting and disease and insect control are similar to conventional tillage practices. Weed control is similar to that for No-till. Strip-till adds an additional option for fertilizer application. Residue management, controlled traffic, soil conservation, erosion control, and other environmentally-friendly management options are all compatible with Strip-till. Strip-till appears to be a major improvement in conservation agriculture. Strip-till Today The fundamental basis of Strip-till is the preparation of a seedbed in tilled strip zones in undisturbed soil and residue cover, where future rows will be located (fig. 1). According to the Conservation Technology Information Center (CTIC, 1995), the tilled strips should be no more than 25% of the field area. That means that for typical 30-inch row spacings, the strips should be no wider than 7½-inches wide. The strips provide tilled soil, which has been loosened [warmed and dried seed zone in cold spring conditions] to resemble tilled soil in conventional tillage systems. The intervening 75% of the field surface will be at partially covered by residues and the soil will be undisturbed (fig.2). These residue-covered zones between the tilled strips provide areas for support of wheel traffic, water infiltration, water storage, erosion control and other benefits associated with No-till. 2 Why use Strip-till ? If No-till can be successfully used for row crop production and there are no problems with plant stands, troublesome soil conditions, need for exotic planters, etc., then there is little reason to switch to Strip-till. But, if No-till management and problems are elusively difficult, then Striptill may be the technology that you have needed all of the time. Please consider the following: ▪If you have cold, wet, sticky soils for spring planting, then Strip-till can warm and dry the seed zone and make it possible to get your crops planted on schedule. ▪If you want to apply your fertilizer materials ahead of planting or in bands below where the seed row will be located, then Strip-till could be the best system. ▪If you want to plant back into the same crop rows, year after year to keep tractor track lanes between the softer soil of crop rows, then Strip-till may be your answer. ▪If you require incorporation of herbicides or insecticides for pest controls, then Strip-till can include these applications. ▪If you are about to give up on No-till, but still want to do conservation farming, then the use of Strip-till may provide the type of management system better suited for you. ▪If you have tried five or more different types of “No-till attachments” on your planter and still have problems, then Strip-till may be just the thing for you. Appropriate Soils for Strip Tillage Strip tillage is a potential management practice for all mineral soils, even poorly drained, "hardsetting", high clay, and other problem soils. It should be noted that appropriate tillage is conducted in the narrow strips, while the untilled interrow zones remain protected with crop residues. Our work in Central Texas has been conducted on the clays and silty clays of the Texas Blackland Prairie. These are self-mulching, non-scouring, shrink-swell clays which form large clods when tilled dry and smear when tilled wet. The local opinion is: “that if a machine system will work in these soils, it will work anywhere”. The Role of Residue Cover Protective crop residues are either cleared from the narrow tilled strips and accumulated in the interrow areas or incorporated into the soil where the Strip-till procedures are conducted. Residues in the interrow areas support the loads of wheel traffic to reduce rutting and make equipment mobility possible under wetter soil conditions (Bashford et al., 1987). This is especially important on clay soils that have only one-third to one-forth the wet bearing strength of sandy soils (Dao et al., 1994). Residues reduce water runoff by microimpoundment of surface 3 water, by providing raindrop energy dissipation to reduce surface sealing, and by allowing more time for water infiltration (Mutchler and Young, 1975). Clearing Strips Through Residues for Crop Rows For spring planting of annual row crops, the residues from previous crops are usually partially deteriorated, brittle, fragile, easily cut, and reduced in volume from their original condition. Also, over-wintered stubble is usually only slightly anchored due to deterioration of the roots. Therefore, strip clearing in the spring is successfully accomplished with the use of rolling coulter blades and/or one of the many brands of row clearing residue rakes, which are available as planter attachments. Some type of path clearing is necessary unless the residue and stubble has been cut or shredded into short pieces to flow around the in-row Strip-till equipment. Row clearing is more difficult and critical in fresh residues with anchored stubble. Farmers usually operate the Strip-till units beside old stubble rows to avoid having to cut and uproot anchored stubble. Long pieces of fresh, tough residue, such as corn, sorghum, or cotton stalks, will require pre-cutting with a flail, rotary, or