Information Sheet 1.7 - NHMRC Public Consultations

advertisement

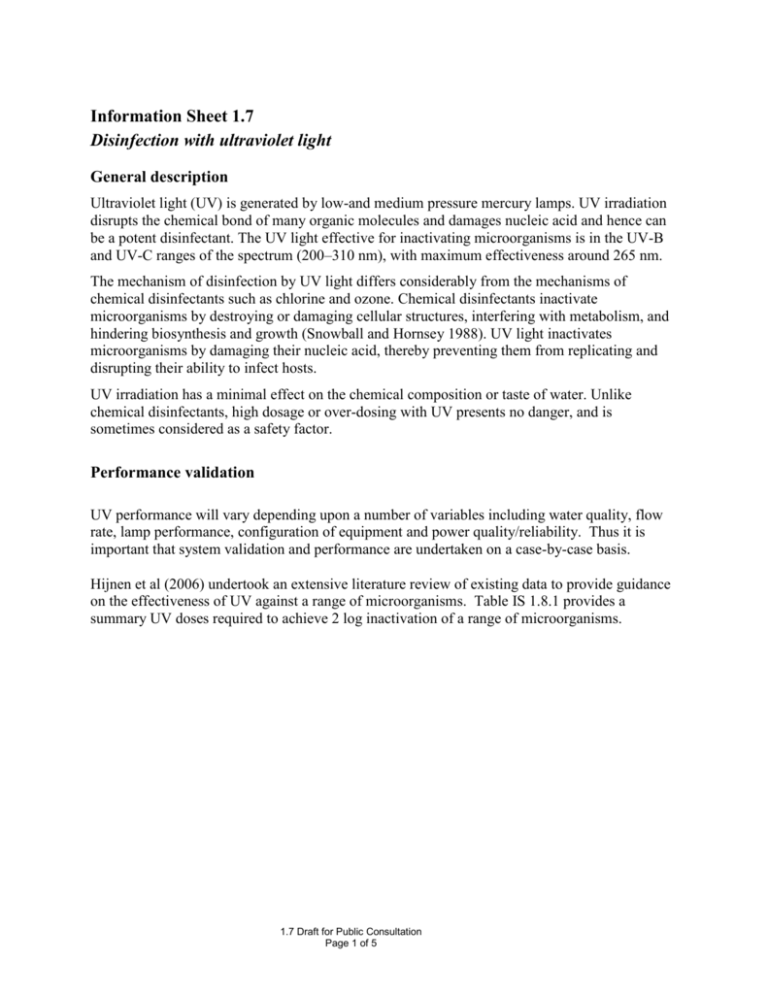

Information Sheet 1.7 Disinfection with ultraviolet light General description Ultraviolet light (UV) is generated by low-and medium pressure mercury lamps. UV irradiation disrupts the chemical bond of many organic molecules and damages nucleic acid and hence can be a potent disinfectant. The UV light effective for inactivating microorganisms is in the UV-B and UV-C ranges of the spectrum (200–310 nm), with maximum effectiveness around 265 nm. The mechanism of disinfection by UV light differs considerably from the mechanisms of chemical disinfectants such as chlorine and ozone. Chemical disinfectants inactivate microorganisms by destroying or damaging cellular structures, interfering with metabolism, and hindering biosynthesis and growth (Snowball and Hornsey 1988). UV light inactivates microorganisms by damaging their nucleic acid, thereby preventing them from replicating and disrupting their ability to infect hosts. UV irradiation has a minimal effect on the chemical composition or taste of water. Unlike chemical disinfectants, high dosage or over-dosing with UV presents no danger, and is sometimes considered as a safety factor. Performance validation UV performance will vary depending upon a number of variables including water quality, flow rate, lamp performance, configuration of equipment and power quality/reliability. Thus it is important that system validation and performance are undertaken on a case-by-case basis. Hijnen et al (2006) undertook an extensive literature review of existing data to provide guidance on the effectiveness of UV against a range of microorganisms. Table IS 1.8.1 provides a summary UV doses required to achieve 2 log inactivation of a range of microorganisms. 1.7 Draft for Public Consultation Page 1 of 5 Table IS1.8.1 Examples of dosage rates to achieve 99% (2 log) inactivation of various microorganisms by UV irradiation Organism Bacteria Bacillus subtilis E. coli O157 E. coli Legionella pneumophila Campylobacter spp. Yersinia enterocolitica Clostridium perfringens Streptococcus faecalis Shigella dysenteriae Vibrio cholerae Salmonella typhi Viruses Adenovirus type 40 Adenovirus type 2, 15, 40, 41 Adenovirus Rotavirus SA-11 Coxsackie virus B5 Poliovirus type 1 Hepatitis A Protozoa Cryptosporidium Giardia Acanthamoeba Based on Hijnen et al. (2006) Dosage for drinking water (mJ/cm2) to achieve 2 log removal 111 9 9 15 7 7 95 16 5 4 12 111 83 50 20 17 15 11 6 5 71 For protozoa, the outcomes of recent investigations (Clancy et al.,1998ab; Bukhari et al.,1999; USEPA, 2006; Craik et al., 2000) using mouse infectivity or cell culture showed that low or medium-pressure mercury vapour UV lamps, or pulsed UV technology, can achieve 3-log inactivation of Cryptosporidium oocysts and Giardia at UV doses less than 15 mJ/cm2. The important conclusion to draw from Table IS1.8.1 is that, at the typical dose rate used in Australian drinking water supplies (i.e. 40 mJ/cm2) UV will effectively inactivate most vegetative bacteria and protozoa, but will not be effective against all types of virus. Given that the UV process will be a critical control point (CCP), other important issues that will need to be considered to ensure the effectiveness of the process are: establishing target criteria (section 3.4.2) and critical limits for the UV