Protraction of a Three Joint Robot Leg: Trajectory Optimization and

advertisement

A Review of Function Modeling: Approaches and Applications

M.S. Erden, H. Komoto, T.J. van Beek, V. D’Amelio, E. Echavarria, T. Tomiyama

Intelligent Mechanical Systems Group, BioMechanical Engineering,

Delft University of Technology, the Netherlands

E-mails:

{m.s.erden, h.komoto, t.j.vanbeek, v.damelio, e.echavarriauribe, t.tomiyama}@tudelft.nl

Abstract: This paper aims to establish a common frame and understanding of function

modeling (FM) for the research activities going on in the Intelligent Mechanical Systems

Group at TU Delft. A comparative review of some literature is performed in order to grasp

the various FM approaches with their commonalities and differences. The relations of FM

with the research fields of artificial intelligence, design theory, product development, and

maintenance are discussed. In this discussion the aims are to highlight the features of various

classical approaches in relation to FM, to delineate what FM introduces to these fields, and to

discuss the applicability of various FM approaches in these fields. Lastly, the basic ideas

underlying the projects in the Intelligent Mechanical Systems Group are introduced with

reference to the general framework of FM.

Keywords: Function modeling, function reasoning, model based reasoning, function,

behavior, structure, state, design, maintenance, service.

1. INTRODUCTION

Function modeling (FM) is the name given to the activity of developing models of

devices/products/objects/processes based on their functionalities and the functionalities of their subcomponents. It is acknowledged by researchers that developing such a high level representation

scheme of objects provides many facilities. Some of them include an overall system description to

facilitate the communication and understanding between engineers of various disciplines, and

means to make use of computers for reasoning purposes. The basic concern of FM is how to

represent knowledge about function. The representation frame is important, on one hand, to serve as

a general and common communication frame, and on the other hand, to facilitate the use of

automated reasoning systems.

Once such a representation scheme is developed, computers can be used for identification,

explanation, verification, and selection purposes concerning the design, development, diagnosis,

and maintenance processes. The definition of FM given above needs clarification and formalism.

This is important because computer based applications require explicit representation of the

knowledge in a structured and formalized way.

One important role that FM can play is a basis for solving representation problems in product

development of complex products of which development processes are also complex. The

complexity in product development is a result of both the inter-disciplinarity in the process and the

physically, geographically, and temporally distributed nature of design teams (Szykman et al., 2000,

2001; Tomiyama and Meijer, 2005). As Szykman et al. (2000) state, “a single designer or design

team can no longer manage the complete product development effort”. FM provides a framework

for overall system description. With FM the barriers between the sub-disciplines might be

overcome by using the common language of functionality. By supporting decomposition of

functionalities within one consistent model, FM bridges the gap between the high-level

requirements and the low-level details. Such a common model provides a holistic view of the

system above the domains of different expertise and makes it possible to go back and forth in the

1

design process in order to check the satisfaction of high-level requirements by the lower-level

specifications.

The conventional design processes, concerning both applications in industry and education of

engineers, seem to promote one-way, top-down procedures, starting from requirements towards

realization of those. Due to the top-down nature of the procedures little iteration is performed

between the design steps. After a decomposition process the high-level view of requirements is

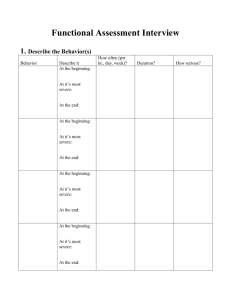

translated into low-level detailed component specifications. This is illustrated by Muller (2007) as

in Figure 1. The small number of statements at the top of the pyramid finally results in millions of

details in the technical product description. The proliferation of details results in a gap of

communication between the upper and lover levels. While the requirement designers in the upper

level start not to understand what is performed in the lower levels, the component designers in the

lower levels start to miss the aim of their own work within the overall system. FM serves as a

means of linking the upper and lower levels of system design and system description. Therefore, it

can be placed in the middle of the pyramid, in the multi-disciplinary section in Figure 1. Having

access to an overall system description with FM facilitates the engineers to be aware of what and

why they are doing.

100

Number of details

101

System

Requirements

System

Design

Decisions

Multi-Disciplinary

Design

Components, connections,

lines of code

Mono-Disciplinary

Design

102

103

10

4

105

106

107

Figure 1: Device Pyramid of Design (Muller, 2007).

Referring to Figure 1, the transition from multi-disciplinary design view to mono-disciplinary subdesign problems is usually made considering the conventional engineering disciplines like

mechanical, electrical and software. The separation of disciplines is more or less a consequence of

engineering educations still anchored to a single domain (Rault, 1992). The laws of physics in

relation to a single product, however, are not always compatible with the separation of disciplines.

Many physical phenomena which can be categorized in different engineering disciplines have

strong physical interrelations (Tomiyama, 2006; Tomiyama and D’Amelio, 2007). As a result of

this fact, engineers of different disciplines working in the same design team have to communicate

and cooperate with each other on various issues. But the solution of “how to bridge the multitude of

models required to support a complex design” (Wang, et al., 2002) is not trivial. The

communication problem between the design groups in the lower levels of the pyramid is another

issue addressed by FM. FM, being a common representational frame above the single domains,

provides means of communication between the engineers of different disciplines. In this sense, FM

2

does not only serve for vertical linking between the upper and lower levels, but also for horizontal

communication within the lower levels in Figure 1.

In the second section, a review of some FM literature is given. This review is performed with the

intention of building a general frame of FM as an intermediate category between human needs and

objects. In the third section, the relation of FM with the research fields of artificial intelligence (AI),

design theory and product development, and maintenance are discussed. In the fourth section, the

ongoing research in the Intelligent Mechanical Systems Group is introduced with making use of the

general FM frame. The aim is both to show the applicability of such a frame for different problem

domains, and to delineate the common denominator of these different researches on the basis of

FM. The basic concepts of these researches, namely “evolvability”, “unpredictable interferences”,

“intelligent maintenance”, and “service design” are the outcomes of the peculiar way of thinking

with FM. Section five concludes the paper.

2. REVIEW OF SOME FM APPROACHES

In this section a review of some literature in relation to FM is performed. Specifically, the

approaches for developing functional concept ontologies (Kitamura et al., 2004) are detailed. At the

end of the section graphs for a generalized frame of FM is given (Figure 2, Figure 3, Figure 4). This

frame is constructed basically following the descriptions of Chandrasekaran and Josephson (2000),

but also by extending it with the descriptions of other studies. The similarities and differences

between the conceptions of Chandrasekaran and Josephson (2000) and other scholars are

mentioned. The reader is encouraged to refer to these figures throughout this section. The general

frame constructed in this section is the reference of description in the following sections.

2.1. Function and Functional Ontology

A functional model shows how the general goal of a system is achieved by realization of sub-goals

via the sub-functions in the system. With the terms of Kitamura et al. (2004), “functional models

represent a part of (but not all of) the designer’s intentions, so called design rationale”. Such

functional modeling is used in FMEA (failure mode and effect analysis) (Rausand, 1996; Klein and

Lalli, 1989) and FTA (fault tree analysis) (Lee et al., 1985) applications. However, the

representation framework of such applications is noted to be task-specific (Kitamura et al., 2004).