other type of residue cutter/shredder, because currently manufacturers are not offering powered residue cutters on Strip-till implements. Strip-Till “Alternatives” for Implement Systems Width of tilled strips may range in width from as narrow as 4 inches to as wide as 10 inches for row spacings of 16 inches to 40 inches, respectively. The tillage conducted in these strips is most easily characterized by depth of the operation. Typical depth alternatives are: a). Planting-depth at 1½ to 2½ inches; b). Cultivation-depth at 3 to 4 inches; c). Chiseling-depth at 6 to 10 inches; d). Subsoiling-depth at > 10 inches. Intensity of Strip-till can vary: 1). Soil loosening with a shallow sweep (fig. 4); 2). Shallow soil loosening with a thin shank tool or knife; 3). Deeper soil loosening and lifting with a shank tool (fig. 3); 4). Surface soil loosening and residue cutting with multiple fluted coulters; 5). Powered rotary-tiller soil pulverization and residue incorporation. Depth, width, and intensity alternatives affect soil tilth, structure changes, and mixing which may vary among soils and soil conditions, as well as among different tillage tools and speeds of operation (M'Hedhbi, 1989). One-Pass Strip-Till, Two-Pass Strip-Till, and No-Till Systems One-pass Strip-till systems typically utilize one of the above “Alternative” procedures integral with the combined seeding and fertilizer and/or pesticide application operations, to accomplish significant in-row tillage of a strip ahead of a planter furrow opener. Two-pass Strip-till systems separate the first, Strip-till, operation from the second, seeding, operation, but may also include 4 the application of fertilizers and/or pesticides into the tilled strips prior to seeding. No-till systems cut or clear a path through residues ahead of seed furrow opening, but do not till a strip. When to do Strip-till ? Two-pass Strip-till systems may include additional management alternatives, including the timing of field operations to take advantage of changing soil and residue properties during the period between crops. Many farmers who wish to apply part or all of their fertilizer with the Strip-till operation, must consider decisions on depth, intensity, and timing. Another consideration on appropriate timing of different Strip-till depths is that subsurface soil can have elevated soil water contents for extended periods during the fall-winter-spring seasons, which almost eliminates deep tillage operations, especially for clay soils. Chisel-depth Strip-till is generally recommended for use in dry soils which will shatter. For this reason the operation is conducted in the early fall, before the onset of rains and slow-drying weather. This operation can produce sizeable clods in the tilled strips, but over-winter weathering reduces the clods to friable soil conducive for spring planting. If chisel-depth operations are conducted when the subsurface soil is too wet, the implement will produce undesirable smeared channels. If the spring soil condition is dry enough for chisel-depth operation, the resulting cloddy soil condition may not have sufficient time to be appropriately weather for quality seeding. Although Strip-till was originally developed as deep, in-row chiseling/subsoiling in the Southeast and more recently for fall strip-chiseling of Corn Belt soils, some Texas Blackland Prairie farmers are successfully learning how to use chisel-depth Striptill. We have conducted field-size research and demonstrations of sweep-tool Strip-till operations up to 3 months to as little as 4 hours ahead of the planting operation. The 3-month operation was to test the effects of operation depth and long time periods and the 4-hour shallow operation was tried when the soil was so wet that it was the first opportunity to get into the field to loosen and dry the seed zone before planting. Both extremes worked well and proved to be better than Notill in sticky clay soils. A Look at Strip-till Implements Strip-till implements are multipurpose machines which can have tools attached to perform Alternative (a), (b), (c), or (d) mentioned above. Features of individual row-units are: a). Individual row-unit flotation, b). Individual depth control, c). Mechanism for clearing of a path through residues, d). Adjustable or controllable vertical force for soil penetration, e). A rolling coulter blade to cut residue and soil, f). Strip-tillage tool with applicator tube(s) for fertilizer, manure, or other material, e). Hilling discs to form a ridge of loosened soil in the strip. Commercial strip tillage implements are available with many of these features, and innovative farmers are fabricating their own versions from old cultivator or tool bar implements. 