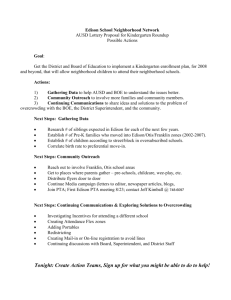

Specifications - Tagliafico Lighting

advertisement

Specifications GRAND DUCHY ALLUMINIO CUT-OFF VES Luminaire brand Tagliafico Lighting American lantern-shaped, made entirely of die-cast aluminum with stainless steel screws for assembly A2. The details are made of turned brass. Finishing and painting surfaces performed in a workmanlike manner. Lantern consists of a central cage, made of one piece, supported by the jaw at four point. This is integral with the frame support the flat glass which relies on the optical silicone gasket. Frame is hinged to the cathedral in die-cast aluminum that prevents the propagation of light upwards. Opening it, the optical compartment integral with the cable attached to the inside, gives you access to the lamp housing. The cathedral with the fireplace and the smoke round the lantern. The top of the lantern is made in 11/10 thick copperplate, burnished and varnished. This cover avoids down-top light pollution. The deburring aluminum castings after the drilling and tapping are sandblasted steel grit blasting SA 2 ½, followed by passivation treatment with Alodine 1200, conforms to MIL C-5541 for improved corrosion resistance and adhesion of the optimization paint on the passivated parts. Thermosetting powder coating with electrostatic application and curing in the oven 140 degrees, made with highly complex systems and equipment to ensure a perfect performance and a superior finish against the erosion of weathering. Coating with an average thickness 60 microns - Resistance to scratch grid standards ISO 2409 - • Resistance to impact resistance test according to UNI 8901 Available colors: Burnished Bronze - Antique Gray. Bronze Burnished Copper combined textured (hats only). The screen top is clear float glass, according to EN 572-9 5 mm thick, tempered at the standard EN 12150. Resistant to thermal shock and mechanical impact, is required to EN 60598-2-3 paragraph 3.6.5, and if broken it crumbles into tiny harmless fragments, according to EN12600. With full transparency, non-yellowing UV exposure is emitted by solar lamps themselves, and are resistant to salt and atmospheric agents in general. Removing the 4 nuts securing the inner compartment leads to the electrical wiring. The housing is molded fiberglass reinforced nylon. Bi-power supply systems that are switched to a reduced power during night hours, ie when the illuminance can be brought from a level of operation to a service, for types of high pressure sodium lamps and metal halide. Electrical equipment are contained in a single unit independent power supply, consisting of a polycarbonate case HT that covers all the gear - power with low losses in compliance with Directive ErP - EUP - Power factor correction capacitor HPF power factor> 0.9 - Igniter digital safe timer - Connector disconnectable screw - replaceable fuse - programmable automatic switch. The wiring is run in Class II insulation, in accordance with CEI. The connections to the supply line and to the lamp, are performed through interlocking connectors, which enable the electrical isolation in the event of maintenance or replacement. All electrical components mounted into the feature IMQ or equivalent and CE marking of conformity with Directive 89/336/EEC on electromagnetic compatibility. These devices are equipped with reactors equipped with a protection device against the effects righting of the lamp. Build to be compliant to the new rules regarding light pollution and energy saving. Internally there is an asymmetrical reflector, for a better distribution of light towards the ground. The reflector is fitted inside the body of the lantern, and is made in UNI 4509 aluminium plate P-ALP 99.8% 10/10mm thick, polished and oxidised. In the asymmetric reflector light, designed for a better distribution of light towards to the ground, the lamp is fitted horizontal regarding to the ground. The lamp-holder must be directed towards the surface to light. The lighting equipment, electrical wiring complete, are CE marked and have IP55 protection shall comply with: Street lighting EN 60598-1:2008 Ed VIII The lighting equipment, lamps wired for high-pressure sodium vapor and metal halide lamps, include thermal protection to users. Lighting pollution compliance: The fixtures with VEP flat glass with an optic closure compartment, and installed without lower glasses, fully complies with regulations in relation to light pollution, with Imax at Gamma 90 equal to 0.00 (cd/Klm). Available in the following versions: TP for pole-head single or multiple installation – on brackets BP for suspension installation on iron tube brackets The lantern is equipped with installation fittings for the selected mounting position. Versions Available: Codice/Code IA058MT070BP2VS IA058MT070TP2VS IA058MT100BP2VS IA058MT100TP2VS IA058MT150BP2VS IA058MT150TP2VS IA058ST070BP2VS IA058ST070TP2VS IA058ST100BP2VS IA058ST100TP2VS IA058ST150BP2VS IA058ST150TP2VS Descrizione/Description GRAND DUCHY AL C-O VEP ES BP MT70-50W CL.2 GRAND DUCHY AL C-O VEP ES TP MT70-50W CL.2 GRAND DUCHY AL C-O VEP ES BP MT100-70W CL.2 GRAND DUCHY AL C-O VEP ES TP MT100-70W CL.2 GRAND DUCHY AL C-O VEP ES BP MT150-100W CL.2 GRAND DUCHY AL C-O VEP ES TP MT150-100W CL.2 GRAND DUCHY AL C-O VEP ES BP ST70-50W CL.2 GRAND DUCHY AL C-O VEP ES TP ST70-50W CL.2 GRAND DUCHY AL C-O VEP ES BP ST100-70W CL.2 GRAND DUCHY AL C-O VEP ES TP ST100-70W CL.2 GRAND DUCHY AL C-O VEP ES BP ST150-100W CL.2 GRAND DUCHY AL C-O VEP ES TP ST150-100W CL.2 W 70 70 100 100 150 150 70 70 100 100 150 150 Volt 230 230 230 230 230 230 230 230 230 230 230 230 IP 55 55 55 55 55 55 55 55 55 55 55 55 Attacco EDISON EDISON EDISON EDISON EDISON EDISON EDISON EDISON EDISON EDISON EDISON EDISON Lampada/Lamp HCI-TT 70W/WDL E27 HCI-TT 70W/WDL E27 HCI-TT 100W/WDL E40 HCI-TT 100W/WDL E40 HCI-TT 150W/WDL E40 HCI-TT 150W/WDL E40 NAVT70 NAVT70 NAVT 100 NAVT 100 NAVT150 NAVT150 kg 11,5 11 11,5 11,5 12,5 12 11,5 11 11,5 11 12,5 12,5