Functional modeling needs generalized frameworks in which description and knowledge retrieval

are easily made. The framework which provides the viewpoints and the necessary vocabulary in

order to represent functional knowledge is called a “functional ontology” (Kitamura et al., 2004;

Kitamura and Mizoguchi, 2003).

It is possible to distinguish three domain ontologies intended to model and describe engineering

products. Among those, device ontology regards a device or a system to be composed of black-box

modules connected with input-output relations. In this sense, device ontologies define “agents” of

the system which process their own input data and produce outputs to be transferred to the others.

The design approach of Pahl and Beitz (1988), known as the German systematic design approach,

makes use of the device-centered ontology (Kitamura et al., 2004). The Qualitative Physics

proposed by de Kleer and Brown (1984) is an example of device-centered ontology for artifacts.

In the process ontology approach, on the other hand, the focus is the processes in which the entities

take part, rather than the entities themselves. Therefore there are no agents in process ontology, but

“participants” that take part in the processes. The attributes of the entities are regarded as changing

not as a result of their input output relations but as a consequence of the processes that affect them

(Kitamura and Mizoguchi, 2004). The Qualitative Process Theory developed by Forbus (1984) is a

pioneering example of process ontology development.

The functional concept ontology, which is the basic concern of this paper, aims to develop a model

3

of a device/system from a teleological point of view (de Kleer and Brown 1984; Kitamura and

Mizoguchi, 2003, 2004). Namely, the FM aims to develop a model based on the question of ‘what

the device and its components do’, or ‘for what purpose the device and its components are’. The

functional concept ontology aims to develop the necessary framework and language to model the

functionality of a system from the subjective viewpoint of the human (the designer, user, or

developer). The work of de Kleer and Brown (1984), Chandrasekaran and Josephson (2000),

Umeda et al. (1996), Umeda and Tomiyama (1995), Yoshioka et al. (2004), Gero (1990), and

Keuneke (1991) are attempts to build functional ontologies. These will be detailed in the succeeding

review section.

Function is considered by Umeda and Tomiyama (1995) as a bridge between human intention and

physical behavior of artifacts. The authors state “there is no clear and uniform definition of a

function, and moreover, it seems impossible to describe function objectively”. The subjective

character of function and being intermediate between intentions and objects is acknowledged also

by Chandrasekaran and Josephson (2000), Keuneke (1991), and Balachandran and Gero (1990).

However, in the literature there are conceptions of function which differ from those. Rodenacker

(1971) defines a function as a relationship between input and output of energy, material, and

information and this definition is widely accepted in design research (Pahl and Beitz, 1988; Welch

and Dixon, 1992). The set of a functions defined by Pahl and Beitz (1988) are considered to be too

abstract to describe details of intentions (Kitamura, et al., 2004). Bracewell and Sharpe (1996)

represent functions based on extending the Bond Graph technique (Rosenberg and Karnopp, 1983),

which introduces the concepts of “flow” and “effort to cause a flow” in the system. Value

engineering represents function in the form of “to do something” (Miles, 1972). This representation

as “verb+noun” is noted to be incapable of avoiding inappropriate modeling (Kitamura, et al.,

2004). In this paper, basically the conceptions of Umeda et al. (1996), Umeda and Tomiyama

(1995), and Chandrasekaran and Josephson (2000) are followed. Function is considered as a

subjective category which links the human intentions/purposes residing in the subjective realm to

the behaviors and structures in the objective realm.

2.2. Function as an intermediate concept between Needs and Objects

Chandrasekaran and Josephson (2000) identify two viewpoints of “function”. In the “environmentcentric viewpoint” the function is a matter of the effect of objects in the environment they are

placed (Figure 3). The function from environment-centric viewpoint is called “function as effect”.

In the “device-centric viewpoint”, on the other hand, the function, which is called “function in

device centric terms”, is a matter of internal parameters of the object (Figure 4). In Chandrasekaran

(2005), there is mentioned a priority between the two views. Function as effect is achieved as a

result of the combination of the function in device centric terms and the “mode of deployment” of

the object (Figure 2).

In the environment-centric view (Chandrasekaran and Josephson, 2000), function is considered as a

concept in the intermediate between the objective realm of the object per se and the subjective

realm of human intentions (Figure 3). The intentions of human are linked to the objects via the

realm of functions. The human needs undergo a few stages of “abstraction levels”. The function that

is related to the objective realm is defined in the last abstraction level. The object itself is placed in

the objective “world” in a particular manner, which is conceptualized as a particular “mode of

deployment”. Depending on its mode of deployment, the object realizes some “roles” in the world it

is placed. The object, the mode of deployment, and the roles take place in the objective realm and

are immune from the intent of human. It is when some of the roles realized by the object are

recognized as functions that the contact with the objective and subjective realms is maintained. The

functions identified in this way are called as “function as effect”. These are basically the functions

of the object as effects on its environment.

In the device centric view (Chandrasekaran and Josephson, 2000), as well, function is an

4

intermediary between the objective and subjective realms (Figure 4). However, this time, the focus

is not the effect of the object on its environment, but its internal configuration, named as its

“structure”. It is possible to identify different structures for the same objective system in different

abstraction levels. For example, it is possible to consider a calculator both as a structure of electrical

circuits composed of transistors and as a structure of logic operation system composed of adders,

logic gates, etc. Based on the abstraction level of the structure, some behaviors are observed with

the object. All these – namely, structure, abstraction level, and behaviors – take place in the

objective realm. Some of the behaviors realized by the object are recognized as the function. This

recognition takes place in the subjective realm, and depends on the intentions of human.

The environment-centric function is an intermediary step between the “needs” and the devicecentric function (Figure 2) (Chandrasekaran and Josephson, 2000). The needs of human are

expressed as environment-centric functions after various steps of narrowing down through

abstractions. The needs are defined as functions when the possible lowest level of abstraction is

reached. For example, the illuminating function of a reading lamp is reached not directly from the

need to “read” but after some transformations: the need to be able to read is transformed into the

need to illuminate the paper, and then the need to illuminate with proper lighting, etc. The link

between the environment-centric function and device-centric function is achieved by the mode of

deployment. The environment-centric function of illuminating the paper is transformed into the

device centric function of “turning the light on when pushed on the button” via the specific mode of

deployment according to which a reading lamp is used in a room. This deployment dictates, the

lamp should be turned on and off with the control of a button, the button should be close to the

reading place, etc. Chandrasekaran (2005) states that the mapping between the needs and artifacts is

a many-to-many mapping. This means an artifact might fulfill more than one needs, as well as a

need might be fulfilled by more than one artifact. For example, a lamp can fulfill the function of

heating, besides providing light. But obviously to make use of a lamp would be an inefficient way

of satisfying the need of heating. Therefore, Chandrasekaran and Josephson (2000) mention that the

expression of needs as an environment-centric function should not only be in the lowest level of

abstraction but also consider the efficient fulfillment of the need.

The FBSg1 model, developed by Gero (1990), defines function as an intermediate between the goal

of human and the behavior of a system. The focus of the FBSg model is more on the design process,

which is considered to be a transformation from “intentions” to the “structure”. In Balachandran

and Gero (1990), the authors define function, structure, and behavior as three classes of properties

of a design object: “Function properties dictate its intended purpose requirements, structure

properties represent the description of the whole and its constituents, while the behavior properties

spell out how the structure of the object achieves its function.” The “expected behaviors” are

derived from the intended functions by making use of “teleological knowledge” (Figure 4). This

means, the selection of behaviors to be associated by the intended function is not explained by the

physics underlying the behaviors, but by their consequences that are useful for the intentions.