5 SUMMARY OF RESEARCH ON TEXAS BLACKLANDS 1995-1998 Experimental Plot Strip-till Trials, Temple, TX A. Cotton In 1995, cotton (Gossypium hirsutum L.) studies compared cotton growth between conventional chisel tillage, Strip-till, and No-till systems. Strip-till treatments used a thin knife-chisel in each row strip to prepare soil for planting. Research treatments were: 1) conventional fall chisel plowing and tandem discing; 2) fall Strip-till knife-chiseling; 3) spring Strip-till knife-chiseling; and 4) No-till. Planting was done with experimental triple-disc row units on a Case-IH #800 Cyclo Planter as described by Morrison and Gerik (1983) and Morrison (1988). Strip-till knifechiseling consisted of a smooth, rolling coulter followed by a thin 7/16-inch thick fertilizer applicator knife (Wiese, #CO-50), operated at a depth of 8 inches. Cotton plant growth and yield performance were monitored on Houston Black clay (fine, montmorillonitic, thermic Udic Pellusert). Cotton treatments in 1996 were a repeat of the 1995 treatments, but conducted in undisturbed corn stubble residue. RESULTS (Cotton) Cotton plant stands were higher in both the 1995 chisel-till and spring Strip-till chisel-knifing than for No-till, indicating superior seedbed conditions (table 1) (Jost, 1996; Morrison et al., 1996). Due to sufficient summer rainfall in 1995, there were no differences among tillage treatments for cotton plant height, biomass development, or yields (not shown). Cotton studies in 1996 were comparisons between sets of treatments on two different tillage histories. There were similar plant emergences, growth heights, and biomass between tillage treatments (table 2). Although 1996 was a dry season, the results were essentially the same as for the wet season in 1995, but not enough data was available to form conclusions. There were (non-significant) trends for no-till to produce the lowest plant emergence and for spring Strip-till to produce the highest plant biomass measured 8-9 weeks after planting. B. Corn Corn tests in 1996 were conducted in shredded corn residue from a 1995 conventional tillage corn crop. Two soils were used: Houston Black clay and Austin silty clay (fine-silty, carbonatic, thermic Entic Haplustolls). Plots were 3, 30-inch spaced rows, each 300-feet long. Tillage treatments were: 1) conventional fall chisel plowing and tandem discing; 2) fall Strip-till knife-chiseling (fig. 3); 3) spring Strip-till knife-chiseling; 4) winter shallow-depth sweep Strip-till (fig. 4); 5) spring shallow-depth sweep Strip-till. Strip-till knife-chiseling was with a 7/16-inch thick fertilizer applicator knife (Wiese, #CO-50), operated at a depth of 8 inches. Shallow-depth Strip-till was with a 8-inch wide, flat style, low- 6 disturbance sweep (Nichols Tillage Tools, Inc., #SF-8), operating at a depth of 2 inches. All treatments were planted with a conventional John Deere #7100 MaxEmerge planter without any special attachments, and without any planter adjustment among tillage treatments. Counter-CR insecticide (American Cyanamid Co.) was applied as a 6-inch band over the planted rows. Corn tests in 1997 duplicated the 1996 tests and treatments were placed on the same plots. RESULTS (Corn) In 1996, corn final emergence was similar for all treatments (table 3), except for lower emergence from winter than from spring shallow Strip-till in the Houston Black soil (Morrison 1999; Morrison, 2002a). Plant growth was statistically higher for shallow Strip-till treatments over deep knifing, and for all Strip-till treatments over conventional chisel plowing on both soils. The deep knife-chisel treatments dried the soil prior to planting and thus reduced growth in the drought conditions of 1996. Yields were very low because of drought, but seven of the eight conservation Strip-till treatments produced higher yields than the conventional chisel-plowed tillage treatments. A drought-induced crop failure occurred on the conventionally-tilled plots on Houston Black soil. Repetition of the corn experiments in 1997 produced similar final emergence responses to tillage treatments on both soil types (table 4). Plant height at 53 days was superior over conventional tillage for both sweep Strip-till treatments on Austin soil, and for all knife and sweep Strip-till treatments on Houston soil. An infestation of corn root worms (Diabrotica virgifera zeae, Krysan and Smith) influenced the yields to an unknown extent. Yield trends in the Austin soil did not follow emergence and growth trends, resulting in the conventional tillage and two shallow Strip-till tillage treatments producing the highest yields (table 5). Yields in the Houston Black soil generally agreed with the earlier growth rates, where the two sweep Strip-till treatments increased yield as much as 1300 lb/acre over conventional tillage. In a companion study on the compatibility between tillage system, planter presswheels and planter openers, it was concluded that for Strip-till we can expect adequate planting performance with conventional double-disc planter openers. This was true when the planters were equipped with either standard dual rubber, dual cast iron, or dual spoked presswheels (Morrison, 2002b). In summary, Strip-till is an improvement in terms of corn growth and yield over strict No-till for the soil types in this experiment. The experimental Strip-till practices used conventional doubledisc-opener planters without available row-cleaning attachments. Both deep and shallow types of Strip-till increased corn growth and yield in most cases over conventional chisel plowing and tandem disking tillage. There was no advantage to the use of the deeper knife-chisel tools over shallow sweep tools in the soils tested. The data were inconclusive for cotton, but did not include shallow-sweep-type treatments, so more study is needed. For the conditions tested, use of Strip-till procedures provided more management options than strict No-till and higher yields than with conventional tillage in drought years. 