irradiation process 1.7 Draft for Public Consultation Page 2 of 5 preparing and implementing operational procedures (section 3.4.1) and operational monitoring (section 3.4.2) for the process preparing corrective action procedures (section 3.4.3) in the event that there are excursions in the operational parameters undertaking employee training (section 3.7.2) to ensure that the UV irradiation process operates to the established target criteria and critical limits It is recommended that validation is undertaken for each system to ensure appropriate treatment is in place for the water quality and level of risk. Water quality considerations The performance of UV disinfection is not affected at turbidity levels of 1 NTU, and UV may remain effective at higher turbidities than 1 NTU, as long as the transmittance of UV through the water is not compromised. However, the lower the turbidity of the water the more effective the performance of UV will be. UV irradiation is not pH dependent and the temperature effect between the ranges of 5 to 35oC is minimal (USEPA 2006). The presence of algae in the water being treated may reduce the UV transmittance and interfere with the UV disinfection process and should be considered in the design phase if the supply is prone to algal blooms. Highly coloured water is not suitable for UV disinfection as the dissolved organic matter which gives the water its colour strongly absorbs the UV light, greatly reducing the effectiveness of the UV disinfection process. Practical considerations The equipment required for UV irradiation is fairly reliable, the technology required is relatively simple and controls for the process are being developed. There are a number of factors that should be considered in relation to UV such as: reliability of power supply, in particular the start-up and restart times should be factored into operational and response plans; water quality aspects, such as algae, high colour and turbidity, hardness and organic matter, as they can reduce the amount of UV radiation reaching microorganisms and necessitate higher doses of applied radiation for effective disinfection; a site-specific mercury spill response plan should be established to minimise mercury release in the event of a lamp breakage; and, Units require regular cleaning and maintenance to remain effective. Persistence 1.7 Draft for Public Consultation Page 3 of 5 At the proper dosage, UV requires only a short contact time, but has the disadvantage that it leaves no residual disinfectant, which would provide an additional barrier within the distribution system. By-products Few data are available on the by-products of UV disinfection. At the UV doses typical for drinking water supplies (less than 200 mJ/cm2), there is no evidence of the formation of byproducts or exacerbation of DBP’s if post UV disinfection occurs (USEPA 2006). UV has been reported to convert nitrate to nitrite at a conversion rate of approximately 1% (Sharpless and Linden, 2001). Given the typical values of Australian waters, the nitrate to nitrite conversion is unlikely to result in the exceedance of health guidelines for drinking water. Application UV disinfection is a treatment option that can contribute to the effective implementation of a multi-barrier approach that reduces microbial risk in drinking water supplies. UV disinfection can be used as the primary disinfectant for the