However, the actual physics that underlie the behaviors might result in unexpected behaviors

besides the ones determined as a result of the teleological knowledge. The difference between the

set of all behaviors output by the structure (structural behaviors) and the expected behaviors is

named as unintended behaviors in Figure 4. Dorst and Vermaas (2005) provide a detailed analysis

of various papers of Gero and his colleagues about the FBSg, in order to identify the ambiguous

points in the model.

In the FEBS (Function-Environment-Behavior-Structure) design model (Tor et al., 1999; Deng et

al., 1999, 2000), “the working environment” corresponds to the environmental elements that

contribute to the functions of the design. This conception is in analogy with the conception of

“mode of deployment” (Chandrasekaran and Josephson, 2000) in Figure 3. “The physical structure”

1

In order to distinguish the Function-Behavior-Structure model of Gero and his colleagues from the FunctionBehavior-State model of Umeda and Tomiyama, the former is abbreviated as FBSg, and the latter with FBS.

5

signifies the object of the design. The authors mention that an object might exhibit many behaviors

not necessarily recognized as functions. “The intended behaviors” among those are the ones

associated with the intended functions. They argue that only intended behavior need to be

considered in the functional design process. “The required functions” are incorporated in the design

because they are used to delineate the design intention. A function is defined by specifying the set

of physical structures (objects) necessary to achieve it.

2.3. Function and Structure, Mental Simulation and Behavioral Simulation

Keuneke (1991) considers functional representation as a means of constructing a new organizational

structure. The actual physical structure of the system that resides in the objective realm corresponds

to the visible topology, in which physical simulation can be performed (Figure 4). Qualitative

physics, for example, can be used to simulate the physical structure. However, what is needed in the

design phase is in fact a “mental simulation”, which tests if the design corresponds to the human

needs (Figures Figure 3 and Figure 4). Functional representation transforms the behaviors in the

physical structure into the realm of functions. A mental simulation is possible within the new

organization achieved with functions. Keuneke (1991) defines explicitly four types to capture all

possible functions

Far and Elamy (2005) consider functions as means of switching from MBR (Model Based

Reasoning) technology to functional reasoning technology. While MBR technology deals with

“what a device does”, the functional reasoning technology deals with “what a device is for”. This

understanding is very close to the understanding of the separation of objective and subjective

realms in Figure 3 and Figure 4. While MBR takes place in the objective realm, functional

reasoning takes place in the subjective realm.

Umeda and Tomiyama (1995) delineate two phases for the design process. In the first phase the

user describes functions independent of any physical behavior or system structure. In the second

phase the designer enters the objective realm by embodying the functions into behaviors and

structural models. Umeda and Tomiyama (1995) mention that manipulation of the behavioral

structure is possible by making use of qualitative physics. On the other hand, the mental simulation

of functions is noted to be still difficult to be done by computers. The FBS (Function-BehaviorState) modeling is proposed as a new knowledge representation scheme to systematize functional

decomposition in the subjective realm and then to develop a CAD system that helps the

embodiment of the designed functions into a behavioral and structural system in the objective

realm.

In their FBS model Umeda, Tomiyama and their colleagues (Umeda et al., 1990, 1995, 1996, 2005;

Umeda and Tomiyama, 1995, 1997) develop a function representation, in which the subjective and

objective realms are related to each other with function-behavior relationship. The authors define

the function as “a description of behavior recognized by a human through abstraction in order to

utilize it”. They argue that it is difficult to disassociate function from the behavior; therefore, they

represent function as a tuple in which both the human intention (function as to do something) and

physical semantics (behavior) are represented. In this way they come up with a representation

through which the subjective selection of some behaviors as a function is formalized. In their

scheme the objective realm is placed in a frame which they name as an “aspect”. This aspect

corresponds to the abstraction level, or, with their terms, “physical situations of the current

interests” (such as discipline of electrical, mechanical engineering), in which the entities, attributes,

relations, and physical phenomena are defined in a particular way (Figure 4). (In Umeda et al.

(1990), the authors use the term “view” instead of aspect, in the same meaning.) The authors state

that selection of these views is subjective, and something that effects the subjective choice and

decomposition of functions. The authors (Umeda and Tomiyama, 1995) mention that their

representation of function is less formal than that of Keuneke (1991), in the sense of being

applicable to a wider range of functions including the ones that cannot be grasped the latter’s four

6

types.

The “physical phenomena” taking place in the “aspect” results in the change of “states” of the

system. A state corresponds to a particular set of entities, attributes of entities, and relations

between entities. In Umeda et. al (1990) the authors argue there is no meaningful distinction

between “state” and “structure”. They claim the difference between the two in conventional usage is

just a matter of duration: structures that change in a short time are generally called as states.

Therefore they adopt the term state rather than structure in their FBS model, with the intention of

covering both meanings in conventional usage. Different sequences of one or more changes of

states correspond to behaviors that take place in this objective realm. A “behavior” is therefore

defined as a sequential change of states over time. As mentioned before, some of the behaviors

taking place in the objective realm are recognized a “functions” in the subjective realm.

The SBF (structure-behavior-function) model developed by Goel and his colleagues (Goel and

Chandrasekaran, 1989, 1992; Goel, 1991) considers behavior as an intermediate concept between

the structure and subjectively defined functional requirements. The structure in the modeling of

SBF is composed of the components and the substances in the system. The substances in the system

are defined by their location with respect to the components and the behavioral properties they

have. The structure is represented as a hierarchy of these components, substances and their

relations. The relations are expressed with terms such as “part-of”, “includes”, and “parallelly

connected” (Goel and Bhatta, 2004). The behaviors in the SBF model are the concepts that are used

to explain the realization of the functions with the concrete structural elements in the device. They

can be considered as descriptions of what a component in the structure does. In this sense,

behaviors are intention independent. Behaviors are represented as sequences of transitions between

behavioral states. A function in the SBF model is an abstraction of behaviors, associated with an

input-output relation. The behavioral states that realize the function are considered to be the input of

the function. The behavioral states that are produced by the realization of the function are

considered to be the outputs. In this scheme the subjective category of function can be considered to

be a hypothetical link between structural behavioral states (Goel and Bhatta, 2004; Bhatta et al.,

1994).

2.4. No-function-in-structure Principle

Keuneke and Allemang (1989) discuss the validity and applicability of the “no-function-in-structure

principle” proposed by de Kleer and Brown (1981). They quote, “this principle states that the rules

for specifying the behavior of any constituent part of the overall system can in no way refer, even

implicitly, to how the overall system functions”. The principle is aimed to serve for developing

functional model of devices based on solely the functionalities of their components. De Kleer and

Brown (1984) aim to describe the behavior of a system based on the generic models of its

components that are potentially listed in a model library. Such an understanding is claimed to ease

the modular operation and replacement of any functional component with another one(de Kleer and

Brown, 1984).

