Lukes_INPUT OPTICS C..

advertisement

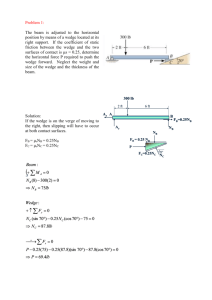

INPUT OPTICS CHANGES -Get new table dimensions, orientation, and document number (Discuss at meeting) -Put bases on New Focus mounts (Done) -Rotate bases on New Focus mounts, so they fit on the table (Waiting on new table dimensions) -Check MC footprint, is it 16.748” X 9.661”? (Ask Janeen at meeting, based on PROJECTS BY LUKE/input optics/reference files/SUSPENSIONS GROUP/MCSUS_01.exe) -Add bevels to MC1,2,3 (Done) -Is beam well within AR coating? [Assuming beam radius is 2.114mm(T020027, pg 27), then there is a 22.4mm gap between the edge of the coating to the outside edge of beam] (20.4mm for refracted beam exiting MC1) -Add reflected beam exiting MC1, determine how it can exit chamber (Done) -Should we add a wedge to the back of MC2, if so how much? (Review before meeting, see David’s email, and PROJECTS BY LUKE/input optics/ mode cleaner optics/mc_curved_wedge.xls) -Show beam transmitted through SM1 [Done, assuming same index of refraction as MC (1.44963), no wedge on SM1] -Show Faraday pickoff beam (Old Faraday isolator pasted in, don’t know what is best way to route pickoff beams. Why isn’t exiting beam collinear with entering beam?) -Add thermal lensing compensator (Add when dimensions become known) -Is beam exiting Faraday Isolator too close to chamber flange? (~2.9” from edge, assuming working diameter is 60.75”) -Should we move MMT1 to the left, so that PRM is easier to access? (Discuss at meeting, wedge?) -Determine MMT2 suspension footprint (Discuss at meeting, see Willems and Romie emails, Coyne layout) -What is the best way to make the layout available to others? -PDFs blur the lines, and distances cannot be measured, so DCC is bad choice. -I can post the most current CAD file on my webpage: http://www.phys.ufl.edu/~luke/ -Who should be notified when changes are made? -Questions, suggestions, or requests?