7 1997-1998 On-Farm Strip-till Trials On-farm corn tillage trials were conducted in 1997 and 1998 at Rosebud, Texas (Morrison, 1999; Morrison, 2002). These were replicated field-scale tests with 12-row (30-inch rows) machines used in a continuous corn cropping system. Eight tillage treatments were applied in mid-winter and tested the use of applying additional phosphate fertilizer in conjunction with the winter tillage and Strip-till. All treatments received solution in-furrow starter-fertilizer at 100 lb/acre of 10-34-0 (N-P-K) plus 0.6 gal/acre of chelated zinc when planted, and 130 lb/acre of N sidedressed between crop rows after crop emergence. Treatments were: 1. Strip-till, deep knife-chisel (6-inch depth and 12-inch knife spacing) w/o fertilizer. 2. Strip-till, deep knife-chisel w/ 34 lb/acre of P2O5 fertilizer in 100 lb/acre of 10-34-0 (N-P-K) (same for all treatments w/ fertilizer). 3. Strip-till shallow sweeps (2½-inch depth with 8-inch wide sweeps) w/o fertilizer. 4. Strip-till shallow sweeps w/ fertilizer. 5. No-till, only, w/o fertilizer. 6. Winter tandem disked + Strip-till deep knifing w/o fertilizer. 7. Winter tandem disked + Strip-till deep knifing w/ fertilizer 8. Winter tandem disked, only, w/o fertilizer Planting was done with a 12-row John Deere MaxEmerge #7100 planter with Yetter Residue Manager row cleaners. Planted rows followed in old-crop stubble rows, spaced at 30 inches. Plant emergence, plant growth, and yields were measured for three replications. The crop was machine harvested with a 6-row combine and the total yield weighed with a weigh-wagon in 1997 and detailed yields recorded with a yield monitor (Ag Leader Technology #PF3000) in 1998. RESULTS (On-Farm Corn Tests) The 1997 large farm-scale plot trials produced final plant emergence for all other tillage treatments greater than for No-till (table 6). The winter fertilizer application did not produce a trend in plant emergence. Plant height at 76 days ranged from 82 to 87 inches and was not conclusive for a particular type of tillage or fertilizer treatment. Yields (table 7) were similar for all treatments with and without the winter fertilizer application, except for lower yield from strict No-till, which corresponds with the lower plant emergence results. In 1998, a cold and late spring was followed by below average precipitation causing both late planting and a summer drought. The two Strip-till treatments produced higher final plant emergence than the two tandem disked treatments, and winter fertilizer application did not affect emergence (table 8). Plant height at 40 days was greater for both Strip-till treatments than for the tandem discing treatments. Winter phosphorus fertilizer applications improved plant height at 40 days for the two Strip-till treatments. No-till plant final emergence and 40-day height fell numerically between tandem disking and Strip-till. Yields for all treatments (table 9) were limited by insufficient seasonal precipitation, but three of the Strip-till treatments yielded more than two of the tandem disked and the No-till treatment. Winter applications of phosphorus fertilizer with the Strip-till treatments did not consistently improve corn emergence or plant growth, and the one case of small yield improvement may not be enough to justify the fertilizer 8 input cost. Based upon the results of this trial, the farmer was advised that the winter phosphorus fertilizer applications were not cost effective, but that Strip-till techniques could improve plant stands and yields over his current No-till practice. 1999-2000 Comparison of Eight Systems A two-year field study compared eight tillage/planting systems during four planting dates, two years, on two soils, and for both corn and grain sorghum (Morrison, 2000; Morrison and Sanabria, 2002). The systems compared were two variations of one-pass No-till, four variations of one-pass Strip-till (more soil disturbance than No-till), and two variations of two-pass Striptill systems. The planter units were John Deere #7100 MaxEmerge (systems 1, 2, 3, and 4) and Case-IH #800 Early Riser (systems 5, 6, 7, and 8). No-till systems were commercial planter units with commercial row cleaner attachments to clear paths. It should be noted that 312 lbs. of ballast was attached to the MaxEmerge planter unit (system 3) to cut residue and penetrate soil to achieve the same planting depth as the other seven planter units, in the traditional undisturbedsoil No-till system. The addition of this extreme amount of ballast made that No-till system work, but we forced it to work in a manner that would not be recommended to farmers. Onepass Strip-till systems (systems 1, 4, 5, and 8) were experimental