View the complete report - Building Science

advertisement

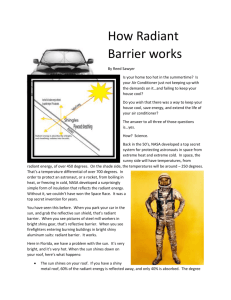

Radiant Barrier Impact on Selected Building Performance Measurements Model Home Case Study Centex Homes – Charlotte, NC Appalachian State University Energy Center Summer Study 2008 Bruce Eugene Davis Jeffery Tiller March 31, 2009 Table of Contents Executive Summary 1 Project Objective 3 Background 4 Methodology 5 Results 30 Discussion 42 Conclusions 45 Appendix A – Building Performance Measurements, Centex Model Homes 46 Appendix B – Installation Dates and Labor Efforts 49 Appendix C – Sensor Code Identification Information 50 Acknowledgements Funding for this effort was in part provided by a Building America Grant sourced through the North Carolina Energy Office. The following individuals each contributed to the completion of this case study. Jeff Tiller, Interim Chair, ASU Technology Dept. and ASU Energy Center, originated the general idea, secured the funding, provided the Centex contact, and asked important questions Edwin Woods, Area Construction Manager, Centex Homes, Charlotte, NC, provided guidance and approval for the model home summer study Kristin Bryan, Spicewood Field Manager, Centex Homes, Charlotte, NC, appointed to be Centex direct contact for ASU summer study staff and facilitated the necessary interactions with Centex staff Woodbury Sales Center Staff, Centex Homes, Charlotte, NC, always helpful as ASU staff checked in and checked out of the summer study model homes Andrew Palmer, Woodbury Field Manager, Centex Homes, Charlotte, NC, appointed to maintain ongoing Centex direct contact for ASU staff Lee Ball, Instructor, ASU Technology Dept. and ASU Energy Center, installation partner for all the sensors and in taking the initial building performance measurements Laurel Elam, ASU Energy Center, multiple general support, operational guidelines, and keeps Omnisense and internet cable accounts open to maintain data flow and access. Sharon Yates, ASU Energy Center, provided invaluable guidance on travel and purchasing and ASU project guidelines Andrew Sams, ASU Technology Student and Building Performance Engineering staff, was the main individual helping to air seal the attic ceiling plane Adam Milt, Building Performance Engineering, provided support and background information with regard to Centex Homes, and provided the critical extra assistance for the attic ceiling plane air sealing Andrew Windham, ASU Technology Dept. Graduate Student, assisted with taking follow up building performance measurements, and was one of the three person team that installed the attic radiant barrier Scott Critcher, ASU Technology Dept. Graduate Student, helped prepare some of the materials prior to the attic air sealing, and was one of the three person team that installed the attic radiant barrier Wes Stewart, ASU Technology Dept. Graduate Student, one of the three person team that installed the attic radiant barrier Ben Hannas, Advanced Energy, provided initial consulting support with regard to managing the data created through the Omnisense data logging system Jason Hoyle, ASU Energy Center, managed the first request for and the securing of the initial, massive, raw data down load onto the ASU Energy Center computer Ross Gosky, ASU Math Dept., has provided an opportunity for discussions about exploring the data set Ross Dillon, ASU Technology Dept. Graduate Student, assisted with the site visit to sample the attic insulation depth across the attic of the two model homes, and is analyzing a portion of the Omnisense data for a paper Executive Summary In the home construction industry one common solution to a customer cooling discomfort complaint is to dispatch the HVAC contractor to replace the existing system with a larger one. This case study explored one of several alternative strategies to solve a summer cooling complaint. It is generally accepted that attic radiant barriers can reduce attic temperatures during daily peak temperatures in the cooling season. It is also generally accepted that for homes with R-30 ceiling insulation and no HVAC equipment or ducts in the attic that the addition of an attic radiant barrier does not provide an improvement in the home energy efficiency. However this case study was designed to measure the impact of the addition of an attic radiant barrier in an attic which contained both HVAC equipment and ducts. Beyond documenting the impact on roof deck and top of attic insulation temperatures, this case study explored heat gain in an attic supply air duct between the HVAC supply plenum and the ceiling supply boot. It also documented the subsequent impact on the HVAC air handler run time. Benefiting from a long standing working relationship between the ASU Technology Department and Centex Homes – Charlotte, North Carolina, initial discussions were held to determine if Centex management would be open to an unobtrusive summer study being set up in one or more of their model homes at one of their active subdivision sales centers. Once operational ground rules were established and the design outlines of the summer study were provided Centex agreed to the study. A site supervisor was assigned to be the study staff’s direct contact at Centex and a subdivision was recommended for our review. The Belmont was chosen to be the intervention home and the Parkwood was held as the nonintervention home. This approach allowed for staged modifications to the intervention home to investigate their impact. If measured conditions in the home altered following the modification but did not change for the nonintervention home, then the measured difference in the intervention home is more reliably to have been caused by the building modification. Building performance measurements were recorded for both homes. As appropriate, follow on measurements were also recorded. Omnisense data logging systems [www.omnisense.com] were installed in both homes. Individual sensors were placed inside the home, inside the HVAC system, in the attic, and outside. The sensors send a radio signal to an Omnisense Gateway in each home. Each Gateway is connected to a router which is in turn connected to a cable modem and through the local cable into the internet. Data is stored on the Omnisense server for viewing online or for down loading. Data for each sensor location includes sensor ID, location description, date and time stamp, temperature, relative humidity, grains per pound, dew point, and wood moisture number [if attached to wood with the required stainless steel screws]. Two staged modifications were planned for the Belmont. Air sealing of the ceiling plane was included to remove a confounding variable. The second modification was the installation of the radiant barrier to the bottom of the top chord of the roof truss. A summary of the study sequence includes the characterization of each home, instrumentation, two week baseline data, one week set aside for air sealing, two week data period, one week set aside to apply radiant barrier, and two week data period. 