HSEF0920 1 Oil Transfer and Transport Plan

advertisement

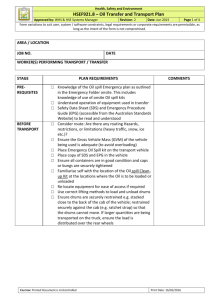

HSEF0920.1 – Oil Transfer and Transport Plan Health, Safety and Environment Form Approved by: Manager Sustainability & Safety Form Revision: 1 Date: 14th May 2012 Page 1 of 3 Form variations to suit user, system / software constraints, legal requirements or corporate requirements are permissible, as long as the intent of the form is not compromised. AREA / LOCATION JOB NO. DATE PERSON/S PERFORMING TRANSPORT / TRANSFER STAGE PREREQUISITES PLAN REQUIREMENTS □ □ □ BEFORE □ TRANSPORT □ □ □ □ □ □ □ □ BEFORE TRANSFER □ □ □ □ □ □ □ □ COMMENTS Knowledge of the oil spill emergency plan as outlined in the Emergency Folder on site. This includes knowledge of use of on site oil spill kits Understand operation of equipment used in transfer Material Safety Data Sheet (MSDS) and Emergency Procedure Guide (EPG) (accessible from the Australian Standards Website) to be read and understood Consider route: Are there any routing hazards, restrictions, or limitations (heavy traffic, snow, ice etc) Ensure the Gross Vehicle Mass (GVM) of the vehicle being used is adequate (to avoid overloading) Place emergency Oil Spill kit on the transport vehicle Place copy of MSDS and EPG in the vehicle Ensure all containers are in good condition and caps or bungs are securely tightened Familiarise self with the location of the Oil spill Cleanup Kit at the locations where the oil is to be loaded or unloaded Re-locate equipment for ease of access if required Use correct lifting methods to load and unload drums Ensure drums are securely restrained eg. Stacked close to the back of the cab of the vehicle; restrained securely against the cab (e.g. ratchet strap) so that the drums cannot move. If larger quantities are being transported on the truck, ensure the load is distributed over the rear wheels Understand the operation of pumps and filter systems to be used in the transfer Check that the correct oil is being used Check if a machine outage is required; if so, check that all isolations are complete and sign on the work permit If draining oil, know the volume of oil requiring storage and ensure appropriate storage facilities / bunding is available Ensure pump, hoses, couplings and storage containers are in good condition Ensure stop cocks and valves are in the appropriate position Spill kit adequate and is close by ready for use Assess the transfer route and place pumps and hoses are as far away from exposed drains as possible Date printed 17/02/2016 HSEF0920.1 – Oil Transfer and Transport Plan Health, Safety and Environment Form Approved by: Manager Sustainability & Safety Form Revision: 1 Date: 14th May 2012 Page 2 of 3 Form variations to suit user, system / software constraints, legal requirements or corporate requirements are permissible, as long as the intent of the form is not compromised. STAGE PLAN REQUIREMENTS COMMENTS □ DURING TRANSFER Where pumps, filters, hoses etc are close to open drains, assess need for specific bunding (i.e. assess the amount of oil that is likely to escape should hoses burst etc). If the risk is high, ensure extra control measures are implemented (e.g. bunding is placed under the pump and hoses, or ‘sausages’ etc are placed in areas where spilt oil is most likely to be lost to the environment). □ Prepare a temporary Bund under and around the tanker or drum, using appropriate bunds or builders plastic sheet and sandbags or similar □ The bund should be large enough to contain the total amount of oil likely to be spilled □ Sandbag any openings in the bund □ Place drip trays under all hose connections and valves □ Drip trays and sorbents should also be placed where the hose comes into contact with other structures, such as handrails etc. as these will be likely drip points in case of a leak in the hose □ Monitor approximate volume to ensure sight valve reflects volume added. If not, stop work and investigate potential blockages / leaks etc. at the fill / drain point, pump, hoses or other pipe work □ If any leaks found, stop pump and repair □ Use Oil spill Cleanup Kit to contain any accidental spillage and report spillage Warning: Static shock and sparks can occur when transferring oil. Actions/Recommendations: You cannot stop static as it will always be there when a product is being moved but you can control it by using a bonding lead or ensuring containers are firmly grounded. The rule for a bonding (static) leads is FIRST ON LAST OFF. The lead must go from e.g. The vehicle to metal on the container frame, this will stop static jumping in the form of a spark or wanting to go to ground through the person. Where possible the lead will go into the ground via a metal spike or be attached directly to an earth mat. Most hoses used for pumping are made with a wire that should bond if the filling nozzle is in contact with metal at the fill point but if you cannot be sure this will happen, a static lead should be used. Date printed 17/02/2016 HSEF0920.1 – Oil Transfer and Transport Plan Health, Safety and Environment Form Approved by: Manager Sustainability & Safety Form Revision: 1 Date: 14th May 2012 Page 3 of 3 Form variations to suit user, system / software constraints, legal requirements or corporate requirements are permissible, as long as the intent of the form is not compromised. STAGE AFTER TRANSFER PLAN REQUIREMENTS □ □ □ □ □ □ □ □ □ COMMENTS Ensure drain / fill points have been closed Ensure all hoses have been fully drained and that no residual oil will leak during transport Place storage containers in location away from high traffic flow areas Ensure bunding is appropriate and in place Wipe any residual oil from pipe work and any equipment used. Ensure used spill gear / oily waste is stored separately to general waste (i.e. as hydro carbon contaminated waste) Follow spill clean up process (as outlined in Emergency Folder) If oil transferred for storage/recycling/disposal, fill in oil/grease usage booklet Obtain disposal certificate (or copy) to be forwarded from Contractor on completion of disposal Date printed 17/02/2016