inactivation of chlorine resistant pathogens (e.g., Cryptosporidium and Giardia), thereby reducing DBP formation. However, UV disinfection typically should not completely replace the use of chemical disinfection. This is because there are a number of other aspects to consider in managing the microbial risk of drinking water supplies, such as: maintaining a disinfection residual within the distribution system; management of taste and odour compounds; controlling cyanobacteria; deactivation of viruses that are not easily treated by UV alone; and ensuring there is an adequate multi-barrier approach for the entire drinking water system. Operational monitoring As there is no disinfection residual to measure following UV treatment, other operational aspects of UV systems should be monitored to ensure that the treatment system is operating as expected. Examples of monitoring parameters are listed below, recognising that each system will need to develop its own operational monitoring specifications reflecting its unique circumstances. UV dose Flow rate Turbidity UV transmittance Lamp outage Other issues that need to be considered with respect to UV is that the performance of the UV lamps deteriorates over time, so that lamps should be changed at the frequency recommended by the manufacturer. Furthermore, biofilm, which can accumulate on the sleeve surrounding the 1.7 Draft for Public Consultation Page 4 of 5 lamp, should be regularly removed from the sleeve. Many UV systems now have automated cleaning systems. References Bukhari Z et al. (1999). Medium-pressure UV light for oocyst inactivation. Journal of the American Water Works Association, 91(3):86–94. Clancy JL et al. (1998a). Inactivation of Cryptosporidium parvum oocysts in water using ultraviolet light. Journal of the American Water Works Association, 90:92–102. Clancy JL et al. (1998b). Innovative electrotechnologies for Cryptosporidium inactivation. CR111090. Electric Power Research Institute, Palo Alto, CA. Craik SA et al. (2000). Inactivation of Giardia muris cysts using medium-pressure ultraviolet radiation in filtered drinking water. Water Research, 34(18):4345–4332. DVGW (2006a) UV Devices for Disinfection in the Water Supply Part 1: Requirements Related to Composition, Function and Operation, in Technical Rule, Code of Practice W294-1. DVGW (2006b) UV Devices for Disinfection in the Water Supply Part 2: Testing of Composition, Function and Disinfection Efficiency in Technical Rule, Code of Practice W294-2 DVGW (2006c), UV Devices for Disinfection in the Water Supply; Part 3: Measuring Windows and Sensors for the Radiometric Monitoring of UV Disinfection Devices: Requirements, Testing and Calibration in Technical Rule, Code of Practice W 294-3 Hijnen, W.A.M., Beerendonk, E.F. and Medema, G.J (2006) Inactivation credit of UV radiation for viruses, bacteria and protozoan (oo)cysts in water: A review. Water Research 40: 3-22. Sharpless, C.M., and K.G. Linden. 2001. UV photolysis of nitrate: Effects of natural organic matter and dissolved inorganic carbon, and implications for UV water disinfection. Environmental Science and Technology 35:2949–2955. USEPA. 2006. Ultraviolet disinfection guidance manual for the final long term 2 enhanced surface water treatment rule. EPA 815-R-06-007. U.S. Environmental Protection Agency, Office of Water, Washington, DC. 1.7 Draft for Public Consultation Page 5 of 5