variations of No-till systems, utilizing row cleaners and shallow sweeps to clear paths and loosen the soil in conjunction with the planting operation. Two-pass Strip-till was conducted one day before planting with an experimental implement with row cleaners and shallow sweeps to clear paths and till strips only about 2-inches deep and 8-inches wide (systems 2 and 6). RESULTS (Corn and Sorghum) Similar yields of corn in year 2000 suggest that a farmer that has plentiful rainfall or available irrigation could use any of the eight tillage system treatments tested in this study without concern about the planting date. Likewise, similar sorghum yields during year 2000 indicate that any treatment is good under plentiful rainfall or irrigation, but the best planting date for that year was between Julian day 61 and 66. In answer to the research objective of identifying Strip-till alternatives that are appropriate for the local conditions of adhesive, shrink-swell vertisol clay soils and annual cropping, the results were consistent across the wide range of field conditions produced by 16 combinations of year, planting date, and soil type. The same response patterns occurred for seedling emergence and grain yield of both corn and sorghum in both soil types (fig. 5 and 6). Highly variable results were produced by the experimental one-pass Strip-till treatments 1, 4, 5, and 8 for corn, and treatment 1 for sorghum (fig. 5 and 6). These one-pass Strip-till system treatments were done with shallow sweeps as the main soil-engaging tool. The sweep loosened a strip of soil, bringing moist adhesive soil to the surface, which adhered to planter furrow openers, depth gauge wheels, and presswheels and caused functional problems in the field. Apparently, those functional problems were reflected in more variable crop performance, that would eliminate further consideration of the four experimental one-pass Strip-till treatments and select either the standard one-pass No-till systems (treatments 3 and 7) or the two–pass Strip-till systems (treatments 2 and 6) for these crops and soil conditions. Recommendation of Strip-till 9 over No-Till is stronger if additional operations such as application of fertilizers or insecticides can be accomplished with the Strip-till operation to justify the additional machine ownership and field operation. A positive field observation: seeding operations were less management-intensive with Strip-till, because planters did not require the addition and adjustment of ballast to achieve adequate seeding depth with changing soil conditions. 2002 Design for a Strip-till Implement The experimental Strip-till implement was designed and developed by the USDA-ARS Grassland Soil & Water Research Laboratory, Temple, TX as field-scale 8-row implement for general field use (fig. 7). It consists of a 7x7-inch toolbar having row markers, manifold and tubing for the application of liquid fertilizer solution, and eight independent Strip-till row units. Each row unit is suspended on parallel linkage for flotation. Automotive air-shocks provide easily adjustable downforce on the units, but compression springs could be used. The units each have a pair of opposing Great Plains TerraTine® row cleaner tine-wheels to clear paths and control depth, a smooth rolling coulter blade equipped with modified Bowerman rotary scrapers for operation in adhesive clay soils, a low-disturbance modified Smith-fin® 8-inch wide sweep with fertilizer tube (other shallow or deep knives or tools could be used), and dual floating CaseDMI covering discs to deflect loosened soil into a low ridge. The units are designed for shallow Strip-till and would need to be of a heavier construction if deep tools, like chisels, were to be used. This machine was used to Strip-till about 200 acres in the spring of 2002, on field sites across five Central Texas Blackland counties as part of a on-farm tillage study organized by the Blackland Conservation Technology Alliance (BCTA). FARMER EXPERIENCE Several local farmers are using No-till and Strip-till for their row crop production. Those using No-till are using conventional row crop planters with staggered double disc openers, modified with residue clearing attachments ahead of each planter unit. They plant spring crops close beside old stubble rows without the cutting/shredding of residues. Wheel traffic is maintained in the same row middles, year after year. Strip-till farmers started into the system by using ½-inch thick vertical fertilizer applicator knives in or beside old crop stubble rows. Some of them cut/shred their stalks while others do no active residue management. If the stubble is well anchored, the farmer will plant close beside old stubble rows. They have successfully operated directly in the old rows, for years when the stubble is easily dislodged,. Rolling coulter blades and row cleaner rakes were added to these on-farm developed rigs. Commercial Strip-till implements are now replacing some of these initial implements. The farmers apply fertilizers with their Strip-till operations. The fertilizers have been solutions of phosphorus, with small amounts of