PPE - Northumbria University

advertisement

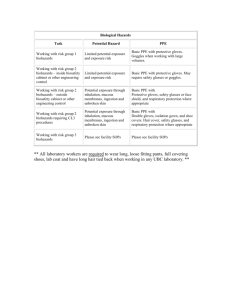

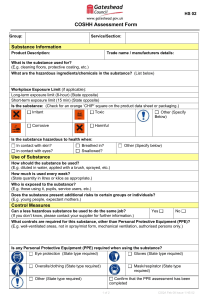

Health & Safety Office Hazard Guides: No 2 Personal Protective Equipment (PPE) What is PPE? PPE is ‘all equipment (including clothing affording protection against the weather) which is intended: ‘to be worn or held by a person at work and which protects him against one or more risks to his health or safety’, eg. safety helmets, gloves, masks, eye protection, high-visibility clothing, safety footwear and safety harnesses. Waterproof, weatherproof or insulated clothing is subject to the Regulations only if its use is necessary to protect employees against adverse climatic conditions that could otherwise adversely affect their health or safety. PPE – the last resort Whatever the risk that protective equipment is intended to protect the employee against, the general rule is that it is a measure of last resort. This means that the manager should seek and prefer methods of working that eliminate the risk of harm, or safety and health control measures that minimize that harm, for everyone, and not rely just on PPE that only protects the individual that wears it, while they are wearing it, and then only if it has been correctly selected and maintained for its task. Because the effectiveness of PPE can be easily compromised, eg by not being worn properly, it should always be considered as the last resort and used only where other precautions cannot adequately reduce the risk of injury. PPE – limitations PPE has a number of inherent limitations. If you decide to use PPE and don’t bear these in mind when selecting it, you are likely to find that in practice it fails to protect the wearer. Consider that: 106747209 PPE only protects the person wearing it, and not anyone else in the workplace; Masks and gloves are often uncomfortable to wear for a long time, especially if the workplace is hot, if the gloves make it difficult to handle equipment, or if the mask restricts vision or makes breathing more of an effort. These can tempt people not to wear PPE when they are otherwise exposed to harm; Negative pressure type masks (that are not air-fed and rely on the wearer to draw breath through the mask filter) that do not fit the shape of a person’s face well will not establish a good seal and so allow contaminated air to leak in through any gaps, increasing exposure; You can expect gloves and masks that are used beyond their service life will offer less of a barrier to the contaminant – for instance, mask filters can allow higher concentrations to reach the wearer at the end of their service life as the filter becomes saturated with the contaminant. To avoid this, they need to be changed when their usage reaches the manufacturer’s recommended service hours; Masks and gloves that are not kept clean by the wearer can become contaminated; Masks that are not inspected and maintained can fail. The exhaust valve in a mask can fail, allowing contaminated air to be drawn in without passing through the filter; PPE rarely eliminates exposure, but is intended to reduce it further, after other measures have dealt with the bulk of the exposure. For example, under HSE’s 1 guidance EH40/2005, Toluene now has a long-term Workplace Exposure Limit (WEL) concentration in air of 50ppm (parts per million). A mask with a filter that has a protection factor (APF) of 10 will reduce a toluene contaminated atmosphere of 200ppm down to 20ppm, well below the WEL. However, the same filter operating in an atmosphere contaminated to 750ppm will reduce that by the same factor (10) to 75ppm, now well above the WEL for this substance. For gloves and masks particularly, if the filter medium or glove material is not carefully matched to the contaminant, it will not prevent it reaching the person and exposure occurring. For example, while Marigold’s lightweight natural rubber latex glove is well suited to work with sulphuric acid, it is not recommended for use with petrol or diesel fuel. Who pays? For PPE that is used only at work, the employer must pay – the employee cannot be charged. Getting effective protection from PPE It is common to find people wearing PPE that will not give them the protection they expect. This can be simply because it is poorly fitted to the wearer, or has not been maintained so that it does the job it was chosen for. Very often, it is the wrong type of PPE to give protection because it was poorly selected for the workplace hazard under consideration. Poor selection is due to a failure to ask some important questions about what kind of protection is needed, the conditions under which the wearer will have to work while wearing the PPE, and how well it fits the wearer. For example: It is pointless wearing a mask fitted with a dust filter when spraying paints containing toluene or Xylene vapour (or other organic solvents), as the filter