1 61 sensors were installed. There are 30 sensors in the Belmont and 29 in the Parkwood, plus 2 outside [1 is on the Belmont front porch, 1 is in a tree shelter tube at the tree line between the two back yards]. Sensors are placed in comparible locations in each home. The installation of an attic radiant barrier attached to the bottom of the top chord of the roof truss was shown to have several air conditioning season beneficial impacts with regard to the energy efficiency of the Belmont model home. 1. The peak temperature measured at the top of the attic insulation was reduced by approximately 23 degrees F at peak temperature for comparible pre and post dates. This reduction in temperature provided a positive benefit across a nine hour period, though to a lesser and lesser amount as the data is examined further from the peak. 2. The run time of the HVAC system for the second floor of the Belmont was reduced by 14% over the total 24 hour period. During the 7 peak hours the run time was reduced by 20%. 3. Heat gain through the R-6 flex duct into the cooling supply air between the attic air conditioning unit and the ceiling supply boot was reduced from 7 degrees F to a heat gain of 3 degrees F. 4. Heat gain of 7 degrees F equaled a capacity loss of 33.8%. Heat gain of 3 degrees F equaled a capacity loss of 14.4%. Thus the radiant barrier improved the efficiency of the cooling air delivered through this duct during the peak attic temperatures by 57%. 5. Air sealing the ceiling plane produced a substantial disruption to the physics of building natural air change for both winter and summer seasons. As measured by a blower door, this 3205 square foot home started with a whole building air leakage of 1700 CFM50 and was air sealed to 1250 CFM50 which is a 26.5% reduction. This included a notable reduction in the duct air leakage to Outside by sealing the boot penetration of the ceiling sheetrock. On the not beneficial side of the energy efficiency effort, the HVAC system cycled on and off more during the peak period and the radiant barrier kept the top of attic insulation slightly hotter, longer over the cool down period in the evening. The Omnisense sensor system, once the initial wrinkles were ironed out, has proved to be very flexible, reliable and accessible building measurement equipment. There are still multiple additional data sets that could be analyzed. Potentially it may be possible to solve the mystery of the differences in attic heating patterns between the intervention home and the nonintervention home attics. 2 Project Objective In the home construction industry one common solution to a customer cooling discomfort complaint is to dispatch the HVAC contractor to replace the existing system with a larger one. This case study explored one of several alternative strategies to solve a summer cooling complaint. It is generally accepted that attic radiant barriers can reduce attic temperatures during daily peak temperatures in the cooling season. It is also generally accepted that for homes with R-30 ceiling insulation and no HVAC equipment or ducts in the attic that the addition of an attic radiant barrier does not provide an improvement in the home energy efficiency. However this case study was designed to measure the impact of the addition of an attic radiant barrier in an attic which contained both HVAC equipment and ducts. Beyond documenting the impact on roof deck and top of attic insulation temperatures, this case study explored heat gain in an attic supply air duct between the HVAC supply plenum and the ceiling supply boot. It also documented the subsequent impact on the HVAC air handler run time. One desirable response with a positive benefit outcome documented would be the conclusion that the addition of an attic radiant barrier could be one more option, when appropriate, in a solutions tool kit for solving customer summer cooling discomfort related to peak outdoor temperatures. Three secondary objectives were also envisioned. To achieve the primary objective, data logging equipment would need to be installed. The decision was made to install equipment that could extend access to the building measurements beyond the required summer period. The Omnisense sensor system once installed to provide the primary period data could continue to provide that secondary objective. Another objective was to provide an opportunity for ASU students to see the range of building measurements over time and experiment with manipulating real world data to extract useful patterns of information with regard to how building operate. The final objective was to set up a two building opportunity to learn how building operate over time and the potential opportunity to introduce additional building modifications and then be able to measure and report impacts. 3 Background During the year prior to the beginning of this case study in May 2008 a student lead laboratory experiment was completed which used a testing module to examine in that setting the impact of a radiant barrier on attic temperature. The module provided for simulated solar heat gain and attic temperature measurement either with or without a radiant barrier installed. The experiment recorded an approximate 22 degrees F temperature difference in attic temperature at the peak of simulated solar heat gain. Since it is nearly impossible [and would be extremely expensive] to completely simulate all the interactions present in a home over time [hours, days, weeks, seasons], this case study was the obvious extension of that experiment. 4 Methodology Benefiting from a long standing working relationship between the ASU Technology Department and Centex Homes – Charlotte, North Carolina, initial discussions were held to determine if Centex management would be open to an unobtrusive summer study being set up in one or more of their model homes at one of their active subdivision sales centers. Once operational ground rules were established and the design outlines of the summer study were provided Centex agreed to the study. A site supervisor was assigned to be the study staff’s direct contact at Centex and a subdivision was recommended for our review. An initial site visit, June 17, 2008, was scheduled with the site supervisor to the Woodbury Subdivision Sales Center Model Homes. There were four models available at the site. Two were chosen for the study, the Belmont and the Parkwood, which are side by side, two story homes built on slabs and have tuck under garages. They both have 4 bedrooms and 2.5 bathrooms. The orientation of the front of the homes is toward the west. The homes were completed by approximately January 2008. The Belmont is on the left and the Parkwood is on the right. The Belmont garage is currently used as a lighting center and has a separate mini split HVAC system. 