nitrogen and trace nutrients. Some farmers also apply starter fertilizer with their planters, while others apply all of their phosphate 10 and starter fertilizers with the Strip-till. Wheel traffic is maintained in the same row middles, year after year. All of these farmers apply liquid nitrogen fertilizer with side-dress operations after the crop is established. Applicator implements are equipped with either thin knives or coulter-nozzle units to place fertilizers beside crop rows or in the middles between rows. Fertilizers are placed in shallow bands beneath residues and the soil surface. Farmers desire minimal reside and soil disturbance. Individual row-unit depth control is used by most farmers to insure that the knives or coulters do not disturb too much soil by cutting too deeply. Recommendations If one-pass No-till is being successfully used, it should continue to be used, because No-till requires the minimum in implement inventories and field trips. If there is a difficulty or risk with the use of No-till, Strip-till systems will provide an ease of management as well as benefits to conservation and environmental protection. Publications Cited Bashford, L.L., A.J. Jones, and L.N. Mielke. 1987. Bulk density beneath a belt track and tire on an agricultural tractor. ASAE Paper No. 78-1054. ASAE, St. Joseph, MI 49085-9659 USA. CTIC. 1995. Survey Guide; Your Guide to Local Participation, Uses, and Benefits of the National Crop Residue Management Survey. W. Lafayette, IN: Conservation Technology Information Center. Dao, T.H., J.E. Morrison, Jr., and P.W. Unger. 1994. Soil compaction and bearing strength. In Crop Residue Management to Reduce Erosion and Improve Soil Quality: Southern Great Plains, ed. B.A. Stewart and W.C. Moldenhauer. pg 40-44. USDA, ARS, Conser. Res. Rep. No. 37. Jost, P.H. 1996. Cotton (Gossypium hirsutum) production and Thiazopyr efficacy in reduced and no-tillage systems in the Blackland Prairie of Texas. MS Thesis, Texas A&M Univ., College Station, TX USA, May 1996. M'Hedhbi, K. 1989. Tillage effects on residue change. MS Thesis, Texas Tech. Univ., Lubbock, TX, December 1989. Morrison, J.E. Jr. 1988. Interactive planter depth control and pneumatic downpressure system. Transactions of the ASAE 31(1):14-18. 11 Morrison, J.E., Jr. and T.J. Gerik. 1983. Flexible mounted double-discs for conservation planters. Transactions of the ASAE 26(4):1044-1045. Morrison, J.E., Jr., T.J. Gerik, F.W. Chichester, J.R. Martin, and J.M. Chandler. 1990. A notillage farming system for clay soils. J. Prod. Agric. 3(2): 219-227. Morrison, J. E., Jr., Jost, Philip H., and Chandler, James M. Row-Zone tillage systems and implements. 1996. In Proc. International Conference on Agricultural Machinery Engineering. Seoul, Korea. pp. 413-422. Morrison, J. E., Jr. 1999. Row-zone alternative to no-till row crop production. ASAE Paper No. 99-1089. American Society of Agricultural Engineers, St. Joseph, MI. Morrison, J. E., Jr. Row-zone strip tillage machines for conservation crop production. 2000. In Proceedings of XIV Memorial CIGR World Congress, Tsukuba, Japan. Morrison, J. E., Jr. 2002a. Strip tillage for “No-Till” row crop production. Applied Engineering in Agriculture 18(3):277-284. Morrison, J. E., Jr. 2002b. Compatibility among three tillage systems and types of planter presswheels and furrow openers for vertisol clay soils. Applied Engineering in Agriculture 18(3):293-295. Morrison, J. E., Jr. and J. Sanabria. 2002. One-pass and two-pass strip tillage machines for conservation row-crop production. (Manuscript accepted for ASAE publication in 2002). Mutchler, C.K. and R.A. Young. 1975. Soil detachment by raindrops. In Present and Prospective Technology for Predicting Sediment Yields and Sources. ARS-S-40, Agr. Res. Ser., U.S. Dept. of Agr., Washington DC, pg 113. _____________________________________________________________________________________________ 12 TABLES Table 1. Cotton emergence, growth, and biomass development in response to tillage treatments and a wet summer season at Temple, TX, 1995 (Josh, 1996). Treatment H Conventional S-T fall knife-chisel S-T spring knife-chisel No-till Final Collar height Collar height Biomass emergence at 53 d at 72 d at 59 d (plants/acre) (inch) (inch) (lb/acre) 101,000ab* 7.9a 24a 700a 97,100bc 7.1a 24a 720a 109,000a 8.3a 25a 830a 89,000c 7.5a 24a 630a * Means in a column followed by the same letter are not statistically different at the 5% level of significance by the LSD test. H AS-T@ is strip tillage. 13 Table 2. Cotton emergence, growth, and biomass development in response to tillage treatments and a summer drought season at Temple, TX, 1996 (Josh, 1996). Treatment H AChisel-till@ Plot Final Collar height Collar height Biomass emergence at 55 d at 62 d at 62 d (plants/acre) (inch) (inch) (lb/acre) 194,000a* 9.7a 13.1a 810a S-T spring knife-chisel 188,000a 10.2a 13.8a 930a ANo-till@ Plot 196,000a 8.7b 12.4a 810a 178,000a 10.2a 13.5a 820a Conventional S-T fall knife-chisel No-till * Means in a column and in the AChisel-till@ Plot or ANo-till@ Plot followed by the same letter are not statistically different at the 5% level of significance by the LSD test. H AS-T@ is strip tillage. 