TITLE PAGE

advertisement

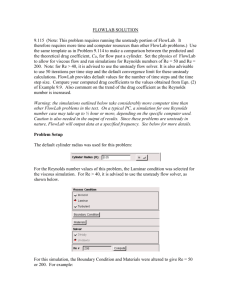

Mech/ChBi 301 Fluid Mechanics FALL 2007 TERM PROJECT Flow around a circular cylinder with FLUENT prepared by Engin Çukuroğlu Birce Erdoğan Işık Işıl Nugay 1 Introduction In this project, the aim was to demonstrate the setup and get a solution using FLUENT for the steady and unsteady flow around a circular cylinder for the defined Reynolds numbers and study. The vortex shedding for the unsteady flow was, also, studied for this purpose. Laminar viscous flow around a circular cylinder body is a problem solved by fluid mechanics theories. The flow pattern is expected to be steady and symmetric according to the geometry of the object. However, the flow regime is highly dependent on Reynolds number. So, the flow is symmetric and steady only at lower Reynolds number values. The streamlines are attached to surface and no flow separation occurs in that condition. If Reynolds number increases, it leads to vortex a shedding phenomenon which is described in more detail at the problem description section. Many different methods are used in order to show and study this vortex shedding phenomenon such as monitor plots and animations similar to FLUENT, LES (wall modeling) [1] programs. Also, additional investigations are made choosing time step, using PISO for transient simulation and calculating the Strouhal number in previous studies [2]. Cylinder geometry is created for modeling, the computational domain is chosen and a computational grid is generated with GAMBIT. The material properties and boundary conditions are set then the grid is transferred to the FLUENT segregated solver and the computations are performed for 2 both steady and unsteady cases. In this report, this study is presented with more detailed description of the problem, result and conclusion section. Description of the physical problem An infinitely long circular cylinder (flow is two-dimensional) of radius R=0.1 m is used in this project. The working fluid is chosen to be water at 20ºC. The free stream velocities are specified to match our Reynolds number assigned. (for case I Re=26, for case II Re=162 ) The outer boundary of the computational domain used must be sufficiently far from the cylinder to avoid influence of the outer body [3]. So, the outer boundary of the computational domain is set at 10R (cylinder radii) far for this purpose. Figure 1: A multi-block grid region surrounding the cylinder. 3 Figure 2: A close-up of the grid in Fig. 1. A structured grid was to be used in this problem as our geometry is a simple one. A multi-block grid topology is used generating this structured grid. This computational grid had to be very fine in order to avoid large numerical errors in results. The grid independent results are ensured setting error tolerance at maximum 10% and by making a grid convergence test for this error tolerance to obtain necessary grid size. The drag coefficient quantity was to be reduced under the error tolerance after a coarse grid is generated and refined afterwards. The drag coefficient being a dimensionless quantity is a characteristic amount of aerodynamic drag caused by fluid flow and is used in the drag equation. Under specified conditions of Reynolds number of flow around the object must be high enough to create turbulent state; the drag force is almost proportional to the square of its velocity. At lower Reynolds numbers, small objects, low velocities the flow around object being laminar the drag coefficient is not a constant but it depends on velocity. Flow patterns and accordingly drag 4 coefficient for some shapes can change with different Reynolds number and roughness of the surface. [4] Initial conditions was to be set as quiescent fluid, no-slip boundary conditions to be applied on surface of the cylinder and free-stream boundary conditions to be specified at far-field. The velocity is fixed to free-stream velocity computed based on Reynolds number at inlet and atmospheric pressure is set at outlet. [3] The modelling of flow field is carried out at these mentioned conditions which gave us the mathematical distribution of fluid density and velocity as a function of time ad position. The most important effect in this problem is the effect of Reynolds number. In cases where Reynolds number is very small, less than 4, streamlines being attached to the surface there is no flow separation which is called creeping flow regime. This flow is steady after a transition period observed initially. As the Reynolds number increases, in between 4 and 40, flow separating from the surface of the object, two counter rotating vortices are created at the back of the object which was the effect to be observed at the first case of the problem. This case is the steady flow as vortices are stable and attached to the cylinder. However, when the Reynolds number is increased further more, in between 80 and 200, the steady property does not exist anymore even if it is still laminar flow in the second case of the problem. In this case flow is unsteady and some vortex shedding was to be observed at particular frequency. Velocity vectors and constant contours were to be used in order to observe this phenomenon. If higher Reynolds numbers were to be observed, there would be turbulent flow requiring more difficult computational analysis.