5 The Belmont was chosen to be the intervention home and the Parkwood was held as the nonintervention home. This approach allowed for staged modifications to the intervention home to investigate their impact. If measured conditions in the home altered following the modification but did not change for the nonintervention home, then the measured difference in the intervention home is more reliably to have been caused by the building modification. Building performance measurements were recorded for both homes. As appropriate, follow on measurements were also recorded. Omnisense data logging systems [www.omnisense.com] were installed in both homes. Individual sensors were placed inside the home, inside the HVAC system, in the attic, and outside. The sensors send a radio signal to an Omnisense Gateway in each home. Each Gateway is connected to a router which is in turn connected to a cable modem and through the local cable into the internet. Data is stored on the Omnisense server for viewing online or for down loading. Data for each sensor location includes sensor ID, location description, date and time stamp, temperature, relative humidity, grains per pound, dew point, and wood moisture number [if attached to wood with the required stainless steel screws]. Two staged modifications were planned for the Belmont. Air sealing of the ceiling plane was included to remove a confounding variable. The second modification was the installation of the radiant barrier to the bottom of the top chord of the roof truss. A summary of the study sequence includes the characterization of each home, instrumentation, two week baseline data, one week set aside for air sealing, two week data period, one week set aside to apply radiant barrier, and two week data period. Summer Study General Time Line: June 17 Site visit to review and confirm the application of the study to the model homes and choose the two model homes for the study and document each with photographs June 19 Receive final approval to proceed from Centex June 20 Begin sensor system and cable access purchases June 30 – July 11 Install sensor monitoring systems and establish that they are running smoothly in both the intervention and the nonintervention model homes Perform and record all building performance measurements and equipment information July 14 – 27 Record and establish baseline conditions in both homes July 28 – August 3 Air seal attic and duct boot penetrations, and redistribute attic insulation evenly 6 August 4 – 17 Record and establish condition changes from first modification to the intervention model home and continue recording conditions in nonintervention model home August 18 – 24 Install Radiant Barrier system in intervention model home August 25 – September 7 Record and establish condition changes from second modification to the intervention model home and continue recording conditions in nonintervention model home September 21 End of summer study and transition to continue recording the data for a full 12 month period Omnisense Data Logging Dates and Sampling Intervals: Sensors installed: 2008 – 07 – 7 and 8 and 9 Data Start: 2008 – 07 – 09 1:00pm [13:00] Baseline Period 5 minute sampling [11 to 12 measurements per hour] Attic Air Sealing – Belmont 2008 – 07 – 28 and 29 Sampling time change 2008 – 08 – 12 1.27 minute sampling [47 to 48 measurements per hour] 10:35am [10:35] Radiant Barrier Install – Belmont 2008 – 08 – 18 and 19 Sampling time change 1 hour sampling [24 per day] 2008 – 09 – 22 1:25pm [13:25] Sensor Installation Locations: 61 sensors were installed. There are 30 sensors in the Belmont and 29 in the Parkwood, plus 2 outside [1 is on the Belmont front porch, 1 is in a tree shelter tube at the tree line between the two back yards]. Sensors are placed in comparible locations in each home. First floor: 2 room sensors 1 at thermostat 2 in supply air boots [in rooms with room sensors] 1 in return air box 7 Second floor: 4 room sensors 1 at thermostat 4 in supply air boots [in rooms with room sensors] 1 in return air box Attic: 2 under attic insulation [1 north end, 1 south end] 2 on top of attic insulation [directly over under insulation sensors] 2 on string, 5 feet above insulation [directly above the previous sensors] 2 in return air ducts at air handler [for first floor and for second floor] 1 in each supply air plenum at air handler [2 for Belmont, 1 for Parkwood-zoned] 4 screwed into top chord of roof truss touching roof decking [nE, sE, sW, nW] Main codes used for sensor naming: Two homes are: B = Belmont – intervention [has two furnaces with A/C in attic, fiberglass attic insulation] P = Parkwood – nonintervention [has one furnace with A/C with zone control in attic, cellulose attic insulation] F = first floor S = second floor A = attic wb = wood block base [allows wood moisture number reading] wt = wood truss [allows wood moisture number reading] All data being generated from the two model homes is stored on the Omnisense server. Additionally a copy of all the data is downloaded periodically and stored on the ASU server. Data from selected sensors were compiled for targeted analysis related to the project objectives. Photo Review Following are a selection of photographs covering the Omnisense sensor placements, ceiling plane air sealing, radiant barrier installation, recording attic insulation depth pattern, and window, equipment, and insulation information. 8 Occupied space conditions [six per home, temperature, relative humidity, wood moisture content, two on first floor, four on second floor] Return air conditions from occupied space [one per floor] 9 Supply air conditions [six per home, two on first floor, and four on second floor] Conditions at thermostat [two per home, one on each floor] 10 Attic air conditions [two per attic] Roof deck conditions [four per attic, temp, RH, wood moisture content] 11 Top of insulation and bottom of insulation at ceiling sheet rock [two sets per attic] Exterior conditions at tree between Belmont and Parkwood homes [weather protected] 12 Return air at air handler [two systems, temp, RH, wood moisture content] Placing sensor on Douglass Fir wood block inside HVAC supply plenum 13 Supply air at air handler [two systems, temp, RH, wood moisture content] Omnisense Gateway, router, and cable modem [equipment pushed back under low furniture to reduce the potential for curiosity tampering] 14 Ceiling plane air sealing at top plate Foam air sealing in progress 15 Attic ceiling insulation was moved aside to allow detailed air sealing protocol 16 Safety first, Ground Fault Circuit