14 Table 3. Small-plot corn final emergence (24 d) and leaf collar height growth (51 d) responses to five tillage treatments and two different soils at Temple,TX, 1996. Treatment HH Austin silty Houston clay, Austin silty Houston clay, clay, emergence clay, collar height emergence (plants/acre) collar height (inch) H (plants/acre) (inch) Conventional 17,900a* 18,400ab 10.2d 6.9d S-T fall deep 19,400a 18,900ab 12.4c 13.4b 19,100a 18,300ab 13.3c 11.8c 18,400a 17,400b 15.5a 14.4a 19,100a 19,500a 14.3b 13.0b knife-chisel S-T spring deep knife-chisel S-T winter shallow sweep S-T spring shallow sweep *Means in a column followed by the same letter are not statistically different at the 5% level of significance by Duncan=s Multiple Range test. H Height of collar of highest developed leaf on day 51 after planting. HH AS-T@ is strip tillage. 15 Table 4. Small-plot corn final emergence (16 d) and leaf collar height growth (53 d) responses to tillage for two soils at Temple, TX, 1997. Treatment H Austin silty Houston clay, clay, emergence (plants/acre) Austin silty clay, emergence collar height (plants/acre) Houston clay, collar height (inch) (inch) Conventional 47,700a* 49,400a 10.7b 11.4b S-T fall knife-chisel 45,900a 53,800a 11.4b 15.7a S-T spring knife-chisel 50,300a 51,600a 12.1ab 15.0a S-T winter shallow sweep 45,100a 54,700a 13.6a 16.8a S-T spring shallow sweep 51,600a 52,100a 13.7a 16.8a *Means in a column followed by the same letter are not statistically different at the 5% level of significance by Duncan=s Multiple Range=s test. H AS-T@ is strip tillage. 16 Table 5. Small-plot corn grain yield responses to tillage on two soils at Temple, TX, 1997. Treatment HH Austin silty Houston clay, clay, yield yield (lb/acre) (lb/acre) Conventional 3411a* 2778c H S-T fall knife-chisel 2944b H 33384abc H S-T spring knife-chisel 2933b H 1991bc H S-T winter shallow sweep 3354ab 3652ab S-T spring shallow sweep 3085ab 4148a H * Means in a column followed by the same letter are not statistically different at the 5% level of significance by Duncan=s Multiple Range test. H A late-season infestation of corn root worms affected plant stands and yields to a visually-noticeable degree in one or more replication of these treatments. HH AS-T@ is strip tillage. 17 Table 6. Farm-scale plot corn final emergence (39 d) and leaf collar height (76 d) responses to six tillage treatments, w/ and w/o P2O5 fertilizer applied in winter, Rosebud, TX, 1997. Treatment HH Emergence Emergence Collar height Collar height w/o fertilizer w/ fertilizer w/o fertilizer w/ fertilizer (plants/acre) (plants/acre) (inch) (inch) S-T deep knife-chisel 20,900a* 20,900a 83.1b 83.1b Tandem disc only 21,100a -na- H 83.1b -na- Tandem disc & 19,700b 21,600a 86.2ab 87.4a S-T shallow sweeps 21,000a 20,900a 82.7b 83.9ab No-till only 18,400c -na- 85.4ab -na- fertilizer knife-chisel *Means within emergence or height followed by the same letter are not statistically different at the 5% level of significance by Duncan=s Multiple Range test. H A-na-@ indicates treatment not conducted. HH AS-T@ is strip tillage. 18 Table 7. Farm-scale plot corn grain yield responses to six tillage treatments, Rosebud, TX, 1997 Treatment HH Yield w/o fertilizer Yield w/ fertilizer (lb/acre) (lb/acre) S-T deep knife-chisel 6125a* 6335a Tandem disc only 6146a -na- H Tandem disc & 6460a 6031a S-T shallow sweeps 6238a 5991ab No-till only 5655b -na- H fertilizer knives * Treatment means followed by the same letter are not statistically different at the 5% level of significance by Duncan=s Multiple Range test. H A-na-@ indicates treatment not conducted. HH AS-T@ is Strip-till. 19 Table 8. Farm-scale plot corn final emergence (24 d) and leaf collar height (40 d) responses to six tillage treatments during drought season, Rosebud, TX, 1998. Treatment HH Emergence Emergence w/ Collar height Collar height w/o fertilizer fertilizer w/o fertilizer w/ fertilizer (plants/acre) (plants/acre) (inch) (inch) S-T deep knife-chisel 20,700 a* 19,300 ab 15.1 bc 16.4 a Tandem disc only 15,600 c -na- H 12.6 d Tandem disc & 15,700 c 18,400 abc 10.9 e 11.7 e S-T shallow sweeps 20,200 ab 20,000 ab 14.7 c 15.9 ab No-till only 17,400 bc -na- H 14.6 c -na- H -na- H fertilizer knives *Means in a column followed by the same letter are not statistically different at the 5% level of significance by Duncan=s Multiple Range test. H A-na-@ indicates treatment not conducted HH AS-T@ is strip tillage. 20 Table 9. Farm-scale plot corn grain yield responses to six tillage treatments in a drought season, Rosebud, TX, 1998. Treatment HH Yield w/o fertilizer (lb/acre) Yield w/ fertilizer (lb/acre) S-T deep knife-chisel 2624 b* 2630 b Tandem disc only 2579 bc -na- H Tandem disc & 2521 c 2446 d S-T shallow sweeps 2531 c 2703 a No-till only 2513 c -na- H fertilizer knives * Treatment means followed by the same letter are not statistically different at the 5% level of significance by Duncan=s Multiple Range test. H A-na-@ indicates treatment not conducted. HH AS-T@ is strip tillage. 