In fact, de Kleer and Brown (1984) already mention about the potential difficulty of applying the

no-function-in-structure principle in an absolute manner, and talk about a “degree” at which it is

achieved. Moreover, they also propose the understanding of “class-wide assumptions” in order to

delineate the limits of the no-function-in-structure principle. De Kleer and Brown (1984) state that

assumptions for a general class of devices must be distinguished from assumptions for a particular

device or a particular use of the device. Based on this distinction it is possible to come up with

“class-wide assumptions” that are generic to that class. Making use of the idea of class-wide

assumptions de Kleer and Brown (1984) relax the original definition of the principle as folllows:

“The laws for the components of a device of a particular class may not make any other assumptions

about the behavior of the particular device that are not made about the class in general.” Though

admitting that the original version of the principle is unachievable, the authors claim that its

7

essential idea is preserved in this modified version with making use of class-wide assumptions.

Referring to the original version, Keuneke and Allemang (1989) argue that the “no-function-instructure principle” is “unrealistic” to be a universal principle for model representation. They argue,

the representation of a device model is more concerned with achieving a proper level of

representation depending on the task. Following such a universal principle does not ease the

representation task, and many times introduces unnecessary burden for modeling. Based on the

proper level and understanding for a particular task the degree of achieving the no-function-instructure principle changes. The “levels” mentioned by the authors can be considered as the

“abstraction levels” mentioned by Chandrasekaran and Josephson (2000), and “view” or “aspect”

mentioned by Umeda and Tomiyama (1995, Umeda et al., 1990) (Figure 4).

The level and type of understanding used in modeling is mostly determined by the assumptions

used for the descriptions of components in the model and the theory used to explain the relations

between the components (Keuneke and Allemang, 1989). The authors state that as the descriptions

obey more to the no-function-in-structure principle, the assumptions that should hold become

easier, i.e., simpler. This is stated to be the actual intend of the principle. The simpler the

assumptions are, the easier to make use of the same device for different tasks and to replace it with

another module.

However, Keuneke and Allemang (1989) further state that simpler assumptions are possible only

with a more and more powerful theory, which is able to function with primitive level information.

The authors give the example of a battery. If the assumption of ‘a battery is used in a closed

electrical circuit’ is made, it is easy to model it as a voltage source. However, if this assumption is

not made, instead the material decomposition of battery is considered, one has to deal at least with

chemistry and physics besides electrical principles in order to model the battery as an integral part

of an electrical circuit. It is true that the detailed material description provides making use of the

device for other purposes. Due to its weight a battery can be utilized as a paper holder. This

functionality can be derived by making use of the theory of physics and the weight descriptions of

the components. However, including such detailed description, makes the derivation of the

conventional function of the battery (voltage supply) computationally very complex. Based on these

arguments the authors conclude, functional modeling of devices is context dependent and nofunction-in-structure is not a realistic principle.

Keuneke and Allemang (1989) mention the idea of “guess”, belonging to Kuipers (1981), for the

implicit assumption of context for making use of a device. The idea of “guess” here is very close to

the idea of “mode of deployment” by Chandrasekaran and Josephson (2000) (Figure 3). The idea of

guess is that the user of a device can imagine the context it is intended for based on its general

usage. For example, for the battery case, the guess that it is intended for an electrical circuit

automatically brings about the description of a battery being a voltage supply. The guess of the

context for which the device is intended makes it possible to define “classes of devices” that

perform equivalent functions in the context. A battery is a device from the class of voltage supplies.

2.5. Functional Decomposition

Umeda and Tomiyama (1995) consider one of the basic tasks in design to be a hierarchical

decomposition of functions, which is followed by embodiment in order to arrive at substantial

components at the objective level. They argue that, hierarchical decomposition is possible only in

the subjective realm making use of function, rather than the behaviors or any other objective

category. In Umeda et. al (1990), the authors argue, there is no objective method nor algorithm for

functional decomposition. The process of functional decomposition includes both “top-down

decomposition” and “bottom-up recognition” of some functions from lower level sub-functions

(Figure 2). The functions are de-composed into sub-functions until they can be associated with

some physical features. Physical features are a set of descriptions of entities, relations among

8

entities, and physical phenomena.

Various approaches have been proposed for representation and decomposition of functional

knowledge. In the FBS modeler, knowledge of decomposition of functions is stored in a

knowledge base (Umeda et al., 1990, 1995, 1996, 2005; Umeda and Tomiyama, 1995, 1997).

Snooke and Price (1998) introduce a function label to relate system components and the behavior at

various hierarchical abstraction levels, and apply their scheme to design and diagnose electrical

devices (systems) in automotives. Similarly, Shemebuilder (Bracewell and Sharpe, 1996)

incorporates decomposition rules in Bond Graphs. Welch and Dixon (1994) develop behavioral

primitives for conceptual mechanical design and name those as “features”. The implementation

generates behavior graphs based on knowledge of available combinations of the primitives. Deng

(2002) defines construction rules for function decomposition mapping model. Those rules

syntactically support development of a function model. In ontological engineering (Kitamura and

Mizoguchi, 2005), the functionalities are defined in the basis of “is-a (function abstraction)”, “a part

of (function composition)” and “is achieved by (relation between function and structure or

behavior)” relations. Kitamura and Mizoguchi (2003) propose the “function way server” as a

knowledge based function decomposition system, which helps the designers to decompose the

function with showing various ways of its achievement.

Function primitives are set of fundamental functions whose compositions describe more complex

functions. While the work of function representation is to clarify the concept of function and offer

domain independent inference techniques (Chandrasekaran, 2005), development of function

primitives is concerned with description of functions in a specific domain (e.g., mechanical design).

Kennueke (1991) classifies functions under the four types of ToMake, ToMaintain, ToPrevent and

ToControl. These primitives are distinguished from one another in terms of simulation procedure,

function capability and expectations. In practice, however, most of the time relatively large set of

function primitives is necessary.

The Kritik system developed by Goel and his colleagues (Goel and Chandrasekaran, 1989, 1992;

Goel, 1991; Yaner and Goel, 2006) takes the specifications of desired functions as input and

produces the specifications of the structure that realize those functions as output. The specifications

of the output correspond to the symbolic representation of the configuration of the components and

the connections between them (Yaner and Goel, 2006). Kritik makes use of the SBF modeling of

the design object (Goel and Chandrasekaran, 1989, 1992; Goel, 1991). In this modeling the

functions and behaviors are represented at multiple levels of aggregation and abstraction in a

hierarchical way. The decompositions of functions and behaviors are performed at the same time in

relation to each other. With the representation of the authors, their model has the scheme of

FBFB…F(S). The higher level functions are associated with some behaviors that

realize them. Then those higher level behaviors are associated with some lower-level sub-functions,

which are again associated with lover level behaviors to be realized. This interdependent

decomposition goes on till the lowest level functions can be associated with concrete components of

the structure (Yaner and Goel, 2006). Goel and Bhatta (2004) consider the function in this schema

as an “index” to the internal causal behavior responsible for its realization. Then some of the

behaviors (state transitions) might be recognized (annotated) as sub-functions, which in turn index

the behaviors necessary to realize those. At the lowest level where the functions are associated with

concrete components, the behavior of the component does not need any further specification, hence

indexing, of its internal behaviors. Since the behaviors of the structure are decomposed into a

number of smaller behaviors, Goel and Bhatta (2004) state that large problem spaces are partitioned

into smaller spaces which are easier to handle.