will not stop the vapour getting into the mask where the wearer will breathe it in; Similarly, natural rubber gloves will not prevent petrol, for instance, from penetrating in seconds or minutes; How do I select the right type of PPE for the job and its risks? Choosing the right PPE is critical. You must match the gloves, mask, or glasses to the kind of harm you are protecting the wearer against. In short, the poorer the match, the less the protection. So where do you start? – a general approach to selection 1. Risk assessment Where PPE is required it should be identified in a risk assessment and the basic principles of risk assessment should already be familiar. The use of PPE must be considered as a last resort for the control of risks, to be used only after all other practicable measures have been taken. Remember that PPE only protects its wearer and no one else in the workplace; and that PPE gives maximum protection only if correctly selected, fitted, used and maintained. For high-risk situations, or complex PPE, the assessment should be in writing and should be reviewed if the work situation changes significantly. Some or all of the following may need to be taken into account: (i) the risks in the workplace; 106747209 2 (ii) the parts of the body which may be affected; (iii) the nature of the task; (iv) the degree of physical effort involved; (v) methods of work; (vi) how long PPE must be worn; (vii) any special requirements, e.g. ease of use with prescription spectacles, or with other PPE. 2. Selection of suitable PPE Departments must choose PPE that gives: (i) adequate control of any risks identified, without in itself adding to the risk (e.g. the use of powdered latex gloves may present a risk to the wearer or to others in the vicinity); (ii) compatibility with other items of PPE (e.g. ear defenders worn with a safety helmet must still provide the necessary degree of attenuation); (iii) minimum discomfort to the wearer. It is usually necessary to have more than one type or size of PPE available, so as to maximise the chances of obtaining good fit and comfort. Uncomfortable or unsuitable PPE is unlikely to be worn and involvement of the user in the selection or specification is often useful in ensuring the best results. 3. Standard of PPE provided All PPE selected must conform to an appropriate British (BS) or European (EN) Standard and some of the current standards are listed in the appendix. Separate legislation governs the manufacturers and suppliers of PPE and only that conforming to relevant standards may be marketed. It must be "CE" marked and comprehensive user information must be provided. The purchase of PPE from a reputable supplier should ensure that suitably certified equipment is being provided (though the onus is on the purchaser to check that the equipment is suitable for its intended use). Gloves Hazards to the hands include thermal hazards (contact with very hot or cold objects) mechanical hazards (the skin may be torn or cut by rough or sharp surfaces) chemical hazards (substances containing strong acids, alkalis, solvents or irritants) or vibration hazards (from using tools such as heavy drills). The handling of small components will require that the glove must be highly flexible and give good dexterity to the operator. Alternatively, a glove to give heat protection might place almost no emphasis on these properties. A range of protective gloves are available to meet all these needs. European standards, CE marking and test pictograms 106747209 3 Chemical contamination will eventually penetrate a glove, and depending on the hazard the glove should be changed regularly. Gloves highly resistant to one substance, e.g. an acid, may give no protection against others such as solvents and mixing substances together may alter their characteristics and may make their effect on the glove difficult to predict. A summary of the main glove standards to look for is given in the table below. EN 374 (Parts Protective gloves against chemicals and micro-organisms 1 to 6) EN 381 (Parts Protective gloves for users of hand held chain saws 4& 7) EN 388 Protective gloves: Mechanical test methods and specifications EN 407 Protective gloves against thermal hazards EN 420 General requirements for gloves EN 511 Protective gloves against cold EN 659 Fire-fighters' gloves: Protection against heat and flame Not only will the glove itself be marked with the specified information, but a significant amount of information will be also shown on the packaging. This will include the names of the manufacture or his representative in the Community, the glove description, size, CE mark, one or more of the pictograms given below and any other relevant information. The pictogram will be accompanied by a sequence of numbers indicating the product's performance in the various tests of the particular standard indicated by the pictogram. The pictograms