Interrupter for all electricity for attic lighting Bathroom exhaust fan prior to sealing exhaust fan and sheet rock penetrations with caulk 17 Top plate and abandoned plumbing hole prepared for air sealing with foam Attic insulation moved aside for air sealing at duct chase and top plates 18 Lid on duct chase prepared for sealing with foam Close up of ceiling plane duct chase lid needing air sealing [duct penetration sealed by HVAC] 19 Cutting radiant barrier material [cutting was quickly moved out of the hot attic] Fitting radiant barrier around truss members 20 Fitting radiant barrier around plumbing and duct strapping Attaching radiant barrier to the bottom of the top chord of the roof truss 21 Completing the first side and it is still hot Sensor now between radiant barrier and roof deck with flagging tape marking location 22 Tough work starting at the edge of the roof with low head space Ridge vent left open to both the attic space and the air path behind radiant barrier 23 Reflecting attic light at the moment Redistributing the attic insulation that was disturbed during radiant barrier installation 24 Finishing touches Close up detail 25 Looking pretty and flex duct to Belmont nW ceiling supply boot reported in this case study Leaning over to measure attic insulation depth, sampling taken in pattern across entire attic 26 Comparing our ruler with the installed attic ruler, it was often not this deep Fiberglass attic insulation card from Belmont 27 Yes it is low-E glass Model information was gathered for all equipment 28 Cellulose attic insulation card from Parkwood 29 Results Following the completion of the initial two week data logging period to establish Omnisense baseline measurements, air sealing protocols were completed. As outlined in the methodology most potential air leakage paths through the ceiling plane, between the home and the attic were sealed from the attic. In addition, all ceiling boot penetrations for both the first and second floors were sealed after temporarily removing their supply grille. These efforts changed the whole building air leakage for the 3205 square foot home from 1700 CFM50 to 1250 CFM50. This elimination of 450 CFM50 equals a 26.5% reduction in whole building air leakage which by itself enhanced the efficiency of the building shell. More importantly, during the heating season a substantial barrier has been installed to retard the continual, passive leakage of warm air out of the top of the home thus substantially disrupting the natural air change physics of the home. In some homes during the summer the action of hot air exiting the attic can create suction on the home, if the attic inlet venting is undersized, and draw conditioned air from the home. This summer action was not examined but would also be disrupted. Duct air leakage to Outside for the home was reduced from 4.9% to 3.8% per square foot of conditioned space, which is a 22% reduction. The improvement was noticeably from the boot leakage air sealing of the second floor system. This system air leakage dropped from 70 CFM25 to 31 CFM25 to Outside. This reduction is part of the successful overall ceiling plane air sealing efforts. The absence of notable duct air leakage also removed a confounding variable from the case study. The air sealing protocols required 27 hours of onsite labor, mostly in a very hot attic, with difficult gymnastics, and moving insulation aside to access the air leakage sites. The insulation was redistributed following completion of the air sealing work. More details of the building performance measurements are located in Appendix A. Appendix B contains the installation dates and labor effort details. This air sealing effort removed one source of potential complicating building physics setting the stage for more reliability should there be measureable changes recorded associated with the installation of the radiant barrier. With the completion of the ceiling plane air sealing, Omnisense data was then continued for an additional two week period. Following this second two weeks of Omnisense data collection was the installation of the radiant barrier and a third two weeks of Omnisense data collection. With this accumulation of data, attention was turned to addressing what building and equipment impacts could be measured and associated with the radiant barrier installation. In particular, what were the identifiable impacts during the daily peak temperature periods when the radiant barrier provides it primary benefit? The first effort was to identify a 24 hour day prior to and post to the radiant barrier installation that had similar, though not identical, solar intensity and peak temperatures. As a beginning point, roof deck sensor data was used to indicate solar intensity and pattern. In both the Belmont [intervention home] and the Parkwood [nonintervention home] the two roof deck sensors attached to the west facing roof at the south and north ends were reviewed. The south end sensors were designated as “sW” and at the north end as “nW”. As a reminder, during this time period the sensors were recording temperature measurements every 1.27 minutes. Detailed sensor code identification information is located in Appendix C. 30 Roof deck temperatures for the Parkwood [nonintervention home] were reviewed for the two week periods pre and post to the radiant barrier installation. August 15, 2008 was chosen as the pre date and August 22, 2008 was chosen as the post. The roof deck temperatures were plotted for visual comparison. These two dates had the most similar, though not identical, roof deck sensor data suggesting similar solar intensity and temperature over their 24 hour periods. On the 15th the sW and the nW roof deck temperatures display a slight difference at the peak temperature of the day of 132 versus 129 degrees F. Otherwise both ends of the roof deck curves closely track each other. For the post data on the 22nd both sensors follow identical temperature tracks and both reach a peak temperature of 129 degrees F. Comparison of the data for the 15th and the 22nd show more variation. The most obvious is that the peak is reached earlier on the 15th and displays a less uniform heating and cool curve than does the curve for the 22nd. Two other elements are that the data for the 22nd shows that during the morning hours the roof deck is 5 degrees F cooler and during the evening it is 7 degrees F warmer. For clarification, the reference to “pre/post radiant barrier” in the title of this Parkwood graph is only a reference to the time period involved. A radiant barrier was not installed in the Parkwood since it is the nonintervention home. 31 Roof deck temperatures for the nW sensors were plotted for both the Belmont [intervention home] and the Parkwood [nonintervention home]. At the peak temperature of