Umeda and Tomiyama (1995) state that their approach in FBS shares the same view with that of

Keuneke (1991) in the sense the functional model does not always correspond to the physical

structure. This means that the physical structure, in fact, does more than what is needed to realize

the intended functions. The realizations (behaviors) which are not captured by some functions are

9

named as “unintended behaviors”. Redundant functions in the subjective realm can be considered as

recognition of some of the unintended behaviors in the objective realm (Figure 4). Umeda and

Tomiyama (1995) give the definition of a redundant function as follows: “A redundant function is

a function that can be realized by other physical features than the feature that realizes the function

in its normal state”. Moreover, their scheme seems to share also the idea of “no-function-instructure”. Their functional definition and decomposition process makes no reference to any

behavior or structure in the objective realm. The relation between functions and the objective realm

is maintained in the phase of functional embodiment after the functional decomposition. The

decomposition knowledge of past experiences is stored in the FBS model to be used in other

decomposition tasks (Umeda and Tomiyama, 1995).

Figure 2: Relations between “needs”, “functions”, and “design object”.

Figure 3: Environment-centric view of FM: From “surrounding of the object” towards “function”.

10

Figure 4: Device-centric view of FM: From “inside the object” towards “function”.

3. RELATION OF FM WITH DIFFERENT RESEACRH FIELDS

One of the aims of FM is to make use of computers for reasoning in the level of modeling with

functions. Reasoning with computer is most of the time implementation of AI techniques.

Therefore, the relation between the AI research and FM is important. The research of design is in

fact the major field from which the discussion of FM emerges. To make use of functions in the

conceptual design phase and to develop tools to support automatization of design are crucially

important. The development of products in order to respond better to the human needs is another

issue where FM plays a role. FM provides a frame in which the needs of human and the physical

behaviors of objects can be associated with, checked for, and modified to satisfy. Lastly, FM plays

an important role throughout the life cycle of products, especially in maintenance. Diagnosis, failure

detection, failure recognition, and generation of solutions might be performed effectively in the

realm of FM. Compared to structural and behavioral analysis used for the same purposes FM

analysis is expected to give results earlier in the phase of conceptual design. This section discusses

the relation of FM with AI, design theory and product development, and maintenance. In the

discussion of each subsection, the relations of some classical approaches with FM are reviewed, and

the directions of improvement by incorporating FM with these research fields are mentioned.

3.1. Artificial Intelligence and FM

Functional models of products/devices provide a high level representational framework in which

activities such as design, diagnosis, verification, and modification can be performed without

reference to the actual structure of the system. Not only the FM itself, but also the tasks performed

on the model, rely on human reasoning and recognition. Since AI techniques are aimed at modeling

and assisting intelligent human activity – at reasoning, planning, diagnosis, and qualitative

11

simulation– they can be utilized to automate the product development related activities with FM.

This section provides a discussion of application of AI techniques for FM.

Function reasoning (FR) is a research field that relates AI technology to FM (Chandrasekaran

1994a and Chandrasekaran 1994b). A FR scheme is composed of three elements (Far and Elamy,

2005). “Ontology” describes the domain and the entities. “Representation scheme” models the

entities and the relations between them. Lastly, “reasoning” infers and explains how the entities

function. A FR-based system can be used for planning and design purposes (verification, design),

conceptualization purposes (representation, clustering), or explanation purposes (fault diagnosis,

failure modes). FR adds functional concepts into model based reasoning (MBR) technologies

(Umeda and Tomiyama 1997): The task of MBR is to derive behavioral description from a physical

structure (i.e., a device model) using qualitative simulation, while the task of FR is to provide

meaning (function) to the physical structure by making use of the behavioral description.

Specific AI techniques such as heuristic search (search for relevant functions), exploration and

exploitation (designing higher level functions from sub-level ones and making use of the ones in the

knowledge bases), pattern matching (comparing functionalities of different structures), clustering

(composing classes of similar functions) should be considered for FR purposes. There exist multiple

correspondences between functional descriptions and behavioral descriptions, and between

behavioral descriptions and a physical structure. In other words function-behavior, behaviorstructure couples are many-to-many mappings. Based on the application, peculiarity of concerns,

and the model that is adopted, some of these couplings are desirable while the others are redundant.

With making use of FM combined with MBR, FR can formally express redundant, unpredicted and

unrealized functions, and point to the most application relevant choices of couples. FR can be

applied to diagnostic tasks with MBR. Once the actual behavior of the system is compared with the

simulated behavior, making use of MBR, the FR can reason about the faulty functions in the

system. For such applications pattern matching and clustering techniques might be used in order to

associate the observed symptoms with the probable underlying faults.

Far and Elamy (2005) provide a view of FR as an extension of MBR. They mention four domain

independent tasks to which FR can be applied: Identification determines the functions associated

with a given structure. Explanation gives answer to why a component is necessary to realize the

intended purpose. Selection is used to determine and combine the components to perform the

behavior necessary to realize the intended functions. Lastly, verification is performed to test the

functionality of the given structure under certain environmental constraints. The type of AI

techniques applicable to these tasks can be mentioned as follows: Direct matching (or mapping) of

functional knowledge to physical structure and physical phenomena (e.g., catalogue search in Parh

and Beitz, 1988), application of qualitative simulation of device and/or process models (de Kleer

and Brown, 1984; Forbus, 1984), and reasoning (verification and identification and) about the

relation between functional requirements and the physical phenomena (features) with qualitative

physics (FBS model of Umeda et al., 1990, 1995, 1996, 2005; Umeda and Tomiyama, 1995, 1997).

FM with FR is applied also to diagnosis of the design. For instance, FEMA (failure mode and effect

analysis) and FTA (fault tree analysis) include function knowledge (Kitamura et al. 2002; Kitamura

and Mizoguchi 2004). FR can reason out the faulty components in the physical structure in the

conceptual design phase. This can be achieved by performing a behavioral simulation and

considering possible symptoms of faults at a functional level. Umeda et al. (1995) develop a

function redundancy designer and apply it to support the design of a function redundant

photocopier.

Performance of functional modeling with AI based techniques depends on the modeling approach.

Modeling is effected by the representation of functions and their relations to the concepts employed

in the modeling scheme (behavior, structure, etc.). The definition of function in the model is

crucially important regarding applicability of AI techniques. The precision of the representation in

the functional model defines a limit on the applicability of AI techniques that make use of those

12

(Chandrasekaran 2005). For instance, limiting definition of function to a transformation between

input and output variables results in difficulty of representing a function that does not transfer

anything (Pahl and Beitz 1988). Similarly, the representation of functions based on extending the

Bond Graph technique such as in Schemebuilder (Bracewell and Sharpe 1996) cannot deal with a

function that transfers power flow. With such definition of functions the search space of the AI

techniques employed are restricted to a very narrow domain. Limiting the search space creates a

major difficulty for application of AI techniques.