show protection against the following hazards: micro-organisms chemicals impact cuts static electricity mechanical ionizing radiation cold heat/fire Selecting the right glove for chemical risks Any substance has to be present in a form that can be (i) absorbed into the body through the intact skin of the hand, (ii) enter through an existing cut or abrasion, or (iii) injected by needle or similar sharp instrument. To counter these risks, you need to select the right glove. There are several ways to select the right glove: 1. Look at the Material Safety Data Sheet (MSDS) produced by the manufacturer of the substance. The MSDS has a number of obligatory headings; under heading 8 ‘Exposure controls/ personal protection’, the manufacturer should specify the type of glove material, its breakthrough time, and any additional measures. 2. You can contact the technical services section of the manufacturer directly and ask them for their recommendation. 106747209 4 3. Manufacturers of protective gloves offer selection charts that enable you to choose the right glove for your purpose; see: Oxford University http://ptcl.chem.ox.ac.uk/MSDS/glovesbychemical.html And http://users.ox.ac.uk/~phar0036/biomedsafety/labsafety/ppe/gloves/ad.html Marigold Industrial http://www.marigoldindustrial.com/GB/index.html Ansell Healthcare http://www.ansellpro.com/specware/guide.asp European chemical resistance chart You may find the following chart summary printed (in white) on your protective gloves, giving information on their performance. A description of the chart contents is provided on the left (in blue). REAKTHROUGH TIME (BTT) - Measured in minutes Pt3 Protection Index - Performance Level 0-6 EN374 PERMEATION RATE (F)ast, (M)edium, (S)low, (0)Zero DEGRADATION (DEGN) - Physical effects on glove Respiratory Protective Equipment (RPE) RPE is a particular type of PPE. It is designed to protect the wearer against breathing in hazardous substances in the workplace air. RPE is divided into two main types: Respirator (filtering device). This uses filters to remove contaminants in the workplace air. They should never be used for protection in situations with reduced oxygen levels; Breathing apparatus (BA). This needs a supply of breathing quality air from an independent source (eg air cylinder or air compressor). RPE should only be selected and used after a justification has been made in the risk assessment required by law. It can be used in the following situations: where an inhalation exposure risk remains after you have put in place other reasonable controls (residual risk); short-term or infrequent exposures where you decide that other controls at source are not reasonably practicable; while you are putting in place other control measures (interim measures); emergency escape – you need to provide RPE for safe exit from an area where hazardous substances may be released suddenly in the event of control systems failures; emergency work or temporary failure of controls where other means of controls are not reasonably practicable; emergency rescue by trained personnel is necessary. However, sometimes you may want to issue PPE including RPE, not because other control measures are inadequate on their own, but to provide additional protection if any of the control measures fail and they no longer protect. The law says that RPE used at work must: 106747209 5 be adequate and provide the wearer with effective protection; be suitable for the intended use; be ‘CE’-marked; be selected, used and maintained by properly trained people; be correctly maintained, examined and tested; be correctly stored. In addition, you will need to keep records of selection, maintenance and testing. Selecting the right RPE The newest revision (February 2005) of HSG53 ‘The selection, use and maintenance of respiratory protective equipment’ contains a step-by-step approach to selecting RPE. This uses the same approach developed by the HSE for COSHH Essentials. HSE forecast that they will incorporate RPE selection into their online COSHH Essentials tool in the near future. Given the care that needs to be taken with the selection and use of RPE, for the moment, your next step should be to contact the Health and Safety Adviser on extn 4709. Face fit testing The performance of RPE which relies on a tight-fitting face-piece will be adversely affected if there is not good contact between the wearer’s skin and the face seal of the mask, eg. because the wearer is not clean shaven. RPE from more than one manufacturer and of more than one type may be needed to meet the face fit requirements of all the employees in a particular area. Proper testing of the correct fit for face-pieces intended to fit tightly is a necessary part of the selection process. Footwear Foot injuries usually result from crushing caused by heavy falling objects or penetration of the foot due to standing on a sharp object. The Personal