[3] 5 Results and Discussion Figure 3: Streamlines of the steady flow past a circular cylinder at Re=26 The results of streamlines shown in figure 3 are exactly as expected comparing to the sample results given in the project handout. The streamlines show that the flow is separating from the surface of the circular object and two counter rotating vortices are just created at the back of the object. Figure 4: Velocity contours of the steady flow past a circular cylinder at Re =26. 6 Figure 5: Evolution of drag coefficient for steady flow past a circular cylinder at Re=26 Drag coefficient values are appeared to be similar to the expected value (3.1). But there is a deviation at the beginning which may be resulted from a mistake in the grid. Nevertheless, the subsequent coefficient values are fine for the steady flow. Figure 6: Stream function velocity vector for the steady flow. 7 Figure 7: Convergence history for computation of steady flow past a circular cylinder at Re=26 The convergence history is, also, very similar to the sample results proving that our steady flow case computational modeling and calculations had very small error percentage. The grid that we had formed is then a sufficiently fine grid. Figure 8: Velocity contours of the unsteady flow past a circular cylinder at Re =162. 8 Figure 9: Streamlines of the unsteady flow past a circular cylinder at Re=162. This streamline results for the unsteady flow were unexpected. The vortex shedding expected to be observed was not apparent. As the steady case had expected results we could not show the source of this error as the grid formation. So, we had troubles determining the source of error. It is said that the vortex shedding is to be observed at a specific frequency which may be our source of error. Trying to use steady solver for high Reynolds number value gave difficulties to achieve convergence but we expected to have good results with the unsteady solver. However, we had again difficulties to achieve convergence. 9 Figure 10: Evolution of drag coefficient for unsteady flow at Re=162. The figure 10 showing drag coefficient changes relative to the time had started from very high numbers and fallen till 0 point which was a very unexpected result. It had to be between 1.5 and 1, after a decreasing period taking limit to 1, it should rise and make small deviations around the same value. Figure 11: Stream function velocity vector for the unsteady flow. 10 The unsteady case gave different results even if we haven’t change any conditions or variables at each run. So, it might be said that the program didn’t work as appropriate as it should be. Also we tried to solve the unsteady condition with the steady flow. Figure 12: Convergence history for computation of steady flow past a circular cylinder at Re=162 Figure 13: Evolution of drag coefficient for steady flow past a circular cylinder at Re=162 11 Drag coefficient is fluctuating between 0.26 and 0.16 which is expected 1 and 1.5, but it is solved as a steady flow in spite of it is an unsteady flow at Re=162 Figure 14: Streamlines of the steady flow past a circular cylinder at Re=162 The streamlines of the steady flow which the reynolds number is 162 is nearly the same as the handout. There is vortex shedding in the figure 14 which is expected at the handout example. Figure 4: Velocity contours of the steady flow past a circular cylinder at Re =162. 12 Conclusions The knowledge gained from this study can be listed as; FLUENT usage for similar fluid mechanics problems, difference between steady and unsteady flows, effect of the Reynolds number, drag coefficient and grid convergence test importance to get accurate result in computational modeling cases. In this project we had good and expected results in steady flow samples comparing with the literature results given in fluent tutorials and our project handout. However, we had unexpected results in the unsteady case where error percentages were very high. As we had use the same grid that we had formed in this project it is hard to conclude that the error rises from the grid structure. Further investigations may be proceeded in order to find possible error sources for the second case. If the problem is rising from the FLUENT program accuracy as discussed in the previous section, a more suitable program should be chosen or the program should be improved. For example, the fact that our installed FLUENT program is a student usage package may be the reason and the professional package may give more accurate results. Despite the fact that we had some experimental errors, the knowledge gained from this project was very satisfactory and arousing curiosity for further study for better understanding of computational modeling and calculations. 13 Acknowledgements We would like to thank our Fluid Mechanics TA Savaş Taşoğlu for his helps answering our questions and providing us a useful FLUENT tutorial. References 1. http://ctr.stanford.edu/ResBriefs01/wang.pdf 2. http://www.fluent.com/software/sf_mesh_and_tutorials/tutorial_ cylinder.htm 3. M. Muradoğlu, Mech/ChBi 301 Fluid Mechanics Project Description Handout, p.2, Koç University, Istanbul, Fall 2007. 4. http://en.wikipedia.org/wiki/Drag_coefficient 14