The FM approaches that adopt direct mapping of functions to components compose another case

limiting the utilization of AI techniques. In such cases, composition/decomposition of functions is

solely managed by designers. Those methods conventionally describe the mappings in a matrix

form (Van Wie et al., 2005; Suh, 1990). The application of AI techniques in these cases is limited to

the search of matching functions to components, or to some matrix based operations of multiple

mappings. The difference between these direct mapping approaches and MBR based approaches is

as follows: The direct mapping approaches treat the compositional relation of functions and

structures as explicitly given information. MBR based approaches, on the other hand, reason out

implicit causal relations. Kritik is an analogy based design support tool using case-based and

model-based reasoning (Goel and Chandrasekaran, 1989, 1992; Goel, 1991; Bhatta et al., 1994;

Yaner and Goel, 2006). Given a function description in the form of “verb + noun + (adjective

and/or adverb)”, the tool identifies a similar function from the catalogue of the existing cases. When

the realization (structure or physical phenomena) of the retrieved function are not fully met with the

functional requirements, the tool provides modification plans. The tool IDEA-INSPIRE helps the

designer browse behavioral descriptions in the animal and plant domain that entirely or partially

match the required artifacts (Chakrabarti 2005).

Application of AI techniques with FM is important also considering product life cycle. For instance,

upgradability is an important emergent concept currently inherited to the design paradigms for

developing environmental-friendly products. Using the concept, partial functions of the products are

upgraded or downgraded in either parametric or structural level. In this way the functionally

different products, developed on the same original structure, share common modules or components

over generations in time. In order for a FM scheme to support the design of upgradable products,

the function representation should deal with multiple function models. Umeda et al. (2005) develop

a design methodology of upgradable products using FBS modeling. Association of different

functions from point of view of upgradability, and building a structure that allows modular

integration/disintegration and functional differentiation in time necessitate prediction and optimal

design facilities during product development.

3.2. Design Theory, Product Development and FM

What FM provides for the design process is basically a model based on the functionalities and subfunctionalities within the system. Making use of such a model in the early phases is significant for

managing the increasing complexity of the design processes. This is acknowledged by America and

Wijgerden (2000) who make use of extensive requirements modeling in a real industrial

application. Bonnema and Van Houten (2006) investigate the use of models in conceptual design.

They observe that models are used by designers to handle large amounts of data, for communication

purposes and for analyzing of the problems. Yoshioka et al. (2004) demonstrate that functional

models provide a structure for the design process and ease the handling of large amounts of data. In

the following first a discussion of two classical design methodologies which are in relation to FM

will be given. Then two design methodologies which are explicitly FM oriented will be reviewed.

3.2.1. Sytematic Design of Pahl & Beitz and Axiomatic Design of Suh

The systematic design approach developed by Pahl and Beitz (1988) divides the design process in

13

four phases. First, a product planning and clarification of the task is performed. In this phase

methods like market analysis, brainstorming, literature search, examination of existing solutions

and preparation of requirements lists are performed. If an analogy with the FM framework

developed in the second section is to be established, these activities can be regarded to take place in

the subjective realm. Second, conceptual design is performed. The most important steps in this

phase are abstraction and systematic-logical thinking in order to identify the essential problems, setup function structures, set-up classification schemes and search for working principles. In the

conceptual design phase the step from the subjective realm to the objective realm is made. With the

terms of FM, the whole process starts from the needs, passes to the functions as effect, to the devicecentric functions and then finally translates all those into behaviors. The third phase is the

embodiment of design. Based on the requirements, functional structure, solution concepts, and

preliminary layouts of main function carriers are developed iteratively. After selection and

evaluation of the layout of the main function carriers the layout for the auxiliary function carriers

are developed and evaluated. This phase is finalized by creating a preliminary parts list and possibly

production documents. Considering the FM framework this phase corresponds to the transition from

behaviors to the design object. The last phase is the detailed design. Detailed analysis on a

component level and preparation of mechanical component drawings characterize this phase. This

activity is not represented in the general FM framework presented.

Pahl and Beitz (1988) define function as the general input/output relationship of a system whose

purpose is to perform a task. It represents a flow, possibly, of energy, materials or signals.

Functions are decomposed into sub-functions and usually have the “noun” and “verb” form. The

decomposition is presented as a block diagram of (sub)functions and is referred to as the functionstructure. The functions in the structure are related to each other with the logical operators of AND,

OR and NOT.

As many FM techniques (Chandrasekaran and Josephson, 2000; Suh 1990; Umeda and Tomiyama,

1995) Pahl and Beitz (1988) decompose function into lower levels of sub-functions. This process

guides the designer in creating a hierarchical functional structure. The resulting function-structure

assists the designer in keeping overview of the system. Function representation of Pahl and Beitz

(1988) is used for structuring and presenting the design problem. The FBS method (Umeda et al.,

1990, 1995, 1996, 2005; Umeda and Tomiyama, 1995, 1997) also subscribes to this and supports

the designer in a similar way. Pahl and Beitz (1988) do not use the function representation for

automated reasoning purposes. Many of the FM developers propose to do so (Chandrasakaran,

2005; Chandrasakaran and Josephson 2000; Yoshioka et al., 2004; Kitamura and Mizoguchi, 2004;

Umeda et al., 1990, 1996; Umeda and Tomiyam, 1995, 1997) and among those Umeda and

Tomiyama implement an automated reasoning system with FM by making use of QPT (Qualitative

Process Theory, Forbus, 1984). The systematic design of Pahl and Beitz (1988) does not provide a

CAD tool to support design.

The Axiomatic Design (AD) developed by Suh (1990), aims quick and systematic development of

complex systems. It proposes a method to structure and organize the design process. AD starts with

considering high level functional requirements (FR). The goal is to satisfy the FRs independent of

one another. First the high level FRs are embodied by high level design parameters (DPs). The high

level FRs are decomposed into lower level FRs, which should be satisfied by DPs. This zig-zag

process continues until the FRs can no longer be decomposed. Within this method, design is

considered to be the mapping process between the FRs in the functional domain and the DPs in the

physical domain. The result of this process is a functional decomposition of the design and a

decomposed physical embodiment.

The main ideas behind the axiomatic design are summarized by Suh (1990) with two axioms. The

first axiom, named “the Independent axiom”, forces to maintain the independence of FRs. During

the design process, the designer goes from the FRs in the functional domain to DP’s in the physical

domain. The mapping between these two must be such that a perturbation in a particular DP should

14

not affect any other FR than its referent. Within a matrix representation of FRs and DPs, such an

“uncoupled design” corresponds to a diagonal matrix, while a “coupled design” to a triangular

matrix. The second axiom, named “the information axiom”, enforces to minimize the information

content. It states, among all the designs satisfying the first axiom, the one with minimum

information content is the best. In other words, the best design is a functionally uncoupled design

that has the minimum information content. However, considering many complex systems, it is not

always possible to decouple the FRs. Suh (1990) states that decoupled FRs are desirable, but there

are no developed means or tools to achieve this. This issue remains as a research topic where FM

can effectively be used. In contrast to other FM techniques (Umeda and Tomiyama, 1995;

Chandrasekaran and Josephson, 2000) AD does not make a separation of objective and subjective

realm in design.

3.2.2. FBSg of Gero and FBS Model of Umeda and Tomiyama

The FBS (Function-Behavior-State) model of Umeda and Tomiyama (Umeda et al., 1990, 1995,

1996, 2005; Umeda and Tomiyama, 1995, 1997; Cagan et al., 2005; Yoshioka et al., 2001) and the

dynamic design proposed by Gero (1990) present design processes which are more FM oriented.

