CEE 395- Materials for Constructed Facilities

advertisement

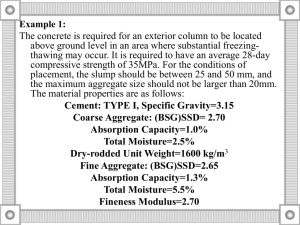

CEE 395- Materials for Constructed Facilities Civil Engineering Materials Aggregate I Week 3, Lecture 05 Aggregate Mass of crushed stone, gravel, sand, etc.. predominantly composed of individual particles ranging from between 0.005 mm to 150 mm in size. Function of aggregate: 1. Main ingridient in making concrete: - As a low cost filler in Portland Cement Concrete (PCC) - As a source of stiffness and stability in Asphalt Cement Concrete (ACC, HMA) 2. Used as underlying foundation in pavements and foundations. Aggregate Sources Natural - Gravel Pits (gravel) - River Run Deposits (gravel) - Rock Quarries (crushed stones) Manufactured - Slag waste (steel mill), Steel slugs and bearings - Expanded shale and clay (light weight) - Syrofoam beads (insulation) Geological Formations - Igneous rocks - Sedimentary rocks - Metamorphic rocks Evaluation of Aggregate Sources Primary Challenge: How to use local materials in the most cost effective manner ? Sources (quarries or pits) are evaluated for 1. Quality of the larger particles (soundness, toughness,..) 2. Nature and amount of fines (sieve analysis tests) 3. Gradation of aggregate Characteristics vary within a quarry/gravel pit Transportation cost is a major component of cost Aggregate Uses Base for pavements: Provides stability and drainage. Tradeoff between stability (more fines) and better drainage (larger aggregate) Portland Cement Concrete - 60-75% of volume, 79-85% of weight - Maximize aggregate for greater stability at lowest cost - It is a filler; Friction between particles should be minimal Notes: Aggregate #1 (Continued) Asphalt Concrete - 0+% of volume, 92-96% of weight - Asphalt cement serves as a binder for aggregates It is the main load-bearing component. Friction (interlock) needs to be maximized. Aggregate Properties (Table 5.1.) Physical (particle shape, size, surface texture, soundness) Chemical (solubility, surface charge, reactivity, affinity) Mechanical (compressive strength, toughness, abrasion resistance, stiffness, etc). I. Particle Shape How the material will pack into a dense configuration The mobility of the particles within a mix Angular aggregates: - From crushing rocks - Generally produce higher stability Rounded aggregates: - From angular rocks weathering and tumbling in water - Easier to work with because particles can more easily slide past one another Flakiness - Ratio of smallest to largest dimensions of the aggregate - Undesirable because they are difficult to compact during construction and easy to break II. Surface Texture How the aggregate compacts and bonds with the binder. Rough texture - better bonding and increased inter-particle friction - desirable for asphalt concrete and base courses for greater stability and reduced rutting. Smooth texture - Easier to compact into a dense configuration - Desirable for a more workable mix in preparing Portland cement concrete Test for uncompacted void content of fine aggregate (AASHTO TP33 Method A) for indirect measure of angularity and surface texture III. Soundness and Durability The ability to withstand weathering. Extremely important since materials are subject to severe weather changes. Aggregate soundness test is covered in ASTM C88 Durability in Portland Cements - Rapid Freezing and Thawing (ASTM C666) - Critical Dilation by Freezing (ASTM D4792) Notes: Aggregate #1 (Continued) IV. Toughness, Hardness, and Abrasion Resistance Collectively refer to the ability of an aggregate to resist the damaging effects of loads. Test commonly used is Los Angeles Abrasion Test (ASTM C131, C535) V. Absorption Surface pores. Extremely important in making PCC and ACC. - Determines the correct water mixture for cement - Important in determining workability - Some absorption required for bonding purposes - Cost Issue and higher absorption rates require greater amounts of cement and asphalt binder 4 moisture conditions: - Bone dry (aggregate contains no moisture) - Air dry (aggregate may have some moisture) - Saturated Surface Dry (voids are filled with moisture but surface is dry) - Moist (moisture content above SSD condition) VI. Specific Gravity Different volumes used in calculation of aggregate's specific gravity: - Vs, Volume of solids - Vi, Volume of impermeable voids - Vp, Volume of water permeable voids - Vc, Volume of ???? - Ws, Weight of solids - Wp, Weight of permeable void in SSD condition - gw, Specific gravity of water Bulk Dry Weight Bulk SSD Specific Gravity Apparent Specific Gravity Effective Specific Gravity Ws / (Vs + Vi + Vp).γw (Ws + Wp) / (Vs + Vi + Vp).γw Ws / (Vs + Vi ).γw Ws / (Vs + Vic ) γw Bulk Specific Gravity Test ASTM C127 (Coarse Aggregates) Different weights used in calculation in bulk specific gravity test: - A, Dry Weight - B, Saturated Surface Dry Weight - C, Submerged weight Bulk Dry Specific Gravity Bulk SSD Specific Gravity Apparent Specific Gravity Absorption (%) A / (B - C B / (B - C) A / (A - C) (B - A) / A (100) ASTM C128 (Fine Aggregates) - Same as the previous test using a 500 gram sample and a constant volume flask called the pycnometer - Equations are the same, except: C is the submerged aggregate in pycnometer, which is defined as (weight of flask with aggregate and water) - (weight of flask and water) Notes: Aggregate #1 (Continued) VII. Strength Portland Cement Concrete and Asphalt Concrete - cannot exceed the strength of the aggregates - aggregate strength is very important in high strength concrete and High Volume asphalt surface coarse Aggregates strength requirement: - Tensile strength (0.7 MPa to 16 MPa) - Compressive strength (35 MPa to 350 MPa) Modulus Modulus of Resilience (Mr) - Resilience modulus test (Figure 5.6) Simulates a moving truck - Deformation response - recoverable or resilience - permanent Layer Coefficients: Used in pavement design as an estimate of structural capacity of base layer. Also used for design of gravel roads. Drainage Capacity (permeability) Used to estimate the amount of water that can be drained through a layer Notes: