223981.IARIGAI-Muck

advertisement

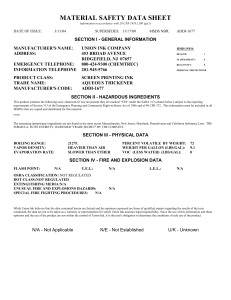

Non-destructive methods in the study of IJ ink – substrate interaction Muck, Lozo, Otahalova, Drzkova, Kaplanova Introduction The quality of ink-jet prints depends to a large degree on the interaction between printing substrate and Ink-Jet ink. The penetration of printing ink should be low in order to retain high optical colour density (1, 2). The surface of the paper also plays an important role: the absorption capacity for printing inks should be controlled. It should not dust and should have a suitable level of smoothness as well as other properties necessary for good operability and printability (3, 4). The scope of the study was to find non-destructive methods that can give a rapid and accurate insight into the Ink-Jet ink penetration in z-direction of the substrate. The aim of the study was to investigate the radial and vertical distribution of Ink-Jet printing ink, both on and beneath the paper surface, on different types of papers, as well as to determine the impact of the paper surface on print quality. Materials and methods The following analytical techniques were used in the study: Penetration - Dynamics Analyser (PDA) is an analytical instrument designed for the investigation of penetration dynamics of liquids into solid samples, such as papers. The analytical technique employed is based on recording the change of intensity of ultrasonic signals transmitted by solid samples while one of their sides is in contact with a liquid (sample is immersed into the water bath). Slit - Scanning Densitometer is used in qualitative and quantitative evaluation of thin layer chromatograms. It was used for investigation of both radial and vertical distribution of different spots of printing ink by measurements in reflection mode (for the wavelengths of 580 nm). We used Ink Jet printer Canon BJC 8500, printing resolution 600 dpi and the colour intensity 100%. Confocal Laser Scanning Microscopy (CLSM) represents a non-conventional method for non-destructive study of interaction of Ink-Jet inks and printing substrate. It was used in the investigation of tree-dimensional paper structure, the determination of pore volume (5, 6) and the evaluation of ink penetration in z-direction (7). The spots of printing ink were observed and measured with the Confocal laser scanning microscope. The scan area was 460 µm × 460 µm, air objective with numerical aperture 0.6, laser beam wavelength 458 nm and resolution in z-direction 2.7 µm. The sample preparation, i.e. cutting the samples in z-direction was done virtually, by computer software. The vertical distribution was made by observing the border of the ink spot with CLSM and subsequently by using software for cutting the slices in z-direction. This software calculated the number of slices necessary to pass from the most fluorescent to the non-visible part of the dot. Photoacoustics and photoacoustic spectroscopy are non-destructive methods for the study of optical and thermal properties of a printed area at different depths beneath the sample surface. This implies the examination of ink penetration into the paper structure. The physical principles of indirect photoacoustic effect and its possible applications in the field of graphic arts are already well established (8, 9, 10, 11). Cross section analysis of prints was made by microtome (slice thickness 30 µm). The slices were then examined by Optical Microscopy (OM). This is a destructive method which enables a detailed access to the undersurface migration of printing ink through the inside layers of the printing substrate. At this point of the study we assessed the relevance of information obtained by different, nondestructive and destructive measurement techniques. Each of these methods, and their limitations, are important in the study of ink – paper interactions, as well as in the impact of substrate on print quality. Therefore, several completely different types of paper were used as printing substrate: Z – Zweckform Photo Paper, recommended for Ink-Jet prints, one-side coated, high glossy, (130 g/m2, 170 μm), K – Carton board, one-side coated multilayered white board, (300 g/m2, 430 μm), I – ICP Permanent Paper made at the Pulp & Paper Institute in Ljubljana, which corresponds to standard ISO 9706, no surface treatment, (70 g/m2, 110 μm), T – Three-ply tissue paper with a low percentage of secondary fibres, (60 g/m2, 185 μm). Papers with wide range of quality characteristics were used to define the limits of each measuring method. Up till now the T sample (tissue paper) could not be measured by Photoacoustics (it splits during the sample preparation); the K sample (carton board) could not be cut by microtome (unsuitable caliper) and therefore Optical microscopy could not be done either; all analysed samples caused various difficulties in Cross section analysis (as the magenta dye ink is water soluble, the microcopy evaluation of the prints should be done in as short a time as possible from the sample preparation). Comment Results obtained in this large study enable us to draw two goups of conclusions. The results of non-destructive methods (Slitt Scanning Densitometer , CLSM, Photoacoustic spectroscopy) correlate among themselves in the analysis of ink penetration in z-direction. The most significant finding of all is that the data obtained by these measurements overlap with those obtained by the destructive method (Cross section analysis by microtome and Optical microscopy). Analysed cross sections of Ink-Jet prints are taken to represent objective truth in the matter of ink penetration. Therefore, correlation of results of non-destructive methods with these data proves their usability and reliability. In this view we can conclude that the study fulfilled its purpose. We believe that nondestructive methods provide trustworthy, quick and exact methods of print analysis. Key words: Ink jet, penetration, Photoacoustics, CLSM References 1 D. Glittenberg, A. Voigt, D. Donigian. Novel pigment starch combination for the online and offline coating of high quality inkjet papers, Sept. 2003, Pap. Technol, vol. 44, no. 7, pp 3642 2 Muck, T., Hladnik, A. Evaluation of radial and vertical distribution of ink jet inks in paper. Professional papermaking, October 2004, vol. 2, no. 2, pp. 62-64, 66-68 3 M. B. Lyne, J. S. Aspier. Paper for Ink-Jet printing, Tappi Journal, May 1985, p.106-110 4 G. Baudin, E.Rousett. Ink jet printing: effect of paper properties on print quality. NIP17: international conference on digital printing technologies, Fort Lauderdale, FL, USA, 30 Sept.-5 Oct. 2001, pp 120-124 [Springfield, VA, USA: Society for Imaging Science and Technology, 2001, 910 p. 5 A. Goel, E.S. Tzanakakis, S. Huang, S. Ramaswamy, W-S. Hu, D. Choi, B.V. Ramarao. Confocal laser scanning microscopy to visualize and characterize the structure of paper. Fundamentals and numerical modeling of unit operations in the forest products industries. 1999 AIChE forest products symposium, edited by Brogdon B N, Severtson S J, Walker C C, pp 75-79 [AICHE Symposium Series vol. 96, no. 324, New York, NY, USA: American Institute of Chemical Engineers, 2000, 105 p. 6 P.G. Auran, A. Bjorkoy. Measuring the pore volume distribution of papers by CLMS for printability. Microscopy as a tool in pulp and paper research and development, Proceedings, Stockholm, Sweden, 21-22 June 1999, p. 220 [Stockholm, Sweden: STFI Swedish Pulp and Paper Research Institute, 1999, 228 p. 7 V. Hoang, H.L. Huy, S. Wei, L.H. Parker. The interactions of ink-jet inks and uncoated papers. 55th Appita annual conference, Hobart, Australia, 30 Apr.-2 May 2001, pp 285-292 [Carlton, Australia: Appita Inc, 2001, 550 p. 8 M. Kaplanova, J. Cerný. Photoacoustic Study of the Ink and Paper Interactions. Advances in Printing Science and Technology, V23, ed. J. A. Bristow, John Wiley and Sons Ltd, p. 301 (1997). 9 M. Drzková, L. Otahalova and M. Kaplanova. Photoacoustic Study of Printed Samples. The First European Conference on Color in Graphics, Imaging and Vision (CGIV), Aachen, April 2004, p. 307. 10 M. Kaplanova, G. Katuscakova. Photoacustic Study of the Thermal Effusivity of Cellulose and Paper.Photoacoustic and photothermal phenomena III, Berlin: Springer, 1992, p.180. Springer series in Optical Science, vol. 69. 11 M. Kaplanova, J. Cerny, Photoacoustic and Photocalorimetric Study of UV Curable Inks and Varnishes, Advances in Printing Science and Technology, V22, ed. J. A. Bristow, John Wiley and Sons Ltd, 1994, p. 107. Authors: PhD Tadeja Muck, University of Ljubljana, Faculty of Natural Sciences and Engineering, Chair of Information and Graphic Technology, Snežniška ul. 5, SI-1000, Ljubljana, Slovenia tel.: +386 1 2003284, fax.: +386 1 4253175 MSc Branka Lozo, University of Zagreb, Faculty of Graphic Arts, Getaldićeva 2, 10 000 Zagreb, Hrvatska tel.: +385 1 2371080, fax.: +385 1 2371 077 Ing. Lenka Otáhalová, Ing. Markéta Držková, Prof. RNDr. Marie Kaplanová CSc. Universtity of Pardubice, Faculty of Chemical Technology, Department of Graphic Arts and Photophysics, Studentská 95, 532 10 Pardubice, Czech Republic tel.: 466 038 031, fax: 466 038 031