Gero (1990) defines the design activity “as a goal-oriented, constrained, decision-making,

exploration, and learning activity that operates within a context that depends on the designer’s

perception of the context.” He points to two research issues for design: “representation

frameworks”, and “transformation processes”. He develops a representational frame with using the

concepts of function, behavior and structure, and then explains the steps of transformations between

these. The design procedure, which is a gathering of these steps, is at the end an iterated comparison

of the structural behaviors and expected behaviors (associated with the intended functions) and

updating the structure in order to match these two. The following steps are delineated as activities in

design: formulation, synthesis, analysis, evaluation, reformulation, and production of design

description. Gero and Kannengiesser (2004) consider design as a dynamic process in which the

view of the designer changes in time depending on the outcome. The change of the external world

and the internal world of the designer determine the dynamic “situatedness” throughout the process.

While Gero and his colleagues describe their design methodology within the framework of their

FBSg model, they do not propose a formalized systematic to decompose the functions or to

associate the functions with behaviors and structure. While their FBSg scheme is useful to

demonstrate the conceptual relation between function, behavior, and structure, the FBS model of

Umeda and Tomiyama (Umeda et al., 1990, 1995, 1996, 2005; Umeda and Tomiyama, 1995, 1997)

provides a systematic of decomposition and embodiment of functional design.

The design methodology of FBS (Umeda et al., 1990, 1995, 1996, 2005; Umeda and Tomiyama,

1995, 1997; Cagan et al., 2005; Yoshioka et al., 2001) is based on decomposing high level functions

into lower level sub-functions till they can be associated with some components (Figure 2). Design

is the composition of the components that are reached in the leaf levels of functional

decomposition. In their discussion the authors propose the understanding of “innovative design” (a

term also used by Gero, 19902; Bhatta et al. 1994) against the conventional understanding of

“conceptual design methodology”. The conventional conceptual design methodology is based on

configuration design and makes use of a catalogue in which functions are associated with some

elements/components. Innovative design, on the other hand, does not only make use of such a

catalogue, but also aims to propose new functionalities by new compositions of components and

new usages of components in response to the dynamically arising needs during the design. In other

words the innovative design does not follow only the “top-down design” path, from function to

structure, but also the “bottom-up design” path, from structure to function (Figure 4). In this way

The term “innovative design” is used by Gero (1990) as a matter of design variables and their values. In this paper it is

considered as a matter of direction between the upper and lower levels corresponding to functional and structural

specifications, respectively. Gero (1990) follows the general classification of design as routine, innovative and creative.

In routine design, both the variables and the ranges of their values are fixed. In innovative design the variables are fixed,

but their range of values can be changed. In creative design both the variables and their range of values can be change.

2

15

the innovative design is performed in an interactive way between the designer and the structure

designed. Throughout this interaction the intermediate level functions between the global intentions

and structure evolve with the structure itself. In Shimomura et al. (1998), the authors explicitly

mention “discovery of functions” as a functional operation of a functional evolution process. The

idea of top-down-bottom-up design aims to achieve theory and phenomena at the same time

throughout the design process. Accordingly, Kitamura and Mizoguchi (2004) mention that function

decomposition should not be performed only in the functional domain but by going back and forth

between functional, behavioral, and structural domains.

In the FBS model, the decomposition process comes to an end when the function-behavior relations

can be related with some physical features. This means that the physical features to realize the

functions are reached by decomposition. A physical feature consists of physical phenomena,

entities, and relations among entities required to activate the phenomena. The FBS model assumes

knowledge bases for function prototypes, physical features, and physical phenomena. The designer

specifies required functions from the function prototypes knowledge base. Aided by the

decomposition knowledge of function prototypes, the designer decomposes the required functions

into sub-functions. Lastly, the designer chooses physical features that can embody each subfunction. After instantiating physical features, the designer might discover that some features cannot

be realized. The FBS modeler is equipped by QPT based reasoning tools which verify the design by

identifying unrealizable physical phenomena, side-effects and unrealizable-functions. Corporation

of qualitative physics with FM and realization of this as a concrete design support software is a

peculiar feature of the FBS modeling compared to the other FM research activities.

3.3. Maintenance and FM

AI techniques such as expert systems and MBR are commonly used for fault diagnostic systems.

Expert systems make use of the subjective information of human. However, it is not always easy to

find the expertise and to translate it into computer language. Moreover, expert systems are not

easily adaptable to changes in the design due to the descriptive nature of their knowledge. A model

based diagnostic system uses a model of the system (product, service, software, etc.) to reason

about its behavior. It simulates the model, finds out what the system is supposed to do, and

compares this with what the actual system does in reality. The use of a model makes model based

diagnostic system more robust in comparison to the ones making use of expert systems.

The most common methods dealing with maintenance are driven by failure analysis. These

include expert systems and model based diagnostic system as explained above, also reliability

centered maintenance (RCM), failure mode and effect analysis (FMEA), failure mode and effect

and criticality analysis (FMECA), functional failure analysis (FFA), fault tree analysis (FTA), and

total productive maintenance (TPM). Usually the common aim of these methods is to reduce the

cost, either by increasing the reliability of the system and/or by improving and optimizing

maintenance strategies. There is extensive literature on these methods. Definitions and some

applications of these methods can be found in Rausand (1998), Labib (2006) and Klein and Lalli

(1989). Description and categorization of functions are used in methods such as FFA. Techniques

such as FTA or functional block diagrams can be used to track causes and consequences of faults in

a system. These techniques are often used in RCM and model based diagnostic systems.

Umeda and Tomiyama (1995) state, a component of a system might perform some functions that

can be used in other ways than intended by the designer. For instance, in a failure situation,

another component, rather than the failed one, can perform the function, perhaps in a less efficient

way. Umeda and Tomiyama (1995) name such a situation as functional redundancy. Conventional

redundancy methods aim to increase reliability by adding redundant components to the system.

These differ from the functional redundancy proposed by Umeda and Tomiyama (1995). In the

latter, redundancy does not refer to a physical component but to the capability of performing a

function. Redundant functions are intended to be found among the components of the system,

16

without addition of new parts.

Functional modeling and qualitative physics are potential tools to develop a framework in which

functional redundancies can be systematically generated. A fault diagnostic system based on

functional modeling can make use of the functional redundancies in order to find out repair methods

to deal with the encountered faults. Section 4.4 discusses the use of functional redundancy and

model based diagnostic systems to increase reliability, availability, maintainability, and safety of

complex systems.

4. APPLICATIONS OF FM IN ONGOING RESEARCH

In this section an introduction of ongoing research in the Intelligent Mechanical Systems Group is

given. These researches are all inspired from and make use of the ideas developed within the FM

framework. The basic concepts of the projects, such as “evolvability”, “unpredictable inferences”,

“intelligent maintenance”, and “service modeling”, are explained with making use of the FM

paradigm. This section is intended both to explain the ongoing research activity and to point to

future work in relation to FM.

4.1. Evolvability

A system is called to be evolvable if its complexity does not increase in unmanageable amounts

when new functionalities are introduced into the existing system architecture. To achieve

evolvability, the new or modified behaviours introduced to the system should minimally disturb the

functions inherited from the previous architecture.

It is usual that, although the fundamental principles are the same, there occurs considerable

difference between the functional description of contemporary systems and those of their first

releases in the past. With the ever growing functional change, complexity of the systems tends to

increase, sometimes to unmanageable degrees. It is not trivial how to deal with increasing

complexity due to system modifications in time. In order to have a good control on complexity it is

necessary to have a good system overview. However, the large amount of data and large teams of

design engineers from diverse disciplines make it difficult to construct this overview.