Protective Equipment at Work Regulations 1992 govern the provision and use of protective footwear. The footwear should be robust enough and have sufficient grip for the working environment. It should also be comfortable, flexible to reduce the risk of tiring the feet and legs, capable of absorbing perspiration and if necessary, waterproof. The following types of safety footwear are commonly encountered: The safety boot or shoe is the most common type of safety footwear and has a steel toecap. Some types have a protected mid-sole. Wellington boots are worn to protect against water and corrosive materials. They can be obtained with resistance to corrosive materials, rot-proof insoles, ankle bone padding and cotton lining. They range from ankle boots to chest high waders. Safety trainers have been introduced in recent years incorporating softer, more flexible materials. They are fitted with protective toecaps and antislip soles. While their resistance to sole penetration is usually less than that provided by the safety boot, they can be worn for a variety of activities, provided the working area is free from materials likely to penetrate the wearer's foot. Head protection 106747209 6 The Construction (Head Protection) Regulations 1989 require suitable head protection, normally safety helmets, to be provided and worn when there is a risk of injury. If you are in control of a site, e.g. as a principal contractor, you need to think about risks of head injury. Selection Helmets come in a variety of designs and it is important that the right type is provided for the work to be done. A properly fitting safety helmet should have the right shell size for the wearer and an easily adjustable headband, nape and chin strap. The range of size adjustments should be large enough to accommodate thermal liners used in cold weather. Safety helmets should be as comfortable as possible. Comfort is improved by the following: a flexible headband of adequate width and contoured both vertically and horizontally to fit the forehead; an absorbent sweatband that is easy to clean or replace; textile cradle straps; chin straps (when fitted) which: o fit around the ears; o are fitted with smooth, quick-release buckles which don’t dig into the skin; o are made from non-irritant materials; o can be stowed on the helmet when not in use. Industrial safety helmets should be designed and manufactured to European Standard BS EN 397, and carry the CE mark. They should be compatible with any other PPE, eg ear defenders or eye protectors. The design should allow them to be worn comfortably and remain effective. Check manufacturer’s instructions regarding the compatibility of safety helmets with other types of PPE. Damage and replacement Normally, helmets should be replaced at intervals recommended by the manufacturer. They will also need replacing when the harness is damaged or if it is likely that the shock absorption or penetration resistance has deteriorated. For example, when the shell has received a severe impact, or if deep scratches occur (ie to a depth greater than 25% of the shell thickness) or if the shell has any visible cracks. Certain chemicals can weaken the plastic of the shell leading to rapid deterioration in shock absorption or penetration resistance. Chemicals which should be avoided include aggressive cleaning agents or solvent based adhesives and paints. Where names or other markings need to be applied using adhesives, advice should be sought from the helmet manufacturer. Eye protection Eye protection serves to guard against the hazards of impact, splashes from chemicals or molten metal, liquid droplets (chemical mists and sprays), dust, gases, welding arcs, nonionising radiation and the light from lasers. Eye protectors include safety spectacles, eye shields, goggles, welding filters, face-shields and hoods. Safety spectacles can be fitted with prescription lenses if required. Some types of eye protection can be worn over ordinary spectacles if necessary. The selection of eye protection depends primarily on the hazard. However, comfort, style and durability should also be considered: (a) Safety spectacles are similar in appearance to prescription spectacles but may incorporate optional side shields to give lateral protection to the eyes. To protect against impact, the lenses are made from tough optical quality plastic such as polycarbonate. Safety spectacles are generally light in weight and are available in several styles with either plastic or metal frames. Most manufacturers offer a range of prescription safety spectacles which are individually matched to the wearer. 