the day on the 15th the Belmont roof deck sensor nW compared with that of the Parkwood reported 135 versus 132 degrees F. The nW sensor data for both homes on the 15th followed similar patterns. However on the 22nd the roof deck nW sensor data for the Belmont reported that it was 14 degrees F hotter than the Parkwood. This is expected since the roof deck sensor for the Belmont following the radiant barrier installation is located behind the radiant barrier which is restricting the roof deck heat flow into the attic. During the non peak periods on the 22nd the roof deck sensors reported similar temperatures for both homes. With these two examinations of the roof deck sensor data it was decided to continue with the comparison of radiant barrier impacts from the August 15th and 22nd data. Prior to focusing solely on the impact of the radiant barrier on the temperature at the top of the attic insulation, two combination plots were created to visually display the roof deck data with the top of insulation data. Graphs were created, first with the nW roof deck data and then with the sW roof deck data. For some, the graphical display may be viewed with an appreciation for its esthetic artistry. Others will notice the similarity of both. Still others will be encouraged by the significant drop in the top of the attic insulation temperatures during the peak period following the installation of the radiant barrier. That review immediately follows these two graphs. 32 Before passing over these two 8 sensor data curves, a couple of comparative observations are of interest. Prior to the radiant barrier installation the Belmont top of attic insulation temperature was 11 degrees F cooler than its roof deck. For this same time period the Parkwood top of attic insulation temperature was 23 degrees F cooler than its roof deck. 33 Heat gain into the home from the attic begins at the top of the attic insulation. The sensor data for the north end of the attic at the top of the insulation for both homes on the 15th and 22nd were plotted. What is immediately noticeable is that although the previously reviewed roof deck temperatures for both homes prior to the radiant barrier were similar at their peak and over their curve the top of the attic insulation temperatures for the two homes are different. At the 3:00pm peak the degree F temperature for the Belmont is 123 and for the Parkwood it is 109. This is a 14 degree F difference. Even though both homes were shown to have been exposed to the same environmental and orientation conditions, the resulting temperature at top of the attic insulation was different. Neither sensor had a duct within close proximity and the duct air leakages for both homes were similar and acceptable. However, this study was not designed to explore the difference in performance of the two different homes. The focus was to determine what impacts could be discerned from installing an attic radiant barrier in the intervention home. In the Parkwood the top of the attic insulation data for the peak depicted that during the post period the peak occurred 45 minutes later at 3:45pm and reached a slightly cooler 106 degrees F. With the radiant barrier installed the Belmont peak did not occur until 4:00pm. Its peak was 100 degrees F which was 23 degrees F cooler than prior to the radiant barrier. Additionally, the separation of the temperature curves in the morning and their convergence in the evening are interesting. Prior to the installation of the radiant barrier the Belmont top of insulation sensor starts to report hotter temperatures than the Parkwood sensor at 11:10am, at 85 degrees F. In the evening the Belmont remains hotter over the cool down period. At 8:45pm the Belmont is 3 degrees F hotter at 79 versus the Parkwood 76. On August 22 these temperature curves separate earlier at 9:00am, at 67 degrees F. The Belmont retains the advantage until around 6:15pm, at 95 degrees F, when their positions flip and the Parkwood is cooler. Across the evening the radiant barrier appears to influence a hotter top of attic insulation temperature. Again, at 8:45pm the Belmont is 4 degrees F hotter at 84 versus the Parkwood 80. Given that the environmental conditions were similar for both August 15th and the 22nd, and that the Parkwood peaks were close and the temperature curves similar, it can be reliably inferred that the radiant barrier did provide a substantial reduction in the temperature at the attic air and top of attic insulation interface. As hypothesized, the benefit of the radiant barrier accrues during the daily peak temperatures. Adversely the radiant barrier retains additional heat in the attic during the evening cool off period. 34 To clearly see the impact of the radiant barrier on the top of attic insulation temperatures just the pre and post radiant barrier top of insulation curves for the Belmont are compared below. 35 Omnisense sensors were placed in several locations within the HVAC system. With the approximate one minute data reporting it was possible to review the ceiling boot temperature data and accumulate the approximate periods of time that an HVAC system was operating and cooling the home for each 24 hour period. Data from the second floor, nW ceiling supply boot was used for this analysis. This information was developed into a bar graph for both the Belmont [intervention home] and the Parkwood [nonintervention home] for August 15th and 22nd. Reviewing the Parkwood data, the indicated HVAC run time was 9.2 hours pre and 9.4 hours post. This supports the position that the two dates, August 15th and 22nd were comparible environmental days with regard to air conditioning needs. The Belmont indicated HVAC run time was 13.7 hours pre and 11.8 hours post. For the Belmont second floor cooling this change in run time is equal to a 14% reduction. The reduction during the top 7 peak hours is 20% which emphasizes the radiant barrier benefit during the hottest period of the day. Although run time is not a direct measurement of energy used for cooling it does indicate a beneficial efficiency. To additionally support that the reduction in HVAC run time was related to the radiant barrier performance the Omnisense data from the four sensors attached to the four thermostats was plotted. Each time that the ASU staff was on-site the thermostats were checked to be set at approximately 75 degrees F. For the Parkwood the pre and post graphs for each the first and second floors follow similar patterns. Comparing the first with the second floor graphs also depicts the whole home with comparible cooling patterns. The Belmont thermostat patterns have more variability but are not wildly different. While the second floor thermostat shifts noticeably at the end of the 24 hour period, after 7:00pm, the difference is only about 1 degree F. Please note that the vertical axes are at .1 and .2 degree F which visually exaggerates the differences. 