Lacking of an overall system view prevents the engineers of having a clear view of the relation of

their own sub-system to the overall. An overall system overview is important to understand the

relation between the sub-systems and to judge the information stream in the process. Overlooking

the relations between diverse disciplines often results in unexpected problems in the design.

Regarding the interaction of different disciplines, and referring to Figure 1, one can argue that not

only the vertical traceability, but also the horizontal traceability is important. A horizontal

traceability is in direct relation with managing the dependencies between the separated disciplines.

An overall system description based on FM is useful for the concern of evolvability, because it

makes easier to understand and model the interaction between the different parts of the system

which are in the field of diverse disciplines. Evolution of a system corresponds to equipping it with

new functionalities by introducing new behaviors. Introducing new behaviors at the end

corresponds to adding new components to the system architecture. Any modification in the

architecture results in an effect on the existing parts of the system. In fact, these undesired

ineractions are the source of the increase in complexity of the system. Therefore the questions,

“how the different parts will be effected”, “how these effects can be minimized”, and “how to

organize the design, at the very beginning, in order to minimize the number of interactions” are

crucial from evolvability point of view. The described overall system view based on the FM

constructs a frame within which such questions can be answered. The last question is in relation to

“detection of unpredictable interference problems” described in the next section.

17

4.2. Detection of Unpredictable Interference Problems

This section introduces the ideas to develop a method to deal with unpredictable problems as the

consequences of destructive couplings of engineering domains. The hypothetical system that is

supposed to detect the unpredictable interference problems is called a Design Interferences Detector

(DID). DID, enables to envision the destructive couplings in advance, in the early phases of

conceptual design. Destructive couplings are undesired and unpredictable interactions that result in

undesired and unpredictable behaviors. A model-based reasoning and an extension of FBS model

(Umeda and Tomiyama 1995) constitute the foundations of the methodology for the DID.

There are already some techniques intended to deal with complexities. The approach based on

design structure matrix (Browing, 2001) and the methodology of axiomatic design (Suh, 1990) can

be cited in this regard. Suh (1990), in his axiomatic design, suggests a method for the elimination

of the “spaghetti” code by identification of a logical structure. His aforementioned independence

axiom aims to maintain the independence of functional requirements. These two methods are based

on the analysis of well formulated interactions of which the designer is already aware. They are not

aimed at dealing with unpredictable interactions among subsystems, within the design paradigm.

The DID method, on the other hand, aims at developing an automated analysis tool which finds out

unpredictable interactions that are not trivially recognized within the design paradigm.

The DID method is supposed to be composed of a conceptual design model described by the

engineer describes, a reasoning mechanism to detect all possible behaviors, and a filter to

distinguish unpredictable problems (Figure 5). The designer describes conceptual description of the

system with the behaviors that are required to happen. The DID reasons out all possible physical

behaviors (structural behaviors) that can occur by making use of qualitative process theory

(Kuipers, 1994). These generated behaviors include both expected and unexpected behaviors

(Figure 4). The unexpected behaviors are filtered out by separating expected behaviors from all

possible behaviors. Unexpected behaviors are the source of unexpected functions realized by the

system and recognized by the user. Once the unexpected behaviors are filtered out the designer can

reason about the future potential problems.

QPT

QRS

Predictable

problems

Model

Possible

Behaviors

Filtering

Unpredictable

problems

Figure 5: The DID process.

The DID model introduced here is an extension of the FBS model (Umeda et al., 1990, 1995, 1996,

2005; Umeda and Tomiyama, 1995, 1997; Kiriyama et al., 1992). The FBS model provides a frame

for both a methodology to structure knowledge and a qualitative reasoning system that performs

verification and identification of functional requirements. In FBS, the relation between a behavior

and state is based on the physical principles applicable to the system. A behavior is a sequence of

state transitions which are the result of some physical phenomena applying to the entity.

Once all entities and relations among them are defined in the FBS framework, the QRS reasons out

physical behaviors based on qualitative process theory. The original FBS, which is without the QRS

18

module proposed here, does not deal with physical phenomena explicitly; therefore, it cannot reason

out unpredicted functions. A behavior can lead to new states which in turn initiate new behaviors.

The mutual dependency between behaviors and states (hence structure) are governed by physical

phenomena, but they cannot be directly reasoned out without an explicit QRS making use of

fundamental physical principles.

FBS Modeling

Function

Behavior

FBPhPhS

Modeling

State

Structure

Physical

Phenomenon

QRS

Figure 6: The FBPhPhS general model description

DID is an extension of FBS, obtained by incorporation of the QRS module. Figure 6 illustrates the

general model proposed for DID, named as FBPhPhS (Function-Behavior-Physical PhenomenonState model). FBPhPhS integrates FBS and QRS by explicitly including the physical phenomena

between behaviors and states. The concept of attributes of relations is included in FBPhPhS model

in order to prioritize the behaviors. A relation with the attribute of “connected” signifies the

distance of the connection between entities. If two entities are not physically connected, the original

FBS does not consider that there might be a coupling between the two. Such a situation might

happen when physical phenomena affect each other from a distance like in the case of

electromagnetic field and heat transfer. Any entity defined in FBPhPhS must have relations with

other entities designated by the attributes. The difference of FBPhPhS with the original FBS is

illustrated in Figure 7. In the first figure the physical phenomenon acts on the two directly

connected entities. In the second figure the physical phenomenon acts on two disconnected entities

and results in their state transition. However, it should be noted here that the described scheme also

results that the QRS reasons out a huge number of unfeasible (superfluous) behaviors.

Figure 7: Difference between FBS and FBPhPhS given by attributes of relations.

19

4.3. Reliability, Availability, Maintainability, and Safety (RAMS)

The objective of this section is to introduce the ideas to develop a design methodology in order to

increase the availability of complex systems which are hard to be reached, such as offshore wind

farms. By means of an intelligent maintenance system it might be possible to respond to faults by

reconfiguration of the system. This would significantly decrease the number of necessary service

visits. The basic idea to achieve this is to make use of the existing functional redundancies within

the system.

FAULT DIAGNOSIS

Condition

Monitoring

Model Based

Reasoner

QUALITATIVE

SIMULATOR

Repair Strategy

Control Type

Reconfiguration

Functional Redundancy

Designer

Extreme Condition

Operational mode

FBS MODELER

Figure 8: Intelligent Maintenance Methodology

The intelligent maintenance methodology (Figure 7) involves two main modules: one applied at the

design stage and the other at the operational stage. At the design stage, the FBS model feeds the

functional redundancy designer (FRD) (Umeda and Tomiyama, 1995), which is responsible for

systematically providing the information on potential existing redundancies of the system. This is

intended to support the component selection. At the operational stage, there is a fault diagnosis

system composed of a qualitative physics simulator and the FRD. A qualitative physics simulator

consists of a reasoning engine based on qualitative physics. At the operation stage two types of

repair methods can be followed: control type and re-configuration (functional redundancy type)

(Umeda and Tomiyama, 1995). Control type repair methods correspond to strategies that can be

applied by a controller in a way of instant response (Shimomura et al., 1995). Re-configuration

corresponds to the repair method by compensating the functionality of the failed component with