106747209 7 (b) Eye shields are like safety spectacles but are heavier and designed with a frameless one-piece moulded lens. Vision correction is not possible as the lenses cannot be interchanged. Some eye shields may be worn over prescription spectacles. (c) Safety goggles are heavier and less convenient to use than spectacles or eye shields. They are made with a flexible plastic frame and one-piece lens and have an elastic headband. They afford the eyes total protection from all angles as the whole periphery of the goggle is in contact with the face. Goggles may have toughened glass lenses or have wide vision plastic lenses. The lenses are usually replaceable. Safety goggles are more prone to misting than spectacles. Double glazed goggles or those treated with an antimist coating may be more effective where misting is a problem. Where strenuous work is done in hot conditions, ‘direct ventilation’ goggles may be more suitable. However these are unsuitable for protection against chemicals, gases and dust. ‘Indirect ventilation’ goggles are not perforated, but are fitted with baffled ventilators to prevent liquids and dust from entering. Indirect ventilation goggles will not protect against gas or vapour. (d) Face shields are heavier and bulkier than other types of eye protector but are comfortable if fitted with an adjustable head harness. Face shields protect the face but do not fully enclose the eyes and therefore do not protect against dusts, mist or gases. Visors on brow guards or helmets are replaceable. They may be worn over standard prescription spectacles and are generally not prone to misting. Face shields with reflective metal screens permit good visibility while effectively deflecting heat and are useful in blast and open-hearth furnaces and other work involving radiant heat. Specification for eye protectors for industrial and non- industrial uses BS EN 166, 167 and 168 Protective clothing Obviously, where employees could be exposed to chemicals or radioactive contamination, they will need protective clothing for such work. It may be needed for workers exposed to simple hazards like cold or foul weather, or strong sunlight. Types of clothing used for body protection include: (a) coveralls, overalls and aprons to protect against chemicals and other hazardous substances; (b) outfits to protect against cold, heat and bad weather; (c) clothing to protect against machinery such as chain-saws Types of clothing worn on the body to protect the person include: (a) high visibility clothing; (b) life-jackets and buoyancy aids. European Standards for design and manufacture of protective clothing include, for example: BS EN 340 (general requirements); 342 (cold weather); 343 (foul weather); BS EN 471 (high visibility warning clothing); BS EN 1073-1 radioactive contamination. 4. Maintenance of PPE Departments must devise written procedures for any necessary maintenance of PPE (this includes, where appropriate, cleaning, disinfection, examination, repair, replacement and testing). Procedures should describe the extent and frequency of maintenance and the names of individuals responsible; manufacturers' maintenance instructions and schedules must be followed. The wearer can usually carry out simple maintenance, but properly trained persons should carry out more complex maintenance (and this may involve returning equipment to suppliers or manufacturers). It is often preferable to use disposable PPE, which avoids having to devise and carry out these procedures. In this case it is important that information provided by the manufacturer is passed to the users, so they can recognise when to discard and replace the equipment. 106747209 8 5. Storage of PPE Departments must provide some means for PPE to be stored when not in use, so as to protect it from contamination, loss, or damage. In most cases this will be very simple, e.g. pegs or lockers for clothing. Contaminated PPE must be stored separately from clean PPE or ordinary clothing. 6. Information, instruction and training Users must be provided with sufficient information, instruction and training to use PPE effectively (this will usually be provided by the supervisor or departmental safety officer). It should include both theoretical and practical aspects (why the PPE is being used; how to fit, wear or store it) and will vary with the complexity of the equipment. For example, with simple equipment such as safety helmets, only very basic user instructions are required, but the use of laser eye protection, or anti-static or conductive footwear also requires an understanding of the theoretical principles involved. Training records should be kept wherever more than very simple instruction is required. 7. Users' duties Users should take reasonable care of PPE and use it according to instructions. Any loss or defect should be reported to the person responsible for the department's PPE maintenance programme. Where can I get more information on selecting and fitting PPE? 106747209 http://www.hse.gov.uk/pubns/indg174.pdf http://www.hse.gov.uk/pubns/indg288.pdf http://www.hse.gov.uk/pubns/indg330.pdf http://www.hse.gov.uk/pubns/cis50.pdf 9 (Extract courtesy of HSE) 106747209 10