06 Public Water Supply Module 4 - Pretreatment

advertisement

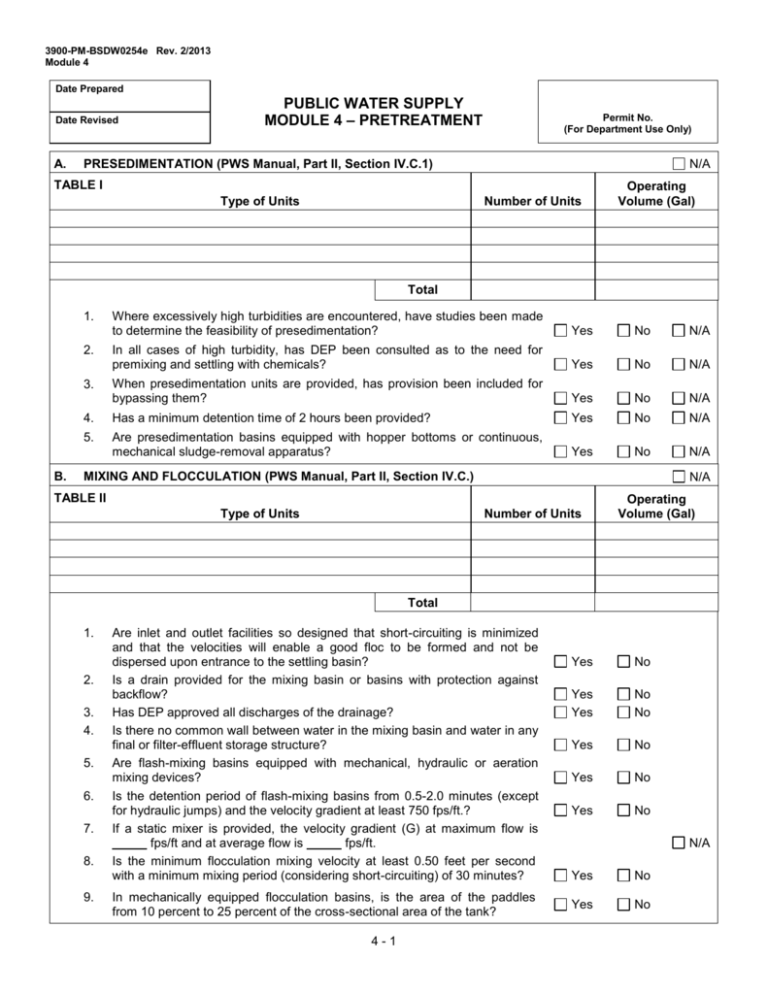

3900-PM-BSDW0254e Rev. 2/2013 Module 4 Date Prepared Date Revised A. PUBLIC WATER SUPPLY MODULE 4 – PRETREATMENT Permit No. (For Department Use Only) PRESEDIMENTATION (PWS Manual, Part II, Section IV.C.1) N/A TABLE I Type of Units Number of Units Operating Volume (Gal) Total Where excessively high turbidities are encountered, have studies been made to determine the feasibility of presedimentation? Yes No N/A In all cases of high turbidity, has DEP been consulted as to the need for premixing and settling with chemicals? Yes No N/A When presedimentation units are provided, has provision been included for bypassing them? Yes No N/A 4. Has a minimum detention time of 2 hours been provided? Yes No N/A 5. Are presedimentation basins equipped with hopper bottoms or continuous, mechanical sludge-removal apparatus? Yes No N/A 1. 2. 3. B. MIXING AND FLOCCULATION (PWS Manual, Part II, Section IV.C.) N/A TABLE II Type of Units Number of Units Operating Volume (Gal) Total 1. 2. 3. 4. 5. 6. 7. 8. 9. Are inlet and outlet facilities so designed that short-circuiting is minimized and that the velocities will enable a good floc to be formed and not be dispersed upon entrance to the settling basin? Is a drain provided for the mixing basin or basins with protection against backflow? Has DEP approved all discharges of the drainage? Is there no common wall between water in the mixing basin and water in any final or filter-effluent storage structure? Are flash-mixing basins equipped with mechanical, hydraulic or aeration mixing devices? Is the detention period of flash-mixing basins from 0.5-2.0 minutes (except for hydraulic jumps) and the velocity gradient at least 750 fps/ft.? If a static mixer is provided, the velocity gradient (G) at maximum flow is fps/ft and at average flow is fps/ft. Is the minimum flocculation mixing velocity at least 0.50 feet per second with a minimum mixing period (considering short-circuiting) of 30 minutes? In mechanically equipped flocculation basins, is the area of the paddles from 10 percent to 25 percent of the cross-sectional area of the tank? 4-1 Yes No Yes Yes No No Yes No Yes No Yes No N/A Yes No Yes No 3900-PM-BSDW0254e Rev. 2/2013 Module 4 Date Prepared Date Revised B. PUBLIC WATER SUPPLY MODULE 4 – PRETREATMENT (cont’d.) Permit No. (For Department Use Only) MIXING AND FLOCCULATION (continued) 10. In mechanically equipped flocculation basins, are the agitators driven by variable-speed motors with the peripheral speed of paddles ranging from 0.5 to 3.0 feet per second? C. Yes No CHEMICAL APPLICATION (PWS Manual, Part II, Section IV.C.) N/A TABLE III Number of Units Type of Units Total NOTE: If ozone is used in pretreatment, complete Module 8. 1. Are various points of application of the chemicals provided for flexibility of operation? Yes No N/A Is a minimum of two chemical feeders per chemical provided on all water supplies requiring coagulation? Yes No N/A Are feeders so located in the treatment plant that chemical dusts will be prevented from entering the laboratory and operation floor? Yes No Is the capacity and design such that each feeder will be able to supply, at the maximum rate of flow through the plant, the necessary amounts of chemicals at an accurate rate for proper treatment of the water? Yes No Is water used for dissolving chemicals protected from any possibility of backflow of chemical solutions into the safe water supply? Yes No a. Does the safe water supply have an air