36 37 38 Heat gain into attic ducts from the time the conditioned air leaves the supply plenum of the HVAC system located in the attic until it reaches the ceiling supply boot was examined. In the Parkwood data the stress of the peak attic temperatures can be seen in the change of pattern in the afternoon of each day. But the afternoon patterns on both days are comparible. Heat gain during the peak is 4 degrees F in the pre period for the Parkwood. 39 Examination of the duct heat gain pre radiant barrier installation in the Belmont during the 3:00pm peak period measured the supply plenum and the ceiling supply boot at 55 and 62 degrees F respectively. This 7 degree F heat gain occurred through R-6 flex duct exiting the supply plenum 5 feet high in the attic air and then traveling across the top of the attic insulation [noted in earlier photo] to the ceiling boot covered in insulation. The HVAC system was continually cooling without stopping during this period from 1:56pm until 3:26pm, a 1.5 hour run time period. Following the installation of the radiant barrier the supply plenum was still producing 55 degree F cooling air. However the ceiling boot air temperature was 58 degrees F. The duct heat gain changed to a 3 degree F rise during the period from 4:37pm until 5:10pm, a 33 minute run time period. That brings up another impact of the radiant barrier. Following the installation, the HVAC system did have less total run time but the pattern of operation shifted to more cycling on and off during the peak temperatures. Data from the sensors at the inlet and outlet of the HVAC equipment for the Belmont second floor system can be used in calculations for several performance elements. On August 15th during the peak at 2:50pm following cooling for 54 minutes the degree F measurements were inlet 76.1 dry bulb / 63 wet bulb and outlet 55.4 dry bulb. The SystemVision HVAC Refrigerant Charging Quick Reference, Chart 2 – Target Temperature Split for Cooling Systems provided a desired temperature spread of 19.2 degrees F. The measured temperature spread was 20.7 degrees F which was 1.5 degrees F above the desired temperature spread. The following calculation was used for determining the air flow for this 2.5 ton cooling system. 25 cfm/ton x 1.5 degrees above desired = 37.5 cfm x 2.5 tons = 93.75 cfm low 1000 desired cfm – 93.75 cfm low = 906.25 cfm actual system air flow The duct heat gain listed above for August 15th was 7 degrees F. The capacity loss for this duct between the air handler supply plenum and the boot was 33.8%. 7 degrees heat gain -divided by- 20.7 degrees spread = .338 loss On August 22nd during the peak at 5:00pm following cooling for 23 minutes the degree F measurements were inlet 75.3 dry bulb / 62 wet bulb and outlet 54.5 dry bulb. The desired temperature spread was 19.3 degrees F. The measured temperature spread was 20.8 degrees F which was 1.5 degrees F above the desired temperature spread. Again, the calculation produced a system air flow of 906.25 cfm giving the same result prior to and post to radiant barrier installation. The duct heat gain listed above for August 22nd was 3 degrees F. The capacity loss for this duct between the air handler supply plenum and the boot was 14.4%. 3 degrees heat gain -divided by- 20.8 degrees spread = .144 loss Thus the radiant barrier improved the efficiency of the cooling air delivered through this duct during the peak attic temperatures by 57%. 40 41 Discussion The primary objective of the case study was to document some of the impacts of the installation of an attic radiant barrier on the performance of a home. With the beneficial outcomes documented in this case study there are now economic and construction practice issues that will need to be addressed with regard to costs. What are the comparative installation costs, for example, if a builder decides to consider choosing between, a radiant barrier, increasing HVAC size, or moving the HVAC system and ducts out of the attic? If an attic radiant barrier is chosen as a potential solution, will it be used as standard practice or will it be used as one available solution for the occasional home that ends up with a peak cooling discomfort problem? With regard to applying an attic radiant barrier as we did in this study as an aftermarket repair, will there be an interest in providing the other half of the attic work which is the ceiling plane air sealing protocol? To provide that air sealing protocol the case study staff used a decidedly very low-tech approach to move aside and then redistribute the attic insulation. A cheap, plastic dust pan with a flexible lip proved most effective at moving the blown fiberglass insulation and a plastic leaf rake worked well to redistribute it. Hopefully a more labor efficient process would be utilized by a crew that provided this work as an ongoing service. However, the case study work does show that a Mr or Ms everyone can achieve the same result without the requirement of paying someone with high tech equipment to perform these tasks. If the decision was made to include a radiant barrier as a standard construction protocol then another existing solution would be the OSB roof decking with the radiant barrier already attached. However this case study does not shed any light on the comparability of these two different approaches to applying an attic radiant barrier. Another question that has been asked with regard to the OSB radiant barrier and the under truss top chord application of this case study is that when the attic insulation is applied following the radiant barrier is there a surface dust impact on the performance of the radiant barrier performance? Turning to the Omnisense sensors, when they are installed in the HVAC system there will be some time delay in the measurement in the change in duct air temperature due to the mass of the sensor. How much of a time delay was not methodically investigated but a sample review of the detailed sensor temperature data revealed measurement fluctuations as small as one hundredth of a degree F and as large as 5 degrees F at the 1.27 minute sensor sampling rate. Whatever the potential delay, it is not a problem for this case study. The study is comparing the same duct location temperatures pre and post the radiant barrier installation. To the degree that there is a measureable time delay [at a minimum the data could be off up to 1.27 minutes on each end of the on cycle], it is the same for calculations of HVAC run time for both occasions. Also in the study the run time is referred to as indicated run time and not exact run time. The data does show that the radiant barrier installation reduced the top of attic insulation temperature and the amount of duct heat gain. It also measures a reduction in the total run time and the run time during the peak temperature hours. These suggest an improvement in home energy efficiency. However the increase in HVAC cycling pattern during the peak introduces a penalty into the efficiency gains that this case study cannot quantify. Another energy penalty that was associated with the radiant barrier was that it supported heat retention in the attic throughout 42 the evening cool down period. This occurred even though the air path from the soffit air baffles behind radiant barrier up to the ridge vent was maintained. One complicating factor in the Belmont model home attic that was not corrected was the R-value of the installed blown fiberglass insulation. During the initial inspections and work the depth of the insulation near the attic depth cards near the center of the attic was approximately 12 inches. However, it appeared that out in the perimeter of the attic the insulation was under blown. Complicating that was the probable loss of some loft in the blown insulation as a result of moving it and then redistributing it to perform the ceiling plane air sealing. The combined result was an average attic insulation depth of 8.73 inches. The depth ranged from 12 inches down to 7 inches with the lesser depths around the perimeter as previously mentioned. The average thermal value across the attic was calculated to be R-21.5 during the study. The depth was not measured during the first two week baseline period. To directly quantify the efficiency improvement from the case study work would require energy use sub metering which was not included. The main surprise at this point in reviewing the data for the two model homes remains unexplained. Why was there a difference for the top of attic insulation temperatures for the two homes which were so similar and were exposed to the same solar intensity and temperature? As stated earlier the design of this study was not to directly compare the intervention and the nonintervention home. But when the data popped up that the Parkwood [nonintervention home] without the radiant barrier had a top of attic insulation temperature that almost equaled the performance of the Belmont’s [intervention home] that had the radiant barrier, one wonders why? Why was the Belmont top of attic insulation only 11 degrees F cooler than its roof deck temperature and the Parkwood’s was 23 degrees F cooler? Maybe upcoming work with the model homes or more analysis from student involvement will discern the cause or causes. The combustion appliances in the Belmont will operate safely within this home. The gas log set is the direct vent type which is aerodynamically uncoupled from home negative pressures. The two furnaces are in the vented attic and are mechanically exhausted, 90 plus condensing types. Given the positive aspect that the home is substantially air tight at 1250 CFM50 for its 3205 square feet, it is recommended that there be a mechanical ventilation strategy added. One strategy that has been used by Centex on other homes is the upgraded Panasonic bathroom exhaust fan which runs constantly at a selectable low speed when the fan switch is in the off position. It then runs at full speed when the switch is moved to the on position. It has the additional benefit of very quiet operation. 43 The discussion section would not be complete without revisiting the graphs of the thermostat temperatures. At first view as presented in the results section the separation between the pre and post thermostat temperature graphs in the Belmont home for both the first and second floors is eye catching. Even though the written commentary stated that the conditions were similar for both August 15th and 22nd and that the reader should notice the fine gradient of the vertical axis it seemed appropriate to show the data again with the 50 to 90 degree F scale that are common to thermostats. The rescaled graphs below may offer a more comforting view and a confirmation that both homes and both floors of each home were indeed being maintained at comparible temperatures. As another reference point the older mercury bulb thermostats generally allowed around a 3 degree F temperature swing. Digital thermostats will often, as in these homes, keep the temperature swing to less than 1 to 1.5 degrees F. Yes the data loggers were capable of measuring differences in temperatures at the thermostats but for the general purposes of this study those temperatures were within allowable variation. 44 Conclusions The installation of an attic radiant barrier attached to the bottom of the top chord of the roof truss was shown to have several air conditioning season beneficial impacts with regard to the energy efficiency of the Belmont model home. 1. The peak temperature measured at the top of the attic insulation was reduced by approximately 23 degrees F at peak temperature for comparible pre and post dates. This reduction in temperature provided a positive benefit across a nine hour period, though to a lesser and lesser amount as the data is examined further from the peak. 2. The run time of the HVAC system for the second floor of the Belmont was reduced by 14% over the total 24 hour period. During the 7 peak hours the run time was reduced by 20%. 3. Heat gain through the R-6 flex duct into the cooling supply air between the attic air conditioning unit and the ceiling supply boot was reduced from 7 degrees F to a heat gain of 3 degrees F. 4. Heat gain of 7 degrees F equaled a capacity loss of 33.8%. Heat gain of 3 degrees F equaled a capacity loss of 14.4%. Thus the radiant barrier improved the efficiency of the cooling air delivered through this duct during the peak attic temperatures by 57%. 5. Air sealing the ceiling plane produced a substantial disruption to the physics of building natural air change for both winter and summer seasons. As measured by a blower door, this 3205 square foot home started with a whole building air leakage of 1700 CFM50 and was air sealed to 1250 CFM50 which is a 26.5% reduction. This included a notable reduction in the duct air leakage to Outside by sealing the boot penetration of the ceiling sheetrock. On the not beneficial side of the energy efficiency effort, the HVAC system cycled on and off more during the peak period and the radiant barrier kept the top of attic insulation slightly hotter, longer over the cool down period in the evening. The Omnisense sensor system, once the initial wrinkles were ironed out, has proved to be very flexible, reliable and accessible building measurement equipment. There are still multiple additional data sets that could be analyzed. Potentially it may be possible to solve the mystery of the differences in attic heating patterns between the intervention home and the nonintervention home attics. 45 Appendix A Building Performance Measurements Centex Model Homes – Woodbury Charlotte, NC Summer 2008 Belmont 3205 square feet, two stories, tuck under garage, slab floor HVAC: two systems in attic, up flow, single pipe 90+ condensing furnaces [they each have second pipe taking combustion air from attic] with SEER 13 air conditioning Equipment Information: 1st Floor Gas Furnace Lennox - G51MP-36B-070-08 Coil Lennox - C33-30B-2F-3 2nd Floor Gas Furnace Lennox - G51MP-36B-070-08 Coil Lennox - C33-30B-2F-3 st 1 Floor Outdoor Condenser- Lennox - 13ACD-030-230-03 2nd Floor Outdoor Condenser Lennox - 13ACD-030-230-03 Ducts in attic and between floors for first floor and in attic for second floor – two returns for each system Building air leakage: Pre ceiling plane and all boot penetrations air sealing = Post ceiling plane and all boot penetrations air sealing = 1700 CFM50 1250 CFM50 [Reduction = 450 CFM50 or 26.5%] Duct air leakage: First floor Pre = 180 CFM25 Total Post = 161 CFM25 Total 86 CFM25 Outside 91 CFM25 Outside Second floor Pre = 131 CFM25 Total Post = 82 CFM25 Total 70 CFM25 Outside 31 CFM25 Outside 91 + 31 = 122 CFM 25 Outside divided by 3205 SF = 3.8% leakage/SF Exhaust fan air flow First floor ½ bath Second floor hall bath master bath area master bath shower broken 41 cfm 41 cfm 46 cfm 46 Building pressures [Both HVAC blowers on, all interior doors closed] Main body WRT Outside = -1.8 Pascals First floor rooms WRT Outside Utility room +3.8 Pascals Half bath +4.3 Second floor rooms WRT Outside NW bedroom +16.0 Pascals NE bedroom +6.8 Hall bath +3.8 SE bedroom +5.3 SW bedroom -2.5 [has return] Floor cavity WRT Home Pre = +17.0 Pascals Garage WRT Home Pre = +25.0 Pascals Post = +16.3 Pascals Pressure Pan Readings in Pascals First floor Liv Din Den Kit Util ½ bath Din Ret Den Ret Pre +0.5 +0.5 +0.5 +0.8 +1.0 +0.5 +1.1 +1.3 Post +0.3 +0.3 +0.5 +0.5 +0.5 +0.3 +1.1 +0.9 Attic Insulation: White fiberglass blown Second Floor NW bd cl NW bd Loft NE bd H bath SE bd Mb bath Mb cl Mb 1 Mb 2 Hall Hall Ret Mb Ret Pre +0.9 +0.4 +0.5 +0.5 +0.4 +0.4 +0.3 +0.7 +0.3 +0.3 +0.4 +0.4 +0.4 Post +0.2 +0.2 +0.1 +0.1 +0.2 +0.1 +0.2 +0.1 +0.1 +0.1 +0.1 +0.2 +0.5 R-2.46/inch Sampling pattern of attic insulation depth measured an average depth of 8.73 inches. Attic R value: R-2.46/inch x 8.73 inches = R-21.5 attic insulation value Windows: Vinyl, insulated glass, Low-E coating on interior surface of exterior pane Radiant Barrier installed to bottom edge of top chord of roof truss 47 Parkwood 2525 square feet, two stories, tuck under garage, slab floor HVAC: one system in attic, horizontal, zoned for 2 floors, single pipe 90+ condensing furnace [has second pipe taking combustion air from attic] with SEER 13 air conditioning Equipment Information: Gas Furnace, Zoned Coil Outdoor Condenser - Lennox – G51MP-48C-090-07 Lennox – CH33-48C-2F-2 Lennox – 13ACD-042-230-02 Ducts in attic and between floors for first floor and in attic for second floor – one return first floor and two returns second floor Building air leakage: Pre ceiling plane and all boot penetrations air sealing = Post ceiling plane and all boot penetrations air sealing = 1323 CFM50 N/A [Reductions = N/A] Duct air leakage: Pre = 192 CFM25 Total Post = N/A CFM25 Total 108 CFM25 Outside N/A CFM25 Outside 108 CFM 25 Outside divided by 2525 SF = 4.3% leakage/SF Floor cavity WRT Home Pre = +15.7 Pascals Garage WRT Home Pre = +23.5 Pascals Attic Insulation: Cellulose blown Post = N/A Pascals R-3.75/inch Sampling pattern of attic insulation depth measured an average depth of 8.6 inches. Attic R value: R-3.75/inch x 8.6 inches = R-32 attic insulation value Windows: Vinyl, insulated glass, Low-E coating on interior surface of exterior pane 48 Appendix B Installation Dates and Labor Effort Placement of Omnisense Sensors, Gateway, Router, and Activation of Internet Access July 7 – 9, 2008 Ceiling Plane Air Sealing: Belmont – July 28 & 29, 2008 Manually removed blown fiberglass insulation from top plates, exhausts fans, and chases Air sealed with foam - top plate penetrations and both edges [excluding low attic at roof edge] Air sealed with foam - penetrations in capped chases Capped one open chase and air sealed with foam Air sealed with caulk - penetrations at bathroom exhaust fans, including fan housing Air sealed with caulk - the boot to sheetrock crack [included ceiling boots of first floor] Air sealed with caulk - the return air filter grille box to sheetrock crack Weatherstripped and added Thermax foam board [layered to R-20] to attic access panel Manually redistributed blown fiberglass insulation across ceiling plane Labor July 28: 7:00am – 1:00pm 6:00pm – 9:00pm 6 hours x 2 persons = 12 3 hours x 3 persons = 9 July 29: 7:00am – 10:00am 3 hours x 2 persons = 6 Total on-site labor = 27 hours [travel and other hours not included] Radiant Barrier, attic: Belmont – August 18, 2008 7:00am – 1:00pm 6:00pm – 9:00pm 6 hours x 3 persons = 18 3 hours x 3 persons = 9 Total on-site labor = 27 hours [travel and other hours not included] 49 Appendix C Sensor Code Identification Information B = Belmont – Intervention home P = Parkwood – nonintervention home F = first floor S = second floor A = attic 15 = August 15, 2008 – pre radiant barrier installation 22 = August 22, 2008 – post radiant barrier installation Sensor numbers 0CD9 = BA top of insul N 0610 = PA top of insul N 10E7 = BA-wt roof deck sW orientation] 0C9B = PA-wt roof deck sW orientation] 112F = BA-wt roof deck nW 1377 = PA-wt roof deck nW orientation] [Belmont attic top of insulation North end of attic] [Parkwood attic top of insulation North end of attic] [Belmont attic-wood truss at roof deck south end, West [Parkwood attic-wood truss at roof deck south end, West [Belmont attic-wood truss at roof deck north end, West orientation] [Parkwood attic-wood truss at roof deck north end, West Run time B-15 = 1328 Run time B-22 = 1328 1328 = BS bdrm supply nW [Belmont second floor bedroom ceiling supply boot north end, West orientation] Run time P-15 = 1C7A Run time P-22 = 1C7A 1C7A = PS supply frt bdrm nW [Parkwood second floor ceiling supply boot bedroom north end, West orientation] 0F5E = BF thermostat 53” central [Belmont first floor thermostat 53” high, central in home] 15D2 = BS thermostat 54” [Belmont second floor thermostat 54” high, central in home] 2051 = PF thermostat [Parkwood first floor thermostat, central in home] 1B4C = PS thermostat mst bdrm nE Parkwood second floor thermostat in master bedroom, north end, East orientation, at door 0F96 = BA-wb supply A/H [upstairs] [Belmont attic-wood block in supply plenum of air handler for upstairs HVAC unit] 114D = PA-wb supply A/H [up & dn] [Parkwood attic-wood block in supply plenum of single air handler zone dampered to condition upstairs and downstairs] 50