21 ILLUSTRATIONS Figure 1. Strip tillage systems are conservation cropping systems wherein at least 2/3 of the field area is interrow surface, which is not tilled and remains covered with protective residues, while the row is strip tilled. 22 Figure 2. Shallow-depth sweep strip tillage in shredded stubble, prior to planting 23 Figure 3. Experimental strip tillage unit with knife-chisel attachment, as used in 1995-1997 studies. 24 . Figure 4. Experimental strip tillage unit with row cleaners, smooth coulter blade, and shallow-depth sweep attachment, as used in 1996-1998 corn small-plot and on-farm studies. 25 Corn yield from eight tillage treatments, ordered from left to right; two years and four planting dates Trt 1 8000 Trt 3 Trt 4 Trt 5 Trt 6 Trt 7 Trt 8 LSD=863 7000 Yield (Kg/Ha) Trt 2 6000 5000 4000 3000 2000 1000 0 62 1999 A 75 1999 82 1999 97 1999 53 2000 61 2000 66 2000 73 2000 Grain Sorghum yield from eight tillage treatments, two years and four planting dates 6000 Yield (Kg/Ha) 5000 LSD=522 4000 3000 2000 1000 0 62 1999 75 1999 B 82 1999 97 1999 53 2000 61 2000 66 2000 73 2000 Planting Date (day of the year) / Year Yield from eight tillage treatments in two soil types 7000 LSD=863 LSD=522 Yield (Kg / Ha) 6000 5000 4000 3000 2000 1000 0 C Houston Corn Austin Corn Houston Sorghum Austin Sorghum Soil / Crop Figure 5. Yield as affected by eight tillage systems (Trt 1 - Trt 8), year, and planting date in corn (A), and sorghum (B); and corn and sorghum yield as affected by eight tillage systems and two soils (C). 26 Corn emergence from eight tillage treatments, ordered from left to right two years and four planting dates Emergence (%) Trt 1 Trt 2 Trt 3 Trt 4 Trt 5 Trt 6 100 90 80 70 60 50 40 30 20 10 0 A Trt 7 Trt 8 LSD=13 62 1999 75 1999 82 1999 97 1999 53 2000 61 2000 66 2000 73 2000 Planting Dates (Day of the Year) / Year Emergence (%) Grain sorghum emergence from eight tillage treatments, ordered from left to right, two years and four planting dates 100 90 80 70 60 50 40 30 20 10 0 B LSD=9 62 1999 75 1999 82 1999 97 1999 53 2000 61 2000 66 2000 73 2000 Planting Dates (Day of the year) / Year Emergence (%) Emergence from eight tillage treatment, ordered from left to right, and two soil types 100 90 80 70 60 50 40 30 20 10 0 C LSD=9 LSD=13 Houston Corn Austin Corn Soil / Crop Houston Sorghum Austin Sorghum Figure 6. Plant emergence as affected by eight tillage systems (Trt 1 – Trt 8), year, and planting date in corn (A) and sorghum (B); and corn and sorghum yield as affected by eight tillage systems and two soils (C). Figure 7. 2002 model of the USDA-ARS experimental Strip-till field machine. Other Sources of Information “Partners” Magazine CTIC, Conservation Technology Information Center 1220 Potter Drive, Room 170 W. Lafayette, Indiana 47906-1383 Tel: (795) 494-9555 E-mail: ctic@ctic.purdue.edu Web: www.ctic.purdue.edu “Strip-Till Instructional Video – 8/20/00”. 1). Grower Segment. TRT: 18:38 Monsanto Company North America Division “No-Till Farmer” Magazine Lessiter Publications, Inc. P.O. Box 624 Brookfield, WI 53008-0624 Tel: (262) 782-1252 28 E-mail: info@lesspub.com Web: www.no-tillfarmer.com Bolton, F.E. and D.E. Booster. 1981. Strip-till planting in dryland cereal production. Trans. of ASAE 24(1): 59-62. Edwards, J.H., D.L. Thurlow, and J.T. Eason. 1988. Influence of tillage and crop rotation on yields of corn, soybean, and wheat. Agron J. 80(1): 76-80. Halvorson, A.D. and G.P. Hartman. 1984. Reduced seedbed tillage effects on irrigated sugarbeet yield and quality. Agron. J. 76(4): 603-606. Hares, M.A. and M.D. Novak. 1992. Simulation of surface energy balance and soil temperature under strip tillage: II. Field test. Soil Sci. Soc. Am. J. 56(1): 29-36. Iqbal, M., S.J. Marley, D.C. Erbach, and T.C. Kaspar. 1995. Effects of coulter treatments on seed furrow smearing and early crop response. ASAE Paper No. 95-1322, ASAE, St. Joseph MI 49085-9659 USA. Karlen, D.L., W.J. Busscher, S.A. Hale, R.B. Dodd, E.E. Strickland, And T.H. Garner. 1991. Drought condition energy requirement and subsoiling effectiveness for selected deep tillage implements. Trans. of ASAE 34(5): 1967-1972. Kaspar, T.C., D.C. Erbach, and R.M. Cruse. 1990. Corn response to seed-row residue removal. Soil Sci. Soc. Am. J. 54(4): 1112-1117. Kaspar, T.C. and D.C. Erbach. 1998. Improving stand establishment in no-till with residue-clearing planter attachments. Transaction of the ASAE 41(2):301-306. Morrison, J.E., Jr. and F.W. Chichester. 1988. Subsurface fertilizer applicator for conservation-tillage research. Applied Engr. In Aagr. 4(2):130-134. Raimbault, B.A., T.J. Vyn and M. Tollenaar. 1991. Maize response to rye cover crop, tillage methods, and planter options. Agron. J. 83(2): 287-290. Sallinas-Garcia, J. R., Cabrera-Sixto, J. M., Morrison, J. E., Jr., LePori, W. A., and Morales-Martinez, A. R. 2000. Tillage system criteria for high surface residue conditions. In Proc. 4th Int. Conf. on Soil Dynamics, 26-30 March 2000, Adelaide, Australia. Smith, J.A., C.D. Yonts, D.A. Biere and M.D. Rath. 1995. Field operation energy use for a maize-dry edible bean-sugarbeet rotation. App. Engr. in Agr. 11(2): 219-224. ________________________________________________________________________