gap of at least 6 inches or 2 pipe diameters, whichever is greater, above the maximum water level of any chemical solution or of water which has not been approved as a public water supply by DEP? Yes No b. If no, has an appropriate backflow prevention device been installed? Yes No Are feeders’ conveniently located near points of application of the chemical and easily accessible for maintenance? Is an adequate containment structure provided for each chemical feed system? Yes No Yes No N/A Are paddles, agitation with air, or other mechanical means provided in the solution tank to keep uniform strength of solution? Yes No N/A 10. Are solution tanks provided for each chemical of such capacity that each tank can operate for at least 24 hours? Yes No N/A 11. Is a drain provided for each tank, with protection against backflow? Yes No N/A 12. Are float gauges provided when necessary to indicate the level of solution? Yes No N/A 13. Are chemical feed lines, from the feeder to the points of application, of durable material, corrosion resistant, easily accessible for dismantling throughout entire length, protected against freezing and as short as possible in length of run? Yes No 2. 3. 4. 5. 6. 7. 8. 9. 4-2 N/A N/A 3900-PM-BSDW0254e Rev. 2/2013 Module 4 Date Prepared Date Revised C. Permit No. (For Department Use Only) CHEMICAL APPLICATION (continued) 14. D. PUBLIC WATER SUPPLY MODULE 4 – PRETREATMENT (cont’d.) Is space provided for a minimum of 1 month’s supply of chemicals at a dry place convenient for the operator’s efficient handling? Yes No SEDIMENTATION (PWS Manual, Part II, Section IV, C.4.) N/A TABLE IV Type of Units Number of Units Operating Volume (Gal) Total 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. Are basins provided with sludge removal equipment? Are at least two basins provided? Does the velocity through pipes or conduits from the flocculation (mixing) basins range from 0.50 to 1.50 feet per second? Is this velocity reduced at the entrance to the settling basin by baffles or by directing the water into an enlarged section so that the velocity through the settling basin will not exceed 1 foot per minute? Is the basin designed to minimize short-circuiting? Is the minimum settling period at least 2 hours? Are outlet devices designed to minimize short-circuiting? Is the rate of flow over the outlet weir not in excess of 20,000 gallons per day per foot of weir length? If submerged ports are used in lieu of overflow weirs, are the ports installed no more than 3 feet below the flow line? Are all basins provided with a valved drain? Are basin bottoms sloped no less than 1 foot in 12 feet toward the drain when mechanical sludge-removal equipment is not installed? Is the discharge of drainage from any mixing or settling basin into any waters of the Commonwealth approved by DEP? When covers are used, are manholes with raised curbs and covers provided? When covers are used, are drop-light connections provided so observations of the floc can be made at several points? Are permanent ladders or handholds provided for safety on the inside wall of the basin above the water level? Are guard rails provided when tanks are elevated above ground level or when walk areas are narrow? Are all flushing lines or hydrants using safe water so constructed, so located, or so equipped with proper back flow preventers as to prevent any possibility of backflow into the safe waterlines? 4-3 Yes Yes No No Yes No Yes Yes Yes Yes No No No No Yes No Yes Yes No No N/A Yes No N/A Yes No N/A Yes No N/A Yes No N/A Yes No Yes No Yes No